How a Quick Change Rear Axle can Transform How Your Rod Looks With Winter Performance

By Chris Shelton – Photography by Precision Hot Rods & Winters Performance

Ah, there’s nothing quite like the look (or whirr) of a quick change rear axle. Inspired by circle track racers who needed to fine-tune their gearing to suit course conditions, the venerable quick change rear axle has made its way under just about everything, including land speed cars, sports cars, dragsters, Modifieds, and even drift cars.

What’s A Quick Change Rear End?

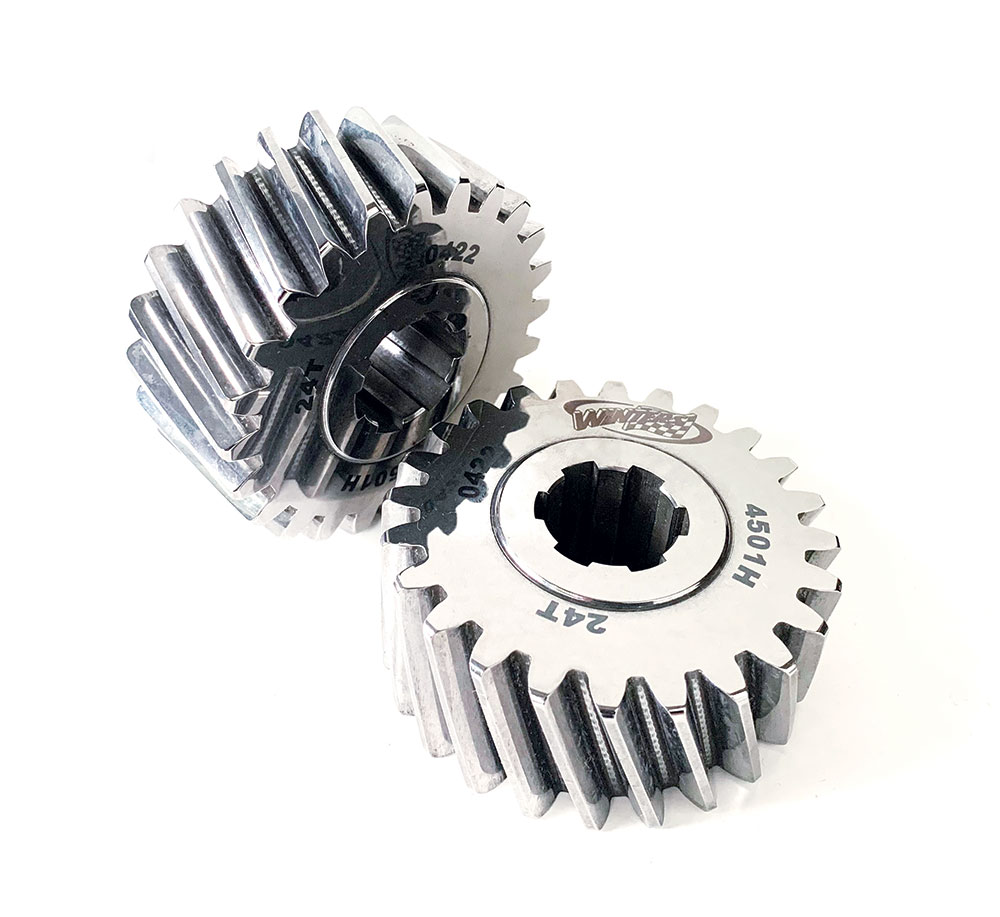

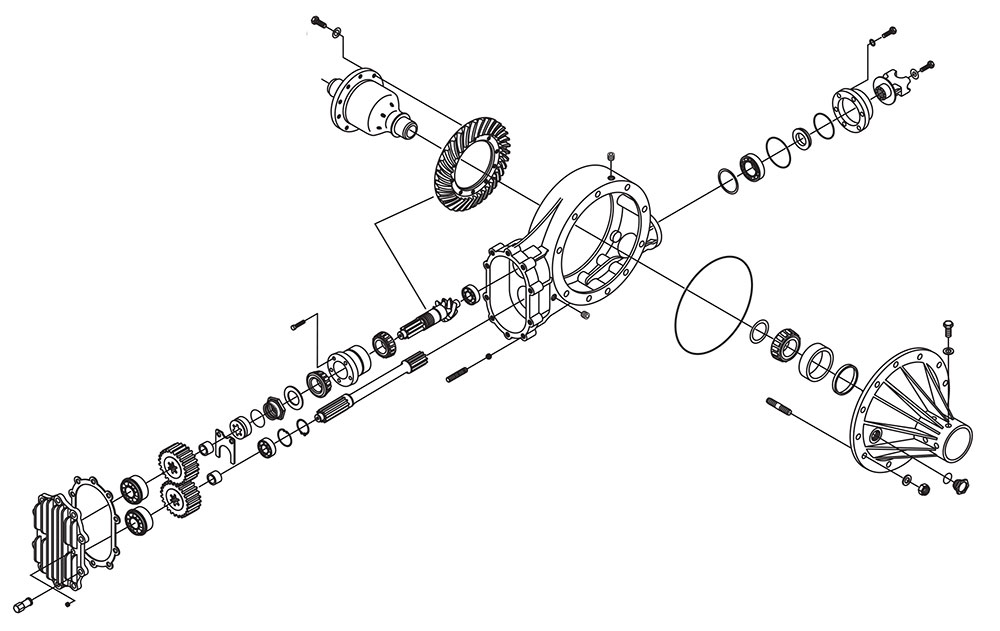

A quick change rear axle is basically a conventional axle with a gear case modified or designed to use a pair of spur gears. In a conventional axle, the driveshaft and pinion rotate at a 1:1 ratio. In other words, the pinion rotates at the same rate as the driveshaft. But the spur gears in a quick change rear axle alter the ratio between the driveshaft and pinion. Depending on how it’s oriented, a spur-gear set can spin the pinion faster or slower than the driveshaft to alter the axle’s final drive, or its total gear ratio. That’s a big deal when trying to tune an engine to operate within its peak powerband on a racetrack.

Benefits Of A Quick Change Rear End?

But one could make the case that nearly as many quick change axles live under cars that will never see a checkered flag. After all, few things convey a sense of performance more than real race car parts. But quick change axles offer real utility to even road-going vehicles. It takes a few minutes to make the change, but there’s a gear ratio for everything from long-haul treks to events and blasts around town once you’re there within one set of properly chosen spur gears.

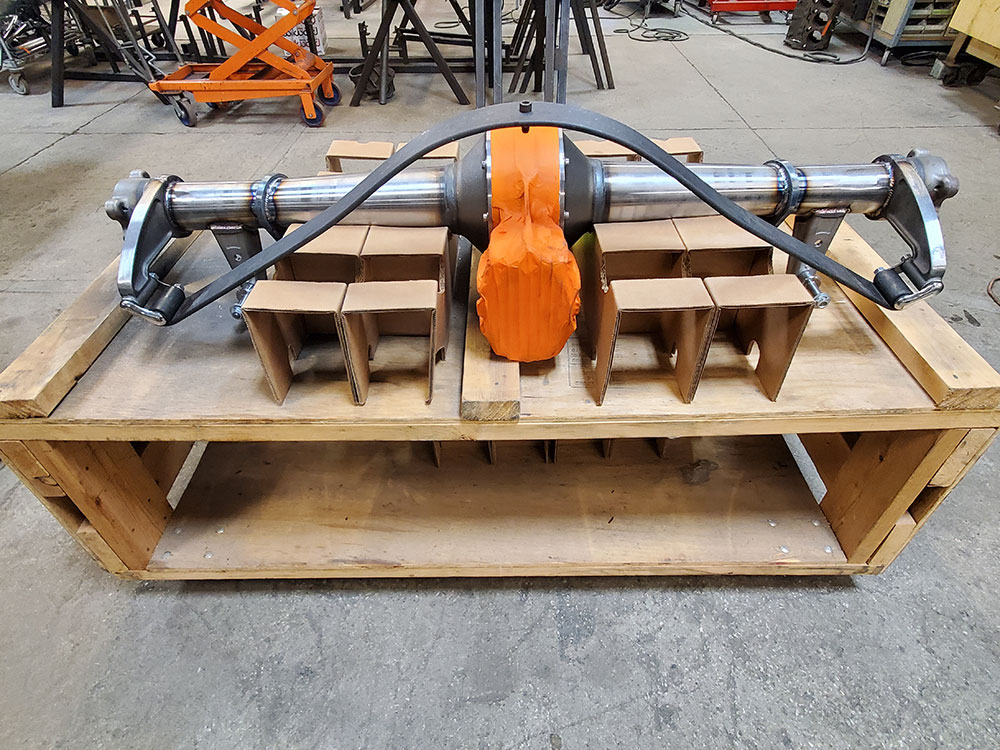

Due to Precision Hot Rods in Macedonia, Ohio, we can add another street-driven example to that list. Danny Tesar and Chico Caraballo recently built a Deuce chassis specifically to house a complete Winters Performance quick change axle.

Factory Gear Housing Vs Aftermarket Gear Housing

Though conceived as a gear case that used existing Ford or Dana components, the quick change gear housing evolved into a complete axle made of entirely new parts thanks to Winters Performance. Building an axle from all-new components pays dividends greater than eliminating the need to hunt down and restore vintage parts. For one thing, building from scratch opens the door to make the axles stronger and perform better.

The Evolution Of The Quick Change Axle

To understand why is to know the origins of the heart of the quick change axle: its gear case. The most popular design in the hot rod world evolved from the banjo-style axle used in ’35-48 Fords. Squint just right at a bare quick change housing and you’ll likely see that—design-wise anyway—a quick change housing is basically a Ford banjo flipped backward and amended with a quill-shaft boss and a spur-gear housing. In fact, the earliest examples of quick change housings are nothing more than Ford banjos that users flipped backward and modified with some castings, a quill shaft, and spur gears.

The Problem With Ford Banjo Axle-Shaft

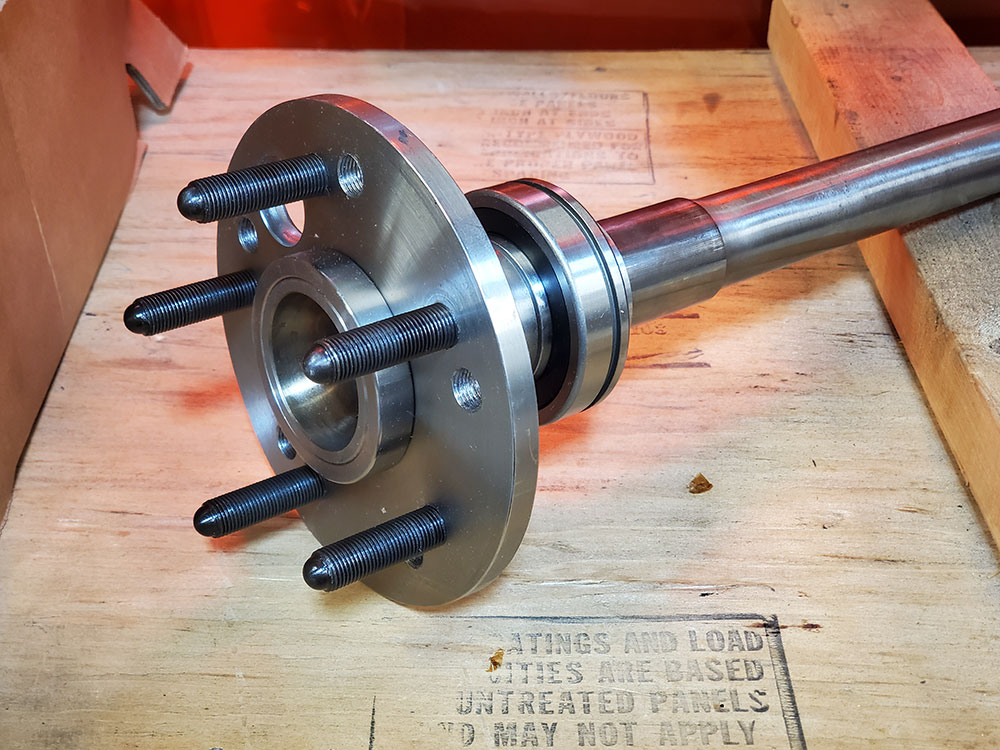

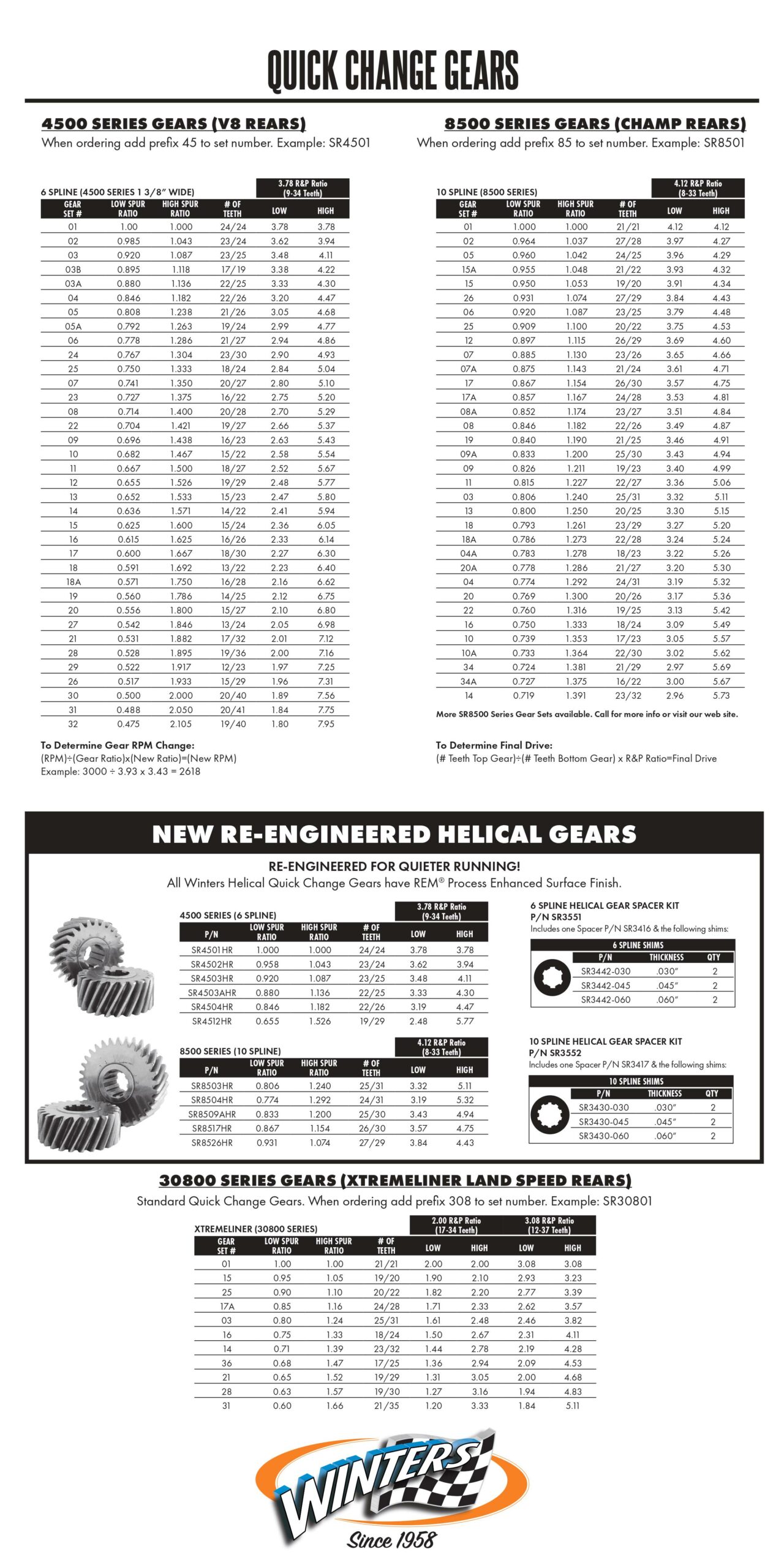

While convenient, Ford banjo parts have a few issues, mostly axle-shaft related. Specifically, those shafts break under duress. Over the years various builders adapted Ford 9 inch rear end bearing housings to Ford axle tubes, opening the door to stronger semi-float shafts. But that still required finding obsolete parts if you wanted to run Ford-style tapered axle bells. Winters Performance took things another step further by making the bells from scratch with the 9-inch bearing housings in place and including semi-float shafts in a complete assembly. Then the company took it upon itself to build a dedicated limited-slip gear carrier, conferring the benefit of equal torque to both drive wheels to the design. According to Winters Performance Curt Iseli, the result is an axle assembly capable of handling 600 hp in an application that can achieve traction sufficient to hook up.

Flexibility Of Axle Combinations

Winters Performance offers the axles in near countless combinations. The standard bell-style axles measure 56 inches wide. But because the tubes straighten out, axles with Ford-style housings can go as narrow as 48 inches and as wide as 60 inches. The ribbed-style axle housings can go narrow enough for Pro Street applications and nearly indefinitely wide. Complete axle assemblies include a limited-slip carrier and 31-spline axles, but Winters Performance sells the components individually if you’re inclined to run a Ford gear carrier.

Ring and Pinion Options

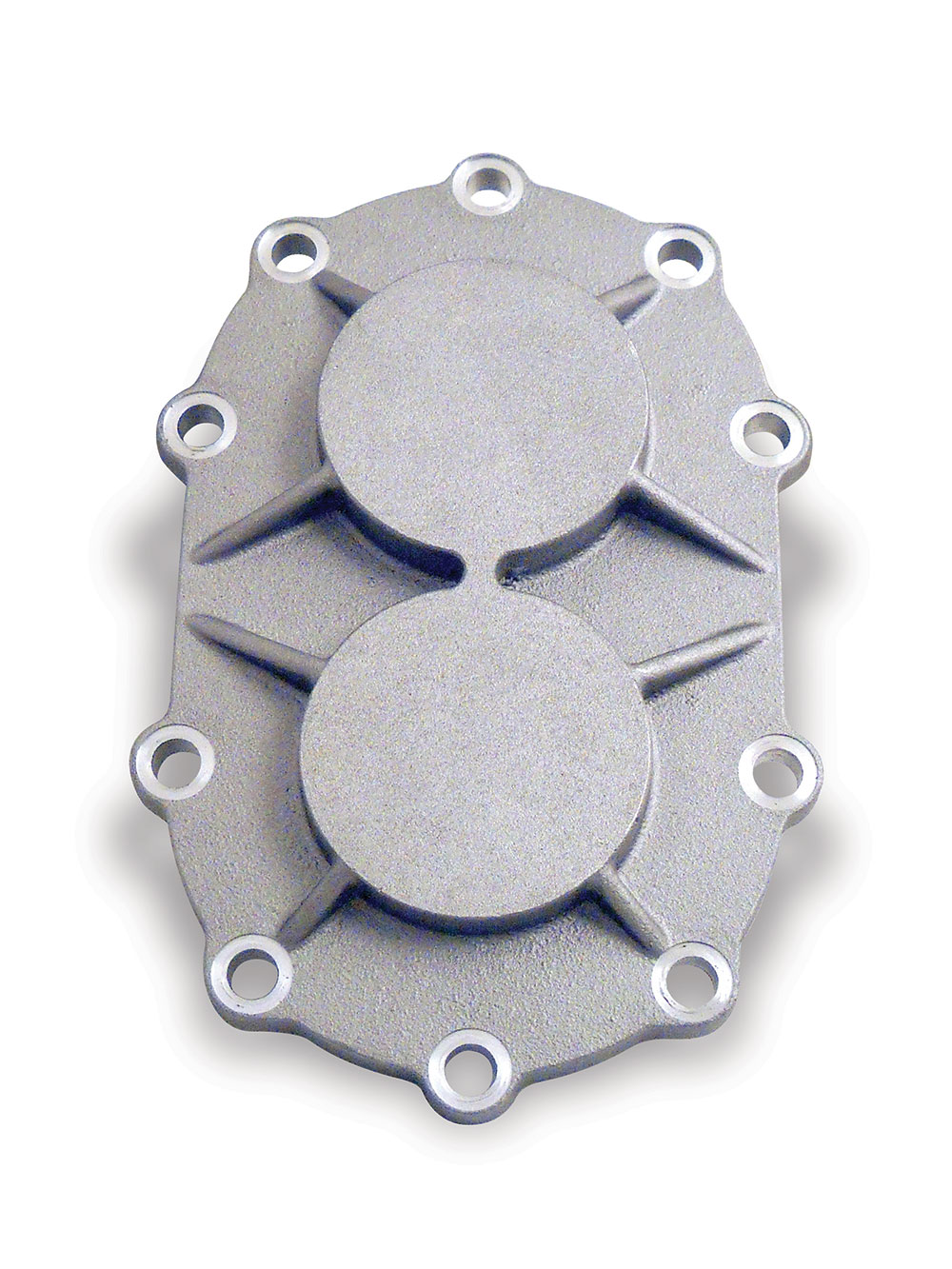

Three ring-and-pinion options and 36 spur-gear options offer a fine degree of resolution across a whopping range from 1.80:1 to 11.33:1. Other options include (but aren’t limited to) numerous gear cover designs, multiple finishes, including polished and Teflon coated, and a variety of brake packages.

Conventional Axle Vs Quick Change Axle

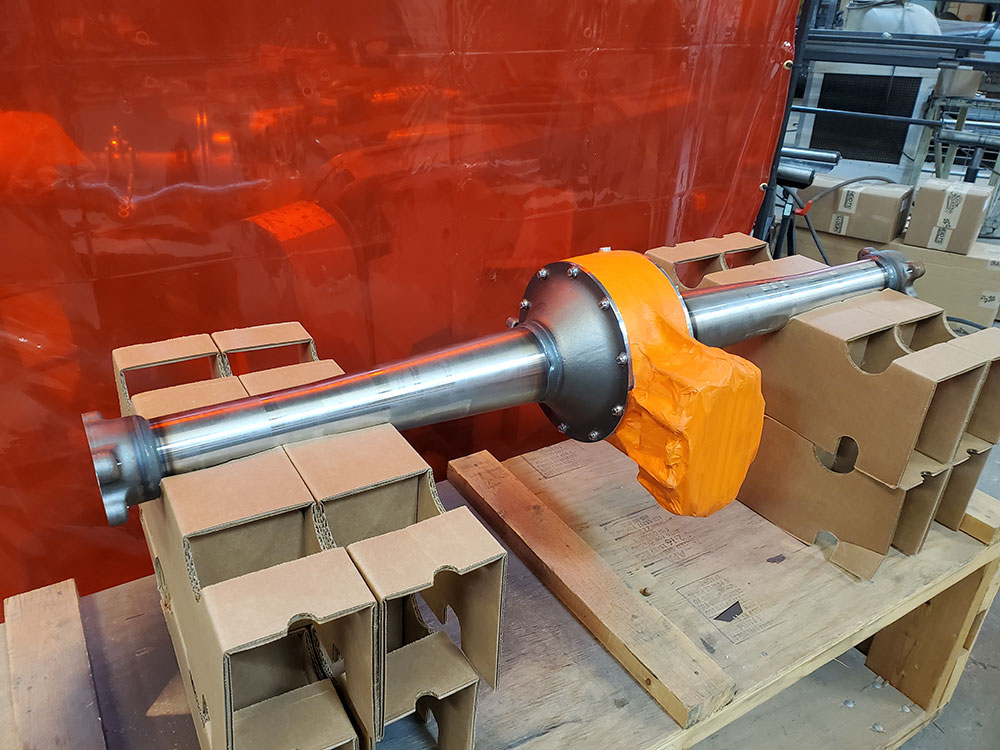

While different internally, a quick change axle assembly mounts much like any other axle, with only one potential exception: spur-gear housing clearance. Though it affects primarily ’32-48 Fords like the subject of this installation, Larry and Tesar show us how they prevailed in what’s probably the most time-honored method. The housings can also interfere with fuel tanks—the Ford Deuce is a known example—but remedies run the gamut from notching the tank to flat-out relocating it as Larry and Caraballo did.

The Drawbacks Of A Quick Change Axle

But beyond that, installing a quick change axle presents few significant issues (even the cost of a complete Winters quick change remains competitive with a new, similarly equipped 9-inch). In fact, the only thing keeping a quick change axle from under your hot rod is, well … you. MR

[Sidebar]

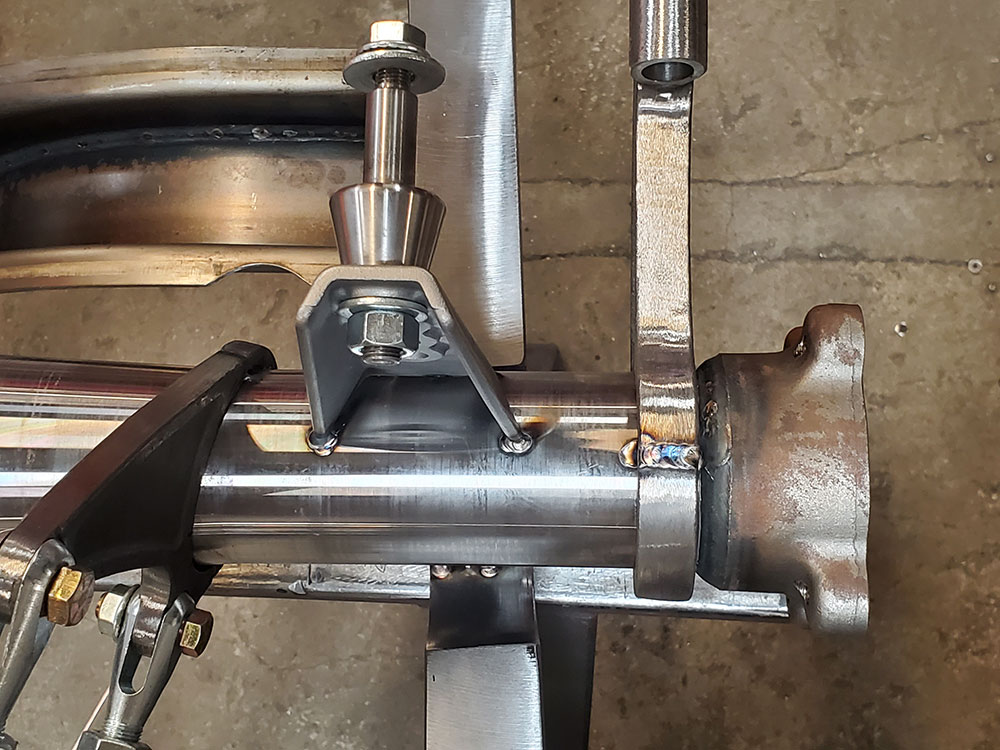

How to Calculate Ratios Axle’s Final Drive

Options are everything but they don’t matter if you don’t know which ones you need. Here’s the formula for calculating the axle’s final drive, or the product of the ring-and-pinion and spur gears.

(Driven-Gear Teeth/Drive-Gear Teeth) x Ring-and-Pinion Ratio = Final Drive.

This is how a 3.78 ring-and-pinion with a #4 (22/26) spur-gear set works out with the 22-tooth gear as driven (upper) and the 26-tooth gear as the drive (lower):

(22/26) x 3.78 = 3.20:1

In this orientation, the spur gears calculate to 0.846:1, or roughly a 15 percent overdrive. That makes an axle with a 3.78:1 ring-and-pinion behave as if it had a 3.20:1 ring-and-pinion. That’s great for reducing engine speeds on the highway.

Now flip that spur-gear set with the 26-tooth gear as the driven (upper) and the 22-tooth gear as the drive (lower):

(26/22) X 3.78 = 4.30

In this orientation, the spur gears calculate to 1.182:1, or roughly an 18 percent underdrive. That makes our axle with the 3.78:1 ring-and-pinion behave as if it had a 4.30:1 ring-and-pinion. That’s great for increasing torque for those stoplight blasts.

Sources

Posies Rods and Customs

(717) 566-3340

posiesrodsandcustoms.com

Precision Hot Rods and Fabrication

(330) 908-0234

precisionhotrodsandfab.com

Roadster Supply Company

(714) 583-4118

roadstersupply.com

Winters Performance Products

(717) 764-9844

wintersperformance.com