By Ron Ceridono – Photography By The Author

Although the hobby we all know and love is steeped in tradition, hot rodding has always embraced technology. Early examples include aluminum heads for Flathead Fords; today, they feature electronic fuel injections like those offered by FiTech.

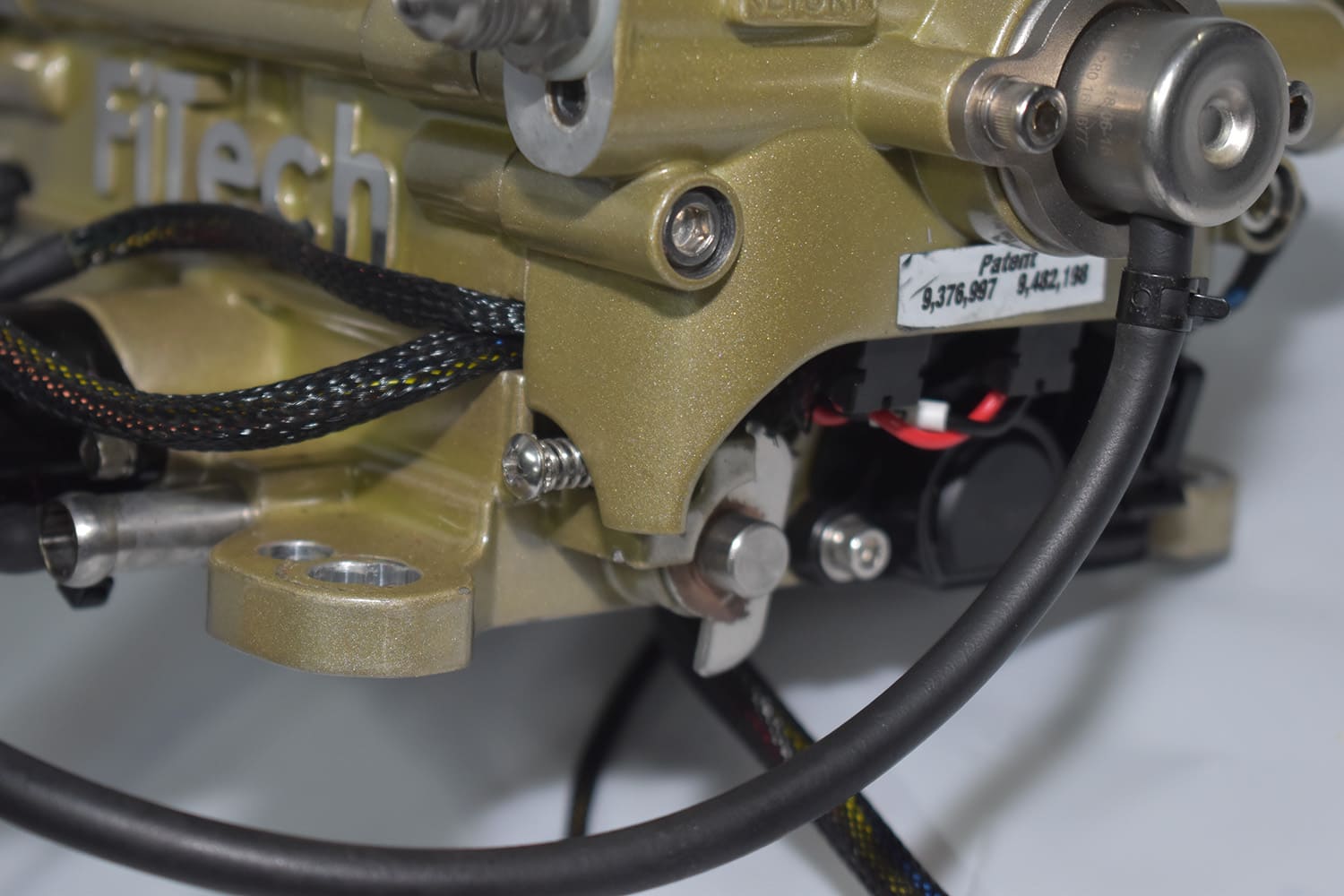

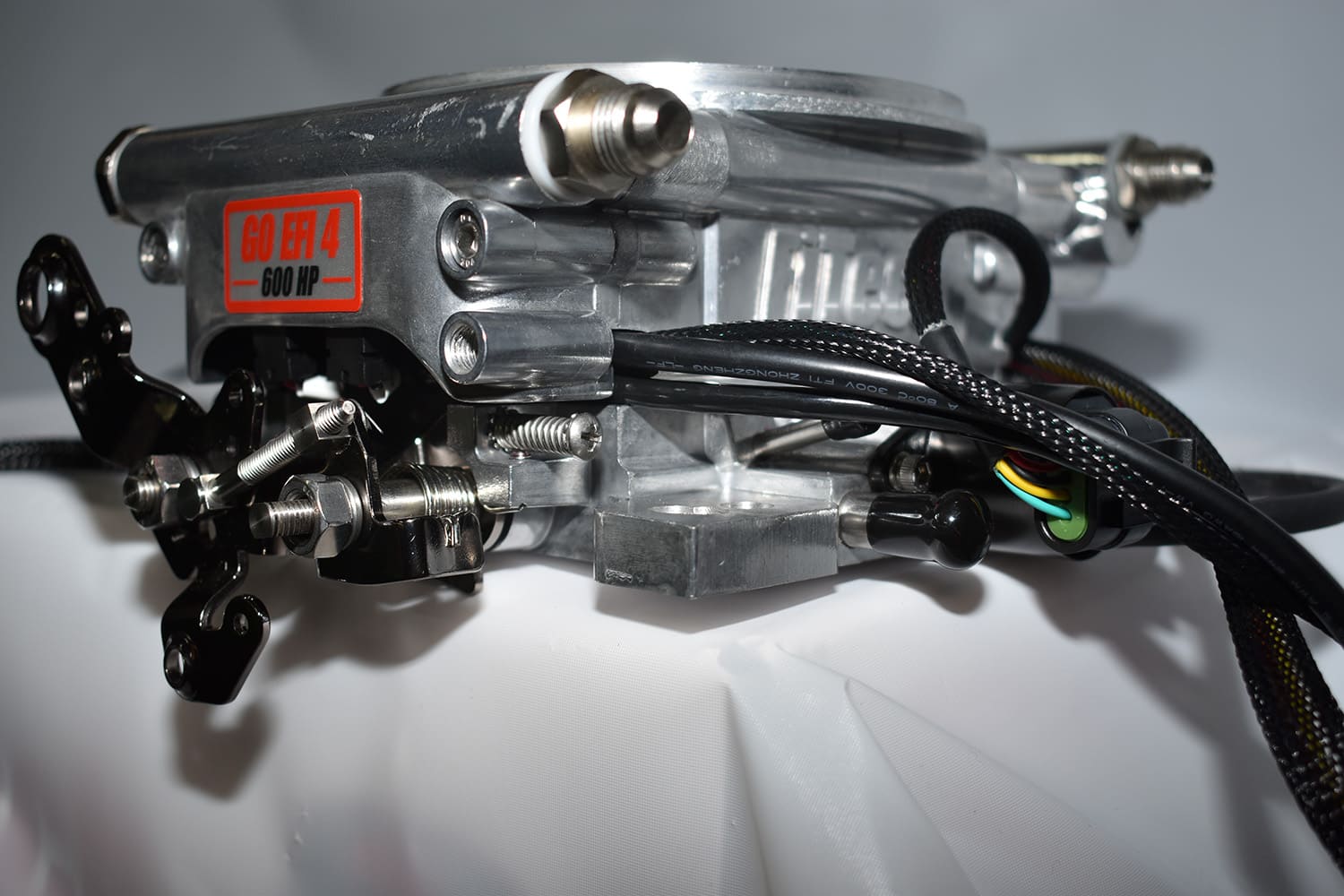

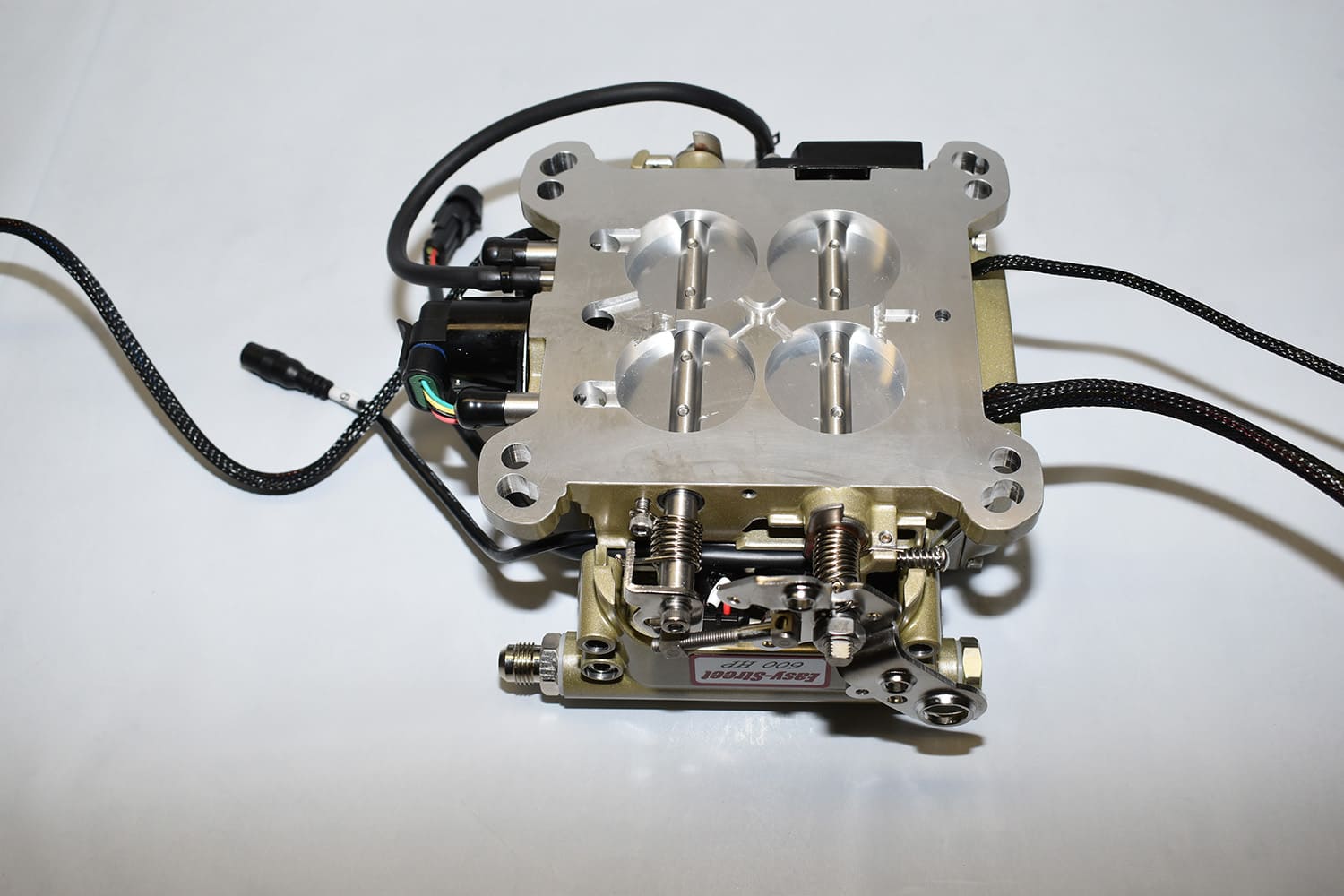

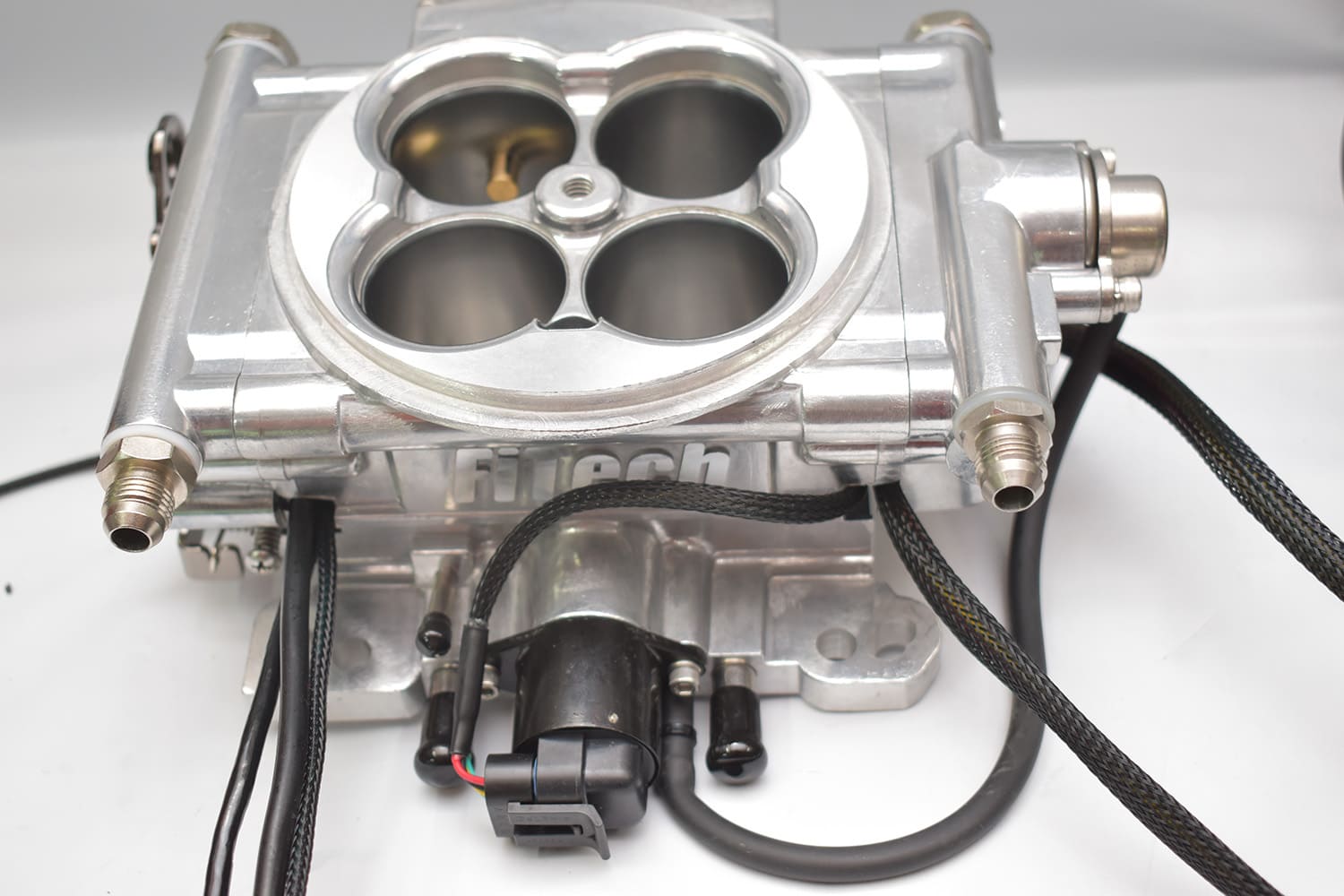

We cannot often conduct long-term testing on hot rod components, but we’ve accumulated nearly 50,000 trouble-free miles using a FiTech throttle body system. So, when it was time to select an induction system for a new project, we again chose the same system we used: a Go EFI 4 600hp system. Although this system is rated for up to 600 hp, it is appropriate for engines producing 200 hp and above.

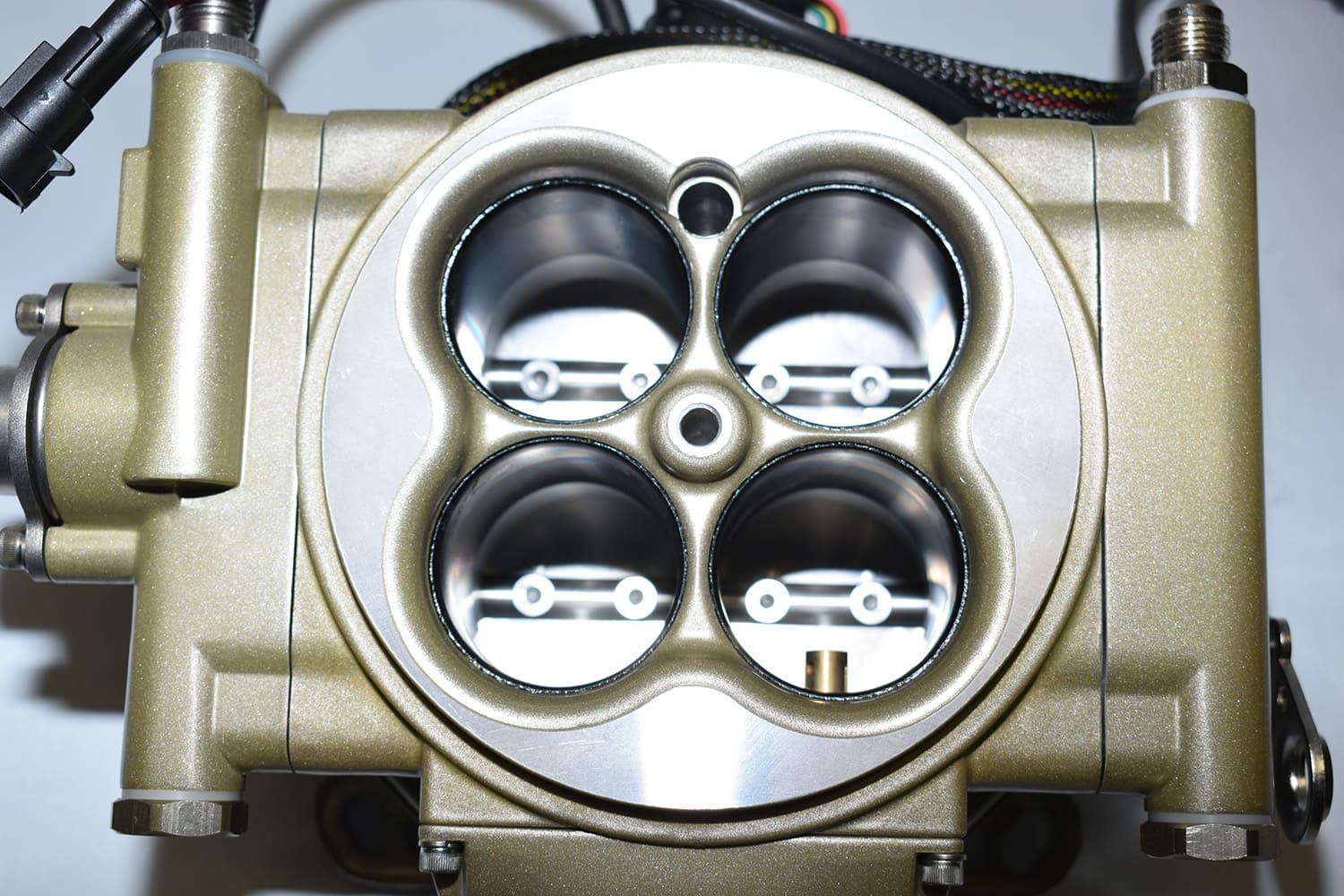

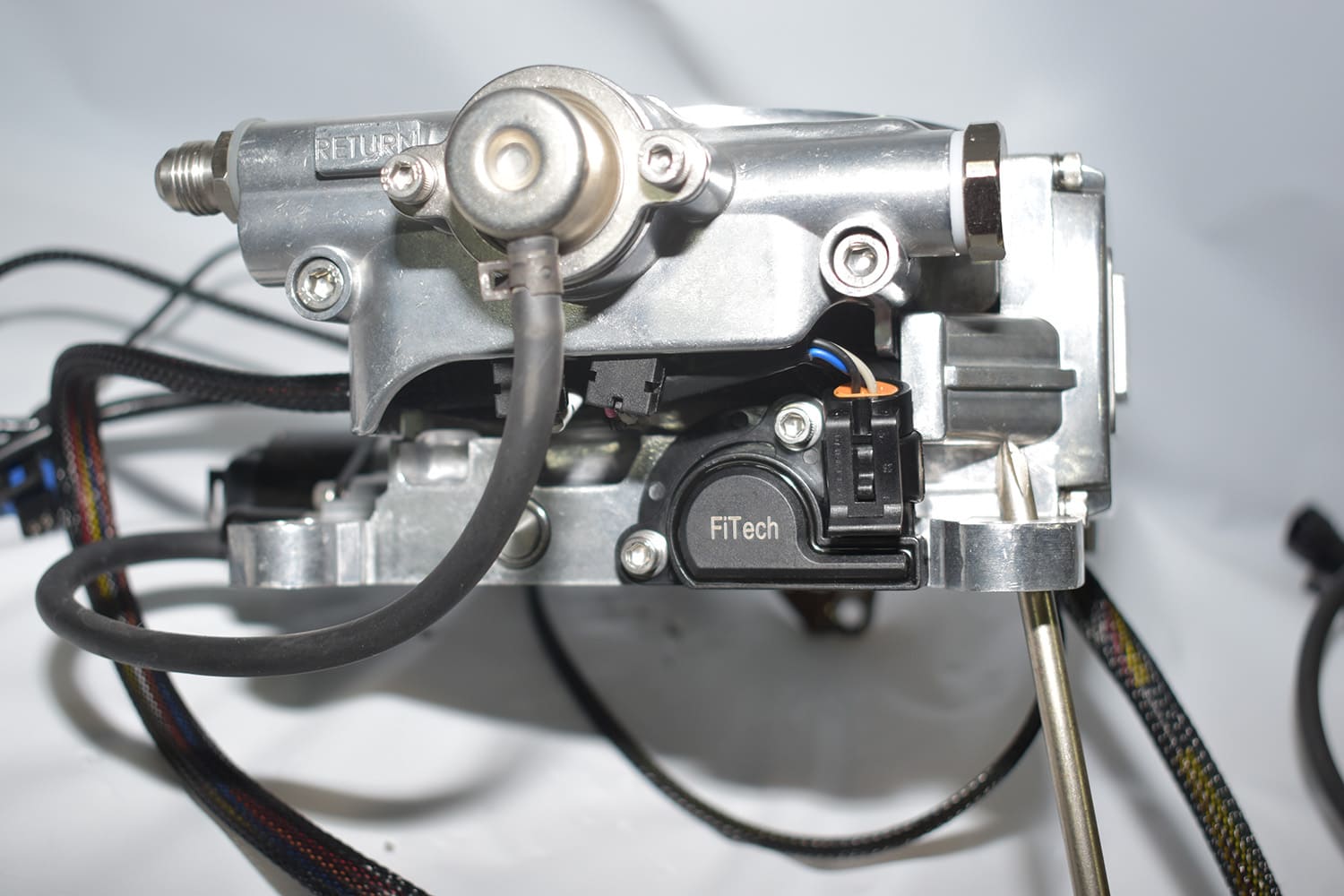

As often happens, FiTech has refined its products over the years, so we decided to examine the similarities and differences in these systems. From a functional standpoint, FiTech got it right from the beginning; the new systems are still self-tuning, and installation remains simple. After basic engine information is entered into the handheld controller, it establishes parameters for air/fuel ratios at idle, cruise, and wide-open throttle. In simple terms, the self-learning function involves the electronic control unit (ECU) using feedback from various sensors to adjust and maintain the air/fuel mixture under all conditions.

Those sensors are:

-Mass Air Flow (MAF) sensors measure the volume and density of air entering the engine

-Manifold Absolute Pressure (MAP) for altitude compensation and load correction

-Coolant Sensor (CTS) monitors operating temperature for fuel adjustments (think of it as the choke)

-Throttle Position Sensor (TPS) feedback for fuel control

-Idle Air Control (IAC) bypasses air to maintain a consistent idle speed

-Inlet Air Temp (IAT) compensates for changes in air density due to air temperature

-The Oxygen Sensor monitors the amount of oxygen in the exhaust to indicate how rich or lean the fuel mixture is

-Besides the oxygen sensor and CTS, all other sensors are housed in the throttle body

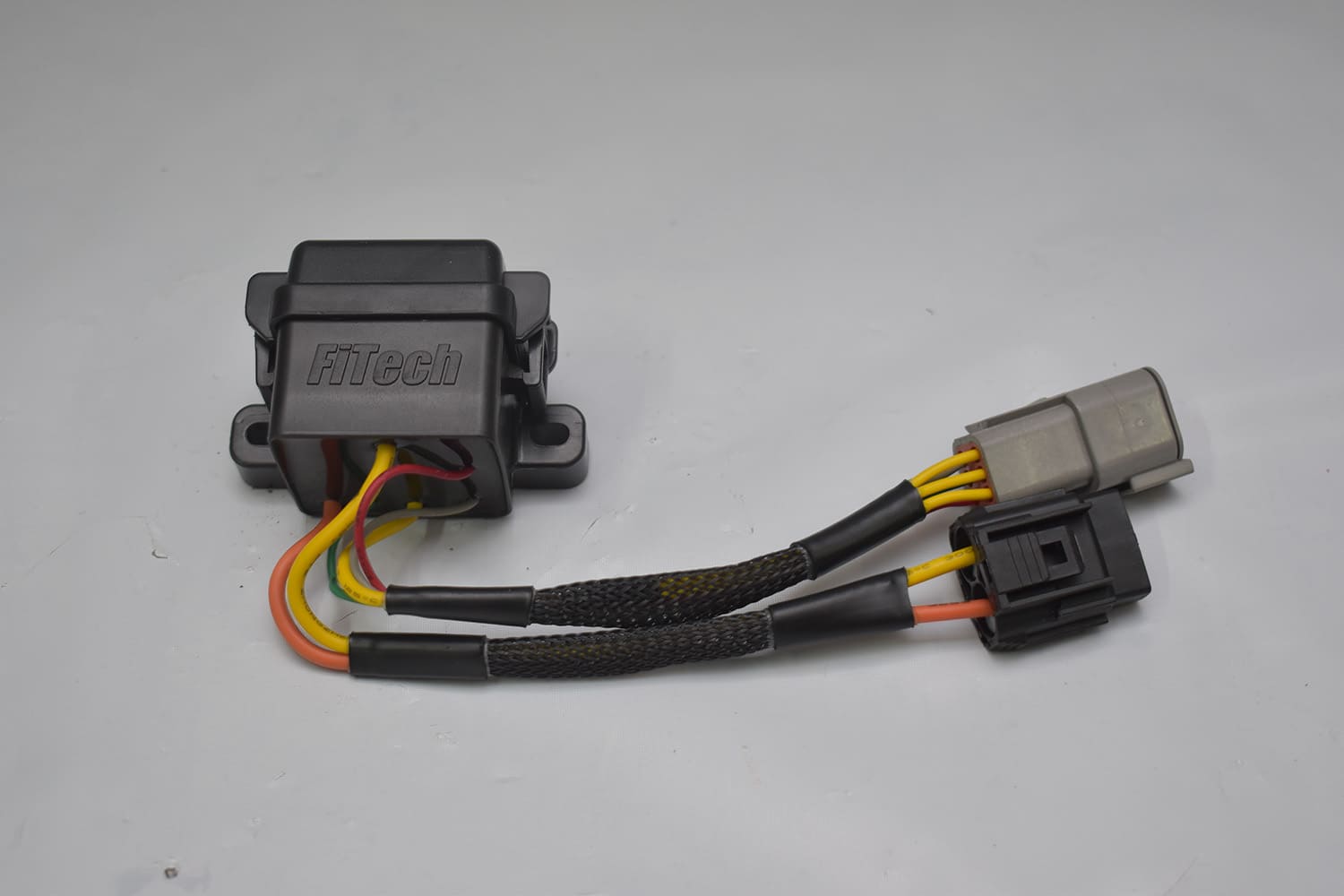

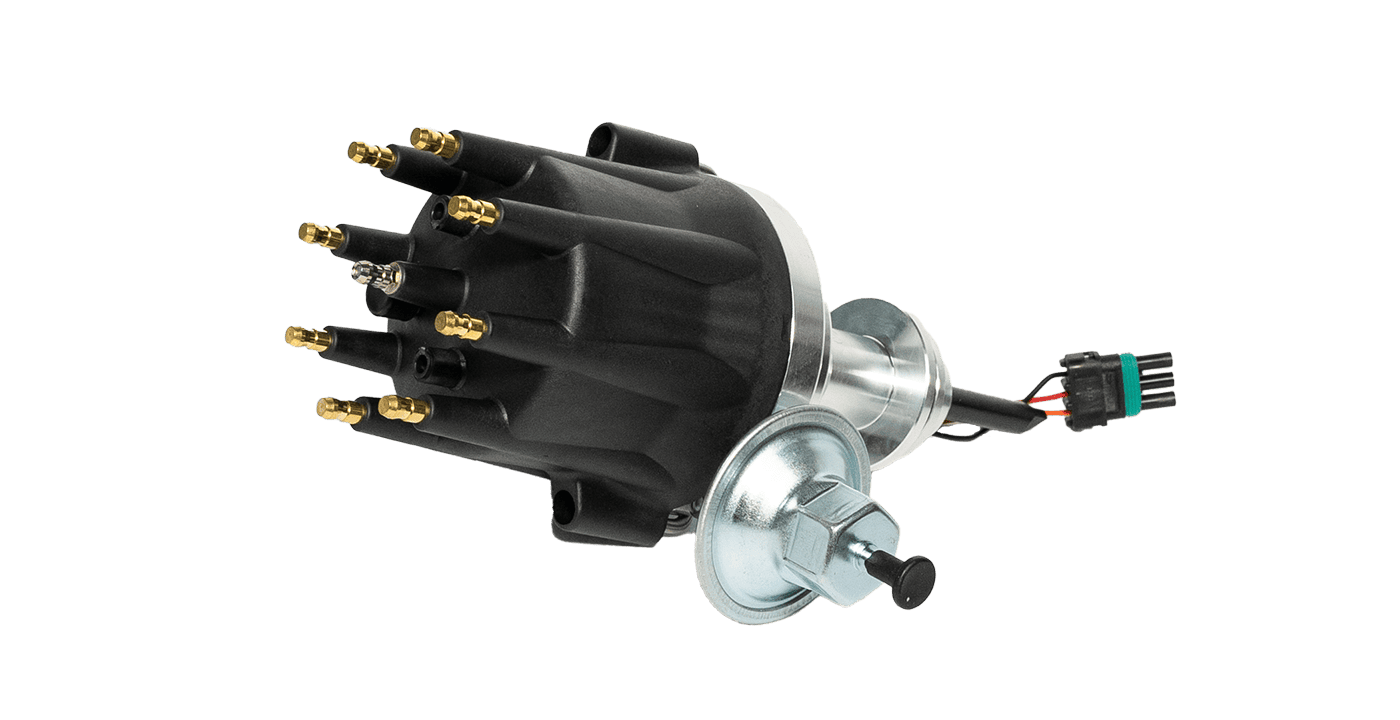

Although there are minor differences in the throttle bodies (as noted in the captions), the installation procedure remains the same as the engine requirements. The engine must be in good condition; EFI won’t cure mechanical shortcomings. The exhaust system must be free from leaks, as these will disrupt the oxygen sensor’s readings, leading to improper air/fuel ratios. Likewise, intake manifold leaks create similar problems. The charging system must be capable of maintaining the correct battery voltage and the system must be properly grounded. Another consideration is the ignition system. Point-controlled systems and Mopar electronic ignitions with the typical rectangular controller and dual-element ballast resistor will not provide the correct tach signal to the FiTech ECU. However, FiTech now offers a line of replacement distributors that solve both problems.

Due to FiTech’s refinements over the years, there are four versions of ECUs and handheld devices. However, rather than making previous systems obsolete, FiTech offers updated software that can be easily installed in the handheld controller via a home computer.

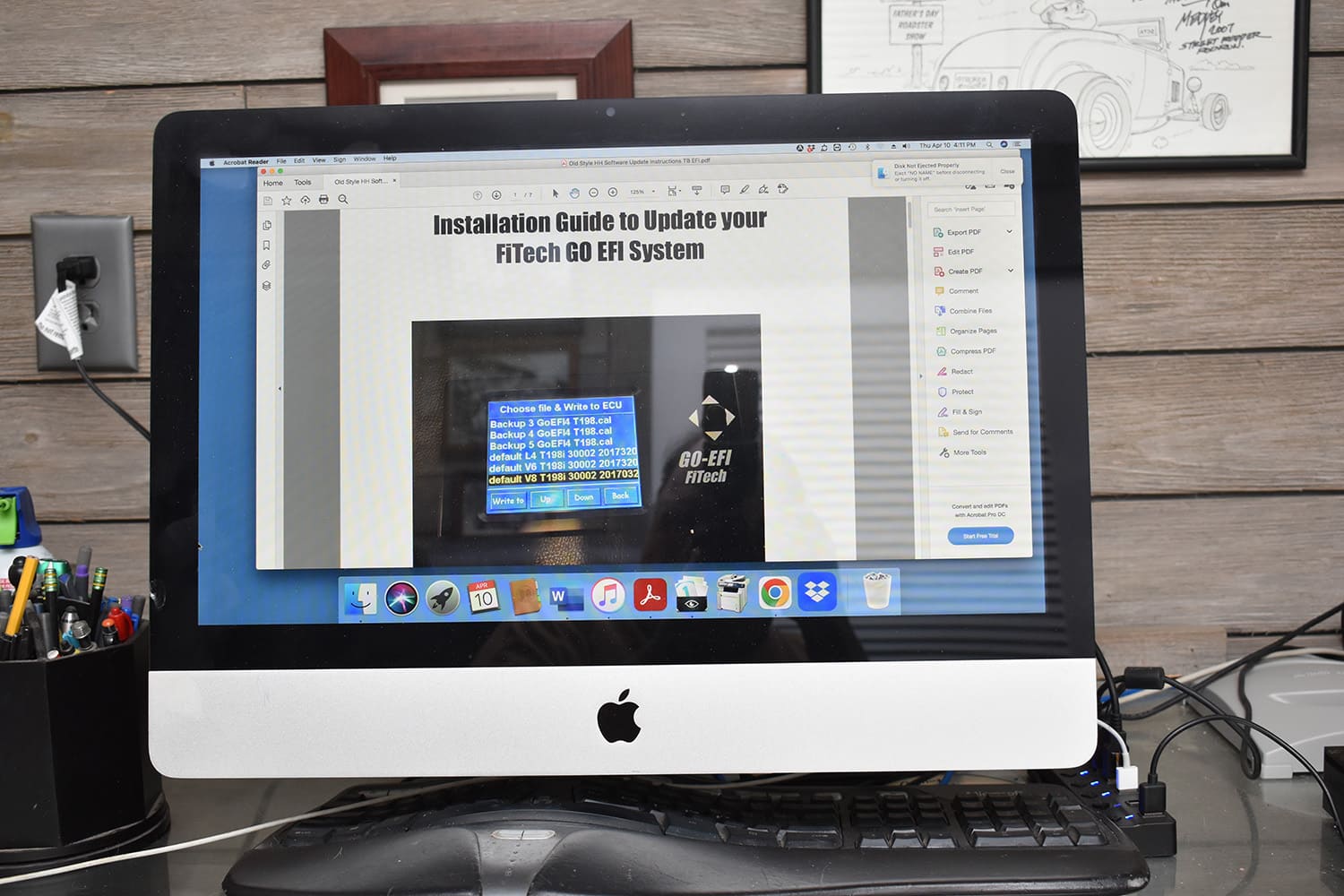

To make software system updates, the version of the system must be identified. This is done through the configuration of the handheld display. The older, smaller handhelds may have nothing around the joystick, while the later, larger handhelds may have four triangles on the right edge or may feature a plain surface with two dots. Once the handheld is identified, FiTech can supply the appropriate software updates, which is critical. Loading the wrong software into the handheld can permanently damage it, void the warranty, and require the purchase of a replacement.

Once the handheld is identified, a FiTech representative will provide the appropriate updated software file. After downloading the update to a desktop computer, the handheld is connected to the computer. Following the instructions on the computer screen, the original software is removed from the handheld, and the new version can be installed. Once the handheld is reinstalled, the ECU in the throttle body will operate on the new system. (FiTech has a complete video showing the update process.)

In subsequent installments of Modern Rodding, we will present more “fuelish pleasures,” such as the complete bumper-to-bumper procedure for installing a FiTech fuel injection system, along with tips on tuning, maintenance, troubleshooting, and additional information on Mopars.

-MR

Check out this story in our digital edition here.

Source

FiTech Fuel Injection

(951) 340-2624

fitechefi.com