By Jeff Smith – Images by Various Sources

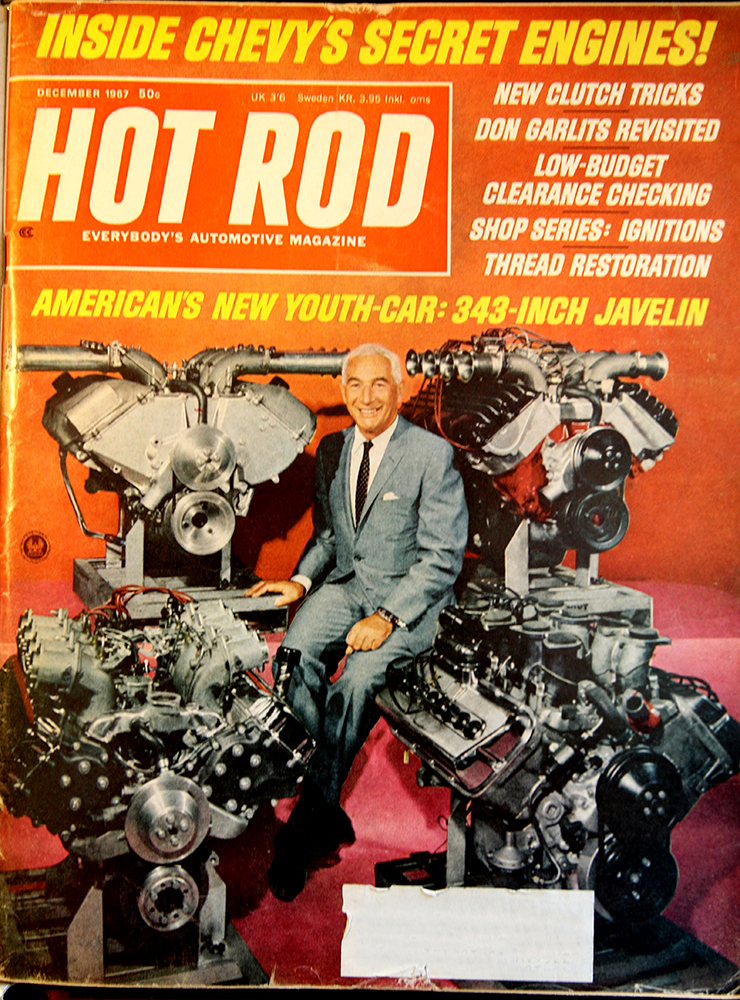

In the performance industry, there are very few products that can claim to have changed the lives of four generations of enthusiastic hot rodders. That’s the impact that the small-block Chevy has had on the automotive performance game. The term “pervasive” does not even begin to explain it all. Along the way, the small-block Chevy has been the powerful backbone of racing sanctioning bodies and made many engine builders and racers more than famous. The small-block’s impact on millions of street performance enthusiasts is immeasurable.

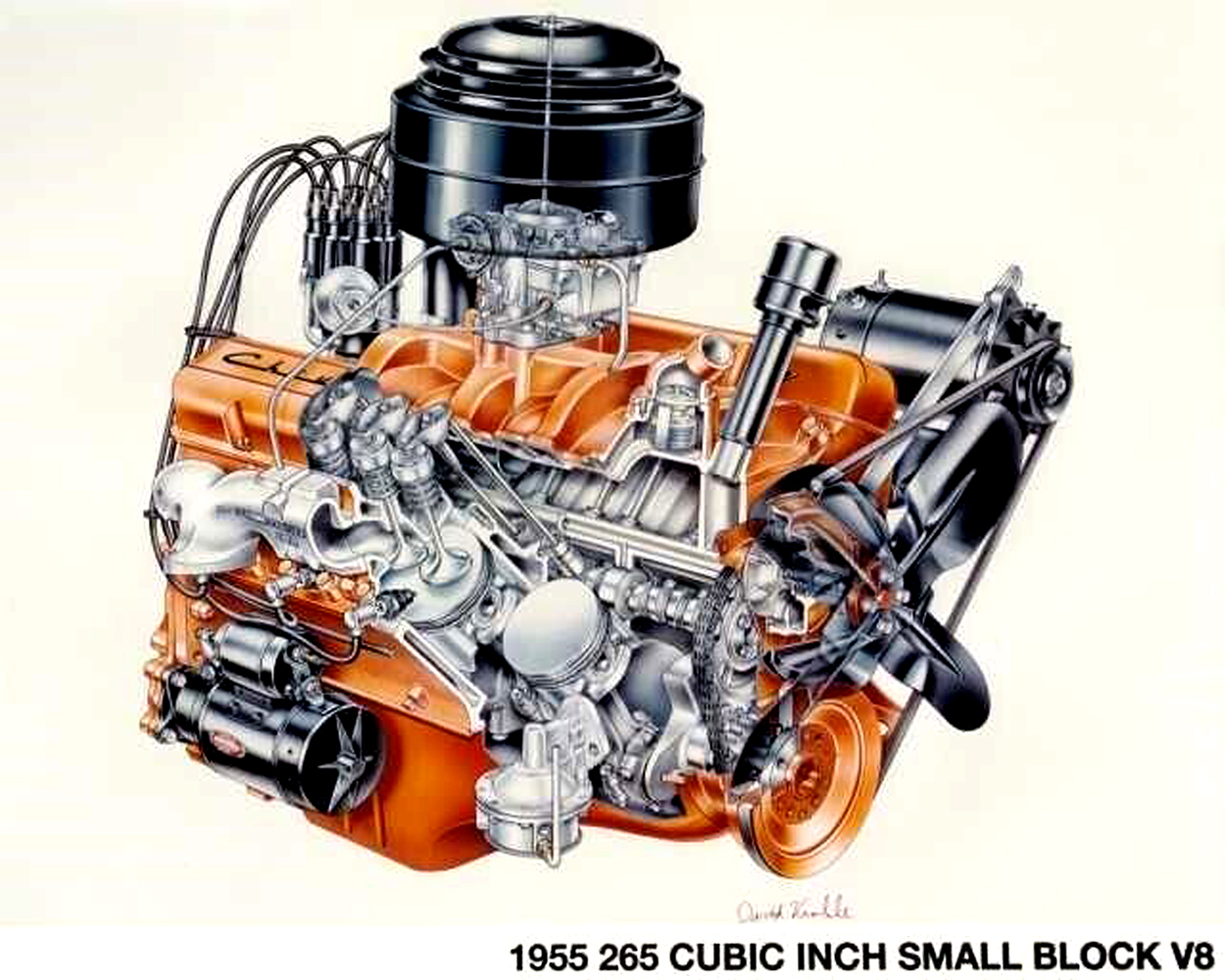

It all started in 1955 with the first year of the small-block Chevy bolted into both the Corvette as well as pedestrian 1955 Chevy sedans and coupes. Some say the small-block saved the Corvette, and likely this is true. The engine with the funny stamped rockers arms wasn’t immediately embraced, but neither did it take long for the automotive industry to recognize its true potential.

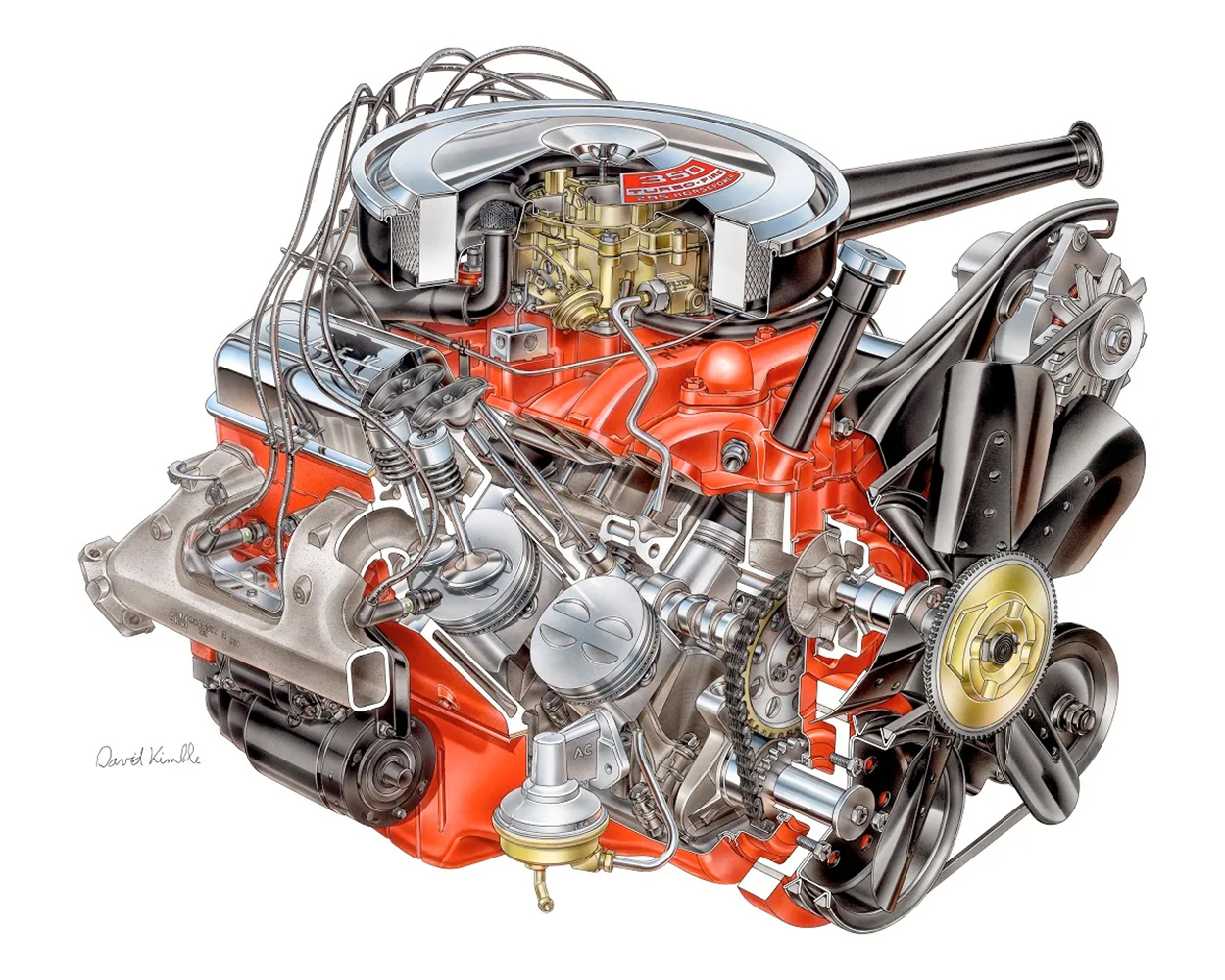

The first small-block was a small displacement V-8 of only 265 ci, designed with supervision by engineering director Ed Cole and with a compact, crossflow cylinder head design by Don McPherson. The first iteration featured a two-barrel carburetor and was rated at a modest 162 hp. However, it didn’t take long for those numbers to grow along with its displacement. By 1957 the little Chevy had expanded nearly 20 inches to 283 ci and would blossom to an aggressive 327 ci five years later in 1962. Eventually, of course, it would enlarge to its ubiquitous 350 ci in 1967. The largest of the production engine displacements hit its pinnacle in 1970 with the 400ci engine while still retaining the same bore spacing and deck height as the original 265.

At the time of its debut, the small-block was something of a radical departure from traditional engine design. Chevrolet would push the envelope further with a Rochester fuel injection system that debuted in 1957 sitting atop a 283 rated at an amazing 283 hp to become the first GM production engine to achieve 1 hp/ci. However, it was not the first domestic production engine to reach that achievement. That accolade goes to the 1956 FirePower V-8 hemi making 355 hp from 354 ci. That first generation hemi has now all but disappeared into obscurity while the little small-block Chevy was just getting started.

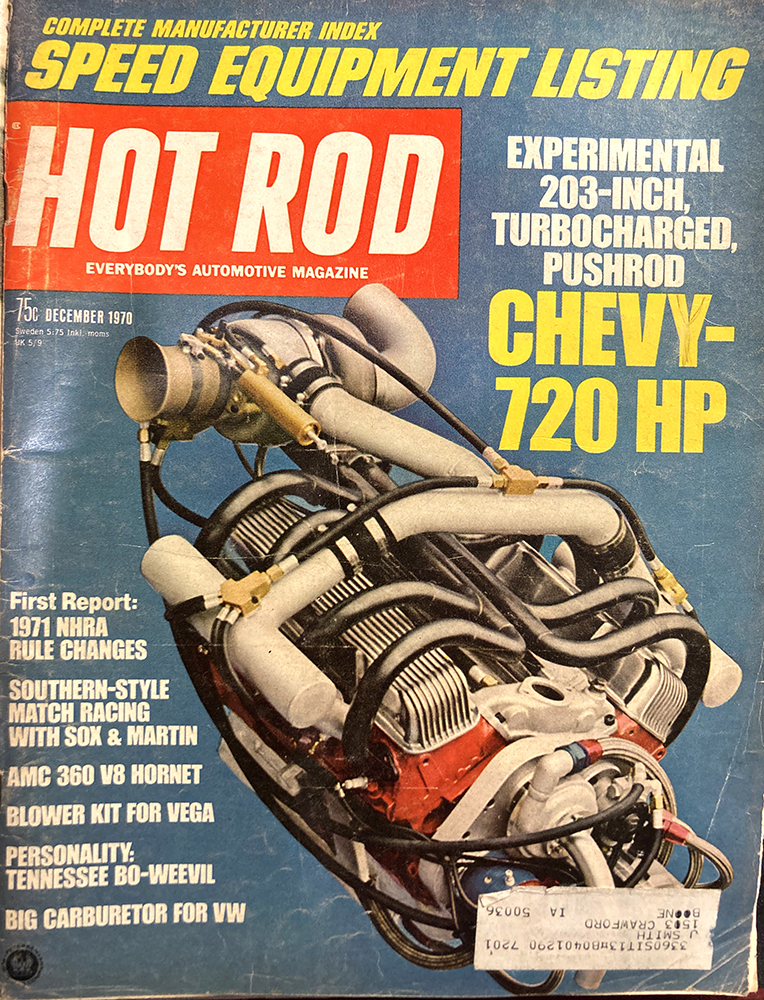

The 1970s would produce both the pinnacle of Gen I small-block horsepower and then just as quickly follow that with some of the worst horsepower ratings in its history. The 1970 LT1 would top the Gen I charts with 11:1 compression and 370 hp from 350 ci. That same year Chevy introduced its largest 400ci small-block with a huge 4.125-inch bore and stretched 3.75-inch stroke. This engine was never allowed to show is true potential and was mainly employed powering midsized pickups, the last of which appeared in 1980.

Emission laws soon squashed compression and that same powerful 350 found in Corvettes and Camaros in 1970 was by 1975 limping along with a pathetic L48 350 rated at a truly dismal 165 hp. But the future of the small-block would soon improve.

By the 1980s this little engine that could began multiplying with several smaller displacements as Chevy engineers experimented with mixing and matching bore and stroke. The famous 1967-1969 Z/28 302 was created to fit the 5.0L (305ci) displacement limit for SCCA Trans Am racing by mixing a 4-inch bore, 327 block with a 3-inch 283 stroke crankshaft. This was the first engine created by simply mixing existing parts. That idea spawned other variations of the small-block theme like the 307, which was the opposite approach created by combining the 283’s smaller 3.875-inch bore with the 327’s longer 3.25-inch stroke.

As emissions and fuel mileage and the dreaded Corporate Average Fuel Economy (CAFÉ) standards tightened, displacements shrank even more. The tiniest mouse motor evolved in 1976 as the 262ci with a 3.67-inch bore and a 3.10-inch stroke. Thankfully, it was short-lived.

These amendments in displacements occurred throughout the small-block’s lifespan while it retained its original mid-1950s design configuration until the mid 1980s when Chevy finally recognized that the two-piece rear main seal was problematic. For 1986, Chevy introduced the first major change in the small-block’s design with a one-piece rear main seal combined with hydraulic roller camshaft and lifters, which also demanded other minor alterations to the block with a stepped cam face and a cam limiter plate to prevent the camshaft from moving forward under high rpm.

Until this point, the production small-block had never varied from its cast-iron roots for both block and heads. Sure, Chevrolet engineering experimented with prototype aluminum heads and blocks as far back as the late 1950s, but these ventures were never pushed into production perhaps because the small-block was already relatively compact and light even when dressed in full cast iron.

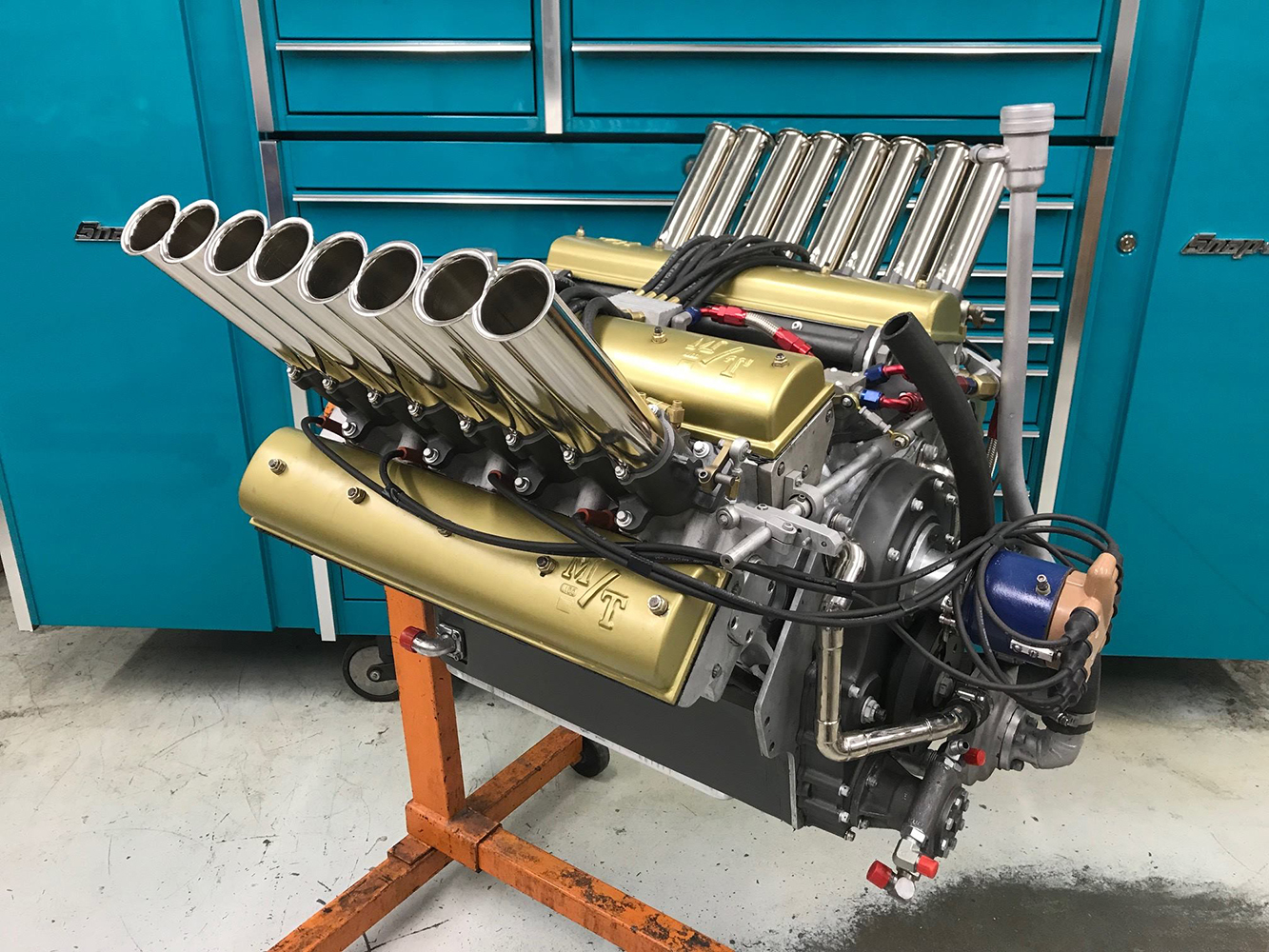

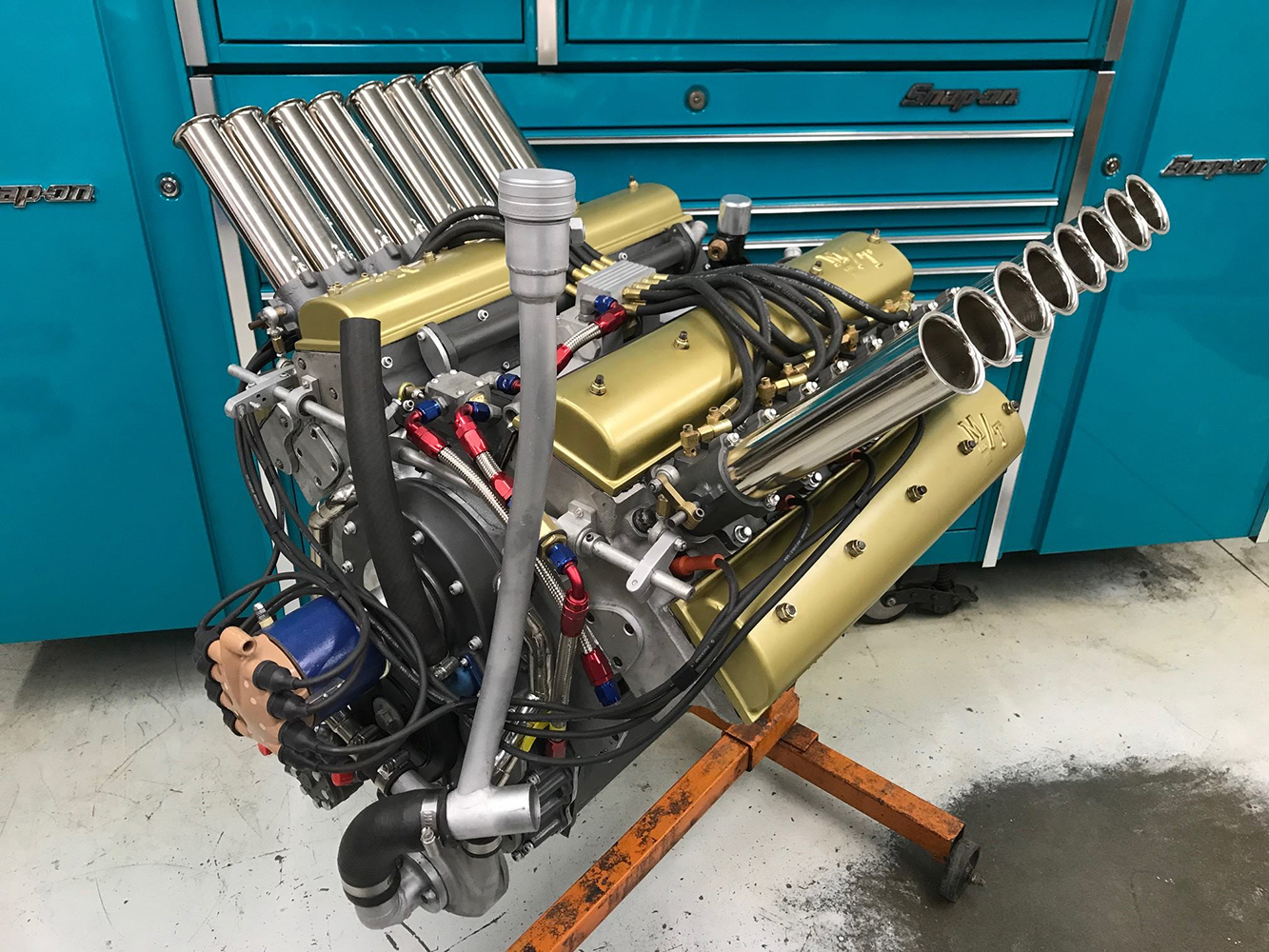

It’s worth noting that the Bill “Grumpy” Jenkins’ win at the inaugural NHRA Pro Stock drag race at the Winternationals in 1970 relied on ported iron castings for cylinder heads that were originally intended for pedestrian sedans. It would take until 1976 for that to change when Warren Brownfield poured the first aftermarket aluminum cylinder heads that eventually became what is now the current Air Flow Research (AFR) heads. Of course, now there are multiple sources, like Brodix, Edelbrock, Trick Flow Specialties (TFS), and many others, pouring aluminum alloy heads for the small-block.

It didn’t take long for companies like Donovan and Rodek to build aluminum blocks for the small-block for racing, and while Corvette chief engineer Zora Arkus-Duntov had several aluminum block engines built for competition, including engines for the Grand Sport Corvettes in the mid 1960s, Chevrolet never saw the need to build an all-aluminum production block. The ZL1 all-aluminum big-block Chevy made more sense from a weight savings standpoint since the small-block would have only trimmed roughly 100 pounds from its iron version.

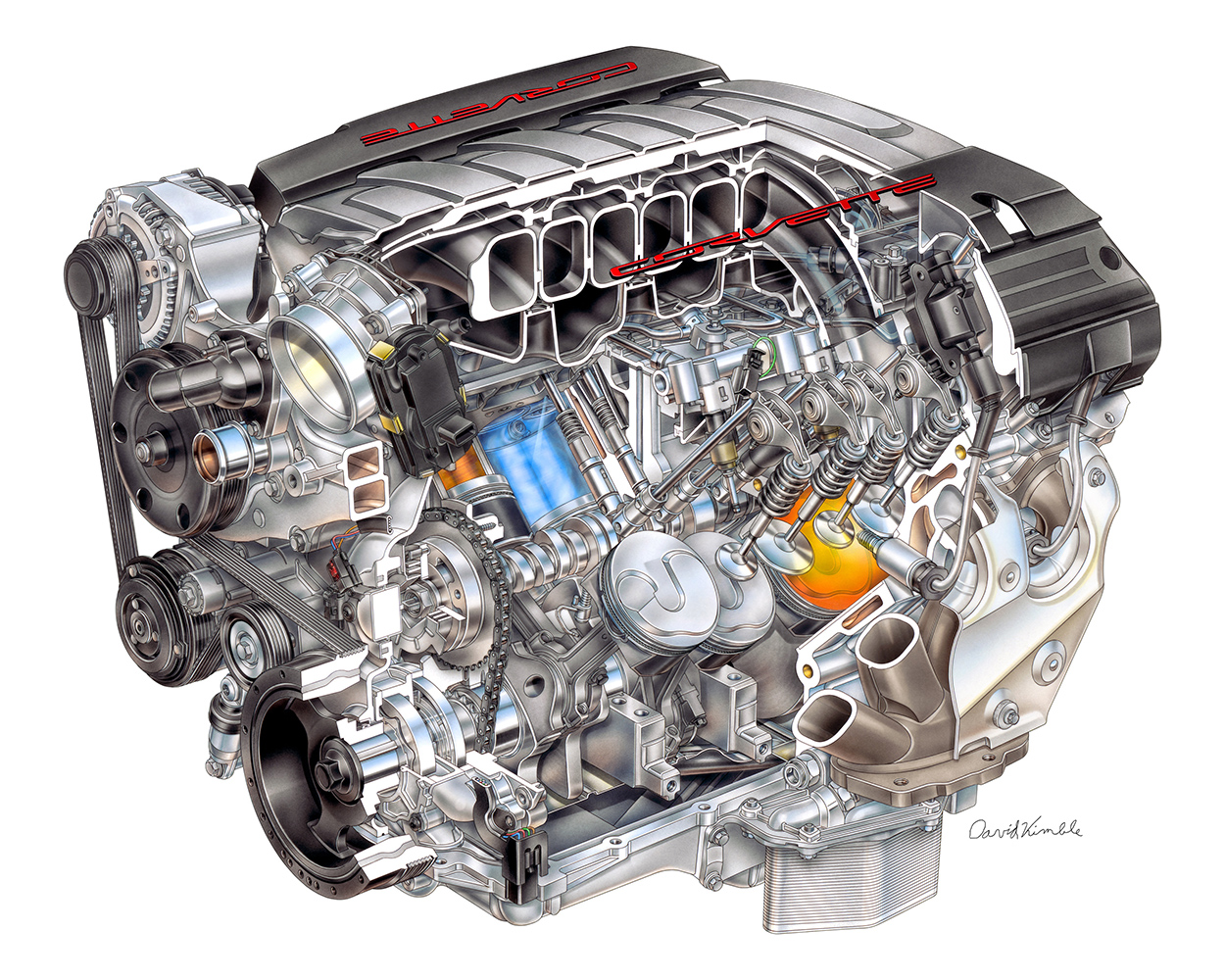

Returning to the small-block’s production history, more evolutionary changes occurred in 1992 with the introduction of what is now called the second generation (Gen II) small-block. Dubbed the LT1, the engine first appeared in the Corvette that year with a completely new appearance.

The Gen II engine is easy to identify because the rear-mounted distributor was relocated to the front of the engine and driven off the camshaft. The ignition, referred to as the Opti-Spark, eliminated both the backlash between the camshaft and distributor gears but also offered more accurate ignition timing at higher engine speeds by eliminating the inherent problem of camshaft twist—especially when the engine was fitted with stiffer valvesprings.

Another major change involved rerouting the cooling system. The LT1 introduced a reverse cooling system that pushed coolant first around the combustion chambers in the cylinder heads where the majority of the heat is generated. Then the coolant was directed downward through the block past the cylinders and returned to the radiator. The water pump was also driven off the front of the camshaft, which eliminated the cumbersome belt drive system.

The LT1 also used a very short runner intake manifold that was in many ways the opposite of its Tuned Port Injection (TPI) predecessor. The TPI featured very long intake runner tubes intended to improve torque while the LT1 offered a manifold with very short runners. The shorter runners offered intake tuning that enhanced peak horsepower but delivered this at the cost of low-speed torque.

The LT1 was quickly followed with the LT4 pushing the LT1’s 300 hp up to 330 peak horsepower. These numbers might now seem a bit tame (especially when compared to today’s 1,000hp production engines) but we must remember that back in the 1960s, Chevrolet and all the other manufacturers tested their engines using what is now called the standard or gross horsepower testing using an aggressive correction factor using 60 degrees F inlet air temperature, 0 percent humidity, and an atmospheric pressure standard of 29.234 inches of mercury (Hg). This rating system changed in 1971 to the J1349 standard of net horsepower ratings, which lowered the output with its more conservative correction factor. This further reduced the advertised horsepower numbers because part of the net power factor demands the engine run with all accessories, including its OE exhaust.

As mentioned, the Gen II small-block was short-lived and quickly dated by what became known as the Gen III or LS series of small-blocks. We won’t dive into the details on this engine but, interestingly, Chevrolet engineers did Chevy enthusiasts a huge favor by maintaining five of the original six bellhousing bolt pattern locations, making it much easier for Bowtie enthusiasts to jump quickly into the Gen III/IV pool. Other items retained by the Gen III small-block include the original small-block’s 4.400-inch bore spacing and the 0.842-inch lifter diameter.

But those minor details were where the new Gen III diverged with an all-new design. The biggest improvement was in valve angle where the old small-block was limited by its 23-degree angle, the LS pushed that over to a much more aggressive 15-degree angle and enhancing combustion efficiency with symmetrical intake and exhaust ports.

So, does the ascendency of the Gen III/IV/V dictate that the original small-block Chevy is dead? That could not be further from the truth. The reality is that while the LS officially replaced it in 1998, the original “Mouse motor” continues to make its presence known as the once and still king of not only race sanctioning bodies but street enthusiasts all over the world. It’s safe to say that the small-block will still be setting records at Bonneville, NHRA competition, and certainly making its mark on the street for decades to come.

| Small-Block Displacements | |||||

| Displ. | Year | Bore | Stroke | Main Jrnl. | Main Bolts |

| 262 | 1975 – ’76 | 3.671 | 3.10 | 2.45 | 2-bolt |

| 265 | 1955 | 3.75 | 3.00 | 2.30 | 2-bolt |

| 265 | 1994 | 3.736 | 3.00 | 2.45 | 2-bolt |

| 267 | 1979 – ’81 | 3.50 | 3.48 | 2.45 | 2-bolt |

| 283 | 1957 – ’67 | 3.875 | 3.00 | 2.30 | 2-bolt |

| 302 | 1967 – ’68 | 4.00 | 3.00 | 2.30 | 2-bolt |

| 302 | 1969 | 4.00 | 3.00 | 2.45 | 4-bolt |

| 305 | 1986 – ’97 | 3.736 | 3.48 | 2.45 | 2-bolt |

| 307 | 1968 – ’73 | 3.875 | 3.25 | 2.45 | 2-bolt |

| 327 | 1962 – ’67 | 4.00 | 3.25 | 2.30 | 2-bolt |

| 350 | 1967 – ’97 | 4.00 | 3.48 | 2.45 | 2- / 4-bolt |

| 400 | 1970 – ’80 | 4.125 | 3.75 | 2.65 | 2- / 4-bolt |

Just for fun, we theoretically created a small-block fusion of sorts by combining the smallest production bore (3.50 inches) block with the shortest OE stroke crank (3.00 inches), which equal 231 ci—not that anyone would want to do that.

Top 10 Strongest Production Small-Blocks

With regard to factory horsepower ratings, keep in mind that all the engines in this list are rated using the traditional SAE J1995 gross horsepower rating system. This correction factory uses healthy standards for air temp and pressure and combined with the fact that the engines were not fitted with an accessory drive or mufflers. A pure stock 1964 375hp fuelie 327 today would be challenged to achieve its rated horsepower if it were fitted with stock iron exhaust manifolds and driving a water pump.

375hp 327 1964, L84 Rochester Fuel Injection

370hp 350 1970, LT1, Holley 4bbl.

365hp 327 1964, L76, Holley 4bbl. (first Holley four-barrel used on a small-block)

360hp 327 1962, Rochester fuel Injection

350hp 327 1965-’67, Holley 4 bbl.

340hp 327 1962, Carter AFB

325hp 327 1967, Holley 4bbl.

300hp 327 1964, L-76, Carter AFB

295hp 350 1967, L-48, Quadrajet

290hp 302 1967, Z/28, Holley

Check out this story in our digital edition here.