By Carson Reed – Images by the Author

It’s been a minute or two since we visited with our up-and-coming teenage trucker, Carson Reed—he’s still in high school, so we’re cutting him some slack! After making good progress with his 1964 Chevy’s “mid-length” chassis all situated with the Scott’s Hotrods four-link and IFS (both custom tailored for extreme-low ride height with his dad Ryan’s tutelage!) and Wilwood brakes fore and aft, Carson buttoned up the wheelbase adjustment on the frame and the bed sheetmetal/Brothers’ oak wood floor. With the Scott’s front crossmember set exactly where he and Pops wanted it, the stroker 383 and his manual gearbox—a Silver Sport Transmissions TKX—that had been patiently waiting their turn in the corner of the shop got a little attention. We’ll let Carson take it from here:

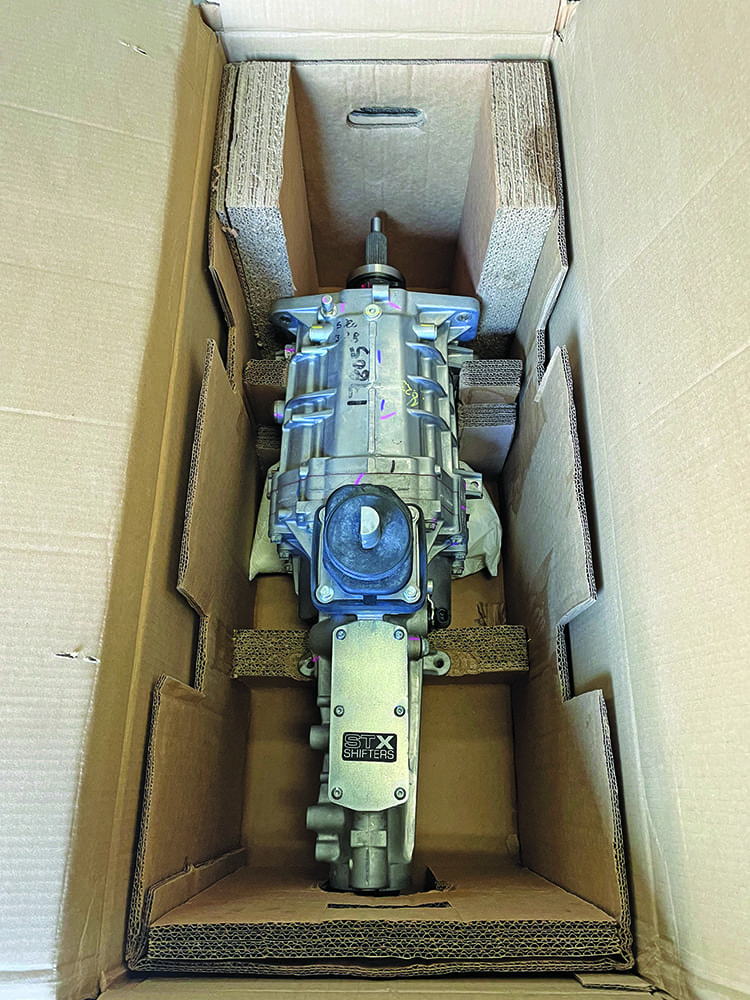

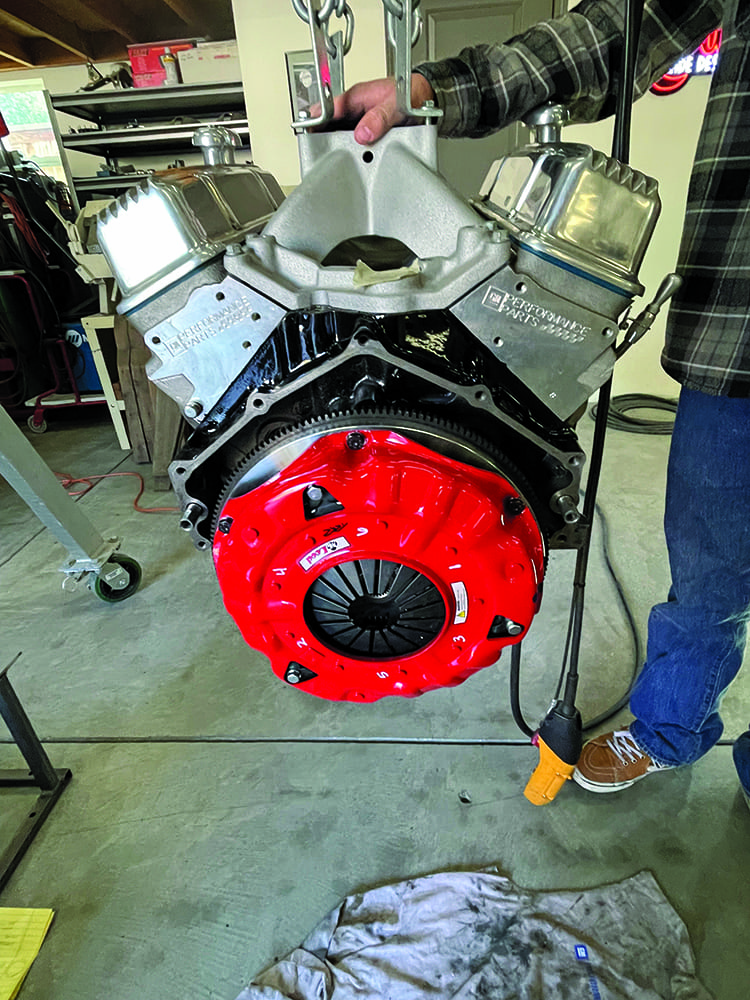

“A manual transmission was something I wanted my first truck to have. My dad and I discussed an automatic, but I felt a manual transmission was right for the 383 small-block. My dad had figured the TKX five-speed was the best option for what I was looking for, so we contacted Silver Sport Transmissions and ordered the complete package, including the McLeod clutch assembly.

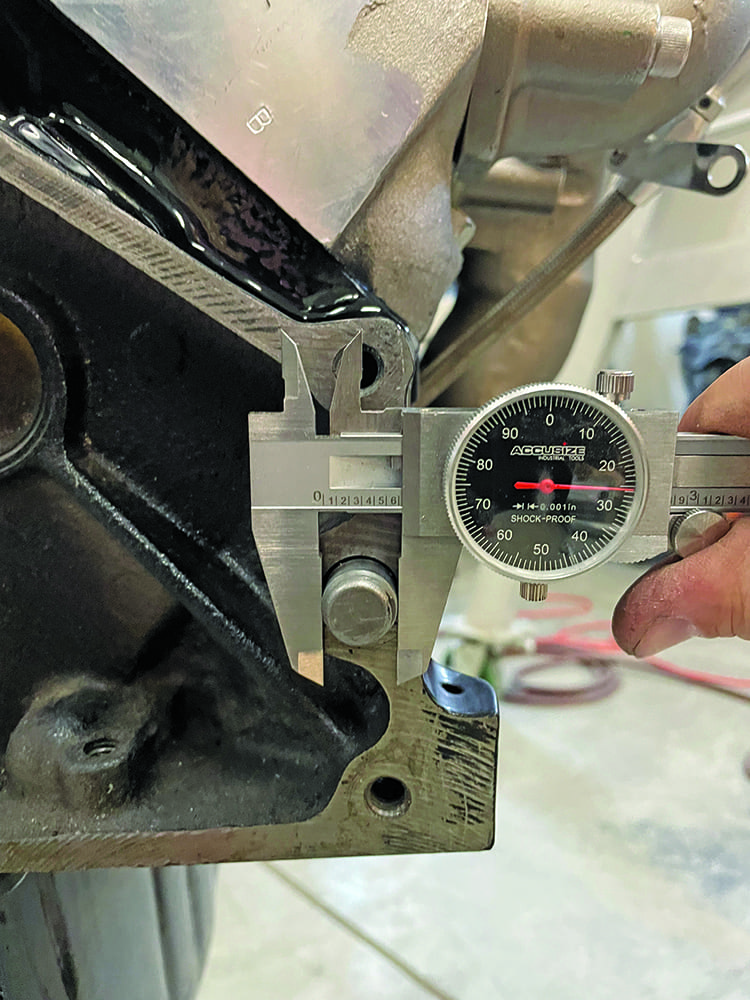

“After Silver Sport Transmissions sent us everything, we took the entire clutch assembly to Mcleod in Anaheim, California, to have it spun balanced. While the clutch was in Anaheim, we detailed the raised areas on the cast-aluminum bellhousing and installed the pilot bushing that was supplied. Once we were satisfied with the finish on the bellhousing, we mounted it on the backside of the engine and checked the id for runout and determined we needed to order 0.007-inch offset dowel pins from Summit Racing.

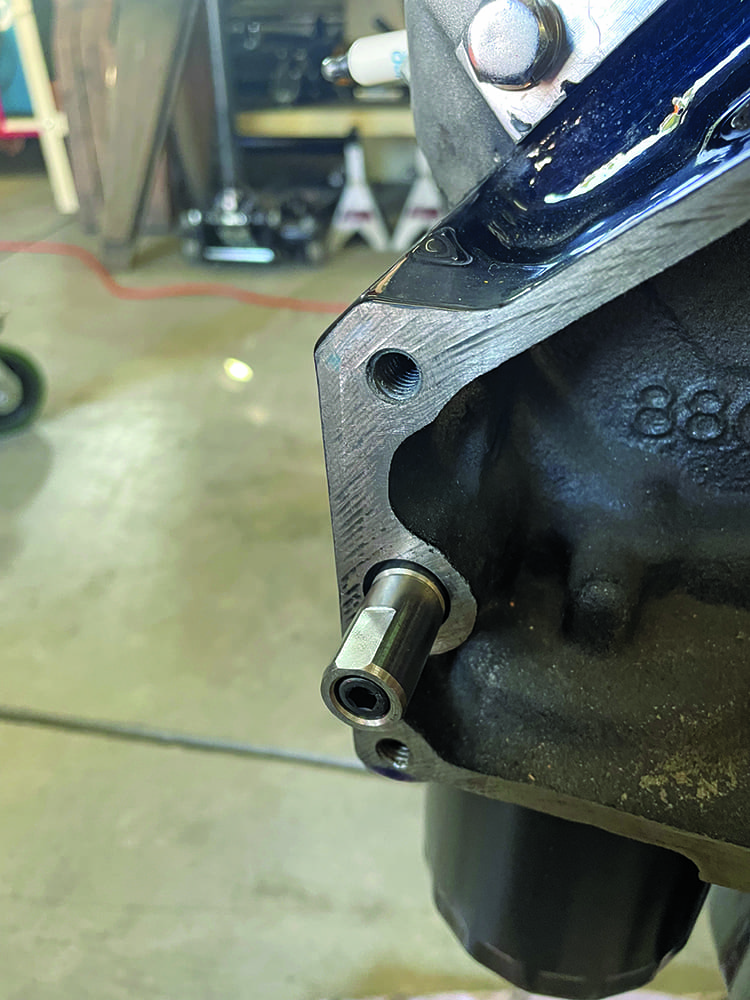

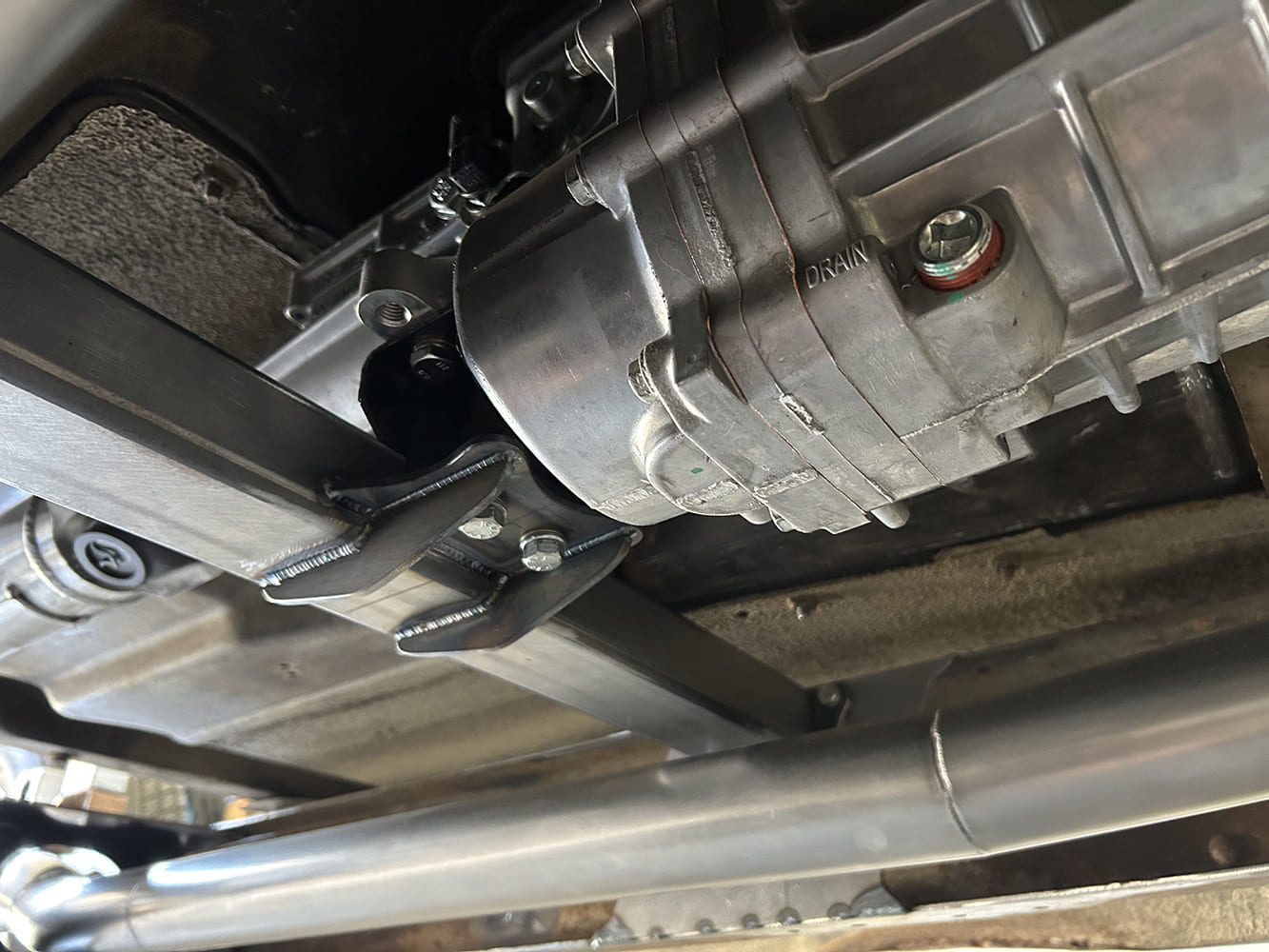

“Once we had everything assembled—clutch, pressure plate, flywheel, and set the right dimensions on the hydraulic throw-out bearing following Silver Sport Transmissions’ detailed instruction sheets—we pushed out the original dowel pins and installed the new offset ones in the engine block. Then we checked the bellhousing’s alignment again with a dial indicator and it was within the required 0.005 inch of offset. Once all that was right, we joined the engine and transmission together.

“Next, we positioned the engine and transmission in the chassis with our 1/2-ton A-frame hoist and although a transmission crossmember was provided, we decided to build our own. Then we made tabs for the engine mounts that were provided by Scott’s Hotrods. Once we had it sitting on its own weight with proper ground clearance, we made adjustments to the stock transmission cover. I had to reposition the shifter opening and use the planishing hammer to achieve more clearance for the transmission. We decided that we were going to run a one-piece driveshaft supplied by Inland Empire Driveline, which meant we had to cut open the floor and fabricate a driveshaft tunnel. For added safety I also built a tubular driveshaft hoop for the front portion of the driveshaft.”

Since wrapping up his driveline install, Carson has also tackled a full-custom stainless exhaust, among other things, while doing what young teenagers do on their summer breaks! We’ll catch up with further developments on his High School Hauler as they, well, develop.

Check out this story in our digital edition here.

Sources

Silver Sport Transmissions

shiftsst.com

McLeod Racing

mcleodracing.com

Inland Empire Driveline

iedls.com

Scott’s Hotrods

scottshotrods.com

Wilwood Engineering

wilwood.com