By Ron Covell

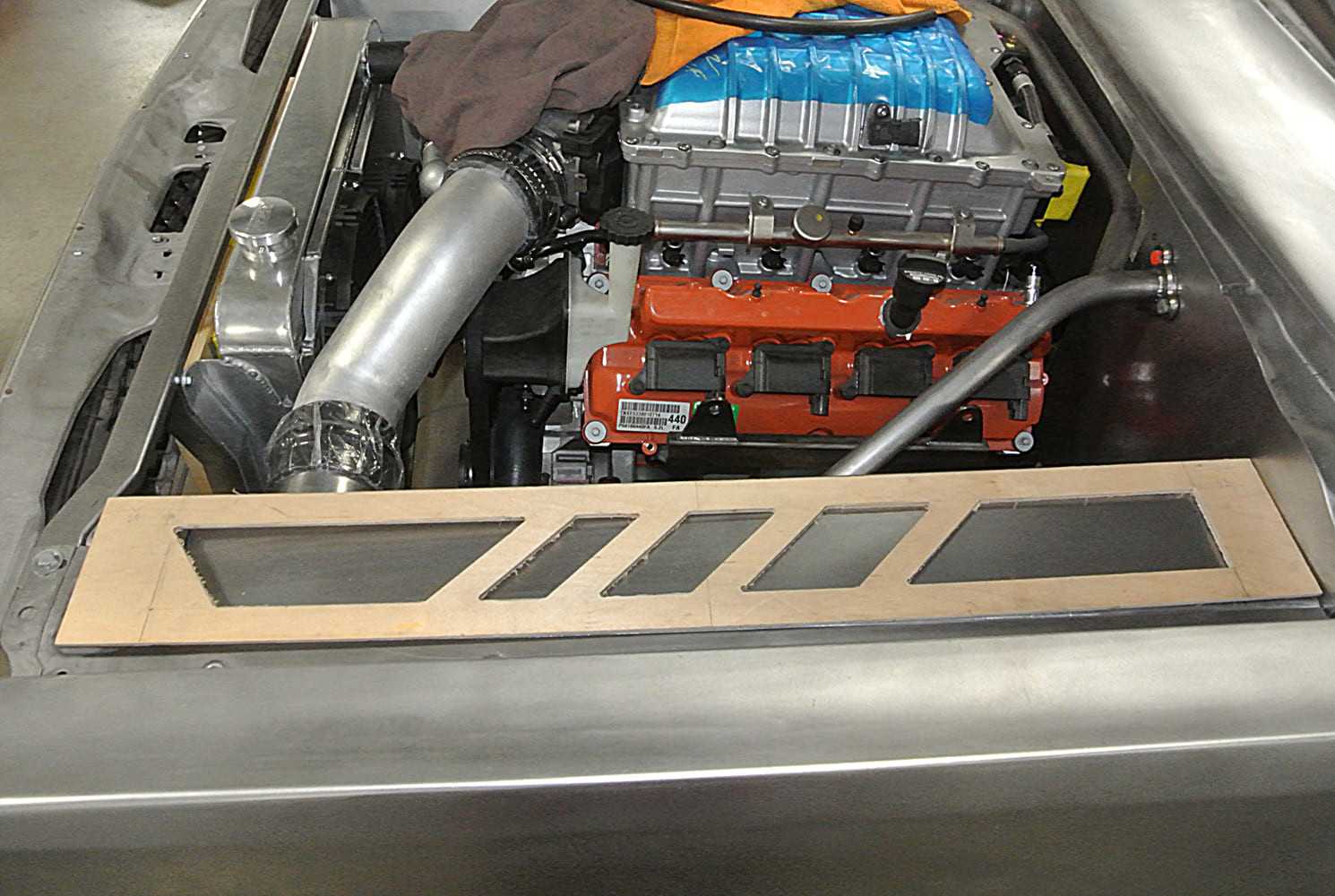

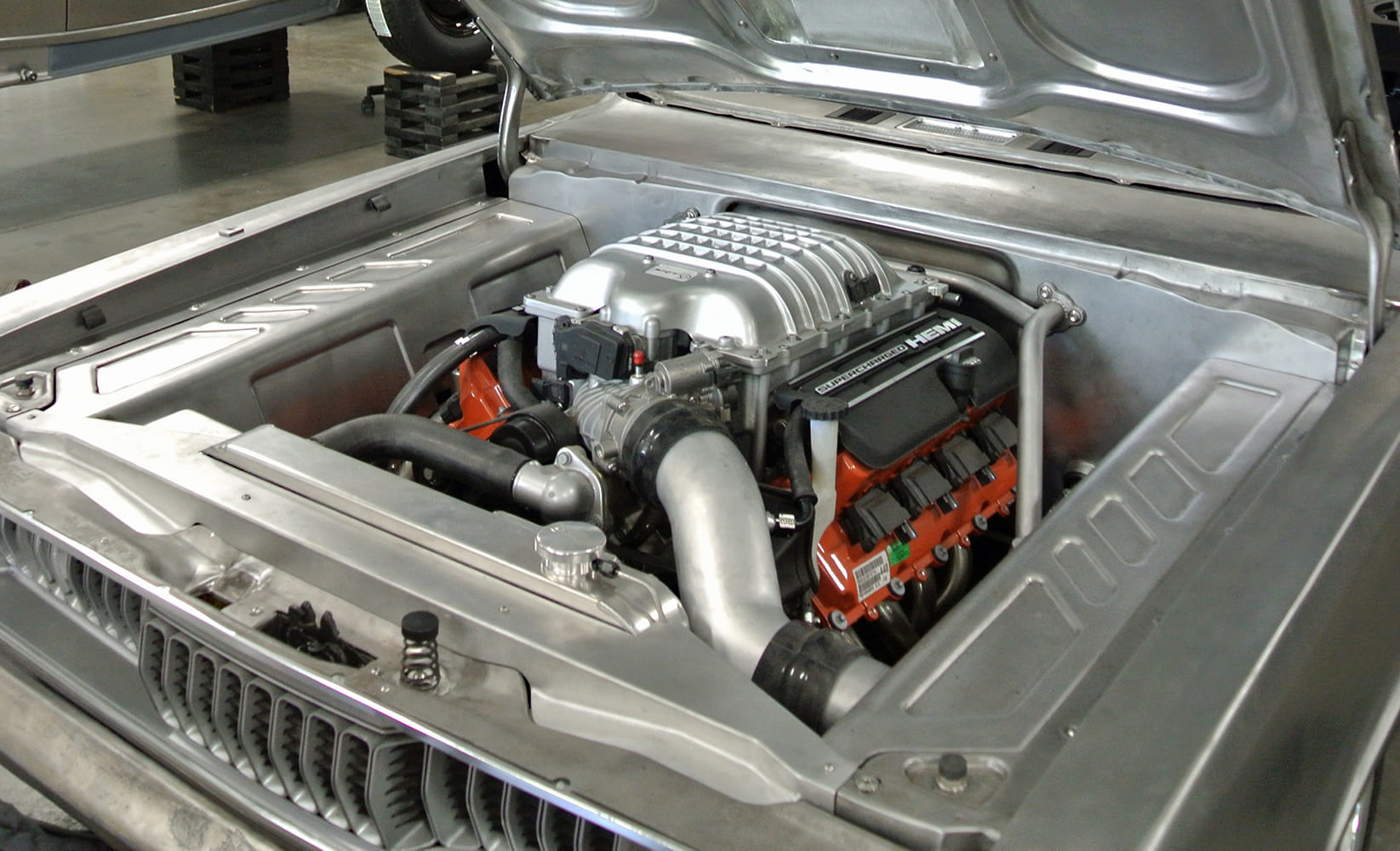

In most high-end project cars, the sheetmetal in the entire engine compartment is completely custom fabricated. This is sometimes necessary to accommodate a specific engine, but it also serves as a “statement piece” that allows the builder to showcase their design and fabrication skills. BBT Fabrications in Mahomet, Illinois, is building a 1971 Plymouth Duster project with a supercharged Chrysler Hellcat Hemi engine; in this article, you will see the unique approach they took in constructing the underhood panels for this car.

As with most projects at this level, one of the first steps is to remove the factory sheetmetal in the engine compartment then examine the space available for the new sheetmetal. Many components must either be built into the design or the design must be configured to provide sufficient room for their removal and reinstallation.

Additionally, adequate clearance is essential for hands and tools during maintenance. More than a few builders have been unhappy because they had to redo extensive work after failing to allow enough room for necessary components, such as the steering box, exhaust manifold, or radiator overflow tank.

Troy Gudgel and his crew at BBT Fabrications have many years of experience, enabling them to anticipate all potential issues. They not only developed a design that truly highlights the powerful Hellcat engine but also created unique designs for the most visible panels, giving this car a character unlike any other. Most of the work was done in 18-gauge steel, with some components made from aluminum.

The firewall on the Duster had many uneven nooks and crannies from the factory. So, before fabricating any other panels, a smooth firewall was constructed and installed, featuring a recess in the center to accommodate the robust engine. With the new firewall, they had a clean, flat target to aim for with the new inner fender panels.

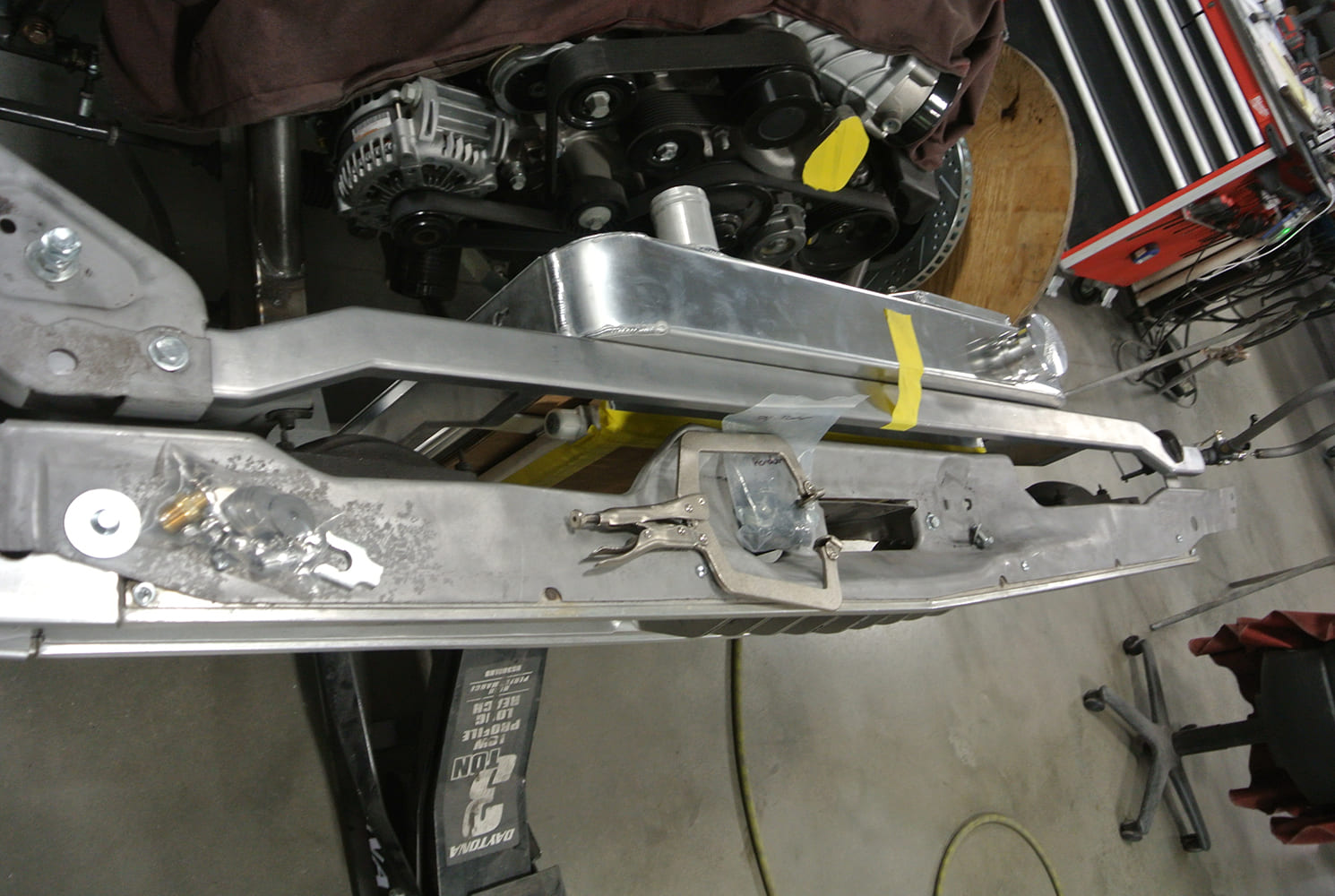

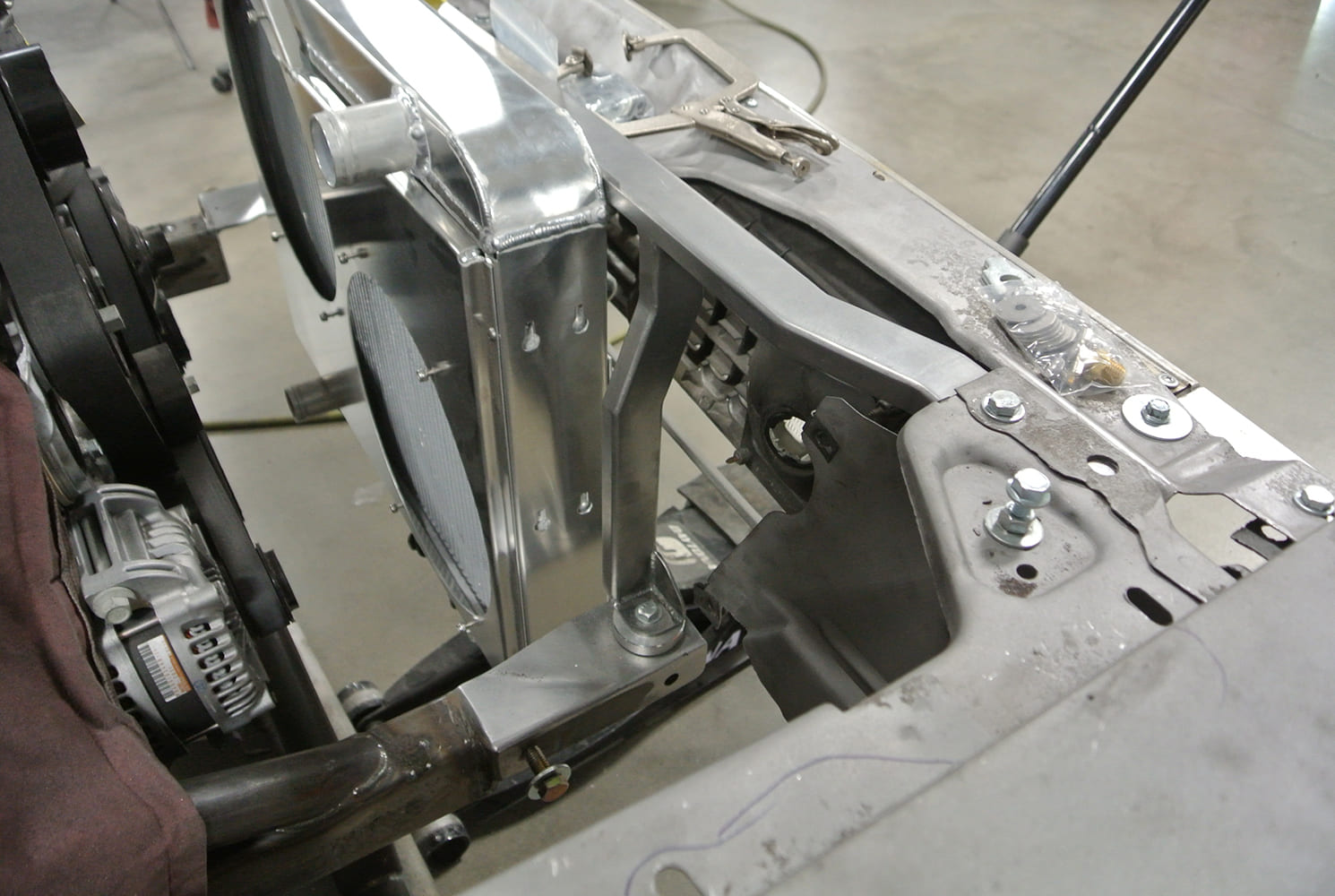

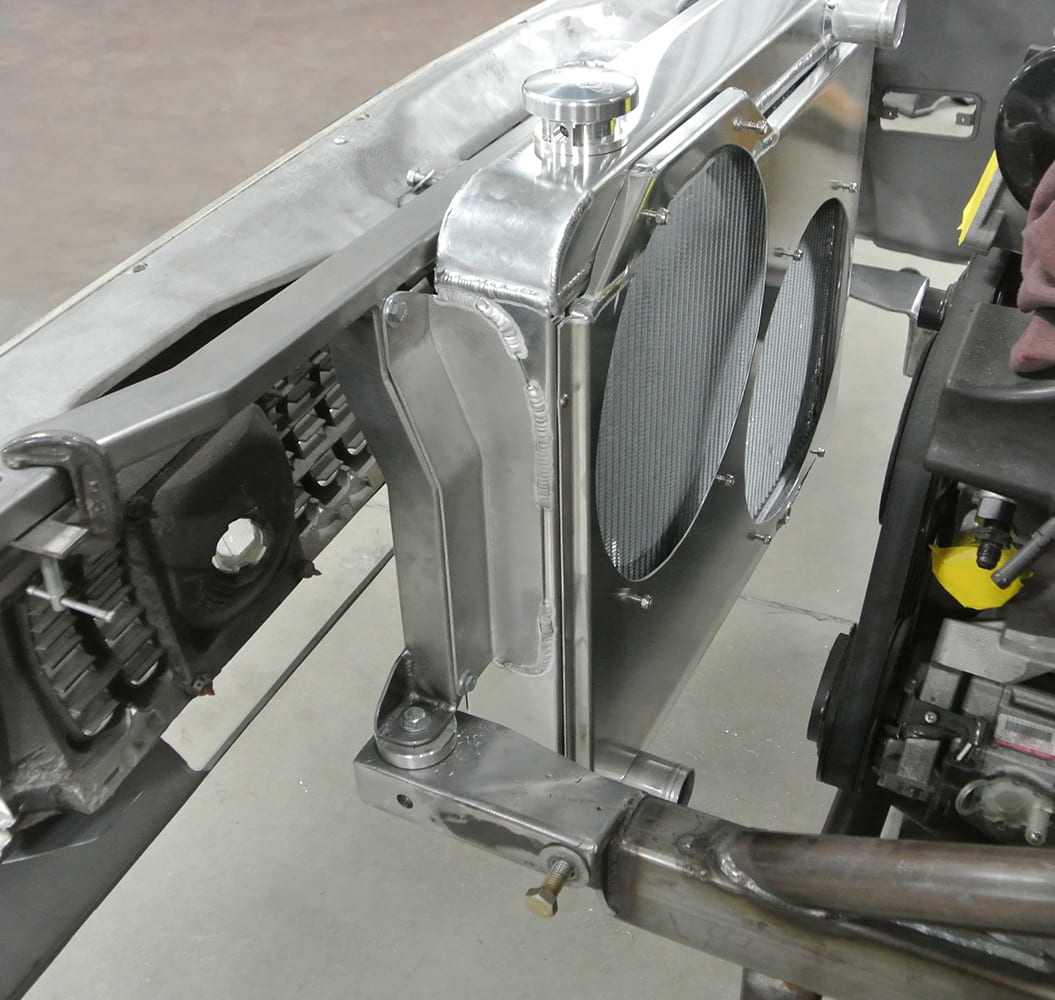

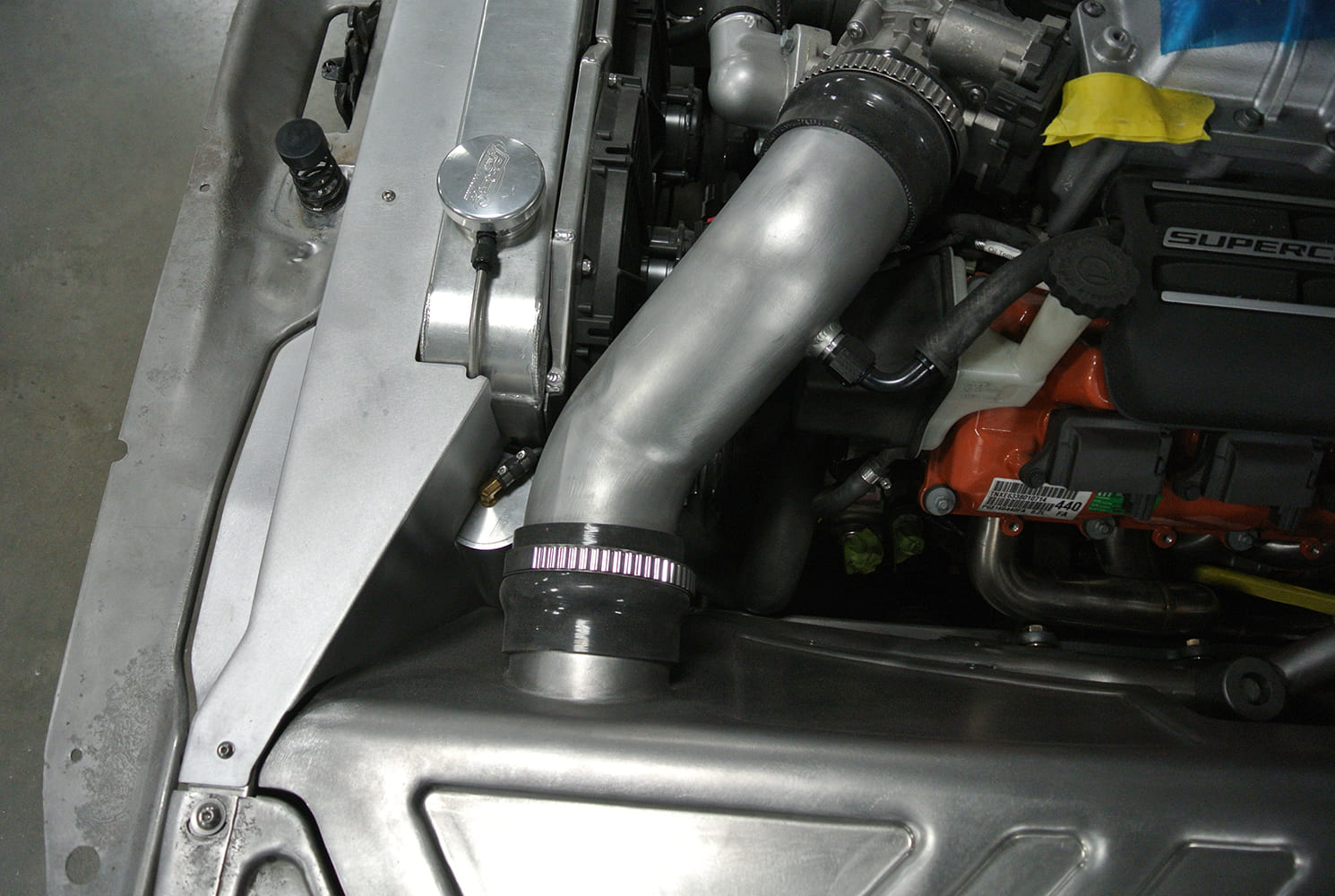

A new aluminum radiator was needed for the Hellcat engine, and little of the original core support was usable. The car features a custom-built chassis as the original unibody construction can’t handle over 700 hp. Extensions were added to the front of the chassis to connect with a structure made from 1×2-inch steel tubing for mounting the radiator. Heavy aluminum brackets were attached to this tubing structure and welded to the side plates of the radiator. This creates a clean, low-profile mounting system, which provides ample support for the radiator to endure the immense acceleration and braking forces this car can generate.

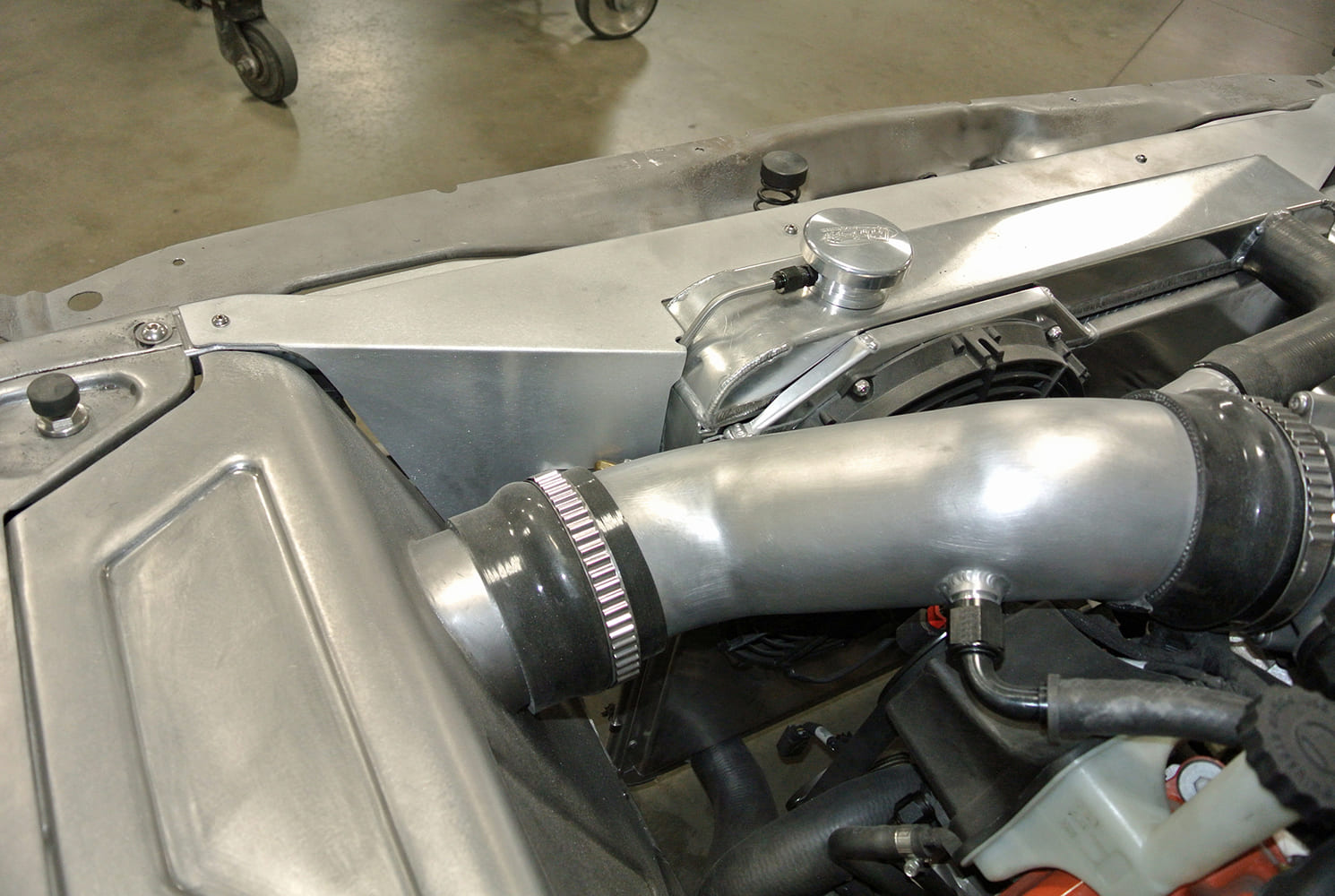

Sheets of 18-gauge steel were shaped on a radius brake to create a smooth, rounded corner. These pieces were then aligned to fit new flanges attached to the fender tops and carefully positioned against the firewall, held temporarily in place with Clecos while the fit was confirmed. Once everything was adjusted, the panels were secured to the fenders using button-head machine screws. The mounting holes in the fenders were embossed with dimple dies to enhance strength and provide a more polished appearance.

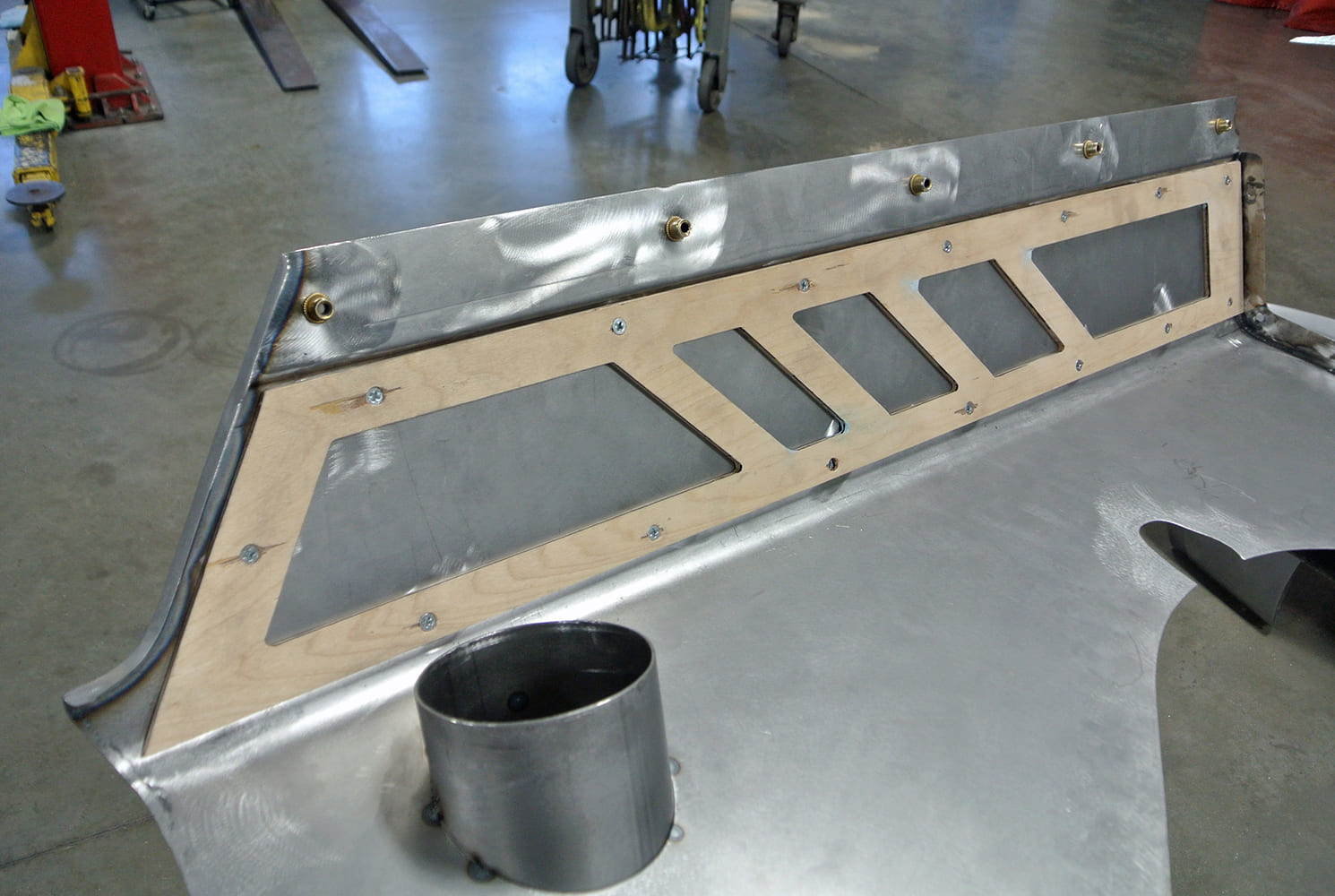

The most impressive part of the fabrication was embossing a bold design into the inner fender panels. This was accomplished using specialized tooling on a Pullmax machine, and simple guides were made from plywood. This method worked perfectly, adding significant “eye appeal” to these panels.

An intricate aluminum panel was built to fill the space in front of the radiator and cover the new crossmember for the core support. It was welded together from several pieces, and the joints were smoothed so perfectly that they are invisible.

If you examine the photos closely, you’ll notice that a lot of problem-solving was employed to ensure all the pieces worked together efficiently. Many of these techniques could probably assist you with a current or future project. MR

Check out this story in our digital edition here.

Source

BBT Fabrications

(217) 586-5699

bbtfabrications.com