CPP Control Arm Assemblies Will Simplify Your 1964 Chevelle Suspension Rebuild

By Tommy Lee Byrd – Photography by the Author

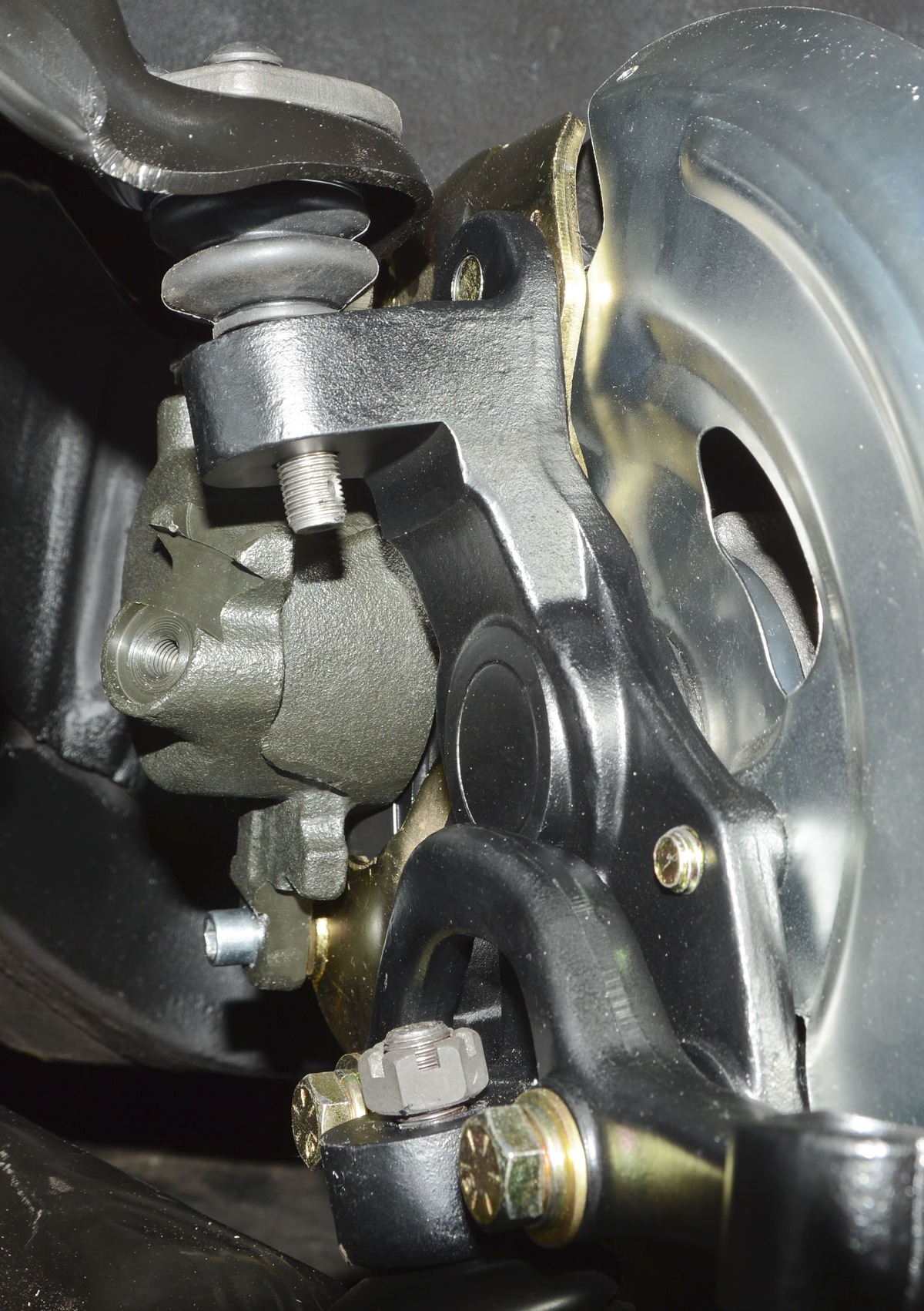

If you’ve ever been on the floor of your garage with your old car on jackstands, you’ve probably noticed a few problem areas. It seems that 50-plus years of service can take a toll on certain components, and with our 1964 Chevelle project car, it was obvious that we had some serious wear as we disassembled the car to swap the original drum brakes for a Classic Performance Products (CPP) disc brake system.

Suspension upgrades and installs are typically a “can of worms” because you’ll eventually replace every component under the car by the time you reach a stopping point. Such is the case with our Chevelle four-door sedan, as we noticed severe ball joint sloppiness and lots of crumbly, dry rubber where the control arm bushings are supposed to live. It would’ve been silly to reassemble the car with those ailing components beneath it, so we grabbed our favorite screwdriver and peeled open the can of worms.

Ball joint replacement can be a pain, no matter how many times you perform the task of grinding, chiseling, and cutting the rivets that hold the upper ball joint in place. Control arm bushings also call for a lot of patience, as it usually requires an air chisel to remove them and a hydraulic press to install the new bushings. By the time we paid for the ball joints and bushings, and then spent the time disassembling and installing the new parts, we would be way ahead of the game by simply buying new control arm assemblies that were already loaded up and ready to bolt into place.

CPP offers new control arm assemblies for many makes and models, including our early GM A-body. Installation is still labor intensive, as the tight fitment of the lower control arms requires special care and the splined upper control arm bolts can cause a headache if not properly removed. But, for the money and the time invested, we were very happy with the complete assembly. For our build we wanted something that was budget-friendly and mild-mannered, so we went with the stamped steel versions with rubber bushings. Of course, CPP also offers tubular control arms with billet cross shafts and self-lubricating plastic bushings that are guaranteed not to squeak.

Installing the control arms requires some simple hand tools, but you can make life a lot easier with an impact and some 1/2-inch sockets, including 11/16- and 3/4-inch sizes. You’ll need a floor jack, a few blocks of wood, a good rubber mallet, and some grease to lubricate the bushings. After the new control arms are installed, and the rest of the front suspension and steering system is completed, we’ll have the suspension aligned. Then, it’ll be time to enjoy the tight feeling of a brand-new front suspension. Safety, comfort, and longevity is what we strive for with our 1964 Chevelle project, and CPP control arms saved a lot of time to get us one step closer to being on the road again. MR

Source

Classic Performance Products

(800) 522-5004

www.classicperform.com