By Ron Ceridono – Photography by Brian Brennan

Riding in hot rods can be like being in a noisy sauna on wheels; they can be hot and loud, making even the shortest trips unpleasant. Of course, there are a number of options when it comes to making the passenger compartment of any car more hospitable. One of the most effective and easiest to apply is Advanced Thermal Acoustic Coating (ATAC) from Design Engineering Inc. (DEI).

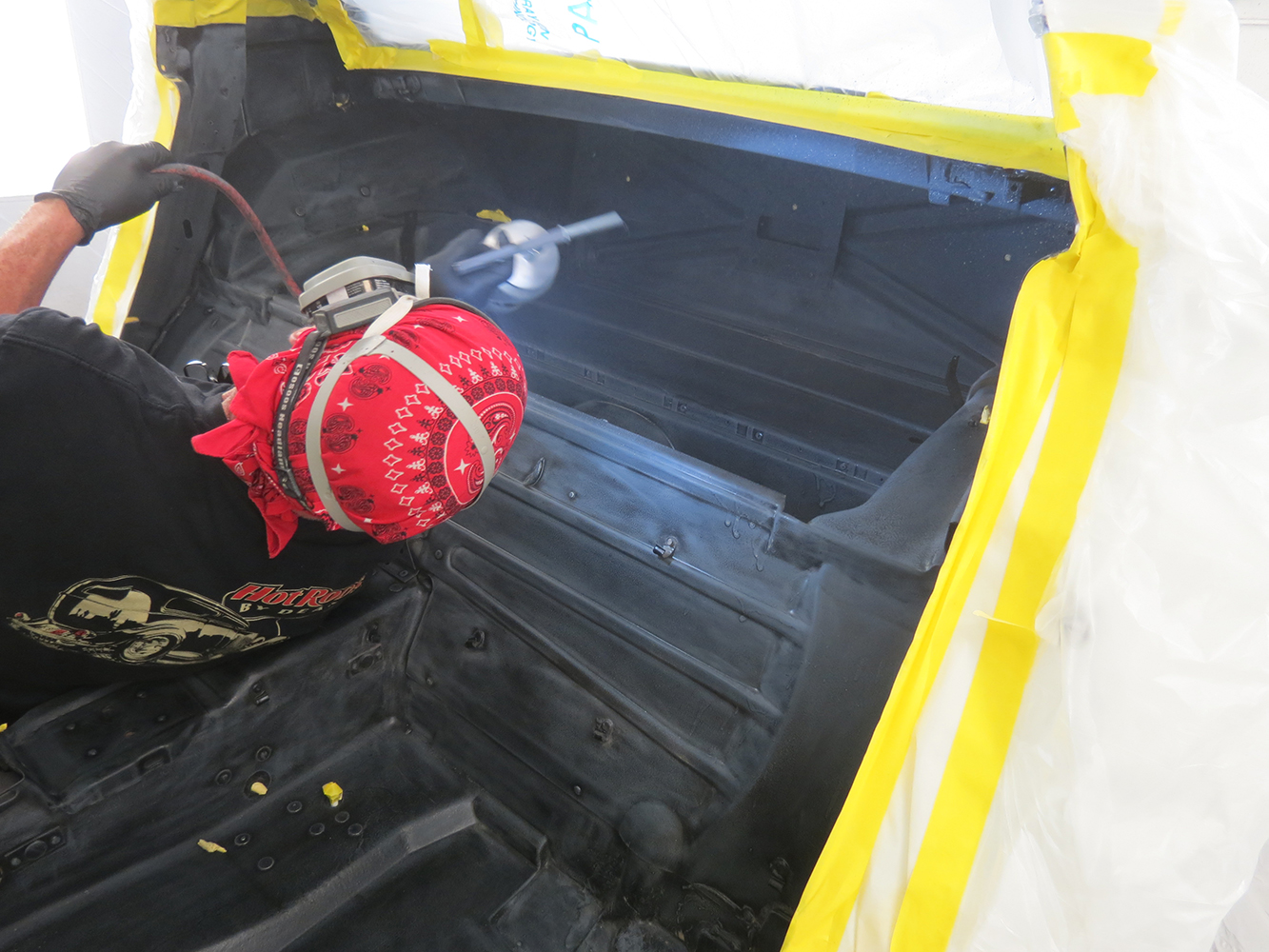

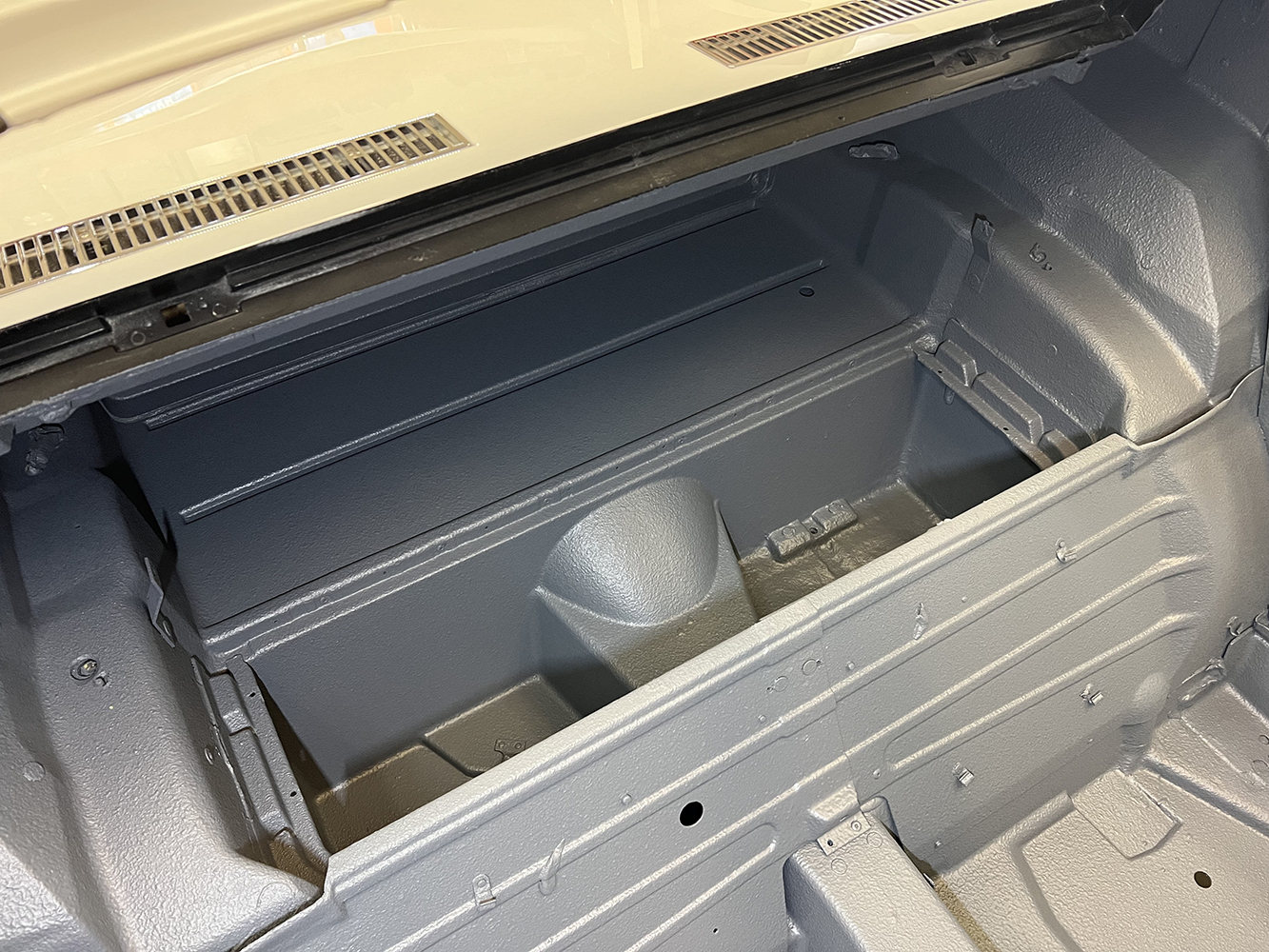

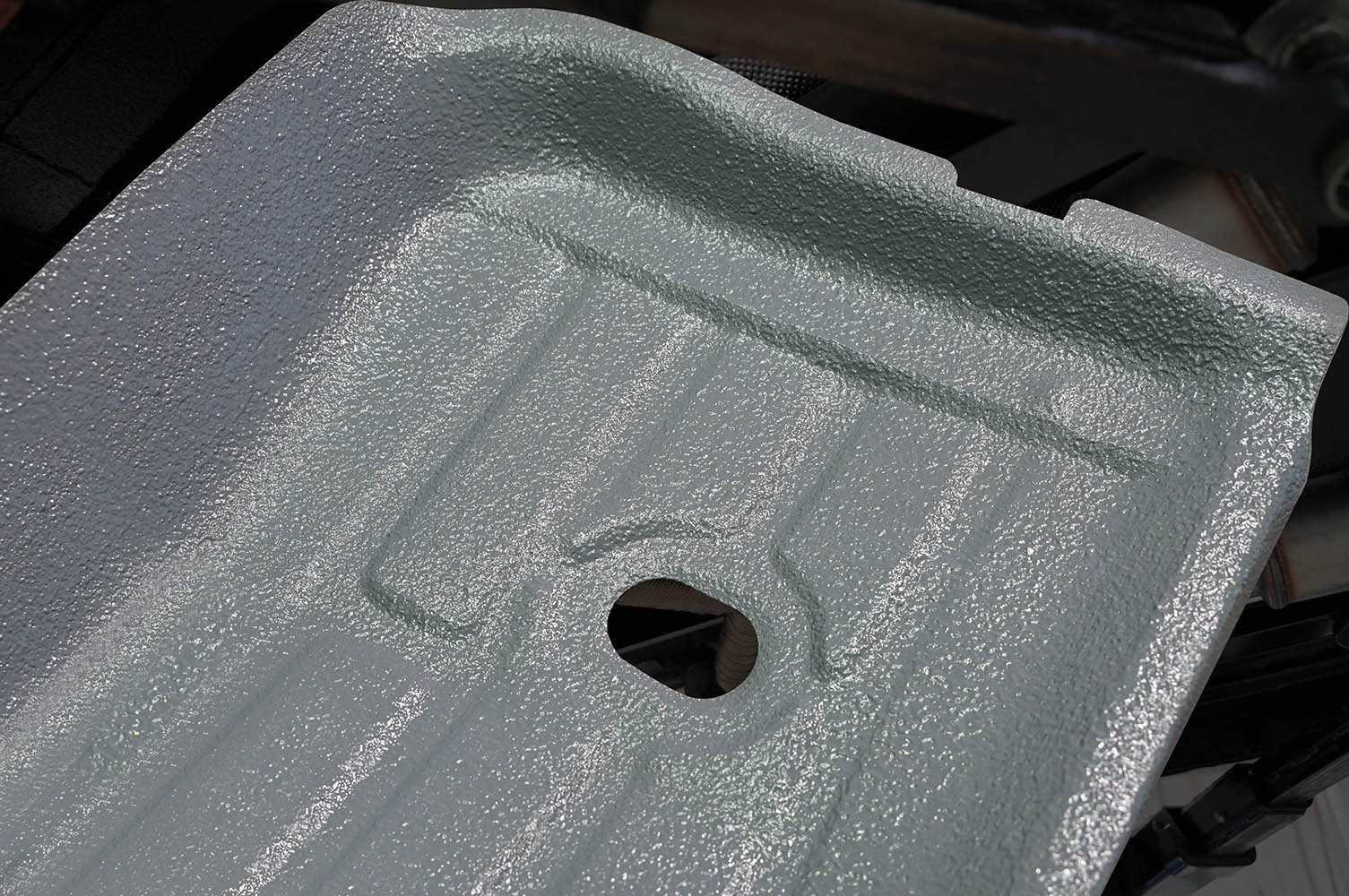

DEI is a major supplier of temperature control wraps, sheet-style insulation, and a variety of heat and acoustic control products, but their new ATAC is their first paint-on product that does both. The unique ceramic micro-sphere technology is a heat and sound barrier that is easy to apply to the interior surfaces of passenger compartments (ATAC is not for use in engine bays). ATAC can be applied to floors, doorskins, trunks, roofs, wheelwells, and any vertical or horizontal interior surface, as well as hard-to-reach areas such as trunk interiors, rear quarters, and inside body panels and doors.

Before applying ATAC, the surface must be thoroughly prepared to promote adhesion. Any rusted areas should be treated with a rust converter, or the rust should be completely removed. Primer must be applied to bare metal or rusty areas that have been treated. DEI recommends the use of a shop vacuum and tack cloth before applying a uniform wet coat of ATAC 12-16 mills thick with the lowest air pressure that still provides good coverage. (Be aware that applying a thick coat at one time can cause the coating to crack.) A second or third coat can be applied after 12 hours if necessary.

Applying ATAC can help insulate the passenger compartment from external sources of heat, which can also make the A/C system more effective. ATAC will also cut down on the sounds you don’t want to hear and make those that you do, like your car’s stereo and conversations with passengers, easier to hear. It will make your hot rod twice as nice.

Check out this story in our digital edition here.

Source

Design Engineering Inc.

(800) 264-9472

designengineering.com