By Jeff Smith – Images by the Author

The spark plug is the one component that has been shared by every spark-ignited internal combustion engine since the earliest days. Oddly, the engine that powered the first Wright Brothers airplane was gasoline-fueled but did not use spark plugs. Instead, the engine builder, Charlie Taylor, employed a set of contact points located in the “T” style cylinder head to create a spark. But for the rest of the automotive world, the spark plug has been in existence in one form or another since the 1860s.

Today, spark plugs have become smaller, more efficient, and now in modern electronically fuel-injected street engines can perform admirably for 100,000 miles or more. But what happens when we build a performance engine like a small- or big-block Chevy or an LS/LT engine with compression, a bigger camshaft, and better cylinder heads? Selecting the proper spark plug becomes a critical process, which is what we will address in this story.

The first step would be to identify the proper construction of the spark plug for your application. This starts by identifying the plug’s basic configuration. The first issue is what the spark plug manufacturers call thread reach. This is the length of the threaded portion of the spark plug where it engages the cylinder head.

This thread reach is critical because this dimension has evolved over time. As engines are redesigned, thread reach has become longer. The original small-block Chevy thread was a mere 0.375 inch. Early big-block Chevys employed spark plugs with longer reach specs of 0.790 inch but then shortened that figure back to 0.433 inch for later engines like the 1972 454. So, consistency within engine families is not something we can assume.

Reinforcing that idea are the Vortec small-block heads with increased thread reach numbers. The reason for this change was to extend the length of the threads to push the working end of the spark plug deeper into the combustion chamber. For these heads, the thread reach jumped to 0.680 inch. Thread reach is critical for all engines but especially for this cylinder head because it’s easy to assume a 0.375- or 0.433-inch reach plug will work. Using short-reach plugs in a Vortec head would be a serious error because this shrouds the spark and kills combustion efficiency. As mentioned earlier, this mistake can also occur with big-blocks where short-reach plugs are incorrectly used in a head that requires longer threads.

Of course, the opposite is also true where a long-reach plug can be incorrectly applied to a short-reach head. In this case, it’s possible this could cause physical damage to the piston from the extended length. Even if this does not occur, the exposed sharp edges could create hot spots inside the combustion space.

The next step in plug selection is to ensure that the plugs employ the correct sealing surface. The two most popular are a tapered seat on the plug body or a metal gasket that seals to the cylinder head. Misapplication of these sealing surfaces is less common but it does happen. Aftermarket aluminum cylinder heads for the small- and big-block Chevy engines often employ gasket plugs while the LS and LT families are more often machined for tapered seats.

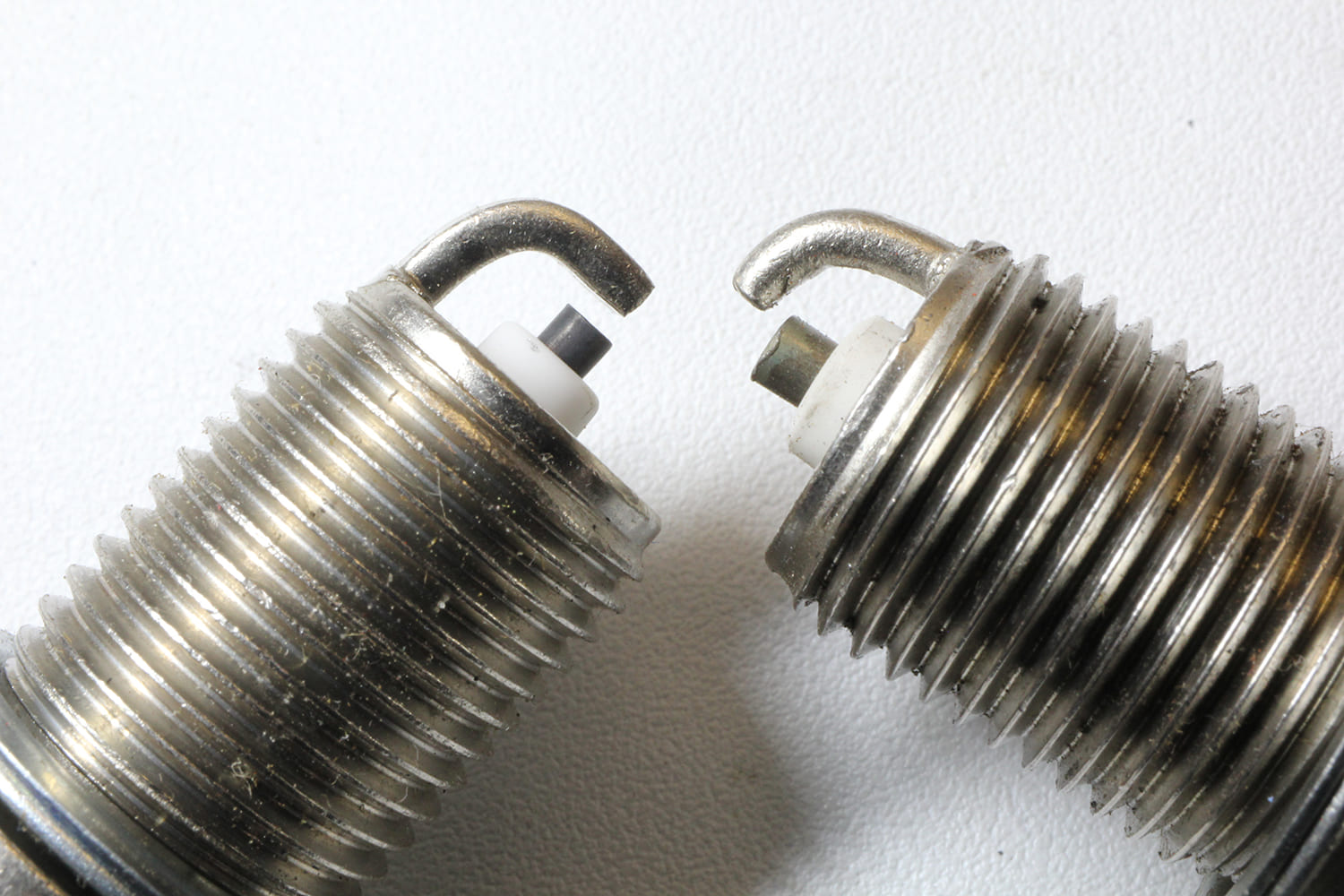

The next step in spark plug selection enters more of a gray area related to positioning the working end of the plug. Early versions for the small-block employed what is now called non-projected or standard-nose plugs where the center electrode barely extends past the end of the threads. Later engines extended this position beyond the end of the threads.

These projected nose plugs do offer advantages by placing the spark closer to the center of the combustion chamber.

Projected nose plugs generally work very well but the engine builder or tuner must verify clearance when using domed pistons. We had an experience with a 1967 Z/28 302ci engine with a domed 11:1 compression piston where a projected nose ground strap was instantly crushed by contact with the piston dome. This can also occur in big-block Chevys with domed pistons. Sometimes projected nose plugs can be accommodated by indexing the spark plug so that the ground strap is moved away from the piston dome.

While we’re on the subject of ground straps, the projected nose design naturally extends the length of the strap. For normally aspirated engines this is not an issue, but this added length can be problematic with supercharged, turbocharged, and especially nitrous engines. These applications create higher cylinder temperatures and pressures. These elevated temperatures put additional heat into the longer ground strap. At a certain point, this longer strap can turn into a glow plug that can cause pre-ignition.

We won’t get into all the details of how pre-ignition differs from detonation but be aware that pre-ignition is exactly what it sounds like—lighting the mixture far in advance of normal ignition timing. It doesn’t take much of an imagination to foresee the kind of internal engine damage that can occur when combustion begins 60 or 80 degrees before its normal ignition point. This is pre-ignition. There’s no warning except when the engine disassembles itself in an instant. It’s ugly.

The point is to avoid this by using a shorter ground strap with high boost levels or with nitrous. You may see factory supercharged engines using extended nose spark plugs and these plugs are acceptable because development engineers have determined there is no danger of pre-ignition. But if the stock boost is greatly increased, or a different fuel like ethanol is used, this could become an issue. Ethanol, for example, lights off very easily and therefore demands a very cold heat range spark plug with a non-projected nose that keeps the ground strap short or even cut back.

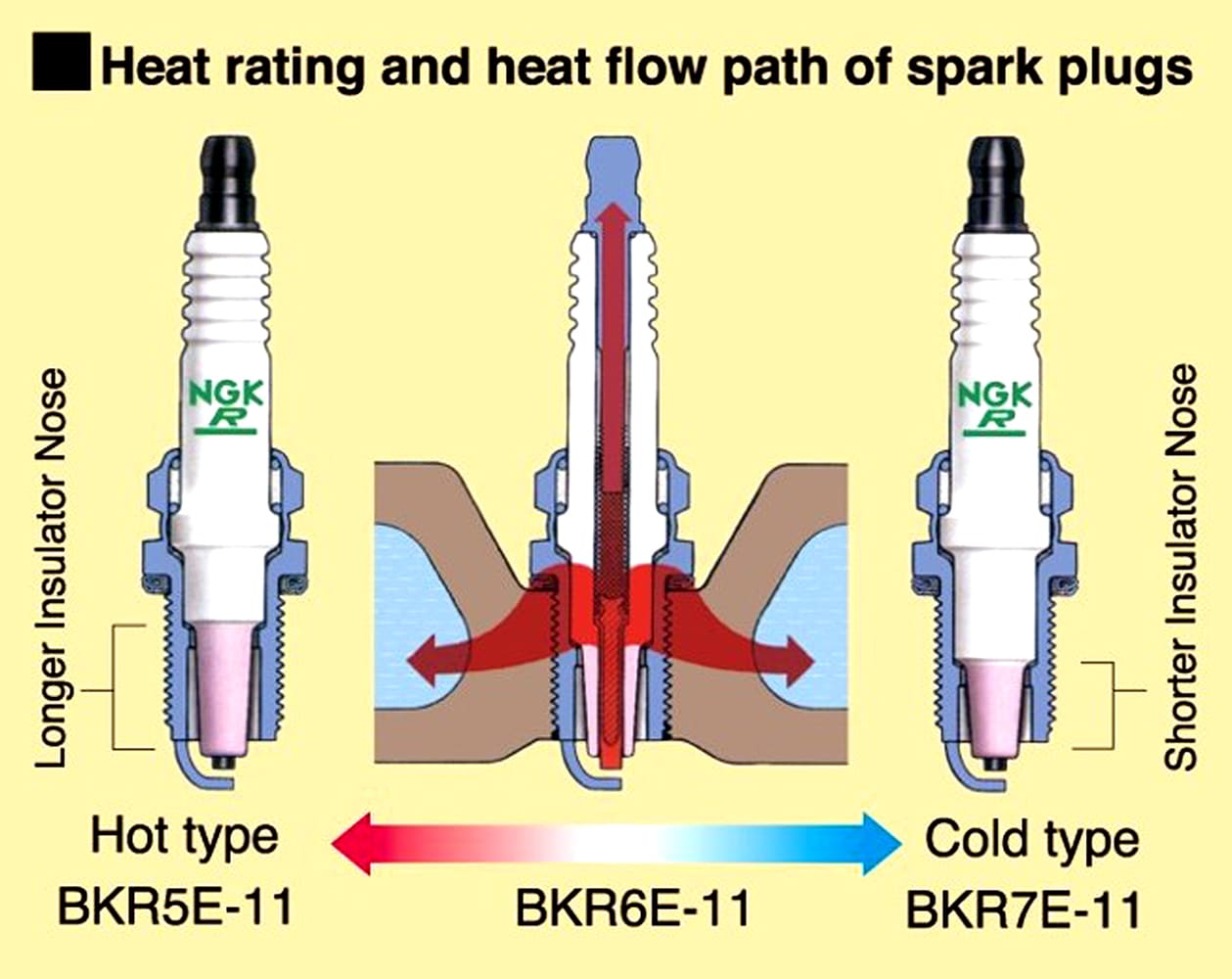

This leads us to the subject of heat ranges. One of the easily altered variables is the operating temperature of the spark plug. The heat range is determined by the length of the center ceramic insulator. The distance from the center electrode to the base of the ceramic determines how far combustion heat must travel through the insulator to the metal body of the plug where the heat is dissipated through the cylinder head.

A hot heat range spark plug increases the length of the ceramic while a cold plug employs a very short distance ceramic. A family of plugs may offer four to six different heat ranges to allow the engine builder to custom select the right plug for the application.

The reason for multiple heat ranges has to do with matching the operating temperature of the spark plug to ensure that carbon deposits on the center electrode are burned off. As an example, let’s say that we have a normally aspirated LS engine with 10:1 compression that prefers a stock heat range plug. But then we add a 200hp nitrous system. This will create more combustion heat and will operate best with a one- or two-step colder plug.

An example, if our small-block Chevy was running aftermarket aluminum heads with an Autolite 3924 spark plug and we want to run two steps colder. Autolite rates colder plugs with a lower number, which in this case would be a 3922. Accel, ACDelco, Bosch, and Denso all employ this same process. NGK however is the opposite so that a colder plug is assigned a larger number.

The correct selection procedure is to choose a heat range where the heat is sufficient to burn off the carbon deposits but not operate at too high a temperature. Excessive plug temperature can cause the plug to glaze over, which will cause misfire and poor performance. But choosing a too-cold heat range plug will allow carbon to build up on the plug, which will also cause misfires and reduced performance.

Most street engines with performance camshafts and pump gas compression will want a spark plug very close to the stock heat range. But each performance engine is different so with a newly built engine you will want to track plug condition to ensure the heat range is correct.

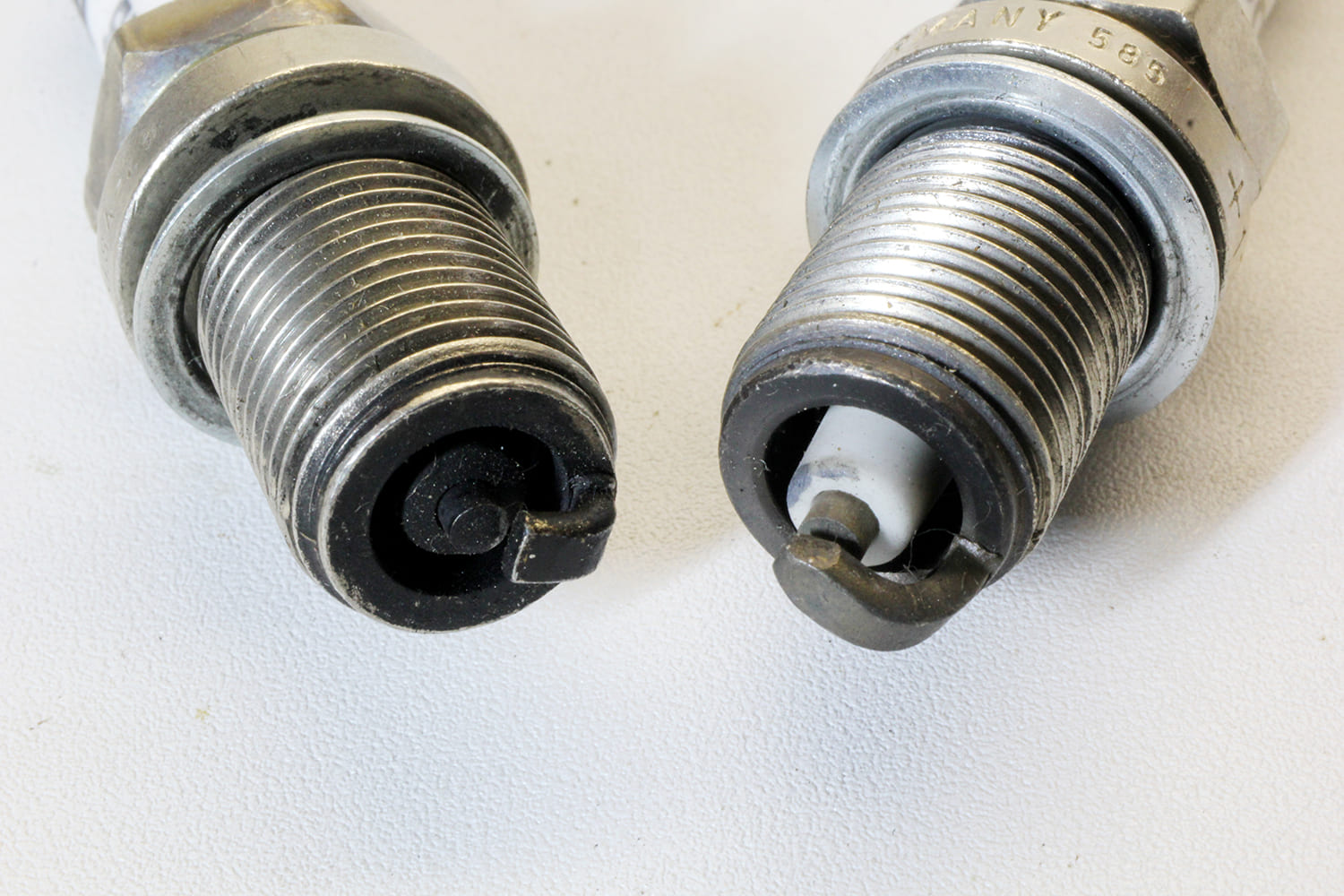

This will require developing skills in reading spark plugs. While a complete guide for reading spark plugs is beyond the scope of this story, some simple recommendations will point you in the right direction. As mentioned, the correct heat range will exhibit minimal carbon deposits on the center electrode and that electrode will have a mild tan to light brown color.

A center electrode that appears glossy or shiny is likely glazed, which indicates it has experienced high plug temperatures. A sooty black condition generally indicates the engine is running an overly rich air/fuel ratio. A plug with a bone white center insulator ceramic indicates the plug is too hot or possibly the induction system is too lean. It’s also possible that the engine is experiencing a combination of those issues.

Among the specialty spark plugs that often excite engine enthusiasts are spark plugs employing rare earth metals, such as platinum and iridium. Generally, these plugs use a very fine wire center electrode or perhaps a platinum tip on an otherwise-standard nickel alloy metal core. Fine wire plugs are often used in production engines because they offer increased wear life compared to the traditional center electrode spark plugs. These fine wire plugs also demand less voltage to initiate the spark, which also increases their life expectancy.

Given these attributes, many fine wire plugs are fitted with a wider spark plug gap that can operate as wide as 0.060 inch. If modifying the plug gap is required, it’s important to work carefully and use a tool that only adjusts the ground strap and does not contact the center electrode. As you can image, fine wire plugs are easily damaged.

You may have read claims that iridium or platinum plugs should never be used in supercharged engines because the fine wire tip can easily become a hot spot that can cause pre-ignition. If this rumor was true, the factory would not use an iridium, fine wire spark plug in its supercharged applications like the 668hp, 6.2L direct gasoline injection Cadillac CTSV-5 Blackwing engine.

This story has touched on some of the important points relative to selecting the right spark plugs for your engine. There is much more to learn, but this should offer a more educated path to follow. There are plenty of different routes the tuner can take to arrive at the correct plug. That’s the beauty of performance engine tuning. You have plenty of choices.

Spark Plug Spec

The following chart breaks down five OE spark plug applications into five important specs. Note that the only difference between the Vortech small-block Chevy plug and the LS version is the plug gap. We used these plugs merely as examples for the specs. Champion, NGK, Bosch, or others could easily be substituted.

| Spark Plug | Thread Reach (in.) | Gasket or Tapered | Electrode | Ctr., Std., or Proj. | Nose Gap | Application |

| AC Delco R43S | 0.372 | Gasket | Copper | Std. | 0.035 | ACDelco R43S is for early small-block Chevy iron heads |

| Autolite AR25 | 0.433 | Tapered | Copper | Mid Proj. | 0.035 | Autolite AR25 is for early big-block Chevy iron heads |

| ACDelcoR44LTS6 | 0.680 | Tapered | Copper | Projected | 0.060 | ACDelco R44LTS6 is for a small-block, iron Vortec head |

| ACDelcoR44LTSM | 0.680 | Tapered | Copper | Projected | 0.040 | ACDelco R44LTSM is for the 2000 LS1 5.7L engine |

| Autolite 3924 | 0.748 | Gasket | Copper | Projected | 0.040 | AR3924 is a common application for aftermarket small-block Chevy aluminum heads |

Check out this story in our digital edition here.

Sources

ACDelco

gmparts.com

Autolite

(855) 200-5200

autolite.com

Bosch

(888) 715-3616

boschautoparts.com

Champion

championautoparts.com

Holley Performance (Accel)

(866) 464-6553

holley.com/brands/accel/

NGK

(877) 473-6767

ngksparkplugs.com