By Kenneth “Stressball” DeKissere – Images by Camren Beattie

Last month, we took a break from Kenneth DeKissere’s amazing work on the 1951 Chevy at Scott’s Hotrods to give him a chance to spread his wings a bit—application-wise, that is—and show off his skills on the hood of an OBS with last month’s part one of Oh Be Still My (Metalworking) Heart. Kenneth exercised his talents and his imagination by creating the most intricate yet flowing inner fenders and front radiator valance we’ve seen. This month, the magic continues in the bed!

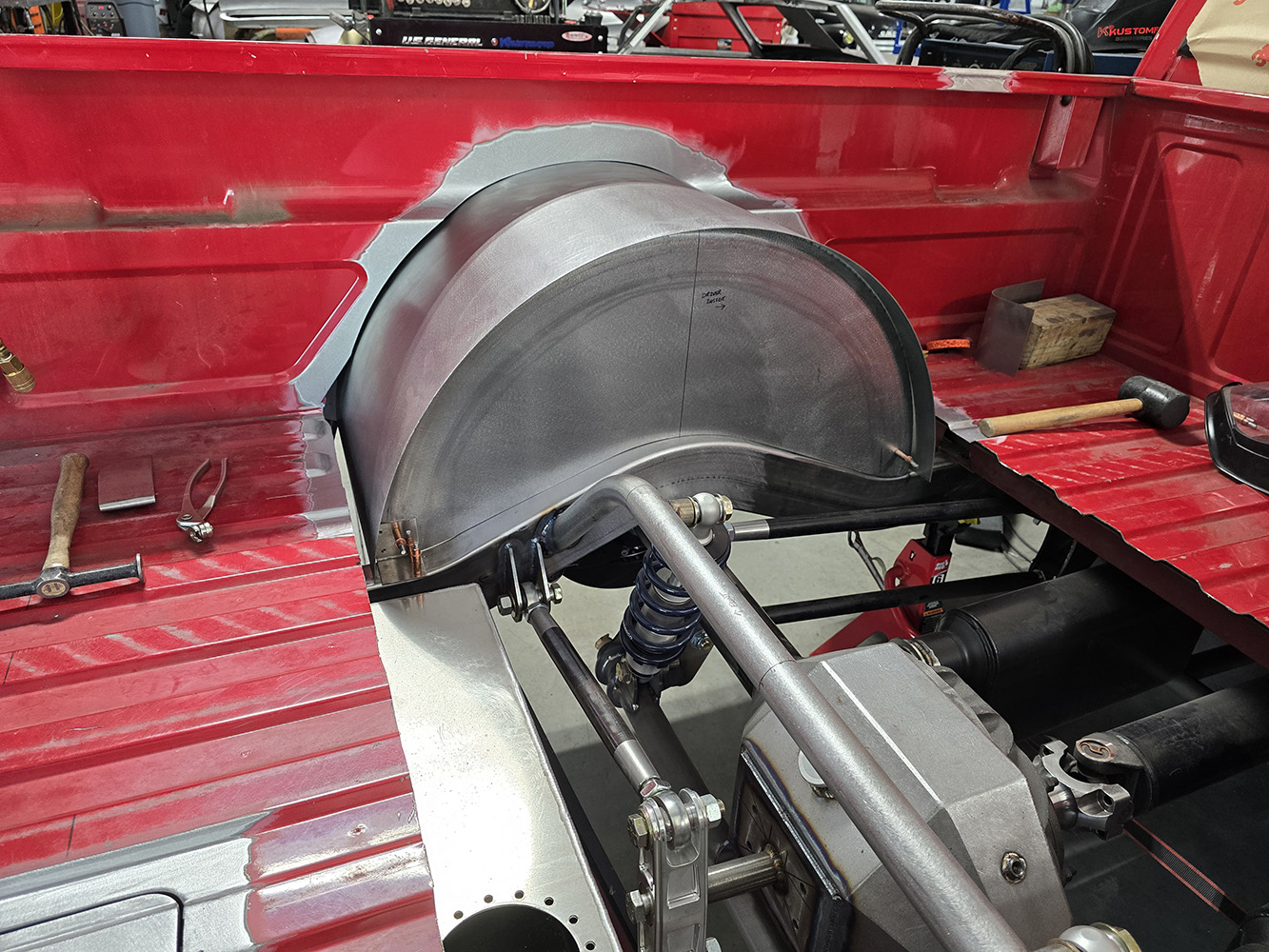

Picking up where I left off, in the rear, the stock wheeltubs were cut out so we could lower the truck more. The original intention was to reuse those tubs and modify them to fit again, but I felt like it was a better idea to do a set of simple round tubs with the same tank roll radius that matches the engine bay panels. Making these tubs would be easier and quicker in the long run and provide a much nicer look. After the tubs were done, we had some factory bed floor replacement panels that I attempted to slip roll, but the factory ribs were too deep to fit in our tooling, so we quickly decided to cut the rest of the stock floor out and make a new one from scratch. Having had to do a bed floor just like this for the 1950 Chevy pickup, I knew how difficult this was going to be. Initially, we planned on doing a smooth floor, but Brian felt it was too plain and wanted to do some sort of design in it, so I came up with something that was simple enough to still manage through the slip roll but unique enough to stand out and act as a focal point for the bed.

Around this time, just before starting to slip roll the bed floor, I managed to talk Brian into building an inner bed skin to clean up the look of the inside of the bed overall. This project kind of snowballed, as is the case with just about anything I’m told to work on! It took some work getting both halves of the bed slip rolled with the huge aluminum “squish plates” sandwiching the steel sheet with Pullmax beads. Took a while to get both sides massaged and back into a usable state before welding them together to make one large panel. Once the bed floor was prepped and cleco’d in place, I trimmed the inner bed skins to fit in the bed again after putting the floor in. At this point, Brian again also felt that the bed skins were too plain and needed something to break the large panels up.

While most wouldn’t hesitate to add more and more, I had a hard time finding any sort of design that would work well with the bed floor design without seeming too busy. After a little persuasion, I managed to get Brian to change his mind and keep the smooth inner bed skins. Before welding everything into the bed, I welded the bed skins together, primed, and applied Boom Mat to the back side of them to help with any sound reverb between both the inner and outer bed skins. Once everything was welded up and metal finished, I built a fuel access door into the bed floor to easily fuel up without having to drop the tailgate.

Check out this story in our digital edition here.

Source

Scott’s Hotrods ’N Customs

(800) 273-5195

scottshotrods.com