By Brian Brennan – Photography By Luke Munnell – Artwork By Eric Brockmeyer Design – Video By Ryan Foss Productions

Yes, this is a brand-new 1932 Ford highboy roadster owned by Scott Lorenzini, but the story behind this hot rod is worth exploring. We spoke with Scott and his dad, Gary, SoCal hot rodders, as well as Justin and Evin from Veazie Bros. Fabrication, at this year’s Grand National Roadster Show, as the roadster debuted in the competition for America’s Most Beautiful Roadster. The Deuce is a striking hot rod with plenty of attitude and craftsmanship, making it suitable for any trip down a strip or boulevard. But in the minds of many hot rodders, the thought is, “I’ve seen this somewhere else?”

We asked Scott to share the background, and what follows is a condensed version; however, we believe you will enjoy learning how this 1932 Ford highboy roadster came to be. Back in 1987, Scott, then 11, recalls how his dad, Gary, instilled in him a passion for hot rods. It all started with a “transformative experience” when family friend Pete Chapouris visited in his freshly built, lime green highboy roadster. After a quick ride around the cul-de-sac with Chapouris and his dad, the excitement grew as Chapouris unleashed the car’s power, lighting up the rear tires and shifting gears swiftly. The adrenaline-filled ride, though short, made a lasting impression on Scott, cementing his passion for hot rods and marking an unforgettable ride in “Limefire.” (Limefire first appeared in the Oct. ’87 issue of Hot Rod. At that time, it was noted that it took 79 days to turn the highboy roadster from “dream to reality.” It later graced the cover of Rod & Custom in Dec. ’88. Now you know the backstory.)

In November 1997, Chapouris and Alex Xydias revived the legendary SO-CAL Speed Shop. One of their early projects was for Bob Garibay whose aim was to build a versatile hot rod that could also be used as a race car, with plans for salt flat racing. Chapouris agreed to take on the project, stressing a careful and unhurried approach. He intended to include lessons from the original Limefire, such as a prototype SO-CAL Speed Shop Step-Boxed chassis, a new steel body from Brookville Roadster, and enhanced safety features.

The cloning project of the iconic hot rod faced numerous challenges over 20 years, starting with creating an accurate blueprint. The project was heavily impacted by Chapouris’ death in January 2017, leaving the car nearly ready for paint. After years of construction and careful oversight of the build, Garibay decided to sell the unfinished project to the father-and-son team of Gary and Scott Lorenzini. They planned to finish the build with new ideas while respecting its Limefire heritage, trusting the work to skilled builders Evin and Justin Veazie of Veazie Bros. The build process stretched from 1998 to 2017 at SO-CAL Speed Shop, and then from 2021 to 2025 at Veazie Bros.

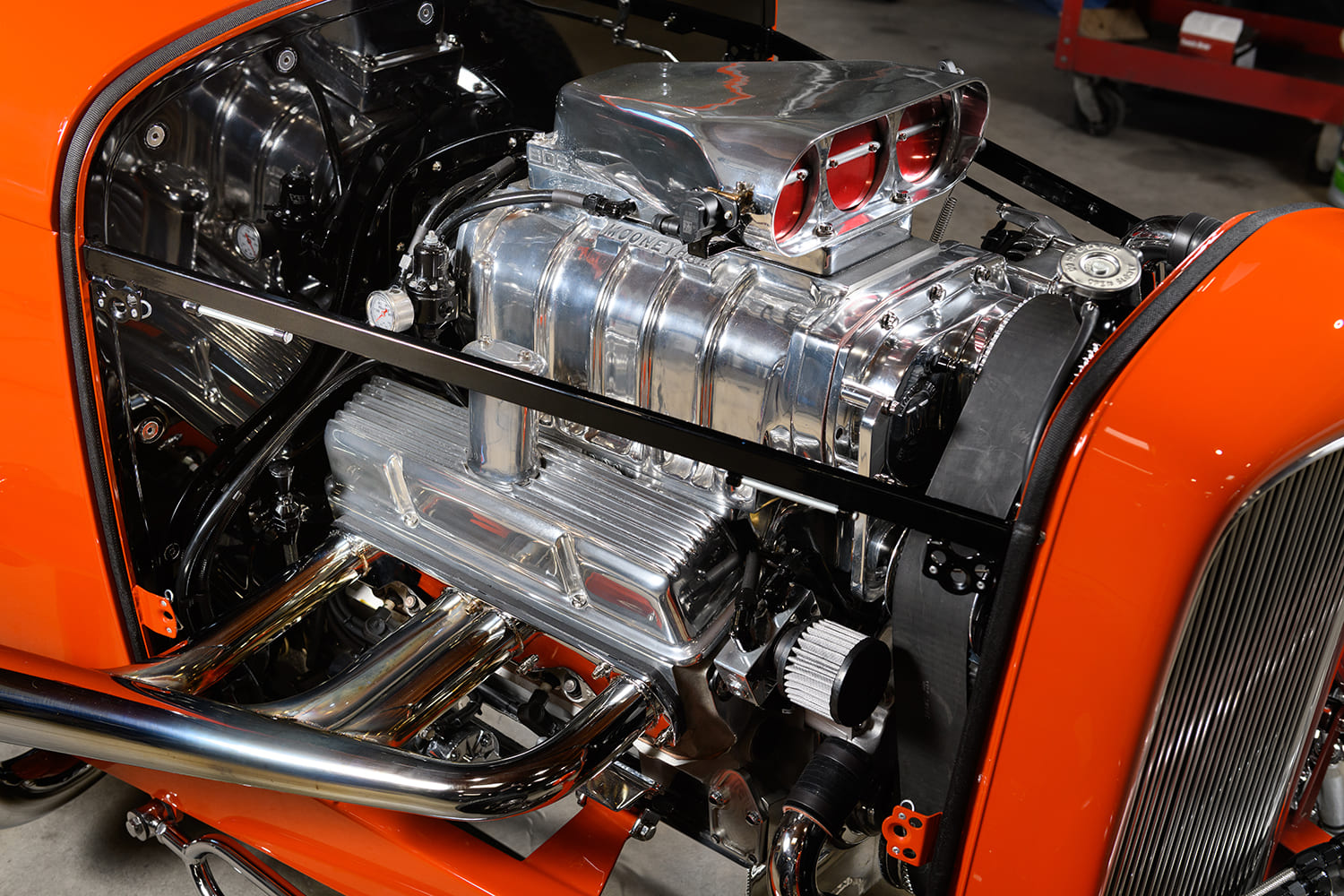

Power, and we mean power, comes from a 383ci small-block Chevy, based on an aluminum-blown and injected Donovan, under the watchful eyes of Ray Zeller, Steve Sbelgio of Eclipse Engineering for the electronic tuning, and dyno testing at Westech Performance Group. Under the guidance of Donny Cummins from Holley MSD, the team transitioned to a Holley HP ECU and dual-sync MSD distributor. Matt Carricaburu from Milling & Turning Tech crafted a new injector plate outfitted with eight separate 80-pound LS “shorty” injectors, seamlessly hiding the internal wiring for the throttle position sensor and injectors out of sight. The electrical system, based on an American Autowire fuse panel and harness, along with an unpinned Holley EFI harness, presented a challenge due to the complex multilayer firewall and aluminum interior. With assistance from Jack Nickerson of Jax Motorsports, the team achieved a sophisticated wiring solution featuring removable harnesses suitable for professional motorsport applications. VBF skillfully arranged the wiring. ARP hardware is extensively used throughout the engine to secure various components. Other engine accessories include Moon valve covers, an MSD HyperSpark distributor, an MSD 6AL box and coil, MSD 8mm wires, and an OPTIMA battery.

The exhaust system features Limefire-style headers but is enhanced and fabricated by Robin Silk with larger header tubes feeding into 3-inch pipes that flow smoothly through the pair of MagnaFlow mufflers. The exhaust system was then ceramic coated by Young Guns Performance while Steve Jones skillfully handled the accompanying plating and polishing. A Turbo 400 transmission with a small-diameter billet converter, assembled at Mike’s Transmission, is ready to handle all that explosive power and quick acceleration.

Scott’s lifelong passion for music influenced the car’s color selection. The color reflects a spectrum found in the drum’s finish, cementing a personal touch. The Lorenzini badge took design cues from the iconic 140-year-old American drum brand, paying reverence to Scott’s musical roots. The burnt orange paint, inspired by the lacquer finish of his Gretsch drum kit, was developed in collaboration with Tom Rodriguez from Cypress Auto Body. It was here that the bodywork and paint were finished by Rodriguez, with final color sanding performed by Serifin Petino. Former SO-CAL Speed Shop Manager Ryan Reed, who pressed louvers for a decade under Chapouris, was brought in to lay them out. These were created with the help of Ryan’s son, Carson, utilizing Eric Vaughn’s louver press, now owned by Ryan. Terry Hegman provided the three-piece hood with Ryan-pressed louvers on the top and sides. The firewall is a double-layered structure made from aluminum with a medium-density fiberboard (MDF) core. (MDF is an engineered wood product that combines wood fibers, resin, and wax.)

To enhance the interior’s aesthetic, a single-piece rear panel replaced the original three-piece design, eliminating seams for a cleaner look. The homage features carefully crafted aluminum interior tinwork by Pauly Rivera and Brandon Nolen, then powdercoated by Young Guns Performance Coatings for a striking finish. Chrome Dzus hardware enhances the appeal, while a custom tube column drop and tack mount create a sleek, tailored appearance. The shifter mount, designed by Veazie Bros., houses a B&M shifter with an integrated parachute release for added functionality. Additional touches include custom-raised floor mats, also by Veazie Bros., making this vehicle not only a powerhouse on the road but also a true work of art.

Ron Mangus finalized the choice of interior materials, Moore and Giles black leather and square-weave carpeting, stitched over a custom-built bench seat that positioned the driver and passenger centrally behind the 3-inch chopped Deuce windshield, ensuring a perfect blend of style and function. Veazie Bros. fabricated a one-of-a-kind hot rod steering wheel, steering column, column drop, tach mount, and parachute lever. The dash panel insert was leftover from the original Chapouris build. Now, with Eamonn Keogh, the engine-turned feature has been added to the panel, which now holds a full set of Auto Meter gauges. At the same time, Brian Petersen, a longtime friend, produced custom sand-cast magnesium skull shifter knobs. Johnny Kaiser, a longtime friend and fabricator, was initially commissioned to create a one-off throttle pedal. Tragically, he died, but his vision was honored when Carricaburu stepped in to complete both the throttle, brake, and clutch pedals.

The SO-CAL Speed Shop Step-Boxed frame, the one used, predates the modern over-the-counter frames and features the correct mounting points for the rollbar and parachute tether mount, which connects to the rear crossmember. You’ll notice that the stock 1932 Ford gas tank is lightly notched for parachute clearance. The front suspension uses a Chassis Engineering chrome 4-inch drop drilled I-beam axle, with Pete & Jake’s tube shocks, 1937-1941 spindles, a transverse leaf spring, and SO-CAL hairpins. The steering system utilizes a Borgeson-Vega–style box attached to a custom-built, hot rod-style steering column featuring a quick-release mechanism for the Corvette-style hot rod wheel, as designed by the Veazie Bros. The braking system features Wilwood calipers and Pete and Jakes components, including a dual-reservoir master cylinder and Ford rear drums.

The original Winters Champ quick-change rearend was replaced with an N.O.S. 1970s Halibrand 301 Champ quick-change, supplied by John Robinson. Ken Sapper of Speedway Engineering modified the centersection to fit a modern 31-spline limited-slip differential, Dutchman axles, and Winters bell-style axle housings. Centering the quick-change is achieved with a chrome ladder bar setup, featuring Aldan coilover shocks and a Panhard bar.

The wheels, which come in two sets, are an interesting mix of polished and raw true magnesium 15×4 Halibrand fronts and 16×11 rears. A moment of indecision over which style of wheel to run–polished or raw—led to having both. We had the chance to photograph the hot rod with both sets of wheels. (You pick which one you like best.) The roadster was displayed at the show for several days, first with polished wheels and then with raw finish wheels. Switching between the polished and raw gives the hot rod a distinctly different look. Polished seems to provide the car with a finished, highly detailed appearance, while the raw look lends the hot rod a “bad son of a gun” vibe—all hot rod. The rubber comes by way of Michelin 145SR15 in front and Firestone Double Diamond 14/31×16.00 rears.

If you think this hot rod won’t see the light of day, you’d be wrong. As of now, it’s headed to Deuce Days. It has already participated in several local rodding events, including the L.A. Roadsters Father’s Day show. MR

Check out this story in our digital edition here.