By Brian Brennan – Photography By NotStock Photography

Introducing America’s Most Beautiful Roadster, presented to Ross and Beth Myers at the 2025 Grand National Roadster Show, a stunning 1936 Ford highboy roadster expertly crafted at Rad Rides by Troy (RRT). This one-of-a-kind hot rod epitomizes automotive craftsmanship, creativity, and personal expression. Hot rods, by their very nature, embody the owner’s unique vision and style, unlike mass-produced vehicles designed to elicit a mere “vanilla” happiness. Every detail, from the engine to the paint, is meticulously crafted, turning aspirations into a masterpiece.

This honor reflects the extraordinary effort of Troy Trepanier and his talented crew at RRT, with special recognition for Adam Banks, who worked tirelessly day in and day out on this project. Banks also supplied Modern Rodding with hundreds of build photos and data, allowing us to prepare the six build articles that have preceded this one (see links to these stories on page xx). There is also the “all-metal feature” before bodywork, paint, and upholstery, which provides a close-up view through the lens of the workmanship, courtesy of John Jackson of NotStock Photography.

The significance of hot rods extends beyond aesthetics; they symbolize independence, a “bit” of rebellion, and the quintessential American can-do spirit. Hot rods blend the nostalgic charm of early automotive history, which began just before World War II and continues to the present, with cutting-edge technology, evolving into something truly exceptional.

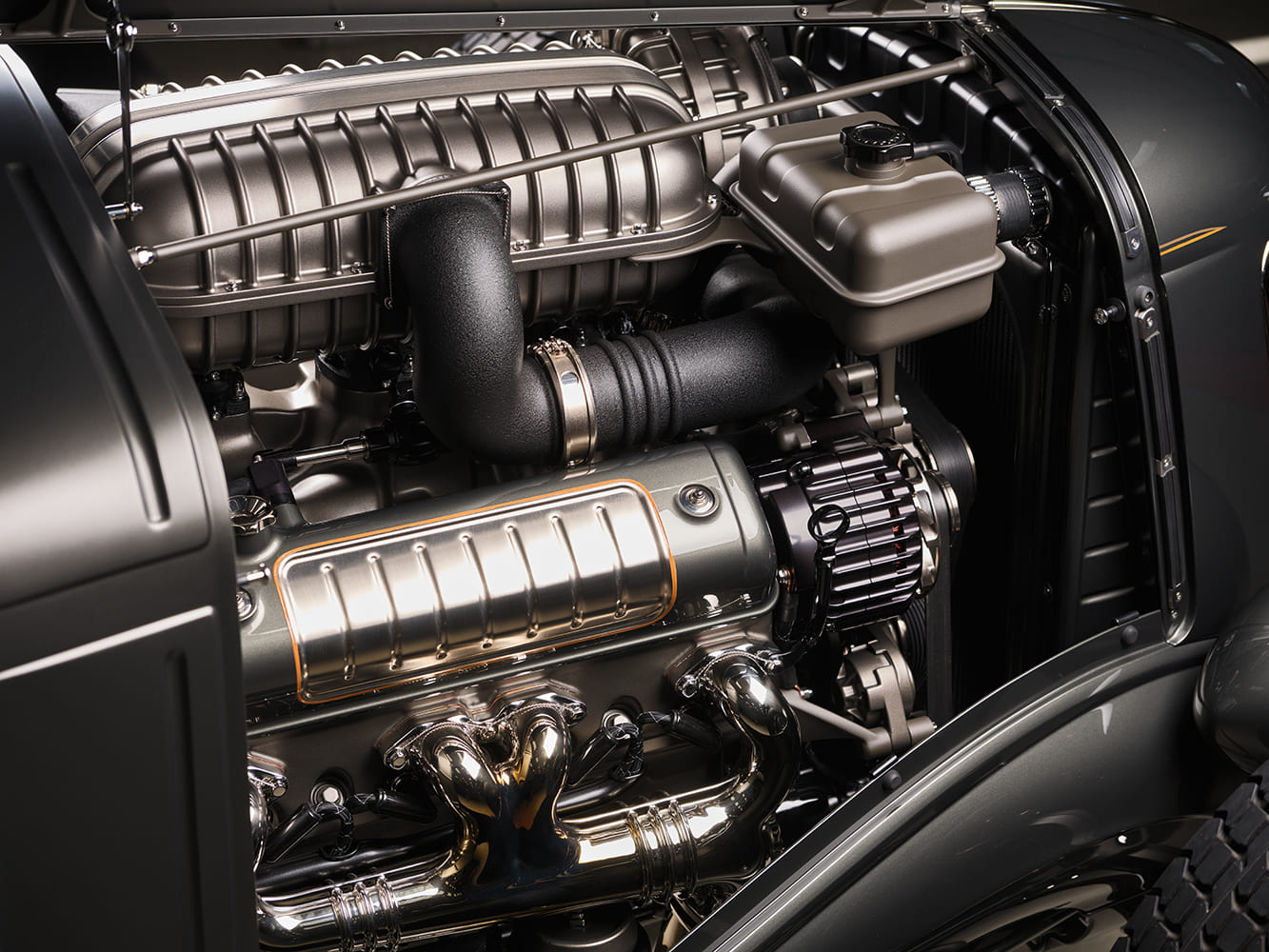

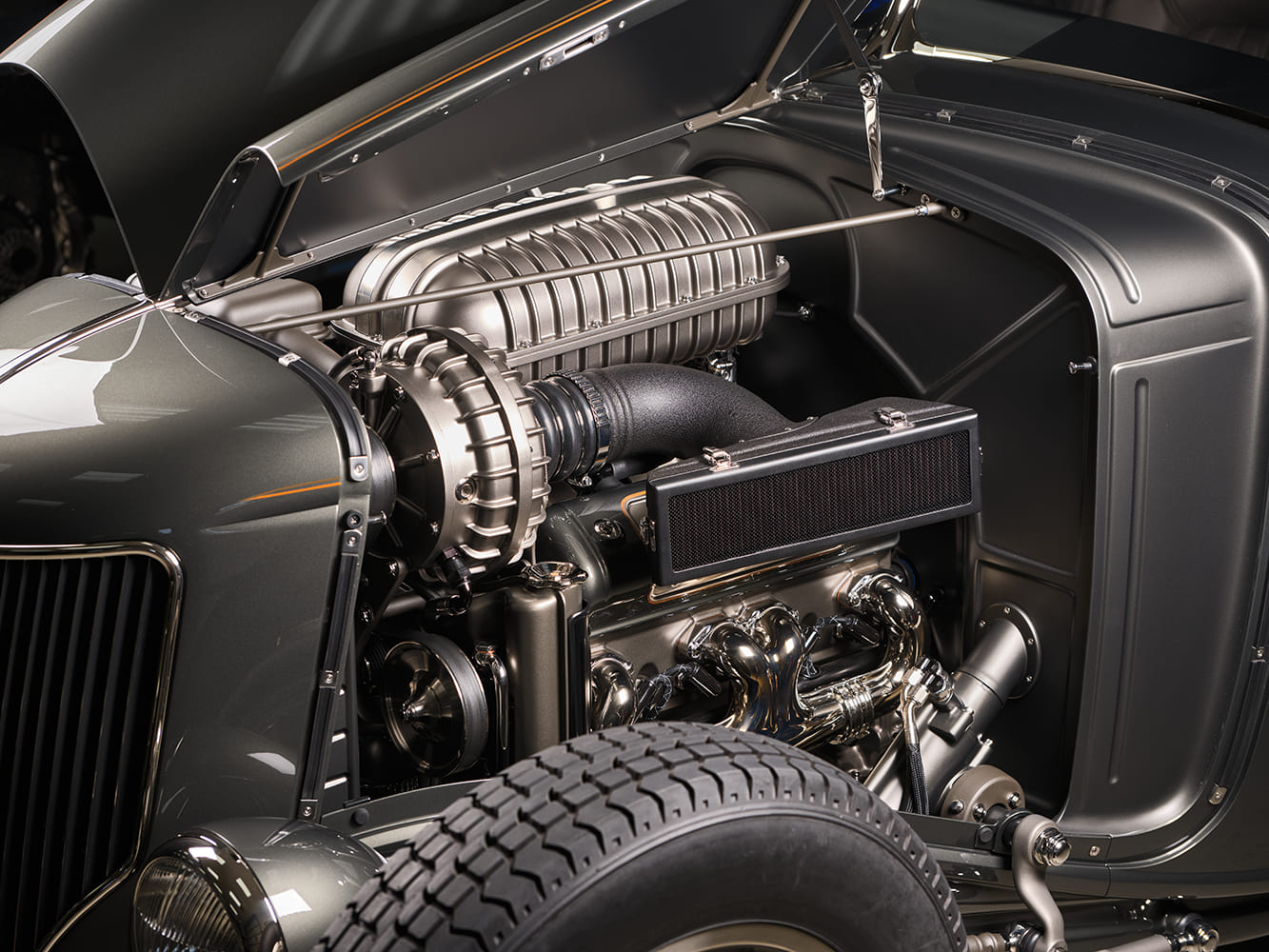

Power for this 1936 Ford highboy roadster is nothing out of the ordinary. At a time when all-aluminum engines are common in the world of hot rodding, the all-iron block and cylinder heads were retained and underwent a myriad of changes–we might all agree, for the better. The craftsmanship of the build and the details that follow are what stories are made of. At the heart of this roadster’s V-8 is a 312-inch 1957 Ford Y-block. The Y-block served as a mainstay for Ford Motor Company from 1954 when it replaced the venerable Flathead through 1964. As Ford’s premier performance engine from 1954-57, the Y-block delivered two consecutive NASCAR Manufacturer’s Championships (1955-56), scored significant victories at the Daytona Speed Weeks, and set a new stock car record at Pikes Peak, being the original V-8 for the early T-bird. FX Engines built the working V-8 (as they have done with nearly all the RRT builds), ensuring that all internal machined surfaces feature O-ring design, except for the cylinder heads and exhaust manifolds.

ARP hardware was used throughout, while a modified 3×2 Fenton intake is now topped with a stunning and detailed McCulloch VR 57 supercharger, along with an intricately designed custom air plenum and custom air cleaner. The K&N air cleaner is simple in its presentation but possesses a bit more intricacy. Note that the air cleaner is visible when the hood side is off, but when the hood side is in place it serves as an enclosure around the air cleaner. During the 1950s and 1960s, the McCulloch VR 57 supercharger was celebrated for its compact design, which facilitated easy installation in various classic American cars. It operates through a belt-driven system that harnesses the engine’s crankshaft power to compress air, thereby enhancing performance.

Notably efficient, the VR 57 features an innovative bypass system that vents excess boost to avoid over-pressurization. There was a time when these were a popular choice among hot rodders. From here, Autotrend EFI throttle bodies are used, along with a Holley HP fuel management system and a Holley HP ECU, forming a plug-and-play arrangement that is ideal for a street motor. The ignition is based on an MSD electronic distributor along with an MSD coil and custom plug wires. The exhaust system is truly impressive, having started as a custom 3-D-printed component featuring Inconel manifolds designed at RRT and printed by Beehive Industries.

The rest of the exhaust system consists of 2-1/2-inch stainless steel, eventually connecting to a pair of RRT custom-built catalytic converters and mufflers, designed by Trepanier and Casey Modert. Inconel alloys are recognized for their exceptional high-temperature properties, ensuring reliable strength and stability for components like automotive exhaust systems. The Inconel engineers reduced the tubing thickness from 1.5 to 0.8 mm, resulting in a significant weight reduction of approximately 40 percent (approximately 20 pounds) compared to traditional exhaust systems. In this context, RRT identified an ideal opportunity within the 1936 roadster project.

This unique V-8 features some standard hot-rodding components, including a Powermaster starter, Billet Specialties alternator, and a Setrab oil cooler. The Y-block is connected to a Bowler Transmissions–prepped 4R70W Ford overdrive automatic transmission, which is cooled by a Setrab transmission cooler. A Lokar shifter manages gear selection. The nearly 400 hp is sent rearward to the Winters Performance Champion quick-change rearend, utilizing helical-cut 3.43 gears with Mark Williams Enterprises axles, which are also sourced from Mark Williams.

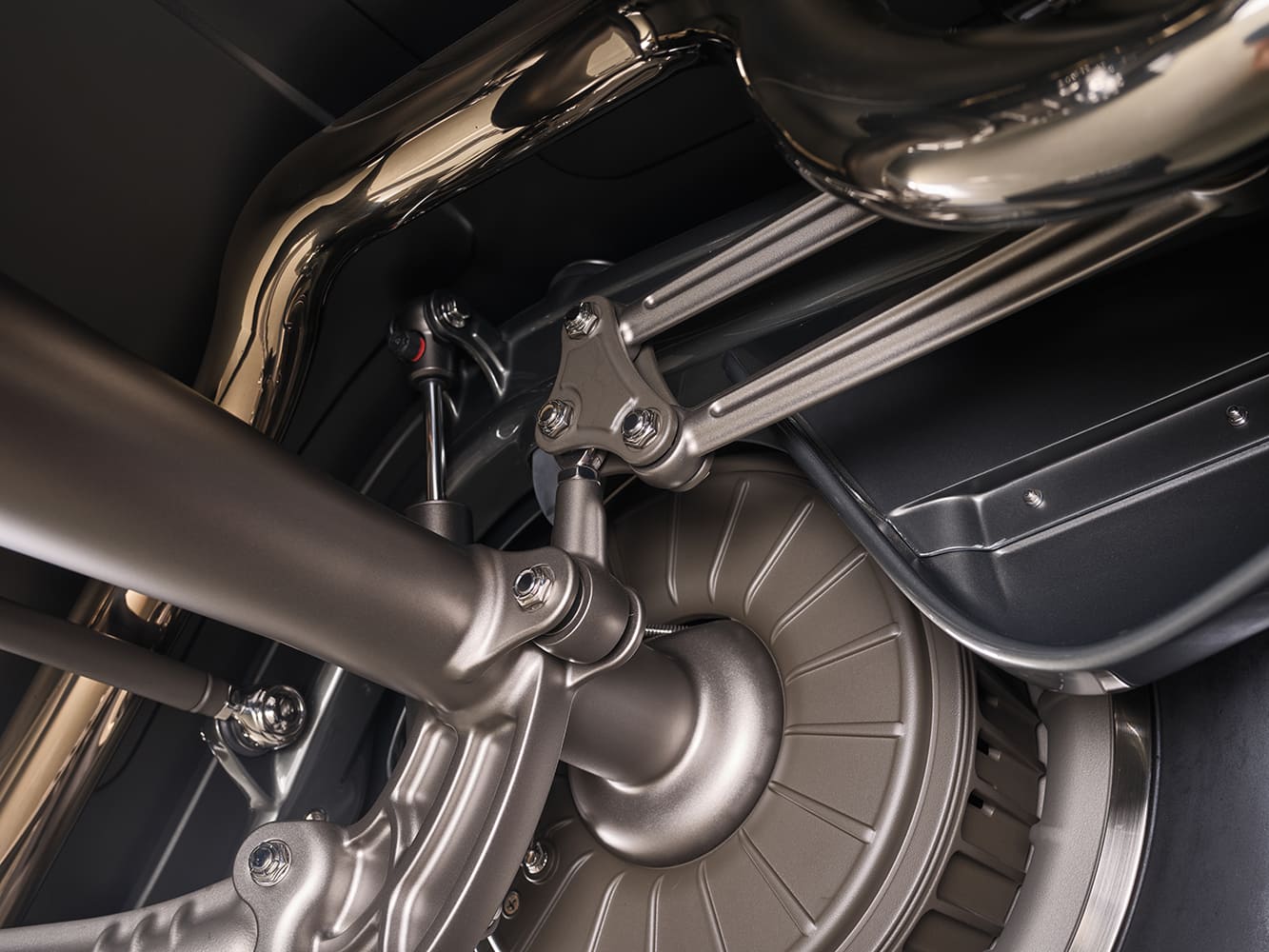

The suspension is housed within a custom RRT 113-inch wheelbase frame featuring fully boxed rails with 1/8-inch walls, fabricated by the dedicated hands of Banks, Modert, and Colby Marshall. The front suspension utilizes a torsion bar combined with custom RRT arms and adjusters, alongside 1940 Ford spindles and Ridetech adjustable shocks. From there, a CPP 500 series power steering box has been modified to enhance its styling and functionality. Centering the rear quick-change is a transverse torsion bar, paired with custom trailing arms and a Chalk Racing Products torsion bar setup.

This setup features Ridetech adjustable shocks, along with a rear sway bar and Panhard bars. The brake system showcases an interesting combination of Wilwood disc brake technology and that of RRT, complete with its brake covers and an I-booster with custom pedals. Jake Murry did the CAD modeling for the wheels as well as the disc brake drum covers, and brake vents front and rear. Murray also did the CAD modeling for the external door handles. The wheel and tire combination represents another collaboration featuring Excelsior Stahl Sport Radial rubber by Coker, measuring 5.50R18 and 7.00R19, paired with custom one-off wheels. Complementing this traditional hot rod rubber is a set of four custom-fabricated wheels from RRT. The wheel design originates from Banks and Murray and is machined by Jewell Group, featuring custom badging with the “Ford” name by enamel artist Karla Maxwell.

There is no doubt that the roadster is a 1936 Ford highboy roadster. However, while it resembles a highly stylized 1936 Ford roadster, the reality is that Ross sent a completely stock 1936 roadster for the staff at RRT to take all the necessary measurements from and then returned the factory-stock 1936. Indeed, all the body panels are bent and shaped to create a one-off 1936 Ford highboy roadster that showcases the designed style changes. The hood and top are made from an alloy material. Banks aimed to make the roadster body look proportionally correct without fenders and running boards. He carefully massaged the sheetmetal metal, which eventually yielded the body, while Modert handled the floor and firewall.

RRT’s own Warren Lewis and Colby Marshall managed the bodywork, initially receiving help from Darryl Hollenbeck of Vintage Color Studio. Lewis was chosen to utilize the BASF Porsche Aventurine Green. The final cut and buff were performed by Lewis and Marshall. During the GNRS, Hollenbeck once again assisted the RRT crew with additional final detailing. A word on the color: Aventura (sometimes also called Aventurine) is a muted medium green metallic with a touch of blue-gray to it.

The interior featured more craftsmanship by Banks, showcasing a custom dash garnished with a unique presentation of Classic Instruments’ reworked 1950 Buick instruments. RRT’s own Lawrence Laughlin machined the instrument bezel. He also did the modeling for the exhaust manifolds as well as the steering wheel. Sherm’s Custom Plating handled the brightwork here on the dash and throughout the hot rod. The interior’s electrics, including the gauges, A/C system by Vintage Air, and the demands of the remaining hot rod electrics are managed by a Painless wiring system installed in-house at RRT by Injection Connection’s Dale Cherry. The steering column is among RRT’s products marketed under the name Rad Rides Performance Parts, featuring a custom-machined RRT steering wheel. The horn button showcases added enamel artistry from Maxwell. The bench seat presentation is tailored; frames, foam, and cover are all provided by RRT’s own Banks. The material used is Spinneybeck North America leather, “hand-tipped” in a medium brown shade. This is paired with a medium-brown square-weave carpet, both of which are expertly stitched by Banks.

Hand-tipped leather is made from a high-quality selection of full-grain raw material. The unique pebble grain texture is achieved through a specific re-tanning process and an extended milling process. The two-tone look is achieved through the base dye coloration and treatment, where the tips of the pebble grain are hand-applied with a darker shade. Additionally, the surface of the leather is enhanced with a light, clearcoat and then treated with a specialized ironing process for a refined finish.

For more on the top, stay tuned as MR will have a complete behind-the-scenes look at how this unique top was achieved.

A distinctive hot rod sets a benchmark for others in the rodding community, sparking innovation and healthy competition among builders. (Editor’s note: While competitive, it should be noted that the hot rod builder’s community is tight-knit, and each is often willing to help one another whenever they can.) This surge of creativity, driven by advanced tools and materials, continually pushes the boundaries of rod building. Furthermore, the process of creating a unique hot rod fosters a deep sense of pride and accomplishment, serving as a testament to dedication, hard work, and passion. In an age dominated by mass production, these vehicles remind us of the artistry and individuality that can be achieved through personal effort, inspiring future generations to dream big and strive for their extraordinary legacies in automotive history.

While it’s true that very few hot rodders will ever have a ride based on this level of imagination, craftsmanship, and overall budget, the fact remains that this year’s AMBR-winning 1936 Ford highboy roadster offers countless creative ideas, allowing other hot rodders to build their versions.

-MR

Check out this story in our digital edition here.

AMBR Winner: 1936 Ford Highboy Roadster

Build Crew: Rad Rides by Troy

Troy Trepanier

Adam Banks

Casey Modert

Lawrence Laughlin

Colby Marshall

Warren Lewis

Brian Ferguson

Alex Merian

Nathan Fetters

Auston Raets

Angie Trepanier

Luke Trepanier

Jack Trepanier

Annette Zimbelman