When it comes to engine stories in the typical car mags, it’s almost always about the big four: heads, camshaft, intake, and exhaust, which is understandable because those are the easiest and most effective ways (except maybe for bolting on a turbo) for improving the horsepower on an existing engine.

But this time we’re going to throw you a curve. After all, when’s the last time you’ve seen a legitimate harmonic damper test? And we promise you, the results are pretty interesting. In fact, we made power by going heavy.

Dampers are normally considered a component that’s necessary for an engine’s health and longevity. And that’s true. A harmonic damper is critical for absorbing damaging harmonic vibrations that travel up and down the crankshaft every time the air/fuel mixture is ignited in one of the combustion chambers. Every time a cylinder fires some of that energy produced actually causes the crankshaft to twist or flex. Even if it is a minute amount, those torsional forces can destroy bearings or even eventually break a crankshaft.

A damper is designed to absorb those damaging harmonics and protect the engine from eating itself. Most work by inserting a semi-flexible rubber ring between the hub and a weighted outer shell. This allows the weighted shell to move a little bit relative to the hub and serves to dampen those vibrations. There are other designs. For example, Fluidampr uses a thick fluid instead of a rubber ring (or rings) but the concept is still the same.

Also, it is important to note that we aren’t saying “harmonic balancer” here. A lot of people will use “balancer” and “damper” interchangeably, but that’s really not the case. A balancer has an offset weight—either integral to the damper or bolted on—that is used to balance the rotating assembly. This is called an “externally balanced” engine. This was common in older stock engines where it was easier and cheaper for the OEMs to use weights on the damper and flywheel or flexplate to balance the engine.

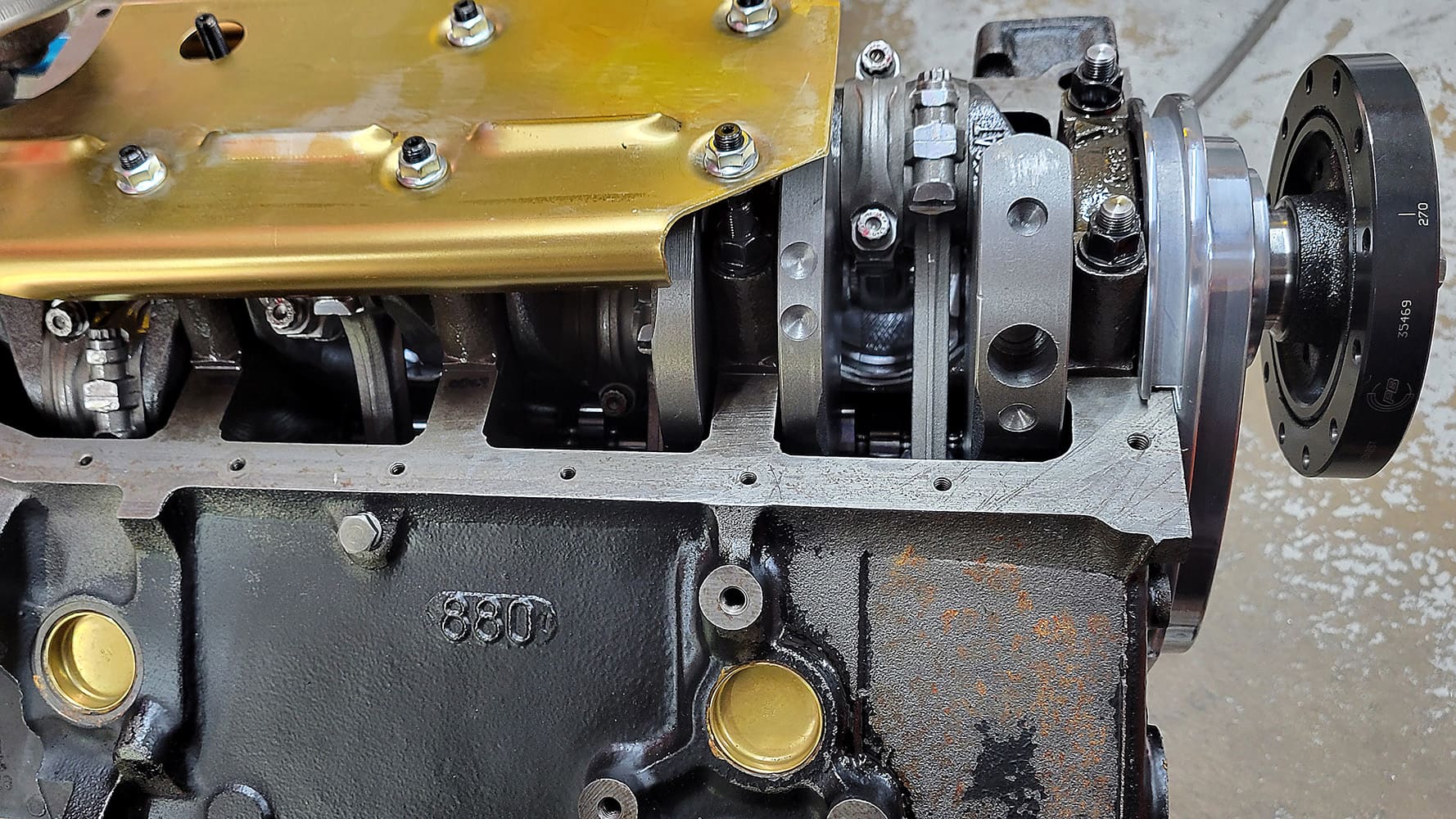

But custom performance engines these days are almost always built internally balanced whenever possible. The more horsepower you make, the more important it is to have your engine be internally balanced. That’s because externally balanced engines put the balance weights way out on the ends of the engine beyond the crankshaft. This can allow the crankshaft to flex at higher rpm. Internally balanced engines either add or remove weight from the crank’s counterweights, so the balance work is exactly where it is needed and does a better job of reducing crankshaft bending loads. Overall, this is easier on both the crank and the bearings.

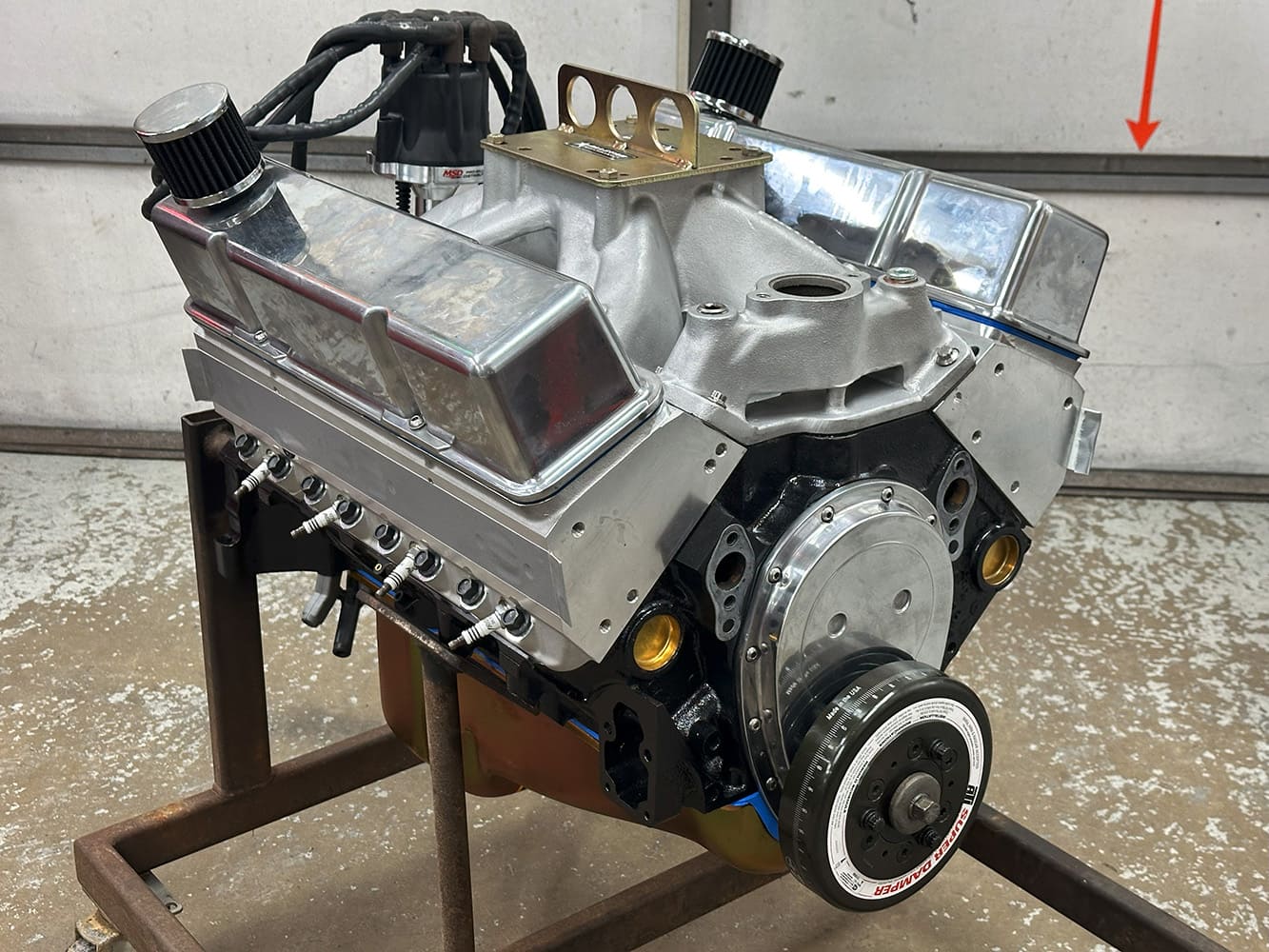

Anyhow, we’re here for the testing, so let’s get to it. The engine is a fairly basic 383ci small-block. The builder is Newcomer Racing, and the engine is for owner Keith Newcomer’s personal use. That’s why he was comfortable using it for testing. By the way, if you aren’t familiar with that name, it’s likely because Newcomer Racing specializes in AMC/Jeep straight-six engines; among the Jeeping community he is pretty famous. But they also do some of everything else, including Chevys.

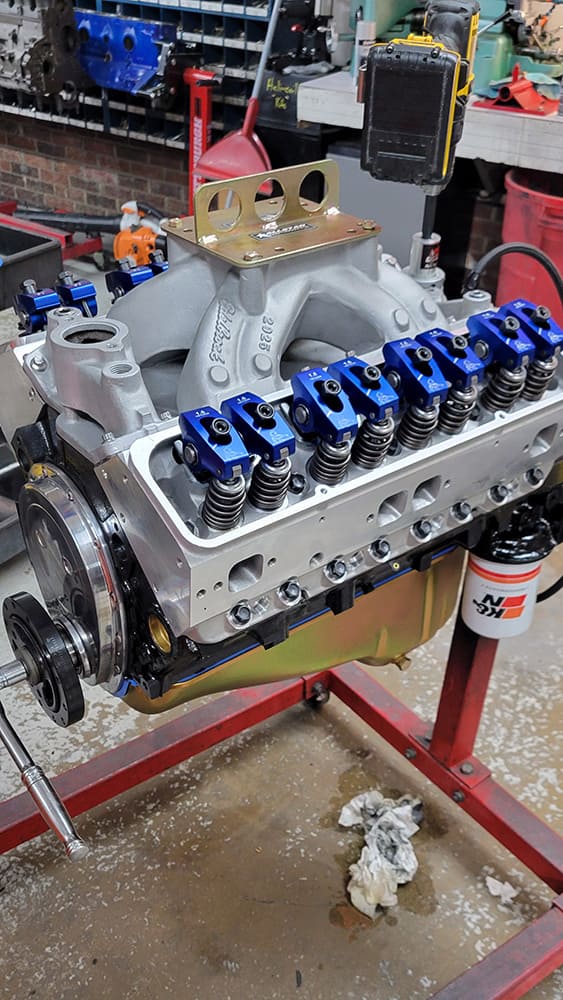

This particular build is an attempt to really maximize the horsepower per dollar spent ratio for a naturally aspirated setup. Newcomer started with a garden variety, OEM Vortec block. It came from the factory with two-bolt mains, but it has been upgraded from main bolts to studs with a kit from Milodon. (We’re also using a Milodon oil pan.)

After completing the machinework on the block, Newcomer stuffed in a cast Scat crankshaft and a set of 5.7-inch I-beam Scat connecting rods. Finishing up the rotating assembly are a set of Keith Black hypereutectic pistons. They do have two valve pockets instead of the stock-style four eyebrows to help keep the compression ratio up around 10.5:1. The piston rings are a lightweight set to help reduce drag at just 1.5 mm for the first and second rings and 3.1 for the third. Since we discussed it earlier, it is important to note that the rotating assembly has been professionally balanced, so there are no external balance weights.

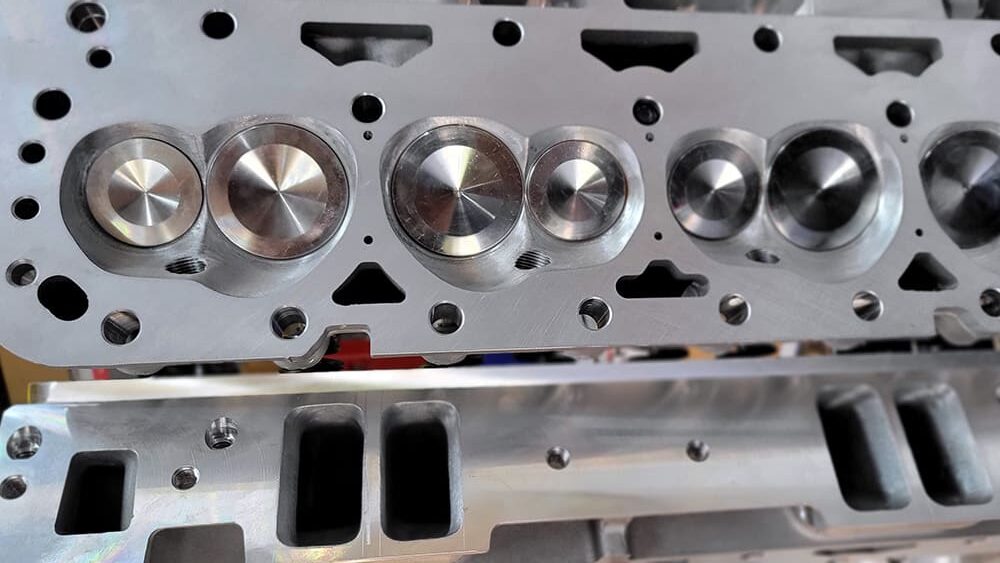

The cylinder heads started out as a pretty vanilla set of 23-degree aluminum castings from Liberty Performance with 200cc intake ports, but Newcomer has hand-ported the intakes and exhausts for pretty significant flow. The valves are sized at 2.055 inches for the intakes and 1.600 for the exhaust.

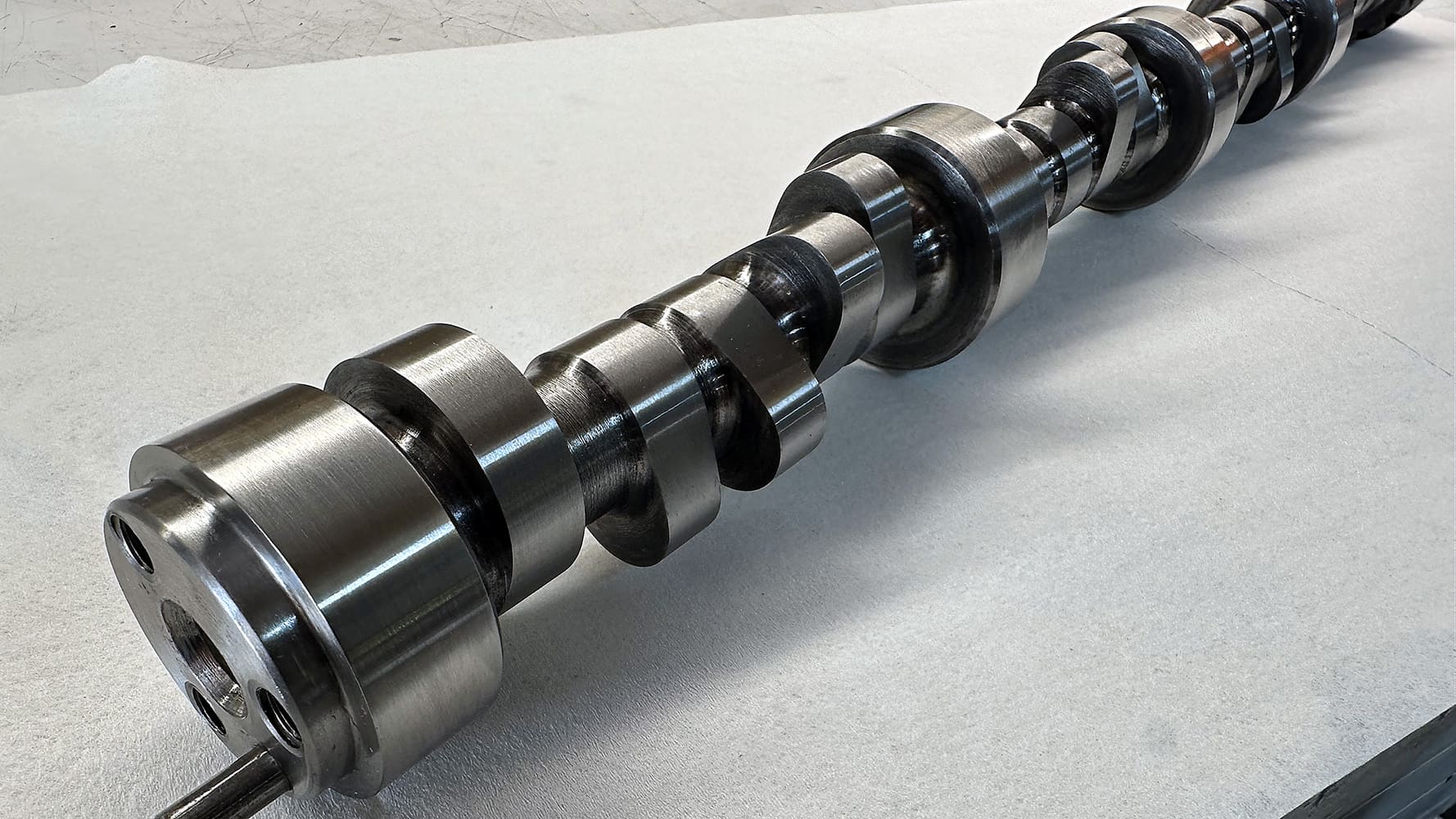

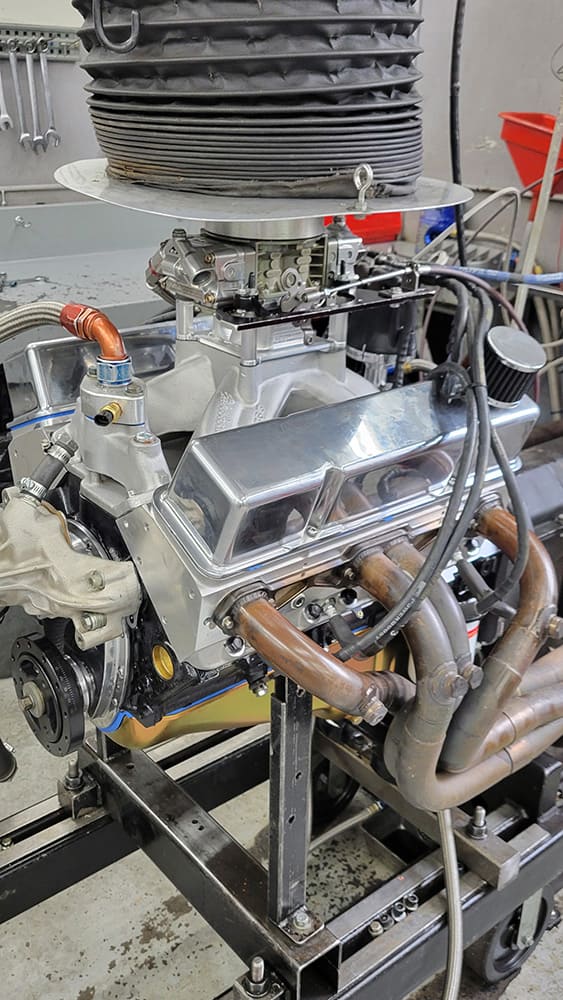

Controlling the valves is a hydraulic roller camshaft with 230 degrees of duration for the intakes at 0.050 inch of tappet lift. With the 1.6:1 ratio Scorpion aluminum rockers, gross valve lift will be 0.585 inches. Finally, all the air is fed through an 830-cfm Holley double-pumper carb and a single-plane Edelbrock Victor intake manifold.

Now that we’ve got all that out of the way, let’s talk dampers. This whole story started out because of a mistake. When ordering parts for this build, Newcomer received a PowerBond PB1012ST damper. That’s a lightweight, 6.080-inch-diameter nodular iron damper that’s designed for street engines. This unit is a low-cost damper, but we’ve found that because of its small size and light weight, it is often chosen by racers in horsepower-limited classes and street engine builders thinking that they can gain quicker acceleration by reducing the amount of weight that the crankshaft has to spin up as the engine gains rpm.

The damper Newcomer had actually ordered was a larger unit, but he decided to test the smaller damper even though he had doubts it would be able to handle the power of this combo properly. So, he installed it on the snout of the crank during the assembly process and ran it on the dyno.

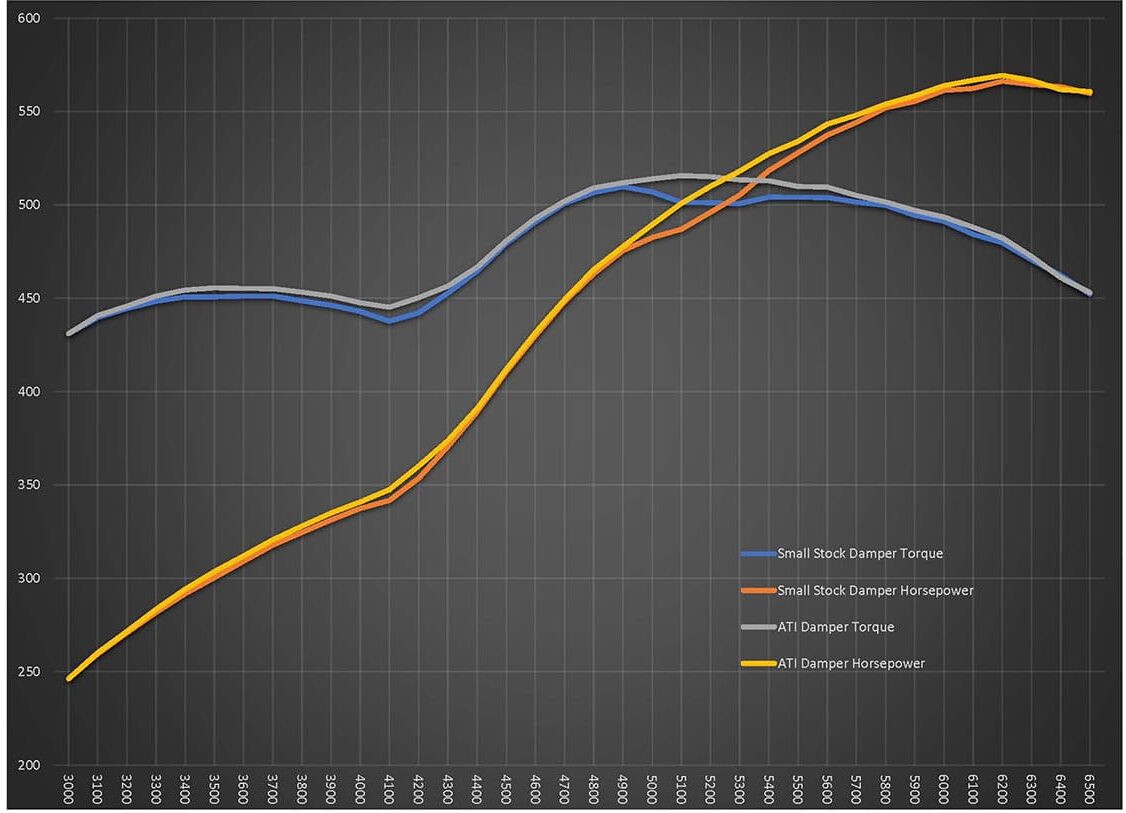

And the results were pretty good—if you only looked at the peak numbers. We saw maximums of 509.7 lb-ft of torque at 4,900 rpm and 566.3 hp at 6,200 rpm. Not bad, but if you look at the entire graph there are two noticeable dips in the graph. There’s one in the lower-rpm band, from approximately 3,900 to 4,200 rpm, and a second around 4,900 to 5,800 rpm.

The lower rpm dip is likely a valvespring harmonic issue and isn’t much of a concern because it is low in the rpm range and not where we are making big power anyway. It is the upper-rpm dip that has our attention. Not only is it right where we want to be making power, but it also is pretty concerning in terms of engine health.

“You could feel it when the engine hit that spot from sitting at the dyno controls,” Newcomer explains. “It was almost like it stalls out, but it got out of balance so hard it shook the ground and you could feel it through the wall in the control room.”

The engine did it in basically the same spot in the rpm range on multiple pulls. Newcomer suspected it was the damper right away and not the valvesprings going into harmonics and losing valve control. “You can tell the difference,” he says, “because when it is the valvespring, the intake hangs open too long, and if you are paying attention you can hear the sound coming out of the carburetor. With the damper it’s just the whole engine getting out of control and the vibrations are so strong they will go right through the concrete floor.”

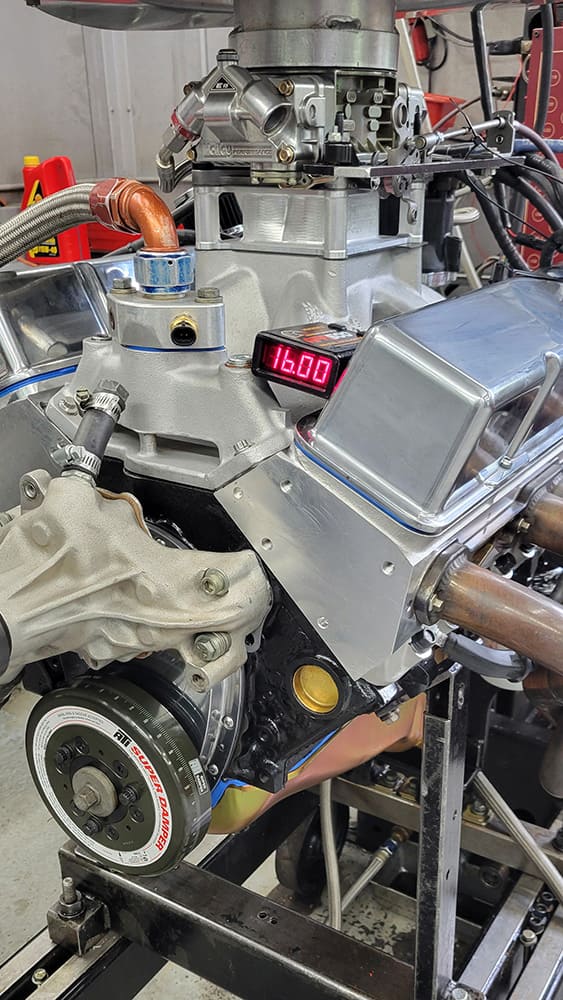

So, Newcomer pulled the small damper and sourced a new, high-quality damper from ATI. ATI is so dominant in racing—and we’re talking drag racing, oval track, and even sports cars—it is almost impossible to find another brand on any car in the pits. ATI units are all SFI certified and instead of just using a chunk of rubber to bond the outer shell to the hub, these units have machined grooves to precisely place different sets of O-rings. The O-rings can be changed out for a different number of rings or either harder or softer rubber to tune the damper for the engine. For this engine Newcomer went with an ATI Super Damper (PN 917780).

The difference on the engine dyno was immediately noticeable. The engine pulled strong all the way through without the stalling behavior in the upper-rpm range. Peak power improved to 515.7 lb-ft of torque at 5,100 rpm and 569.4 hp at 6,200. But more important, the 383 Chevy picked up more than 10 hp from 5,100 rpm all the way through 5,500, with a peak of 13.9 hp more at 5,200.

More important to just about every one of us, the engine was much happier with the ATI damper and no longer went out of balance so badly it shook the ground. Unless you are a tech mogul or an oil baron, buying a new engine is an expensive pill to swallow, so anything we can do to keep our performance engines alive longer is a good investment.

Speaking of investments, the ATI damper is definitely a good one compared to other dampers on the market. As this went to press the Super Damper has a street price of right at $370, while the 6-inch stock replacement can be had for $150. But considering everything else that goes into an engine and the potential cost of a rebuild and replacing a ruined crankshaft, that’s likely money well spent.

After all, how often can you make a single component swap and gain both power and longevity?

Check out this story in our digital edition here.