This C10 right here, Jeremy Rice’s 1970 Chevy Fleetside, is far beyond your typical patina truck. Far. Beyond.

What is typical of the Chevy, however, is the build quality level you’d expect from Jeremy’s shop, Tre5 Customs. So what separates this from any other previous Tre5 build? This truck is the quintessential “platform” for Scott Nelson’s solo venture, REVB Chassis … it’s the very first chassis to roll out of his shop since opening a couple years back, and one that debuted at the 2023 SEMA Show under Jeremy’s turbocharged truck.

To give each a proper podium in which to explain their respective perspectives, I gave Jeremy and Scott the opportunity to contribute a few words here … they obviously went above and beyond the assignment … in a good way!

Tre5 Jeremy Rice

“I bought the truck when Scott Nelson (now of REVB Chassis) was thinking of going out on his own. Derik (Thomas, of DRT Fabrication) actually sent me the Facebook Marketplace ad from somewhere up in Northern New Mexico. I reached out to the seller and had a phone conversation with him. He told me it was his dad’s farm truck that he no longer needed at the farm. It was running and driving, but not good enough to make the eight-hour drive to my house. We struck up a deal on the purchase price, and I called in a favor to have my transport guy go and grab the truck. It sat around at my house for a bit while Scott got REVB Chassis going. Once the design of the new chassis was getting close, I started on the teardown of the truck. [Thomas] offered up the assistance of shortening the bedsides while we waited, so those came off first. Then I brought the truck down to the shop where me and the rest of the guys tore it down to the cab. In-between all the other work going on at the shop, we started chipping away at some custom touches. The firewall was rebuilt with some panels that we put a simple perimeter beadroll into, we tossed the stock door latches in favor of a set of Trique latches, and the surprisingly small amount of rust was repaired in the rear corners. This truck still has the stock rockers intact! Also, while I was waiting on the chassis, I started building up the drivetrain. I wanted this truck to grab some serious attention for us and REVB! I figured a good way to do that was to run a single turbo up through the hood. I’ve seen it more and more these days and even guys with supercars are doing it, so I gave it a whirl. Summit Racing had recently come out with some cool parts to make this job a bit easier, mainly their cast stainless, divided log, single turbo, and passenger-side exhaust manifold. There’s a whole host of Summit parts on this thing, but that manifold and turbo really stand out for me. Although I never had it on an engine dyno, we estimate it to be around 700 hp, at the 15 pounds of boost it sees around 6,000 rpm.

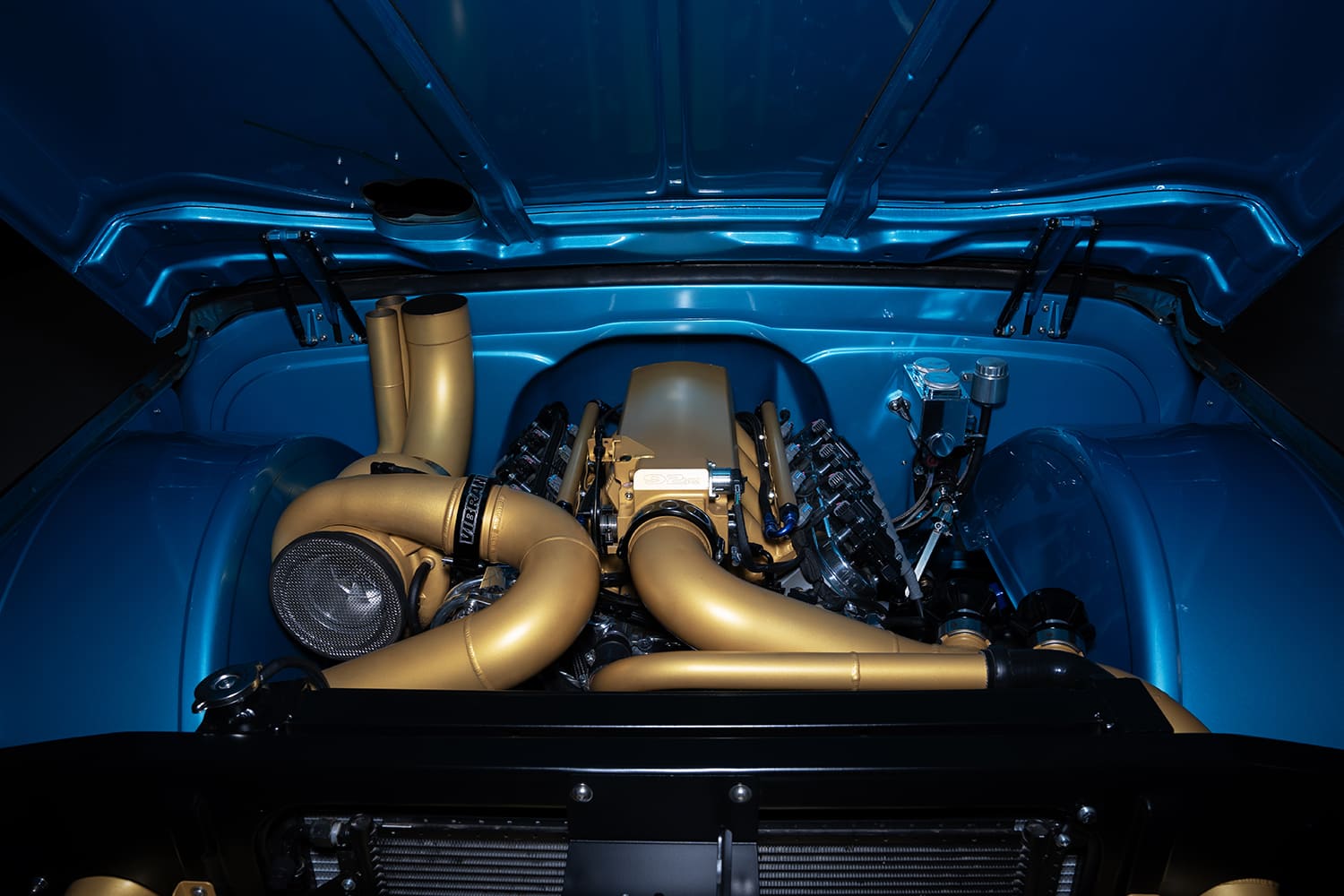

“Once the chassis arrived, we really got into the build. The drivetrain bolted in perfectly and then the cab was lined up to make sure the drivetrain, chassis, and cab mounts were all in the right location in real life … not just on the computer. Once everything was positioned on the chassis, we got to work installing the Hart Fab inner fenders and plumbing the rest of the turbo setup around the engine bay. Originally, I was going to build the truck without A/C in it, but Mike at Restomod Air told me I was an idiot for that stupid idea and basically forced me to put one of his units in the truck. So the A/C condenser and lines were built around the Summit radiator and routed as simply as possible, with all the extra clearance issues from the big turbo underhood. After the engine bay was completed, we moved out back to the bed. The shortened bedsides were set in place over the chassis, and then we built all-new framework for the bed. Since this is the first chassis for REVB and the goal was to show it off. We built a simple sheetmetal bed with custom bead rolled sides and floor panels and a hatch that lifts up to show off the chassis. We always seem to have some extra parts laying around, and one of those parts was a set of hydraulic struts that are designed to stay extended. We came up with a way to hinge the bed floor while using those struts to hold the bed floor open. We then installed some cool looking latches I grabbed off of Amazon to hold it closed. It is totally different from how we normally build our bed floors and it worked out great!

“Once all the fabrication was completed, we tore the truck down for powdercoat and paint. The cab and inner fenders went over to Ikandy Paintworks (next door) and the chassis and parts headed off to Pac Coast Powder in California. I got the factory paint color off the glovebox sticker for Frank to paint the dash, firewall, and inner fenders. He then used the same code to add color to the tintable Sweet Patina N1 bedliner coating. I wanted the bedliner in the bed because I planned to be able to throw a bike or chairs in there and not have to worry about damaging paint or wood. The chassis was done in two colors, a textured brown to play off the surface rust color of the truck and a bright blue to accent the truck. All of the engine parts were done in Glacier Gold Cerakote by Pac Coast Powder Coating as well.

“Once all the parts were back we reassembled everything and started wiring. We installed the Modern Vintage stand-alone engine/transmission harness and mated it to the Painless Performance chassis harness and Dakota Digital gauges. Then Kyle from J&R Performance came over to throw an initial tune in and get it running good enough to go to Steve at Elevated Design for the interior. Before it headed his way we installed, with the assistance of State 48 Glass Company, all-new glass and weather seals from Precision Replacement Products.

“About this time, Mike at Restomod Air called and asked if we had anything that would be ready to go to the SEMA show for his booth. I reminded him about my personal truck and how he gave me shit for not wanting to put A/C in it. He responded with ‘Perfect, can you bring that truck for our booth?’ So now, along with two other trucks we already had scheduled to go, the push was on to finish the truck for its SEMA debut.

“Steve got right to work on the interior. First to go in was the Membrane sound deadening from Restomod Air. Then the full Morel stereo system needed all the wiring ran to the appropriate locations. TMI Products makes nearly everything for the C10 trucks, which helped speed up the job a ton. Steve did end up modifying some of the TMI interior panels. The dashpad received the addition of two speaker pods to the top, which also conceals the defrost vents. The bottom of the TMI door panels were also modified for another set of speakers. Since the floor needed some additional clearance for the American Powertrain T56 Magnum (manual six-speed) transmission, I opted to have Steve build a custom carpet kit. Once the carpet was in, the TMI seats and buddy console was installed. Rounding out the interior is a custom trim/console for the manual shifter, TMI headrests, and a custom-built headliner insert wrapped in matching material from TMI Products.

“Right before SEMA, we sent the truck over to J&R Performance to get a good street tune on it. Then it went straight to the Restomod Air booth at the SEMA show for a week. Immediately following that, we had it on display at Dino’s Git-Down. It has now been to several shows throughout the country and has brought a good amount of attention to REVB Chassis Company, which is what it was built to do!”

REVB Chassis Scott Nelson

“Some people hear ‘Materialistic’ and think designer fashion and fancy or flashy things, but Jeremy Rice, owner of Tre5 Customs in Peoria, Arizona, isn’t just about Rolexes and Italian coast vacations. If he gets the aux … it’s Madonna. So, it was only fitting to call his latest build ‘Material Girl’

“Foundation: Material Girl rides on the very first REVB Chassis; call it a prototype even. Jeremy had significant input in the key features of this chassis. From the boxed upper and lower control arms, integrated height sensor locations and mounts, and triangulated four-link. With a bag on a trailing arm design, allowing for over 11 inches of lift in the rear and smooth ride with lower air pressure for a safe ride height, he is able to remove his large-diameter rear wheel and tire without taking off the bed or dropping the axle. Rolling on 22- and 24-inch Intro wheels with REVB’s custom brakes by Baer poking through the spokes, and ride height controlled by AccuAir eLevel.

“Fitted between the powdercoated by Pac Coast REVB framerails is a Summit Racing 5.3L LS with a killer turbo setup built by Tre5. All Cerakoted gold to really pop against the bright blue paintwork from Ikandy. A hood exit exhaust was only fitting to help with the rowdiness of this ride. A manual six-speed transmission keeps things fun in the cab, which is fully furnished in diamond-stitched TMI bucket seats and console. Restomod air and dark tinted glass keep it cool.

“With all of the talent and great companies involved in this build, Jeremy and his team were able to start this whole process in late July and make it to the SEMA show in November of the same year. Just over 90 days from a marketplace hoopty to a full-blown, turbocharged, body-dropped, bitchin’ and badass show truck, Material Girl is looking good while we are living in a material world.”

Check out this story in our digital edition here.