By Fuelish Media – Images by Fuelish Media

Having built numerous vehicles over the years, Mike Feeney of Scottsdale, Arizona, has developed a discerning taste. With this wealth of experience, he set his sights on a 1967-72 C10 project, envisioning a showstopping ’67 or ’68 gracing his garage in his new dream scenario. So, the hunt began, but despite checking out several trucks and even bidding on a few at the Barrett-Jackson auction, he couldn’t quite find the perfect fit.

Auctions don’t always work the way you want, in that they don’t just line up the trucks you’re bidding on sequentially. There can be hours or days between two potential options, and that gave Mike some time to kill. In the process he got to talking with the folks at Premier Street Rod. They build 1967-72 complete reproduction cabs, beds, and sheetmetal, and happened to have a fine example of their C10 sitting on a GSI chassis right there. Ross from Premier and Mike hit it off and they struck a deal with one condition: Mike wanted Premier to be the shop to finish the build. One handshake later, Mike was the proud owner of a C10.

Mike is, as previously mentioned, particular. Don’t take that to mean he’s fussy or hard to work with—quite the opposite. But he knew what he wanted and that’s what the team worked toward. The overall plan was for something straightforward and simple; the truck already had a solid chassis with coilovers, so that was good to go. But what else is on that chassis?

Let’s start with the steering. It’s a Flaming River rack-and-pinion setup to keep the truck turning accurately on those twisty back roads. The front and rear suspension sit on coilovers, with a custom four-link out back and GSI sway bars. Any truck that’s built to be driven needs decent brakes, and in this case that’s a set of Wilwood 14-inch rotors all the way around with six-piston calipers up front and four-piston models in the rear. All said and done, this was a chassis meant to carve canyons.

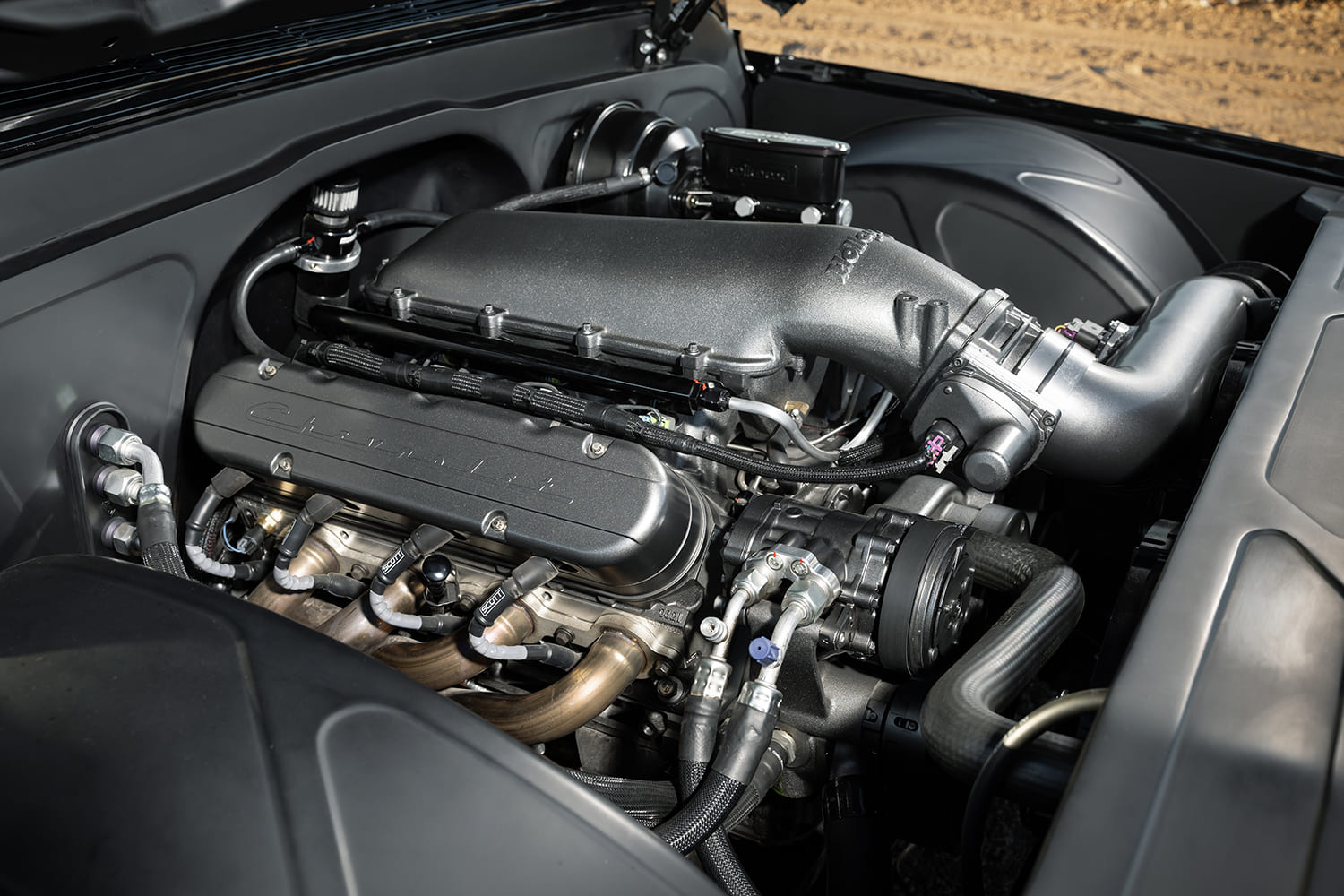

Well, it would be once it had the right powertrain. For that, Mike did an LS3 crate engine from GM and paired it with a 4L75E transmission. The combo puts out 575 horses to the Ford 9-inch rearend, which is more than enough to spin the 20×8.5 and 22×12 Billet Specialties Geometric wheels with Michelin rubber to hold it all down.

Then there’s the interior of the truck, which Mike wanted to be timeless yet simple. For that he went to Marco and the crew at Sew Cal Rods in Ontario, California. Now, you may have an image of what an interior shop looks like, what with the single upholsterer in a run-down garage with a 50-year-old sewing machine that’s hanging on by a thread (pun intended). This is not that shop. Sew Cal has multiple 3-D printers, vacuum forming machines, and all sorts of other technological wonders that take doing your interior into some real futuristic stuff.

When it came time to do Mike’s interior they started with a full 3-D scan of the bare cab. Then, built everything in Solidworks, which is a 2-D and 3-D modelling software they can use to create everything from scratch—which is just what they did. The cockpit was built around a Holley EFI 12.3-inch Pro Dash, which gives Mike all the data he needs while he’s on the road. That monitor sits in a 3-D-printed piece that was then wrapped in Italian leather. The center console was also 3-D printed, and certain accents even used carbon-fiber–infused plastic. Once everything was done it was smoothed and either painted or wrapped. While the seats start with Glide Engineering products, the foam is hand sculpted to match exactly what Mike wanted. As if all the high-tech stuff wasn’t already overwhelming, the leather on the seats was laser perforated. That’s right, they used lasers to build this truck.

The outside is a whole other ball of wax. Again, clean, simple, and timeless were the themes, so Mike wanted a few subtle body modifications. The front and rear bumpers were tucked tighter to the body, which cleans up the truck a lot. Then there was the paint; Mike knew he wanted a two-tone, but what two colors? Well, that involved a lot of spray-out panels, testing, and asking for his wife’s opinion, but in the end Jason Deering from Premier painted the truck PPG Brilliant Metallic Black up top and PPG Storm Gray on the bottom. Continuing the slick theme, Lucky’s Auto Glass stepped with a front and rear flush glass treatment.

Moving onto the bed, which was narrowed by 1 inch for a better profile and on the inside, the modified floor raises in the middle to show off the chassis. Leveling things up, it was dressed up by a company called Dek-X based in Lake Havasu City, Arizona, right near Premier. Yup, that’s boat decking right there, and it not only gets a lot of attention but it’s functional. Mike can toss his golf clubs in the bed without a second thought. It’s pretty great.

With all being said and done, Mike now drives this truck, which is better known as the “Mistress.” Though this was a completely new journey, it took a quite a bit of effort to build something from nothing. At this point, it is now a fully functional driver and that’s how it will be enjoyed from here on out. Because it was built to meet today’s high standards, Mike plans to take the truck—now titled as a 1968 Chevrolet C10—to shows, cruise it around town, and go to a few cars and coffee meets. He built the truck exactly the way he wanted, so he’s going to drive it, too. He’d have it no other way.

Check out this story in our digital edition here.