By Ron Covell – Images by the Author

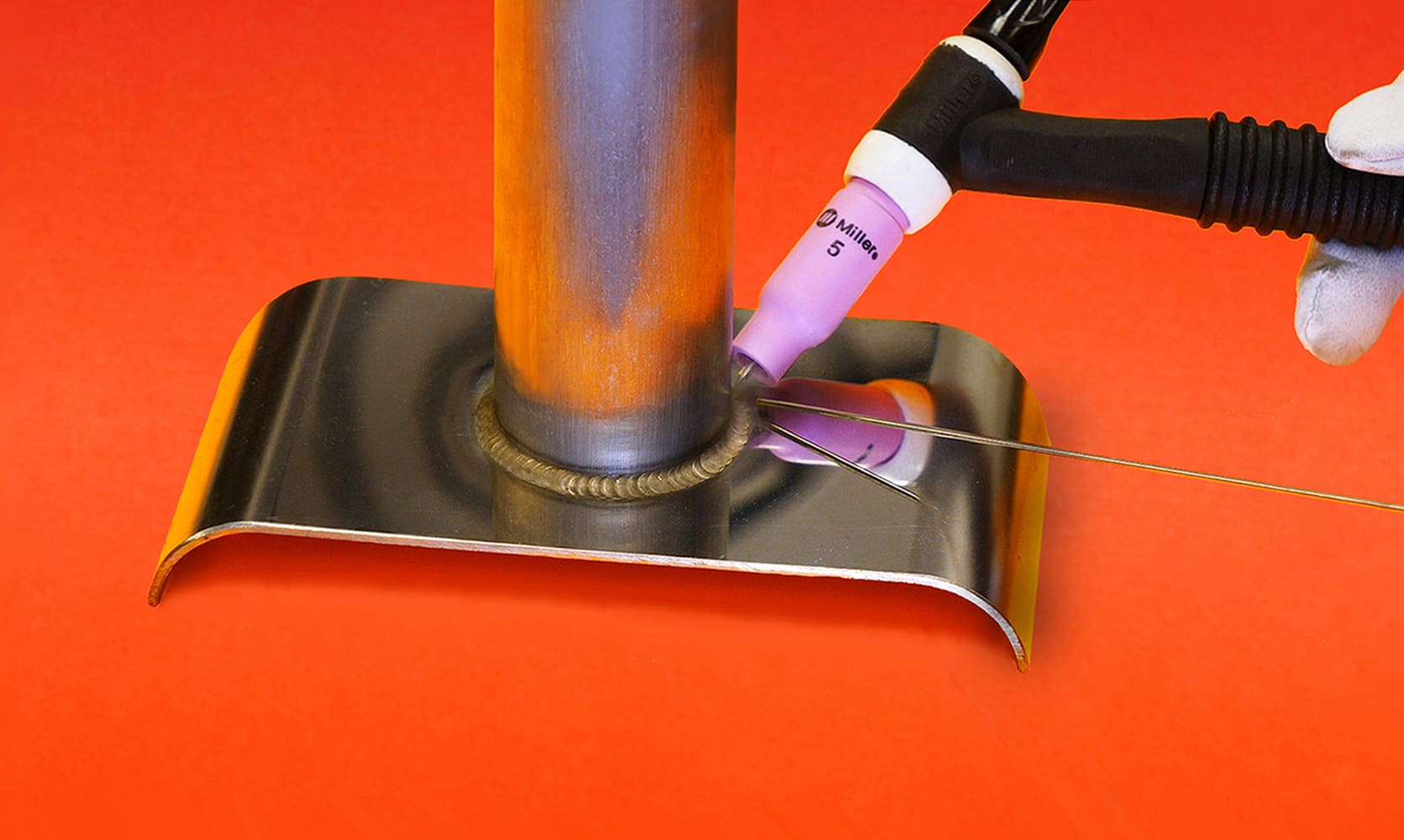

TIG welding machines have become so affordable these days that most professional shops (and many home hobbyists) are now using them. TIG welding offers superior control over every aspect of the welding process. The quality and appearance of a properly made TIG weld is hard to match with any other process.

For anyone not familiar with TIG welding, the heat is created by an electric arc streaming between the electrode in a handheld torch and the part being welded. The arc can be focused with great precision, and if enough heat is applied, a molten puddle will be formed on the base metal. Filler rod is usually manually added to this puddle, fusing the joint together and making the weld.

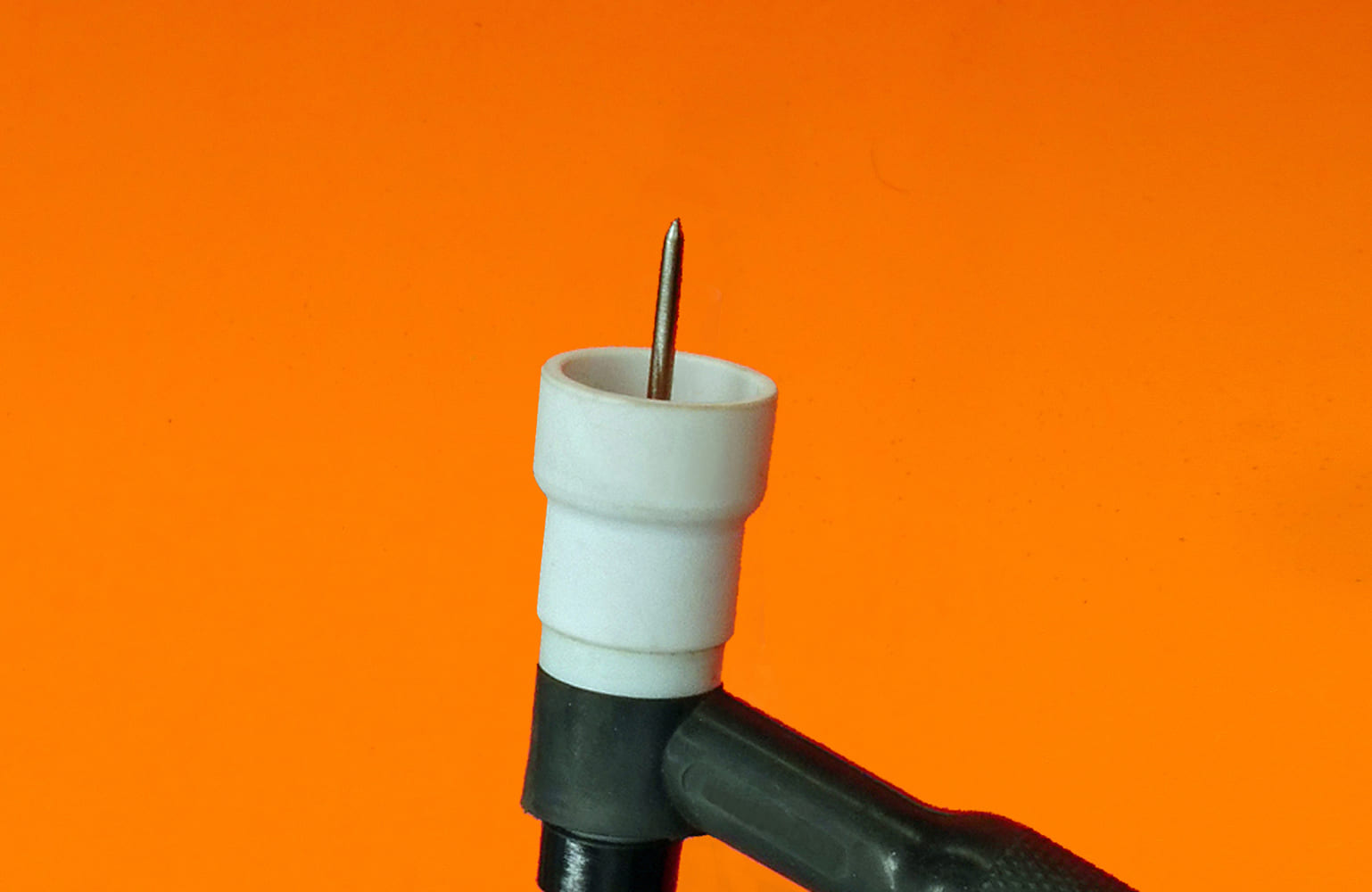

Steel melts at around 2,600 degrees F, so the welding arc needs to be much hotter to melt the base material. Tungsten is used as an electrode for TIG welding because it has the highest melting temperature of any metal and it retains its stability even when heated to the point where it glows red or even white.

In the early days, there were only two electrodes available for TIG torches. One was pure tungsten, designated by a green band applied to one end of the electrode. It was the preferred electrode for welding aluminum and magnesium. The other option, which has thorium added, was designated by a red band, and was used for welding all other metals. While these two electrodes met most welder’s needs for generations, the technology has evolved a great deal, and now these two “old standbys” have been superseded by electrodes that perform better in every way.

For someone just starting with TIG welding, the broad array of electrodes can be perplexing. We’ll give you solid guidelines here to help you make a good choice, based on the kind of welding that most truck projects will require.

While pure tungsten withstands high temperatures and can stream an arc hot enough for welding, the addition of trace amounts of other materials adds important benefits. Let’s go through the list of commonly available electrodes and discuss the benefits of each type. The first three are true all-purpose electrodes, good for AC or DC welding, on thick or thin metals. Electrodes are marked with a band of color on its end, which designates the type.

Lanthanated: (Blue) This is one of the top-rated electrodes, with superior current-carrying capacity and excellent arc starting. This is a true all-purpose electrode that can be used on any weldable metal.

Ceriated: (Gray) Adding cerium to tungsten allows the electrode to carry greater current and improves the arc-starting characteristics. It works with all weldable metals.

Rare Earth: (The specific elements and identifying color varies by manufacturer.) There are several welding electrodes that use a mix of additives; these are good general-purpose electrodes for use on all weldable metals.

The electrodes listed below are not usually recommended for general-purpose work.

Thoriated: (Red) Adding thorium to pure tungsten increases its current-carrying capacity. Thorium is a slightly radioactive material, and there is concern that there may be health risks with long-term exposure—especially if dust is inhaled when grinding the electrodes.

Pure: (Green) While this electrode was favored for years when welding non-ferrous metals, it is not recommended for modern, inverter-based TIG welding machines.

Zirconated: (White) This electrode is designed for AC-only applications and is sometimes used for robotic welding. It is not a good choice for general-purpose use.

Tungsten electrodes are available in many different diameters. In general, the smaller the tungsten, the easier it is to start the arc; and the larger the diameter, the more current it can carry.

Your author has been welding for over 50 years, and my personal preference is for 3/32-inch-diameter, 2 percent Lanthanated tungsten. I almost never have problems with arc starts, even at the low-amperage settings used for thin sheetmetal—and I can use welding power up to 250 amps should I need to lay a bead down on ½-inch steel plate, for example.

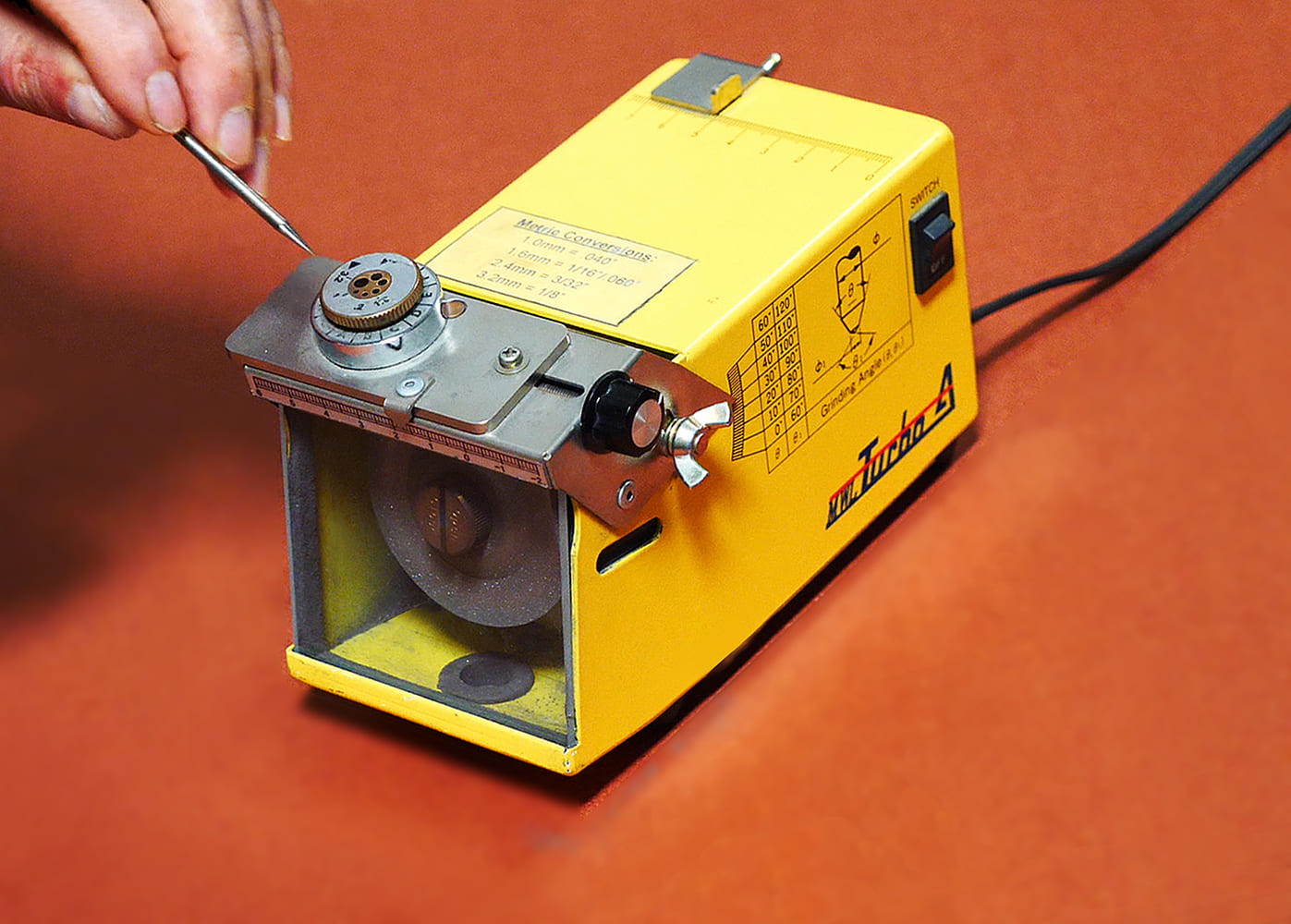

Tungsten electrodes are commonly sold in 7-inch lengths. Sometimes you may need to cut them down to allow the use of a shorter back cap on the TIG torch, which lets you work in restricted areas. You should never shorten a tungsten by breaking an end off since that can cause micro-fractures in the grain structure. These tiny fractures can cause the arc to fluctuate and wander. It’s best to cut through an electrode with an abrasive cutoff wheel.

The tungsten electrode is sharpened to a point, and the geometry of this point has a surprising effect on the shape of the arc—in a manner that is counter-intuitive. The sharper the point on the tungsten, the broader the arc that will stream off the electrode. This can be beneficial in certain situations, such as outside corner welding, where a diffuse arc may lessen the tendency of the weld to sink the center.

The blunter the point, the more it will focus the arc. This may be beneficial when welding very thin metal or when you need to get full penetration when welding in a deep groove.

When welding above 200 amps, putting a small flat spot on the tip of a sharpened electrode can help prevent the electrode from “spitting” tiny bits of tungsten into the weld puddle, which degrades the quality of the weld. Many high-tech applications call for x-raying welds, and any evidence of tungsten contamination will disqualify a weld in sensitive industries like aerospace or nuclear power.

If you own a TIG welder and have been confused about electrode selection, these pointers should give you the knowledge you need to make a good choice.

Check out this story in our digital edition here.

Source

Miller Electric Mfg. Co.

(920) 734-9821

millerwelds.com