By Ron Ceridono – Photography By Tate Radford

When Colin and Sue Radford found this forlorn 1965 fastback Mustang it was obvious that major repairs were needed—being able to see the ground through the floor was one of the first indications of the problems to be dealt with. But the Radfords are not easily discouraged, and they knew everything needed to fix the Ford was available from Golden Star Classic Auto Parts. Based in Texas, Golden Star offers an array of high-quality replacement components for classic cars and trucks from GM, Ford, and Chrysler.

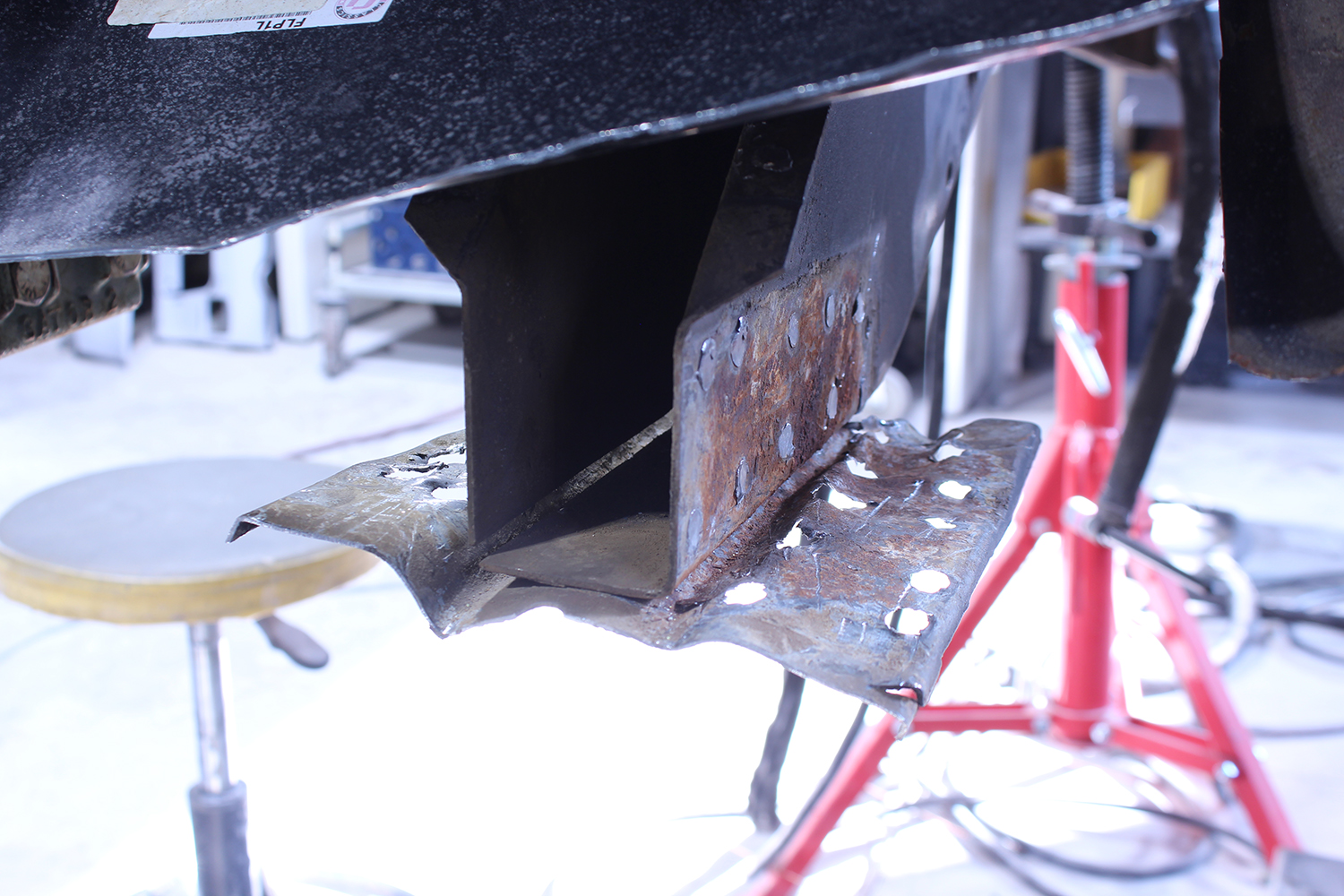

There was a time when making repairs to the damaged floor of a project car prompted all sorts of questionable creativity. Over the years, we’ve seen repairs made with license plates, road signs, galvanized sheetmetal, and odd bits of salvaged body parts. Often, these crude repairs were secured over gaping rust holes with a handful of sheetmetal screws. In this case, the previous owner had attempted to make repairs with actual patch panels, but they were installed so poorly that the only way to make things right was to remove the entire floor and start over.

For unitized construction cars like the Mustang, the lack of a separate frame means the entire body becomes a load-bearing structure. While various supports all add strength, the doorsills, floor, and even the roof are all critical components when it comes to maintaining the rigidity of the body. That means replacing the floor is not only a cosmetic improvement, it’s also a structural repair.

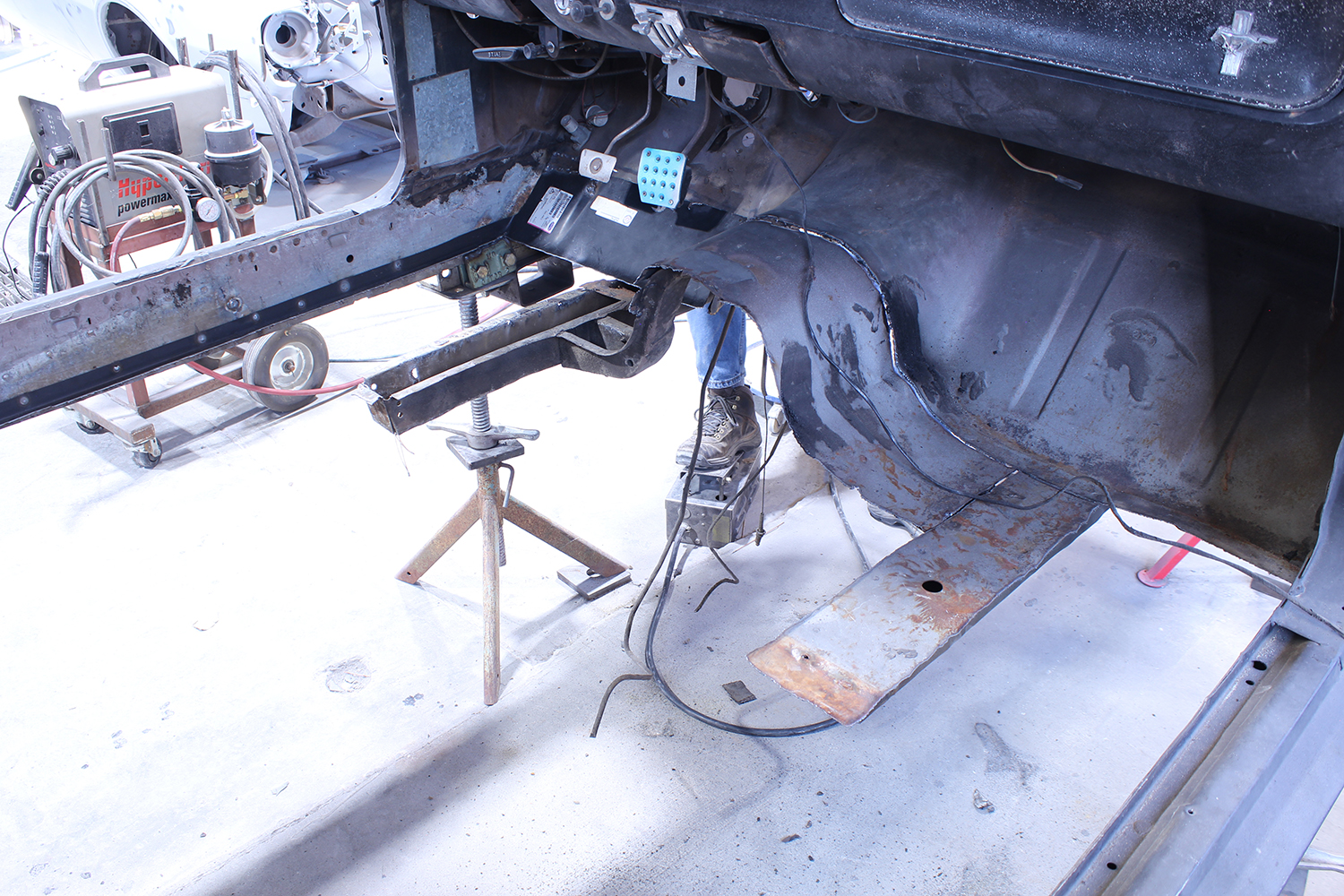

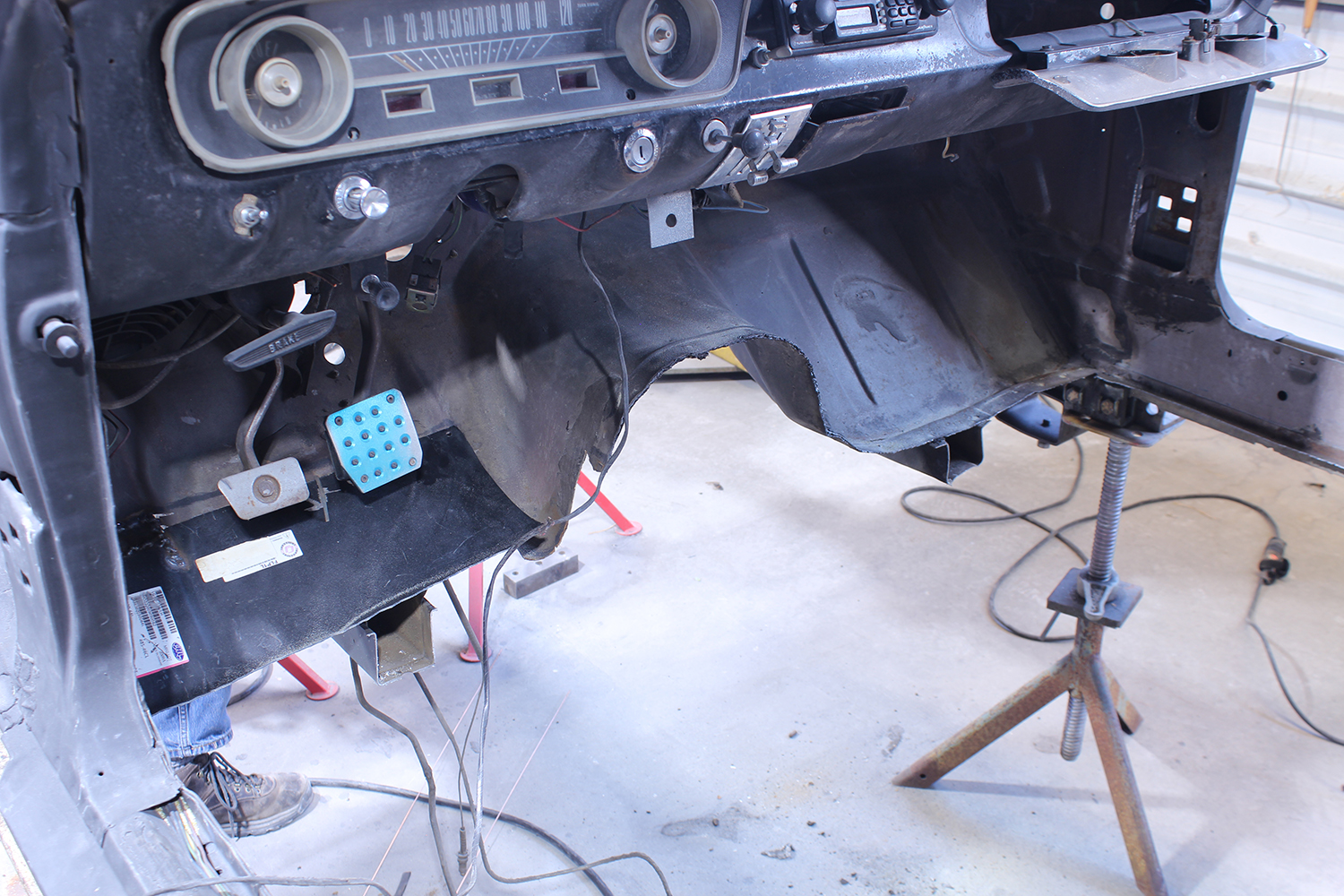

The Radfords’ grandson, Tate, began the repair process by removing the floor from the toeboards and moving it to the back seat supports. With the floor out of the way, the floor-to-firewall supports were also removed. These simple yet critical pieces tie the car’s floor to the subframes that mount the front suspension.

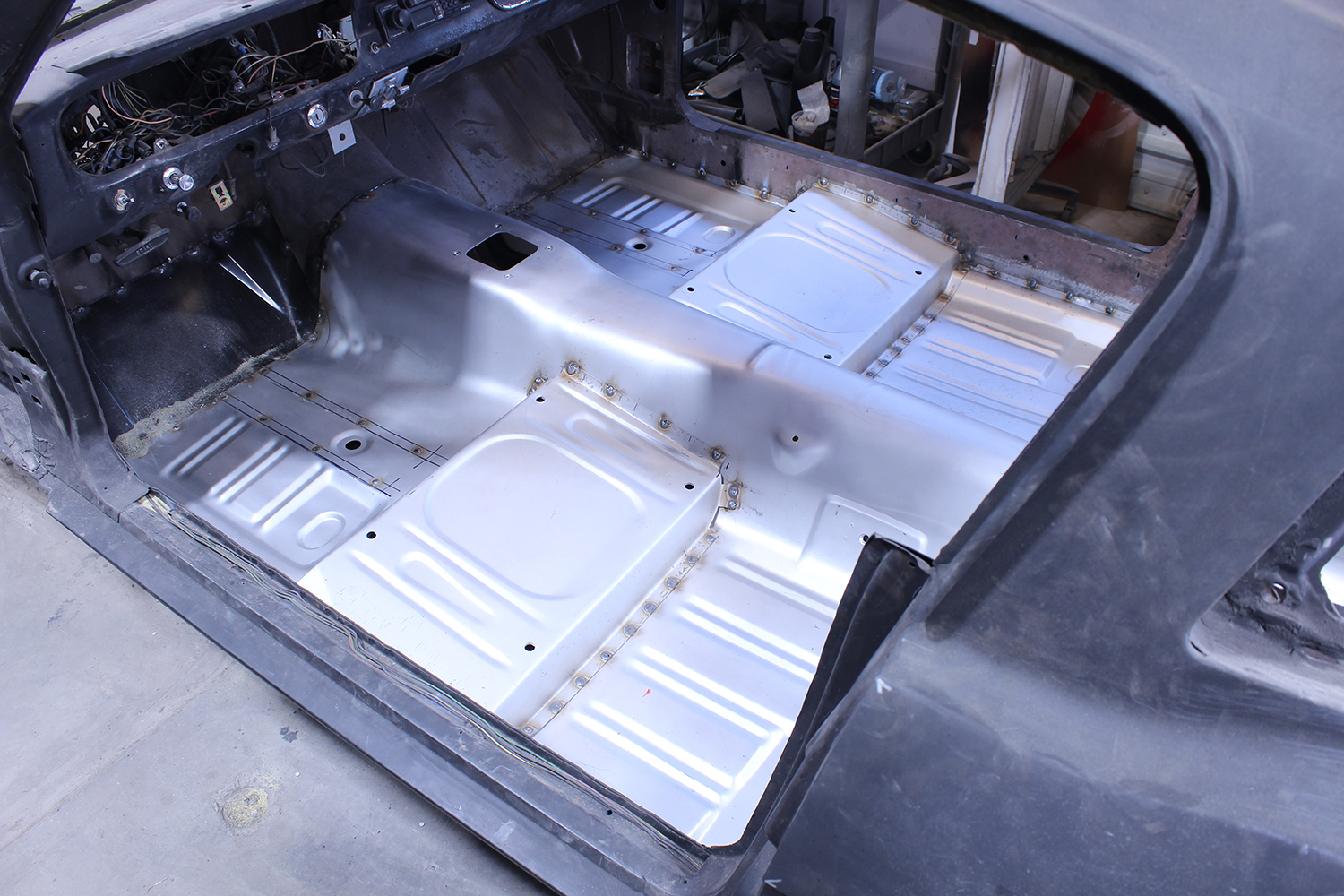

Reconstruction of the fastback began with installing Golden Star’s replacement floorpan to firewall supports (PN FP20-64FF). Next came the complete floorpan (PN FP20-64) (these floors fit coupes and fastbacks; convertible floors are also available). The integral transmission/driveshaft tunnel and stamped indentations make the sheetmetal extremely rigid and duplicate those features found on the factory floors. The complete floorpan included front seat platforms that mount the seats and reinforce the floor structure.

Once the floor-to-firewall supports and the entire floor was replaced, the last step was to add a leftside floorpan to the firewall patch panel (PN LH FP20-641L) to replace the previously poorly executed replacement. Only the driver side panel was replaced as the passenger side sheetmetal was solid.

When Ford introduced the fastback version of the Mustang in 1965, body style 63A (09), a little over 77,000 were sold. While there is slightly more than the number of convertibles produced that year (roughly 73,000), fastback production dropped in the bucket compared to the over 409,000 coupes sold. The following year, fastback sales dropped to less than 36,000, the lowest production of all models manufactured in 1966 (coupe sales reached almost 500,000, and slightly more than 72,000 convertibles went to buyers).

Given the probable survival rate of early Mustang fastbacks, it makes sense to save one if possible, and thanks to Golden Star it can be done effectively. With new floor and supports installed, the Mustang’s foundation was solid again and it was no longer possible to see the ground inside the car. Next time, we’ll focus on repairing more of the abuse our ponycar has endured by replacing the quarter-panels. We will reveal a few tricks to make the job easier.

Check out this story in our digital edition here.

Sources

Golden Star Classic Auto Parts

(972) 315-3758

goldenstarauto.com

Radford Auto

(208) 589-6722

radfordauto@hotmail.com