This is our second article on the 1968 Camaro being built at Roadster Shop.

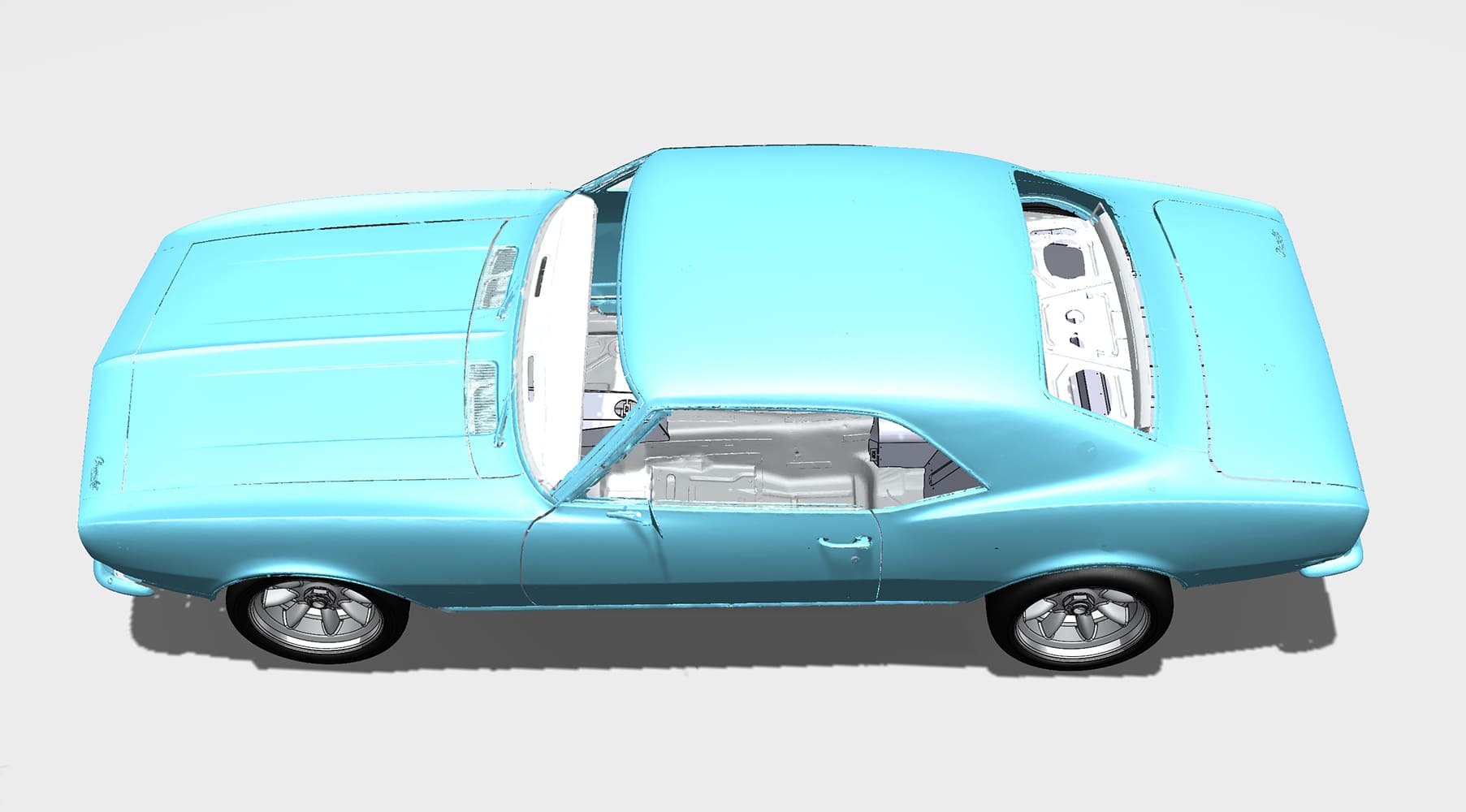

Perhaps more than any other component on a car, the wheels and tires can really set the character of a build, especially for performance-oriented cars. It is not uncommon that the ideal wheel and tire combination will not fit inside the factory wheelwells. When serious modifications take place, careful attention is required to keep everything looking balanced and in proportion.

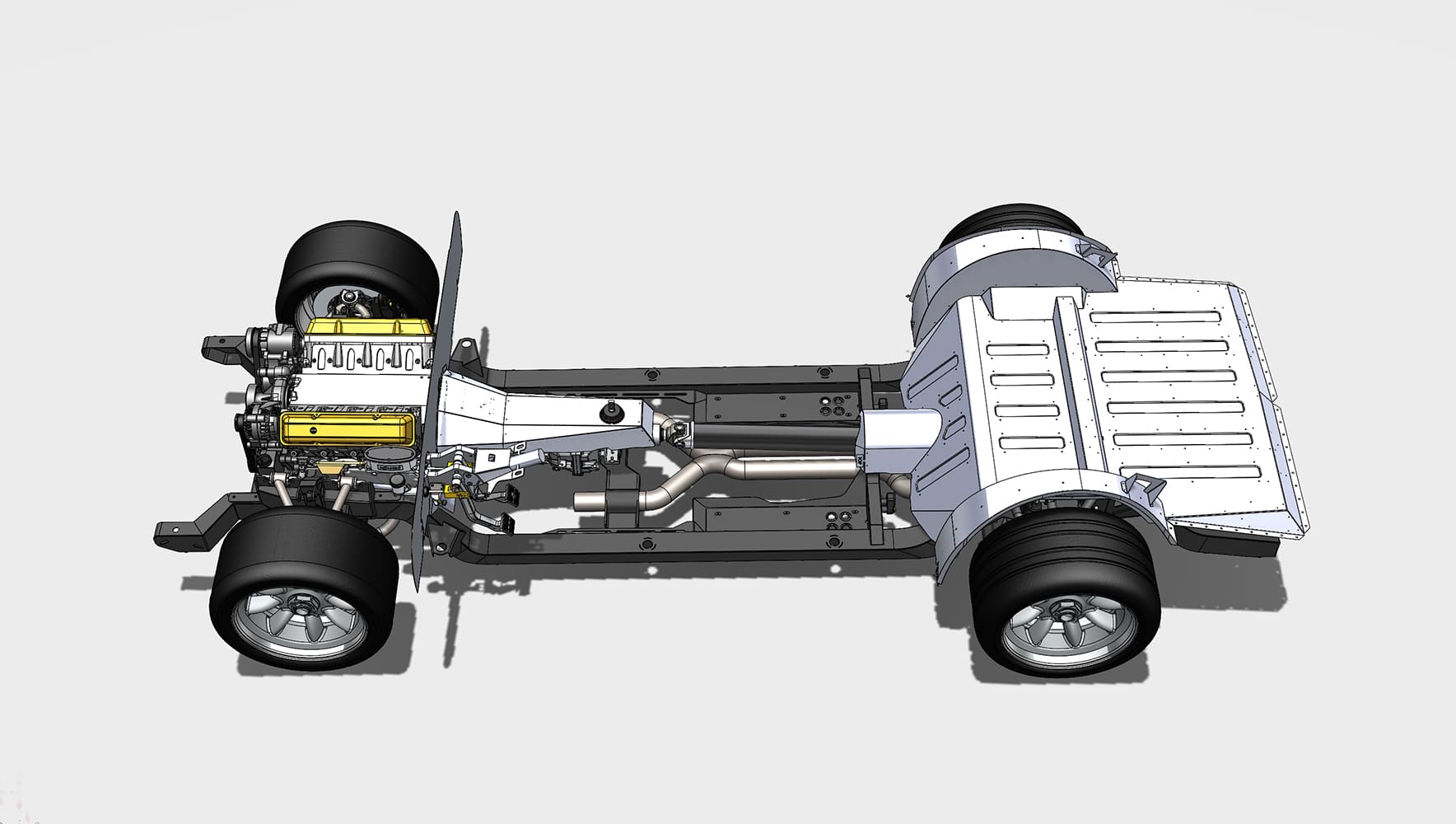

Mike O’Brien, the lead engineer at Roadster Shop, used scans of the body and chassis to experiment with various tire diameters and widths in order to achieve the desired look. They landed on 18×11 315/30R18 fronts and 18×12 335/30R18 rears, with BFG Rival S tires. The wheels were designed in-house by Chris Gray, and machined by Greening Auto Company in Cullman, Alabama.

The goal was to have very subtle wheel flares that resemble the shapes on the original car. To accomplish this, they bowed the rear quarters out roughly ¾ inch to help minimize the size of the flare. They also experimented with different track widths on the front suspension to allow for an outer wheel lip that was proportionate to the rear. They wanted the car to sit relatively level, so when they integrated the IRS centersection, they tweaked the framerail profiles to adjust the ride height. Care was taken to balance all these factors to keep everything proportionate.

Cody Young did most of the metal fabrication on this project. Starting at the rear of the car, new quarter-panels were fitted, and the lips of the wheelwells were carefully cut away. The plan called for reusing them as the outer edge of the new flares.

The quarter-panels get pretty flexible with the original wheelwell lip cut away. They were fitted tightly against the body on the top, front, and rear edges but were pulled outward at the top of the wheelwell, effectively bulging the width of the quarter-panel about ¾ inch. A band of metal about 4 inches tall was cut from the middle of the panels, centered on the horizontal bodyline. This cut allowed the upper and lower portions of the new quarter-panel to be flexed into position, preserving the continuity of the shape as the body was bulged out around the wheel.

Next, new panels were fitted to fill the horizontal cuts. These panels were bent in a break at an angle that matched the horizontal bodyline, then were aligned and tack-welded to the quarters. Finally, the quarter-panels were fastened to the car with Clecos, holding them in position but allowing them to be removed when access was needed to the back side.

The lips from the reproduction wheelwells were re-contoured and held temporarily into place to check the fit against the tires. A lot of this work is done “by eye,” developing shapes that flow nicely into the original bodywork and have a look that is reminiscent of the original wheelwell flares.

With the wheelwell lips fastened temporarily in place, patterns were made for the new flares, which bridge the gap between the lips and the quarter-panels. New metal was cut from these patterns, carefully shaped, then fitted to the quarter-panel.

Once all the pieces were properly contoured, they were trimmed to provide a butted joint and tack welded together. After tacking, the joints were worked with a hammer and dolly to fine-tune the fit, then finish welded.

It was helpful to remove the new quarter-panels from the body at this point to provide unimpeded access to the back side as the panels were smoothed and metalfinished. Then the quarters were reinstalled on the body and checked for fit.

A piece of sheetmetal was folded into an angle and tack-welded into place to establish a consistent gap in the ’jamb area just behind the door. After the fitting and adjusting was perfected, all the welds on the quarter-panels were completed, and all of the joints were metal-finished.

With the front fenders assembled and metal-finished, the overall visual impact truly comes to life. It’s a perfect match for the car, and a testament to the outstanding craftsmanship of the team at the Roadster Shop.

Check out this story in our digital edition here.

Sources

Greening Auto Company

(256) 352-8700

greeningautocompany.com

Roadster Shop

(847) 949-7637

roadstershop.com