By Ron Covell – Photography By Anton Lanesky

Anton’s Hot Rod Shop in Hiram, Ohio, has created an impressive series of exceptional builds. In this article, we will closely examine how aftermarket patch panels can help restore a car (even one in poor condition) to modern-day standards and offer a solid foundation for future modifications.

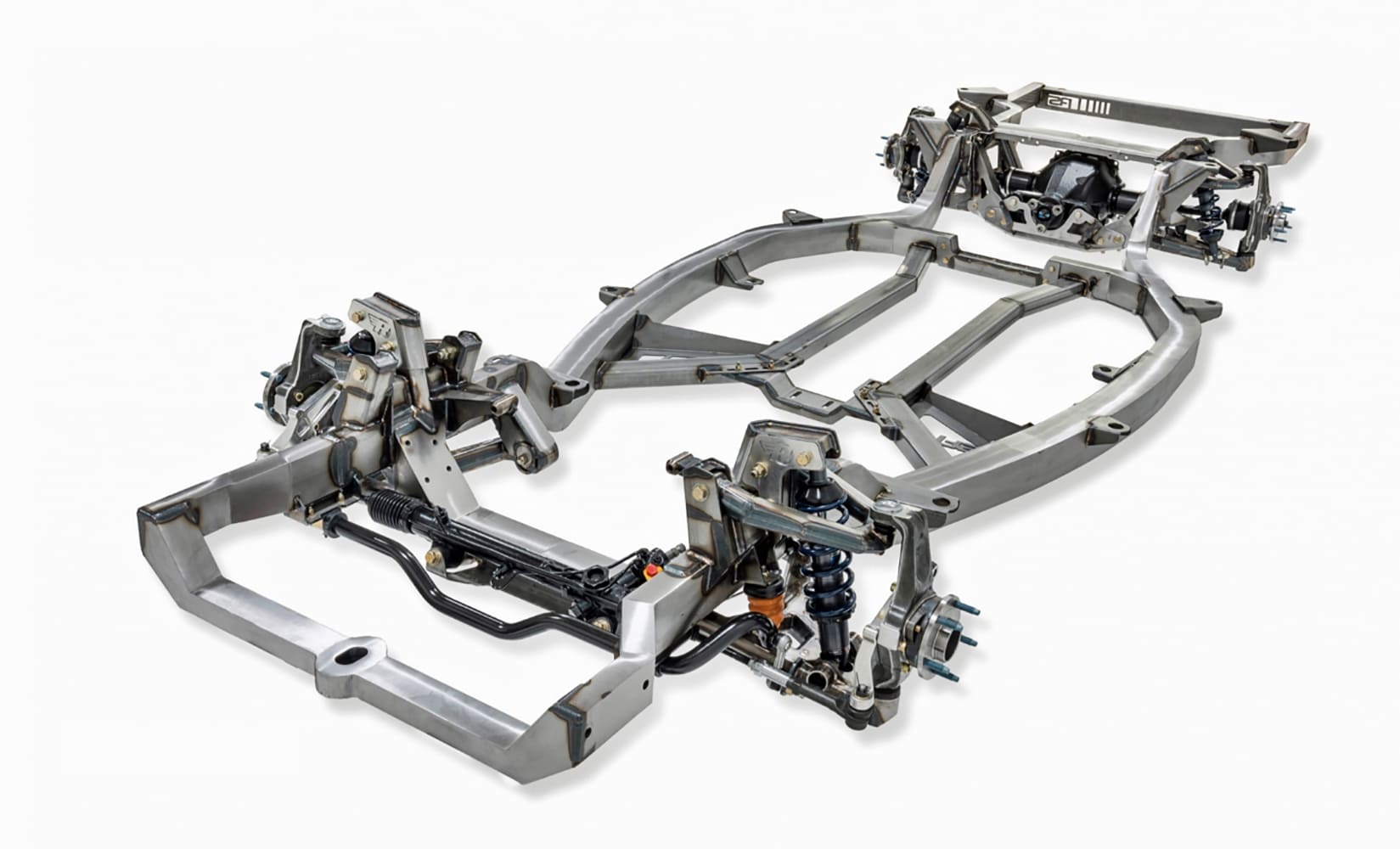

This 1963-1/2 Ford Galaxie project serves as a good example. Although the car they started with appeared decent, it didn’t require much investigation to realize that replacing the floors, quarter-panels, and several other panels with high-quality reproductions was wise. This car will include a Roadster Shop RideLine chassis with fully independent suspension designed for a supercharged Coyote engine prepared by Roush Performance.

The first step in the build was to remove the body from the original frame and test the fit against the new chassis. This chassis is designed to fit the Galaxy without modifications, but it’s always wise to conduct a test-fitting before any serious work begins. As expected, the body fit perfectly, so the next step was to send the body off to be chemically stripped and e-coated, protecting the metal from any future rust or corrosion.

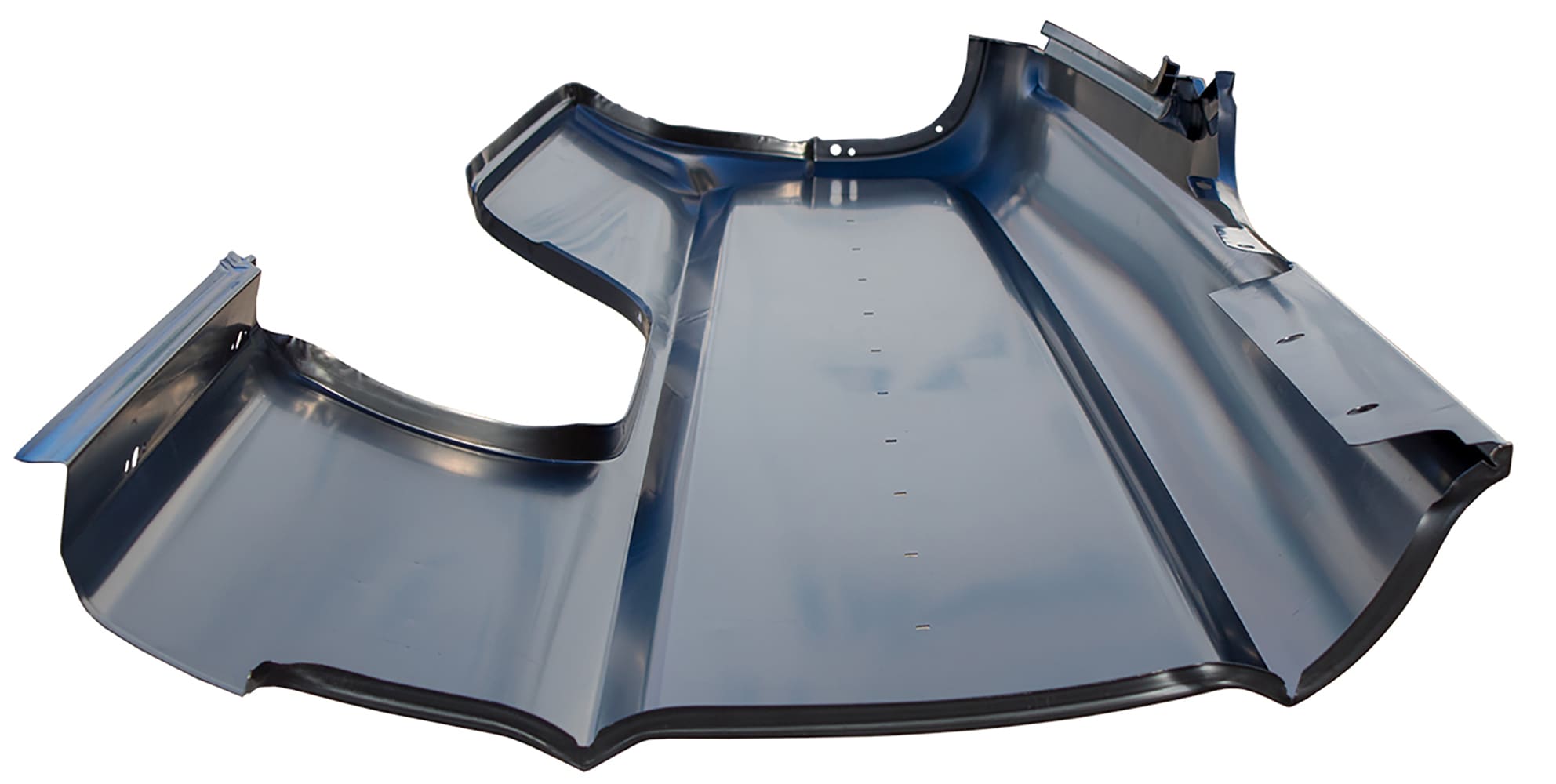

The floor and trunk panels were replaced first, while the outer body skin remained untouched. The quarter-panels were removed following the reinforcement of the bottom of the body with the new panels. All replacement panels were sourced from Auto Metal Direct (AMD), and as you’ll see, they feature factory-style flanges, ensuring a hassle-free fit.

While the quarter-panels were removed, the wheelhouses were widened to fit the large wheels and tires intended for this build. Fortunately, the inner edges of the original wheelhouses provided the necessary clearance, so only the outer wall needed adjustment. This eliminated the need to modify the floorpans.

The main task was to correctly align the large quarter-panels before clamping and tack-welding them into place. Achieving the right fit is crucial; otherwise, alignment issues will persist. After the quarters were tack-welded in position, the fit of the doors and decklid were double-checked to ensure no problems arose. Once the fit was confirmed, all the joints were TIG welded together.

On the original Galaxie bodies, the sail panels (adjacent to the rear window) were attached to the roof with an overlapped joint smoothed with lead at the factory. Anton cut out this problematic joint and replaced it with a strip of body-thickness sheetmetal. This change will eliminate the need for lead filler and help prevent potential problems in the future. Overlapped joints can cause various issues, including trapping moisture (which can lead to rust), and sometimes the joints may show through the paint as the panels expand and contract with weather-induced heat cycles.

Now that the car’s basic body structure is restored, Anton has many exciting ideas to make this build unique, featuring a variety of custom-fabricated details. Stay tuned!

-MR

Check out this story in our digital edition here.

Sources

Anton’s Hot Rod Shop

(330) 741-0262

antonshotrod.com

Auto Metal Direct

(770) 967-0909

autometaldirect.com

Roadster Shop

(847) 949-7637

roadstershop.com

Roush Performance

(800) 597-6874

roushperformance.com