By Ron Covell – Photography By Jessica Roach

MeKenzie Murphy is a real auto enthusiast. When she decided to build a 1932 Ford highboy roadster, she turned to Johnson’s Hot Rod Shop in Gadsden, Alabama, to construct this unique ride. Alan Johnson has a long history of turning out traditional-style hot rods fitted with unique upgrades, and Murphy knew she could count on him to add his special touch when building the car of her dreams.

While the hot pink color is unusual, it has helped to gather a lot of attention for the car, which won the Street Rod of the Year award at the Triple Crown of Rodding show in Nashville. It was also a Top 5 finalist for Street Rod of the Year with Goodguys and a finalist for the America’s Most Beautiful Roadster award at the Grand National Roadster Show.

This car has a traditional character, but many special features make it unique. In this issue, we’ll look at how the cockpit was stretched and how the windshield was chopped and laid back to a radical angle.

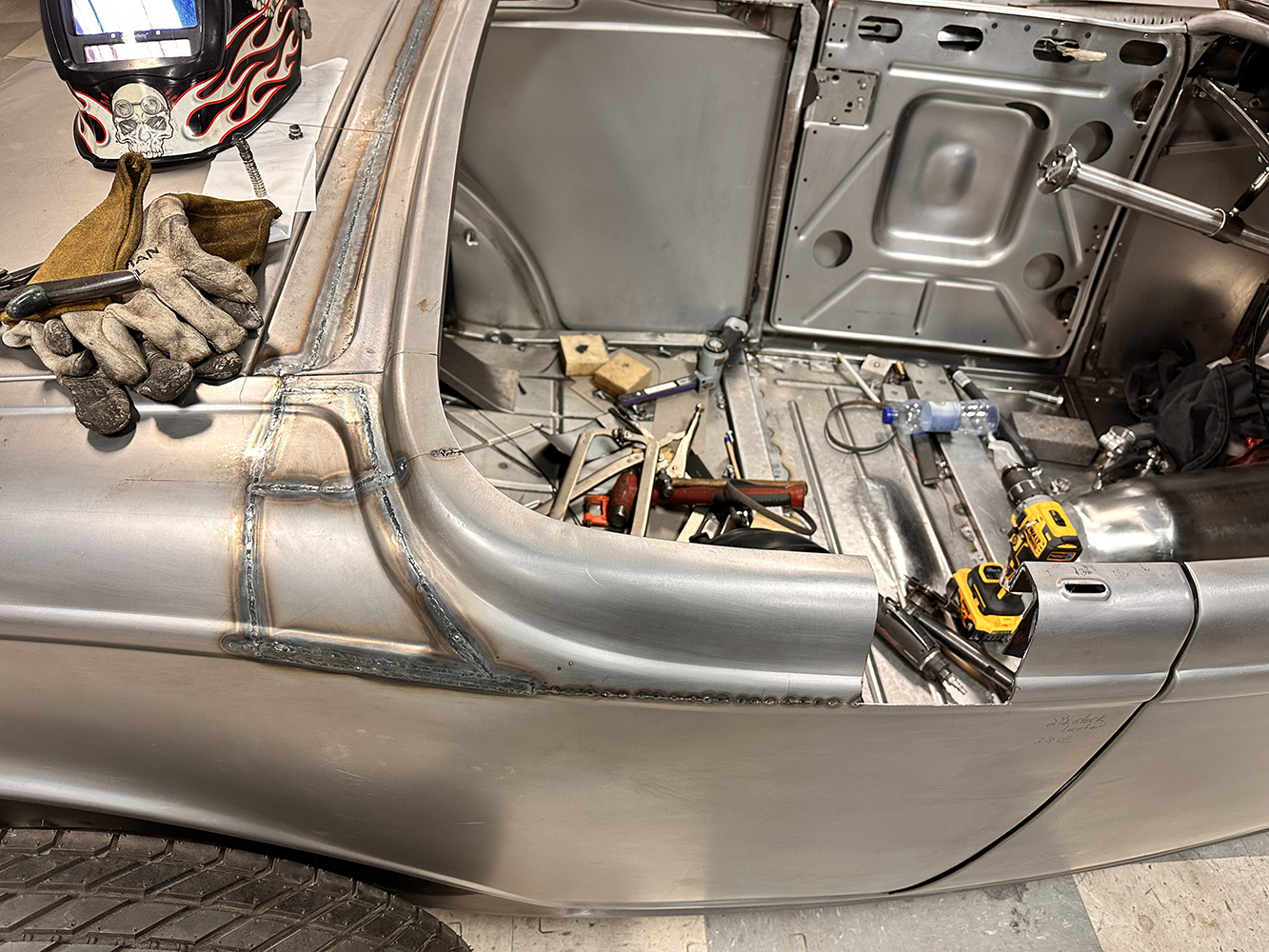

The cockpit was enlarged by moving the rear edge back, and then the quarter-panels were modified to match. Many people don’t see this modification at first glance, but it allows more comfort for the driver and passenger and the use of full-thickness padding on the seatback. Radical changes like this must be handled with care to preserve the classic proportions of the roadster body, which looks great in stock form.

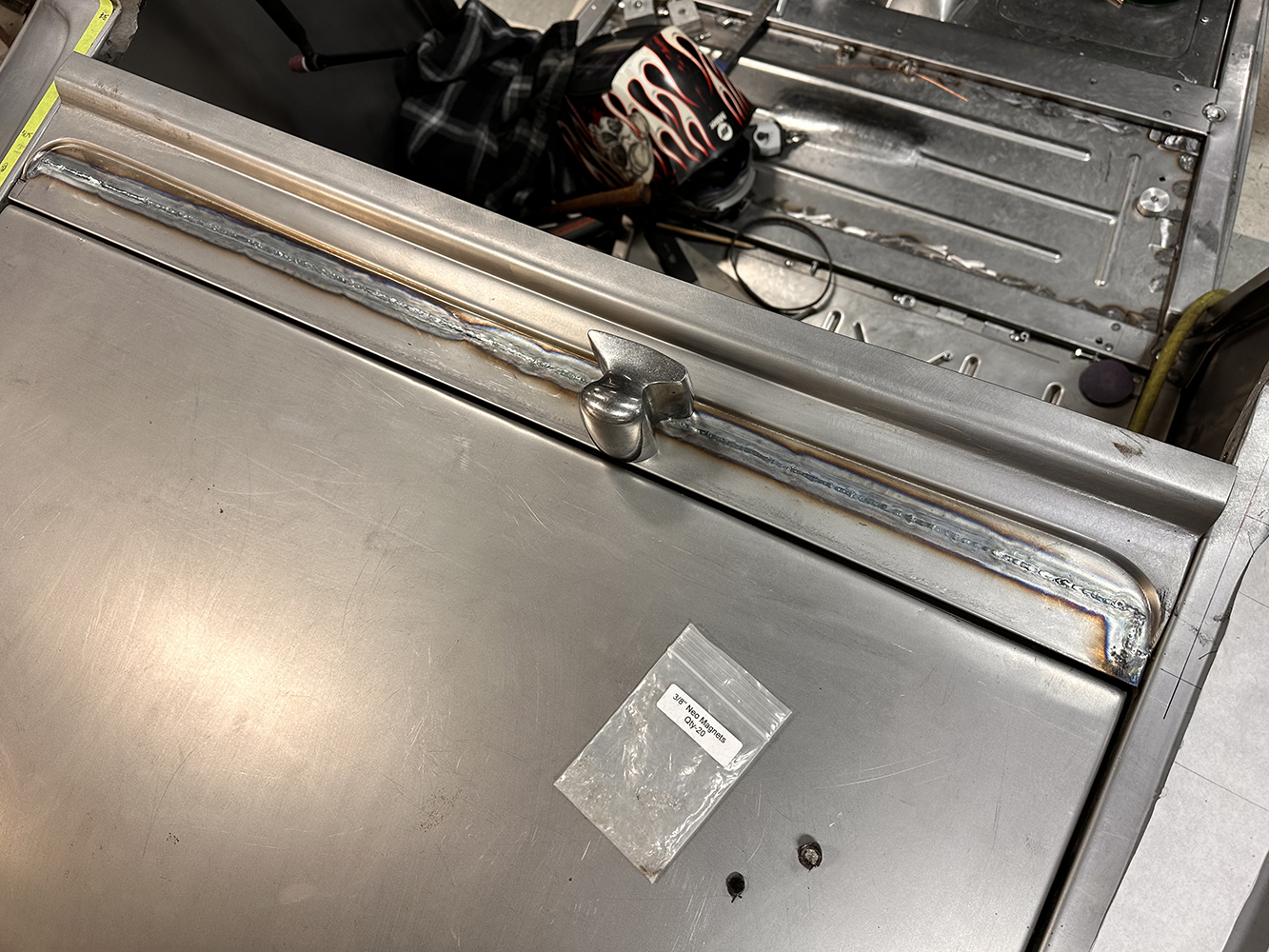

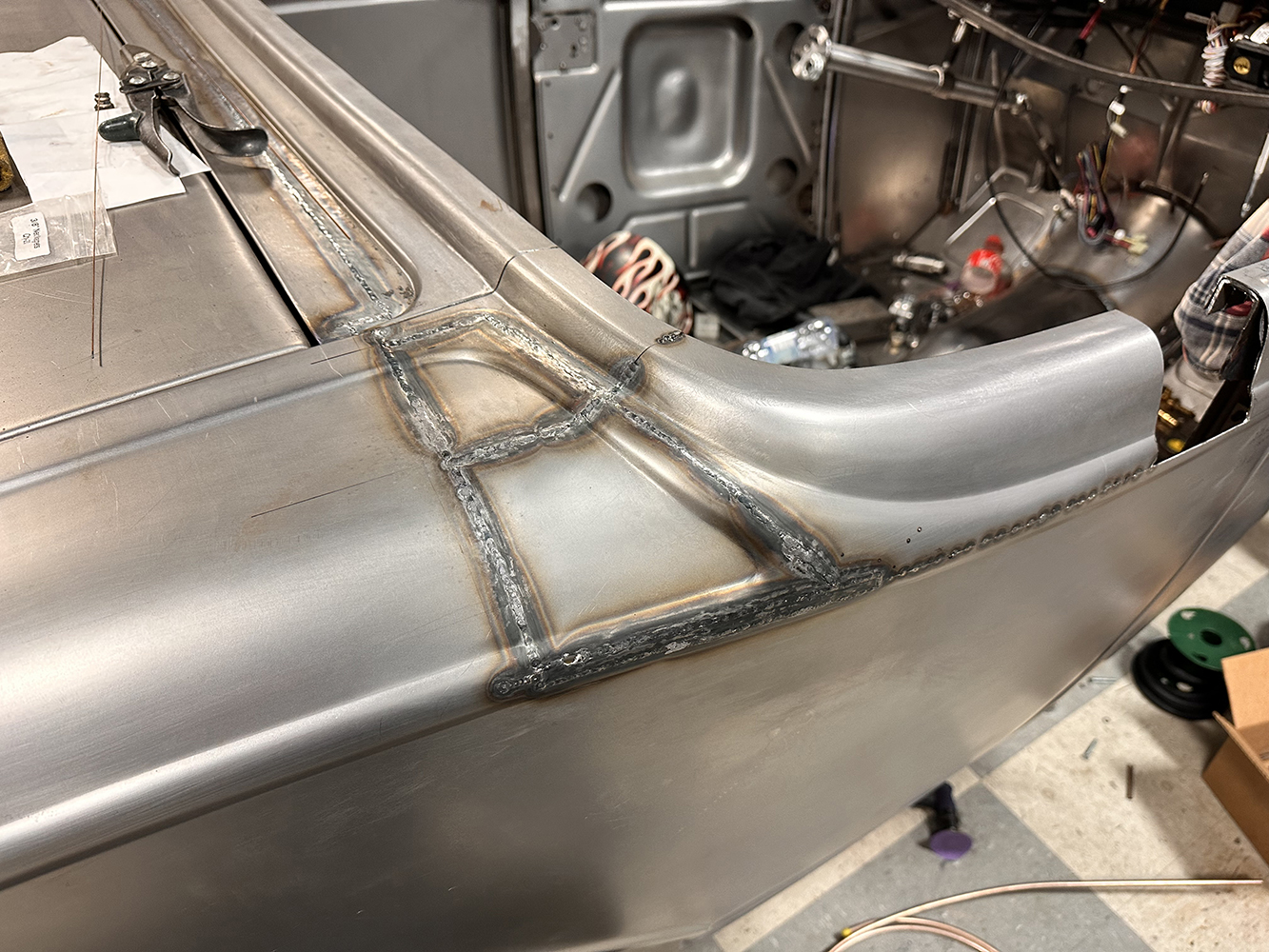

The panel just behind the seatback was cut laterally, and the front portion was moved back 4-1/2 inches. After trimming the panels to fit neatly together, they were TIG welded and the joint was smoothed. The center body panel position provided a target for fitting the complex shapes at the top front corners of the quarter-panels. Many body lines converge in this area, subtly tapering toward the rear, so it took a lot of tweaking and massaging to get this area to retain its visual flow—but the results speak for themselves.

Sturdy tubular bracing was placed inside the roadster body, carefully positioned to be out of the way while providing attachment points for the upholstered panels.

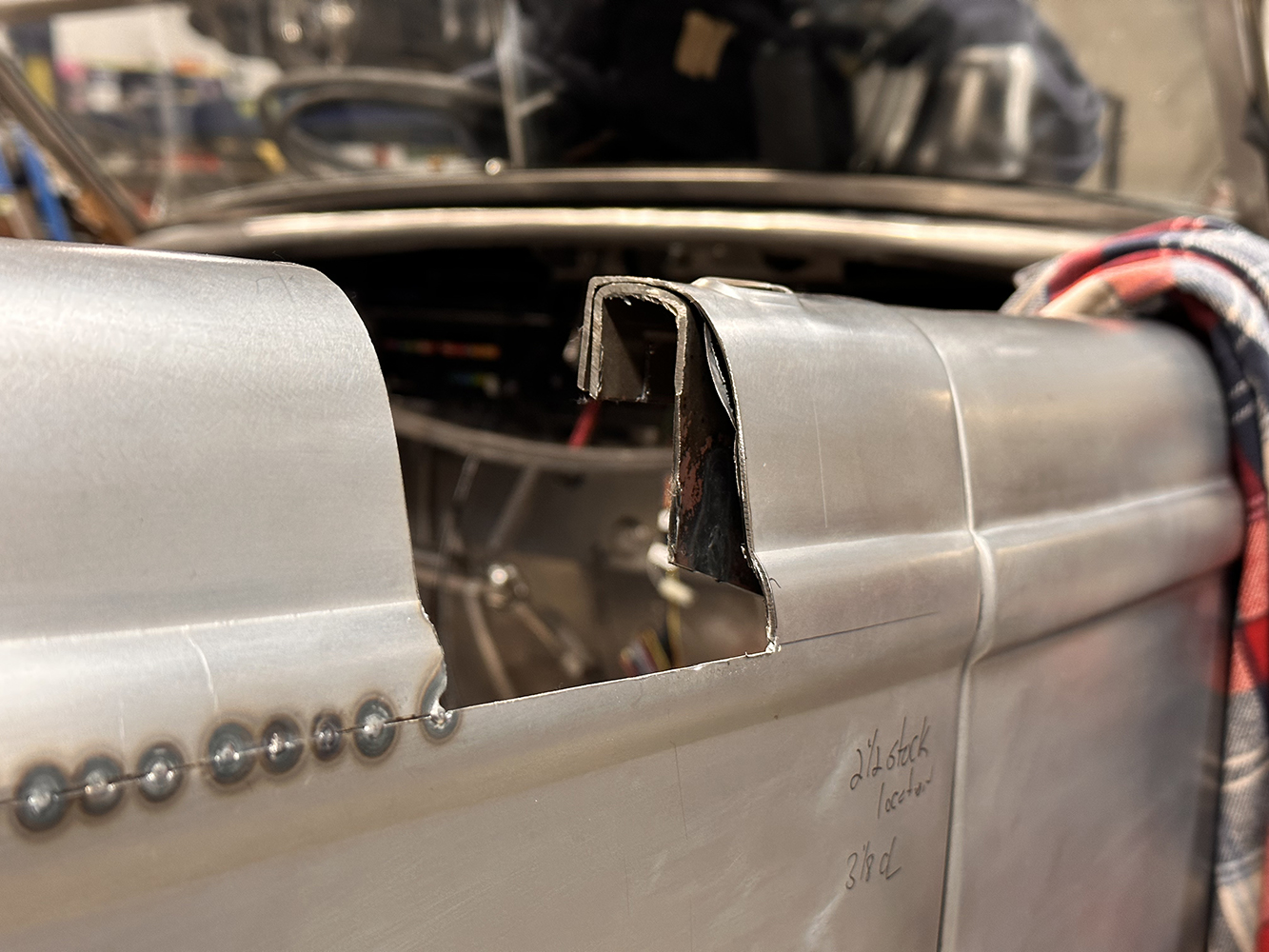

The windshield was laid back a rakish 25 degrees over stock. This required radically reshaping the bead on the cowl that the weatherstrip fits against, and special cast bronze lower stanchions were required to hold the posts at their new angle.

The photos show how this work was accomplished. This unique roadster underwent a host of other modifications, which we’ll examine in future articles.

After welding, all the joints are worked with a hammer and dolly to restore the proper contours.

Source

Johnson’s Hot Rod Shop

(256) 492-5989

johnsonshotrodshop.com

Check out this story in our digital edition here.