How to Pick the Engine Cooling Fan That’s Right for Your Hot Rod

By Ron Ceridono – Photography Courtesy of the Manufacturers

One of the common problems with hot rods is that they are often just that, hot—and not in a good way. Occasionally your hot rod’s cooling system may burp out a little coolant after the engine is shut down and the reason is simple enough. Although coolant is no longer circulating, it will continue to absorb heat and in some cases that will cause enough pressure to build in the system to exceed the pressure rating of the radiator cap. The result is some coolant will be released and there will be a puddle on the ground. The biggest problem with this situation is that if it happens repeatedly the coolant level may drop to a dangerously low level and that will result in a serious overheating problem. A couple of simple cures for this condition are a coolant recovery tank and/or allowing an electric engine cooling fan to run for a short period after the engine is shut off.

While losing a little coolant on a hot day is annoying, severe overheating is a far more serious problem. It can lead to catastrophic engine failure—piston rings may be stuck to the cylinder walls, pistons may seize, exhaust valves can stick in their guides, heads and block often crack. In other words, a good engine can be reduced to junk in short order by overheating. So, what is the ideal engine operating temperature? With today’s fuels, 180 degrees is considered the minimum operating temperature for efficient combustion and is ideal for vintage engines on the street. It’s generally agreed that 190 degrees is a safe operating temperature for modern carbureted engines and contemporary computer-controlled, fuel-injected crate engines 195-220 degrees is considered the norm. The trick is to achieve the proper temperature without exceeding it.

A vital component of the cooling system for maintaining the proper engine temperature is the fan. Granted, once a car is moving at a speed sufficient to provide ram airflow through the radiator a fan isn’t really necessary in most circumstances. While it depends on the design of the car, 30 mph is usually fast enough to provide the necessary airflow, but reality dictates we often move slower, or not at all, which is where a fan comes into play. Ironically, as important as fans are, the space required for one isn’t always taken into consideration. Many a hot rodder has performed an engine swap only to find there was no room for a fan and then went on a frantic search for one that would fit—the results are seldom satisfactory. The secret is to plan ahead by positioning the radiator and leaving plenty of room for a fan before the engine location is finalized.

When it comes to selecting a fan there are a variety to choose from:

Mechanical Fans

Rigid fans are the simplest of the mechanical fans. They’re simple and effective and may have two to six blades. The common objection to engine-driven fans is the amount of horsepower they consume. As you might guess, the more blades and the greater their pitch the more power it takes to spin them, with the worst offenders soaking up to 30 hp or more. On the other hand, when it comes to moving lots of air, an engine-driven fan is hard to beat.

Flex fans are a sophisticated version of a rigid fan. The pitch of the blades on a flex fan will pull lots of air at low speeds, then flatten out at higher speeds for less drag. Of course, not all flex fans are created equal. Some made-of-plastic fans flex very little, while the aluminum and stainless variety seem to be more effective.

Clutch fans are found on many OEM applications. They use a rigid fan attached to a clutch that will disengage either based on temperature or engine rpm. While clutch fans have obvious advantages, their big drawback is the space they require forward of the water pump.

Clutch fans fall into three categories. The viscous/torque type have some slip all the time that limits their speed to a percentage of the water pump speed. Another style is the viscous/temperature-controlled type, these slip less as temperature raises, increasing fan speed. Lastly there is the viscous thermostatic type that turns on and off at a predetermined temperature. With this style of clutch the fan “idles” and doesn’t run at engine speed until needed. The complication is these are calibrated to specific cars or trucks, so successfully adapting one would be a guessing game. Too low a cut-in it would run all the time, too high and it will never turn on.

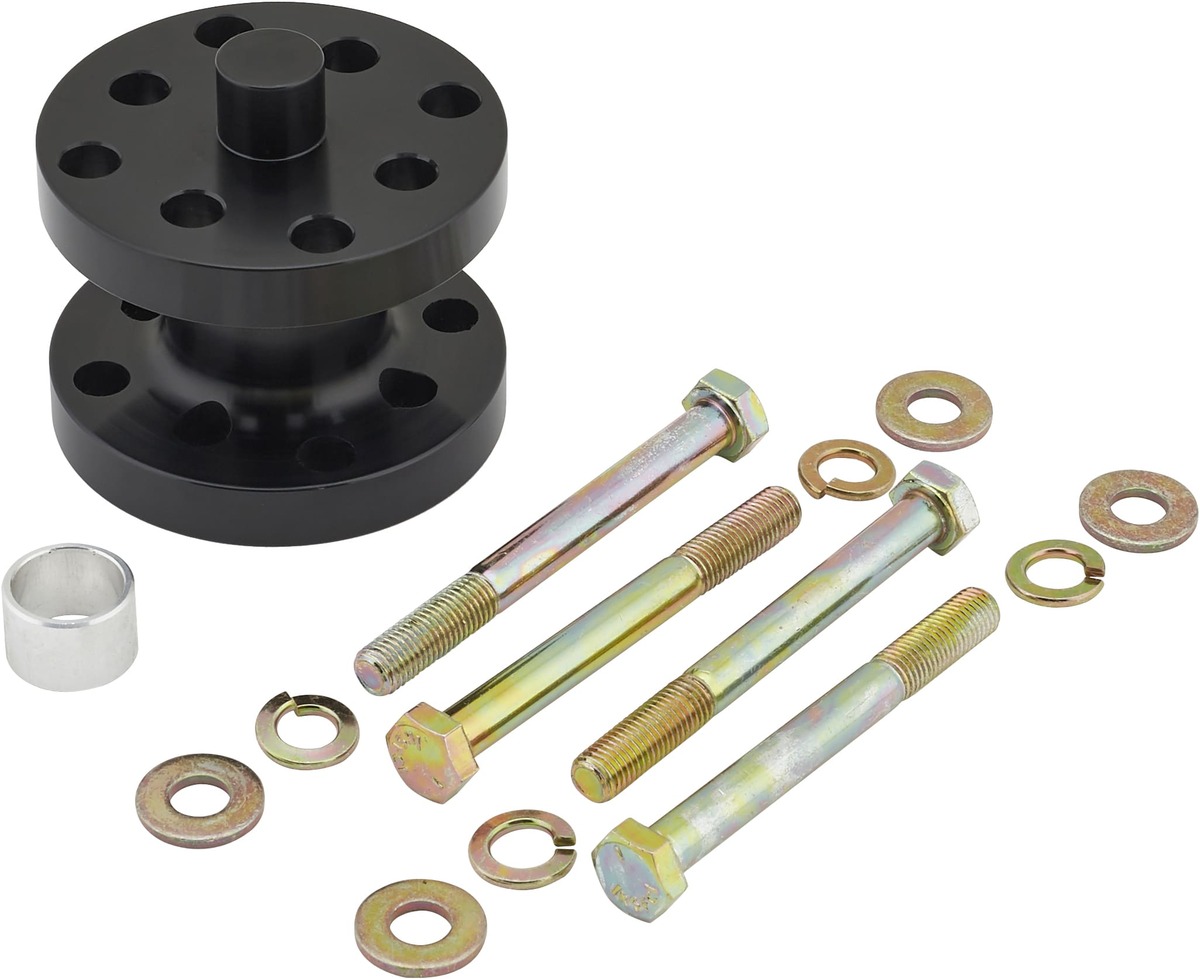

Spacers

To properly locate a mechanical fan in relationship to a radiator or shroud it’s often necessary to use a fan spacer. Realize not all spacers are created equal. Some cheap spacers are not particularly accurate and may cause the fan to have a certain amount of runout, not something you want with the fan hanging off the end of the water pump. The best choice is to spend a few extra bucks for a quality, machined aluminum spacer and limit spacer length to 3 inches max.

Electric Fans

These offer a number of advantages. Obviously they eliminate the horsepower loss of a mechanical fan, which may also improve gas mileage. Electric fans will often provide cooler A/C output at idle and pull air more effectively through radiators with an A/C condenser or transmission cooler in front of them.

When choosing an electric fan there are a number of considerations; one of the most difficult to decipher can be their cfm (cubic feet per minute) rating. Electric fans are normally rated at 0-inch static pressure, which means there is nothing restricting airflow. Put a radiator in front of them and other impediments to airflow like an A/C condenser and an auxiliary cooler of some sort and the static pressure, or the resistance to airflow, increases. That’s when the motor becomes a factor; given equal

cfm ratings a fan with a more powerful motor will be more effective as static pressure increases.

An important factor when selecting an electric fan is its diameter—this is an example of where size really does matter. As much of the radiator core as possible should be covered; in some cases that may require dual fans. Another consideration is the type of fan blades; they may be straight or curved. In operation S-blade fans are quieter whereas straight blade fans generally move more air. For a normal street rod, SPAL suggests using a curved blade fan; for more high-performance applications a straight blade fan is recommended.

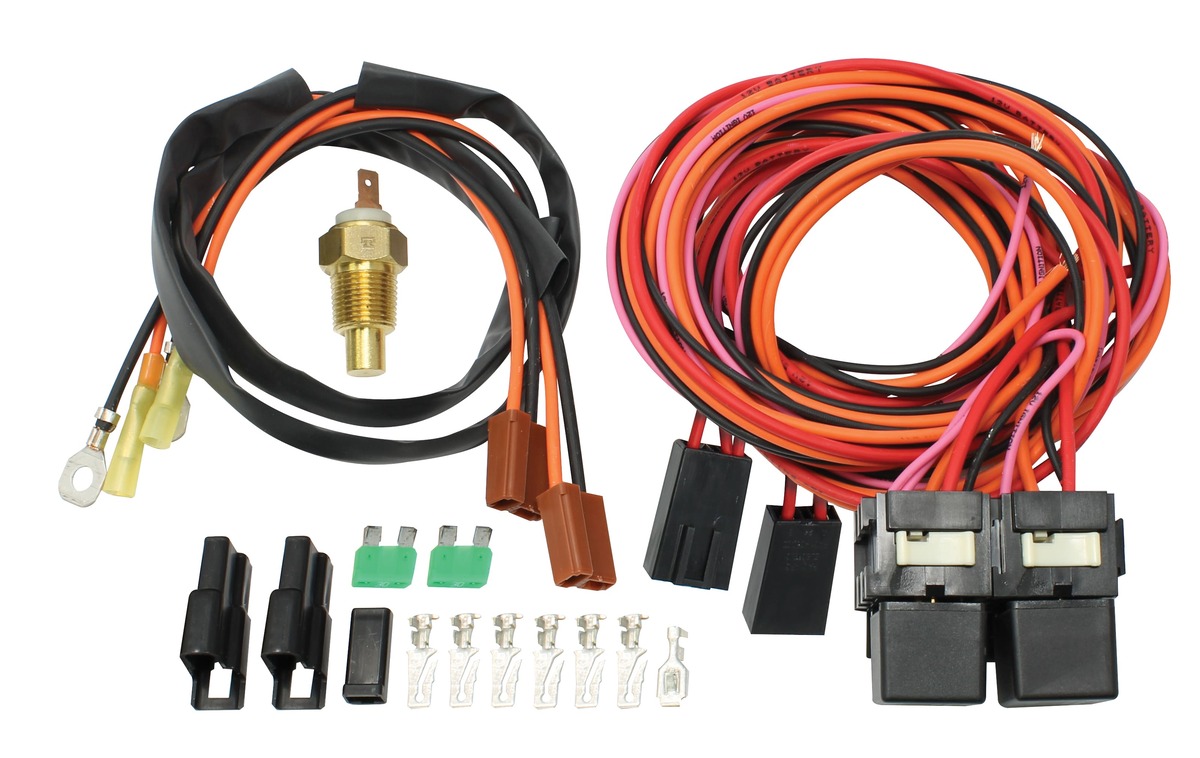

Electrical Considerations

Electric fans can consume anywhere from 4 to 36 amps or more depending on the size of the fan and the efficiency of the motor. Keep in mind when an electric fan starts the current draw will spike and be considerably higher for an instant. As a result of the electrical demands from an electric fan(s) it’s important that an adequate alternator is part of the charging system; typically fan suppliers recommend a 100-amp alternator.

Along with an appropriate charging system, a relay kit should always be part of an electrical fan’s wiring. Although it may be tempting to use a simple toggle switch to activate the fan, there are two issues with this. First the fan’s amperage draw will fry most toggle switches. The other problem is back-feeding through the system. When the ignition is shut off the fan will continue to coast down to a stop. During the brief period an induction motor may act like a generator and back feed through the system and keep the engine running until the fan comes to a stop. A relay will cure both problems.

Brushless Fans

The latest and greatest variation of electric fans are the brushless designs found on many modern cars. Brushless fans are capable of moving more air than conventional fans while consuming less energy, last longer, and are extremely compact. A big plus is their speed varies based on demand.

As Rick Love of Vintage Air explains them, the brushless system contains no control relays. Instead, the battery powers the motor assembly at all times and an electronic controller within the motor housing determines when and how to operate the motor based on a signal that comes from the controller that senses the temperature of coolant leaving the engine.

When a brushless fan engages it begins with a “soft-start” at approximately 30 percent power when the engine is approximately at its coolant thermostat opening temperature, then the fan’s speed gradually ramps up as engine temperature increases. Since these fans are very powerful, they rarely, if ever, reach maximum speed.

Electric Fan Controls

These range from simple to complex. Basic controls are a thermal switch with set points that turn a relay on and off to control the fan. This style switch should turn the fan on approximately 15- 20 degrees higher than the thermostat’s opening temperature and off around the thermostat’s opening temperature. More complicated controllers have adjustable on and off set points, are capable of controlling variable speed or dual fans, and will activate the fan(s) when the A/C is turned on.

Keep Your Cool

There are many viable options when selecting a fan for your hot rod and it’s important to plan ahead and leave enough room for whatever type you choose. When using a mechanical fan there should be at least 1 inch from the blades to the core and the same from the tip of the blades to the shroud to accommodate for engine and radiator movement. When mounting electric fans, avoid the plastic mounts that go through the core; mounting the fan to the radiator side straps is a better choice. With either type of fan incorporate a shroud for maximum efficiency.

Sources

Dakota Digital

(800) 852-3228

dakotadigital.com

Speedway Motors

(800) 979-0122

speedwaymotors.com

Vintage Air

(800) 862-6658

vintageair.com