By Ron Ceridono – Photography By Jason Scudellari

To paraphrase Eli Wallach’s character, Tuco Benedicto Pacífico Juan María Ramírez, in the movie The Good, the Bad, and the Ugly, two types of hot rodders exist in this world: those who love shifting gears and those who don’t. For those who do, TREMEC offers a variety of options, including the exceptional TKX five-speed transmission. Summit Racing Equipment has everything you need for the installation. We’re here with Jason Scudellari of HB Hot Rod to demonstrate how it’s done.

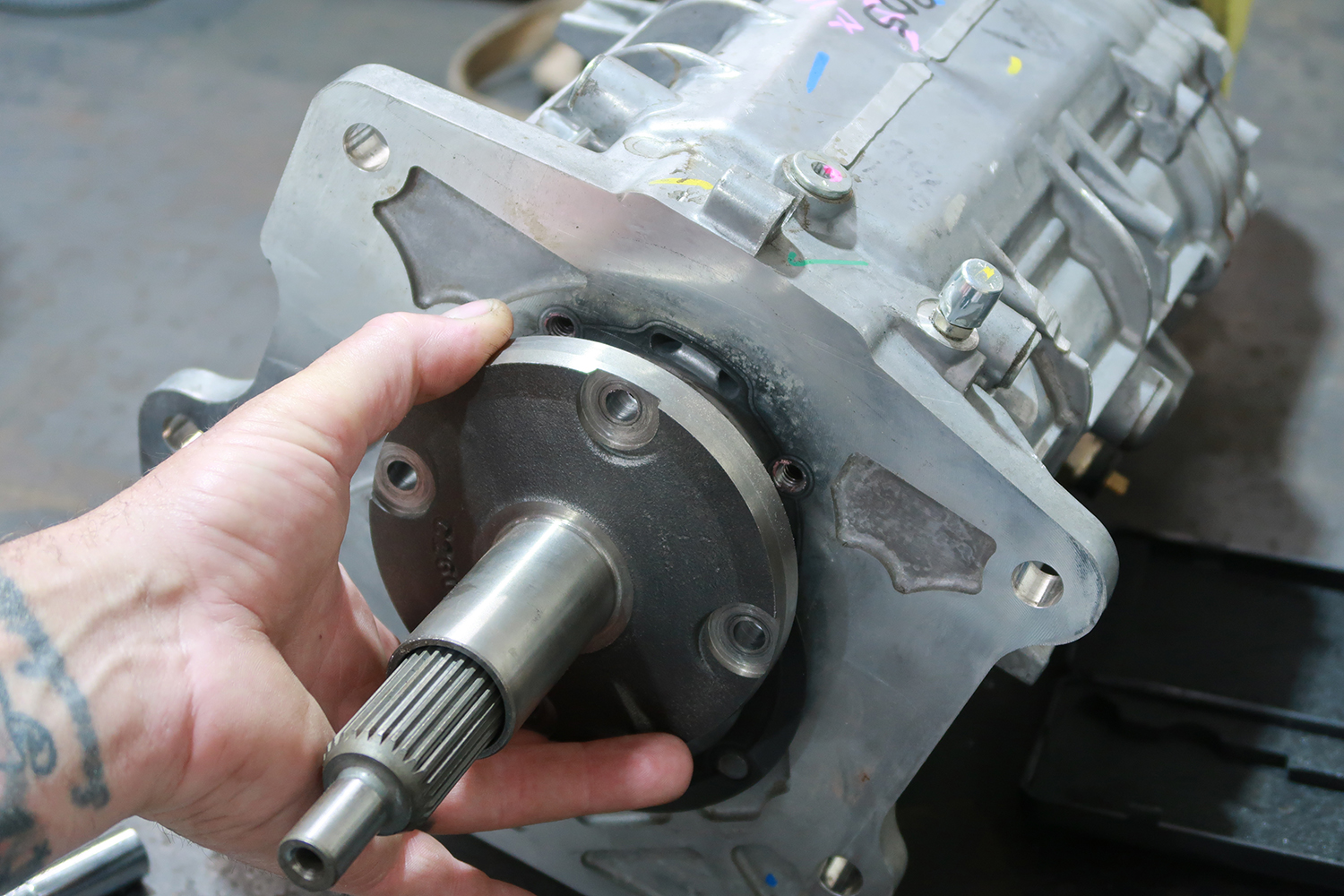

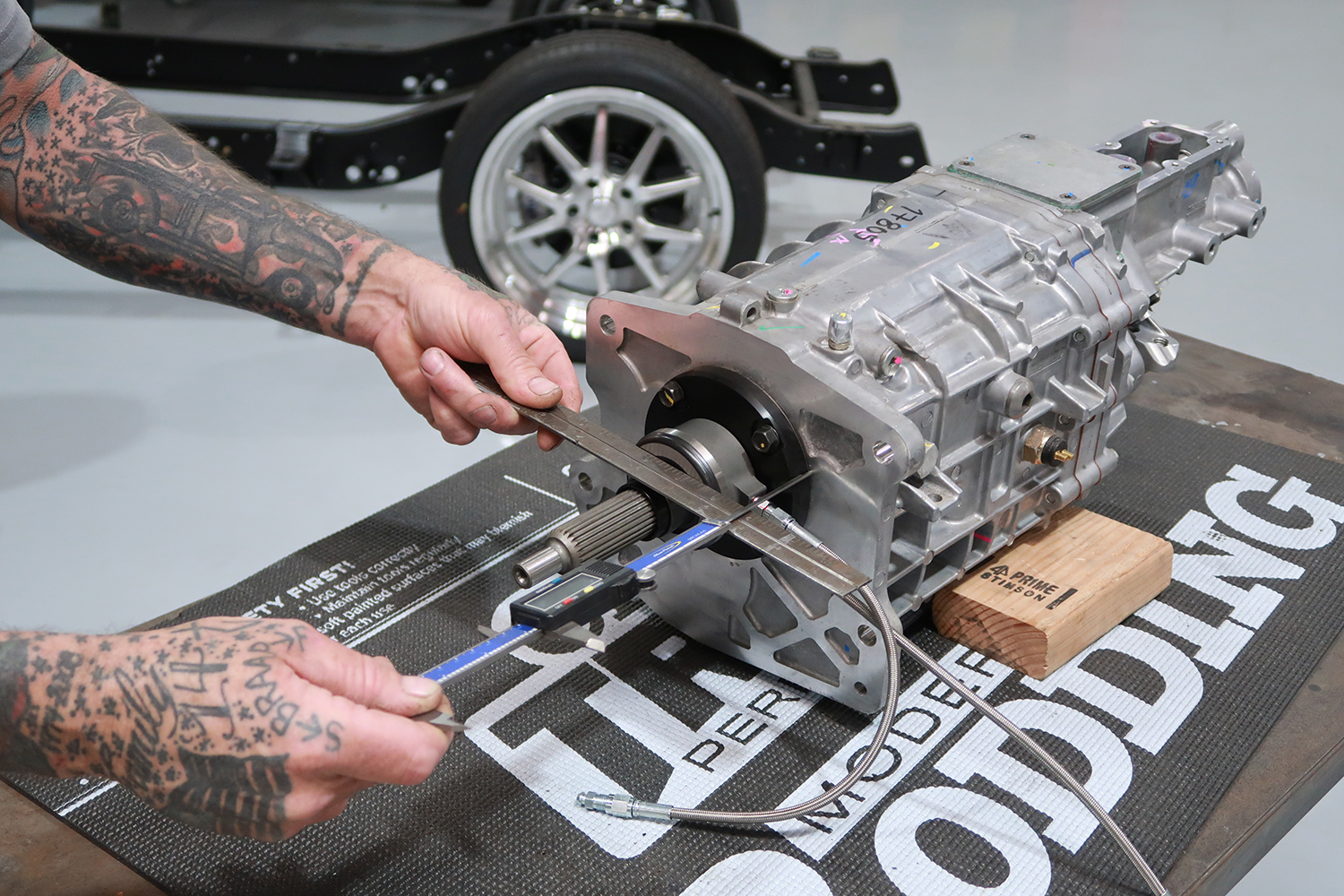

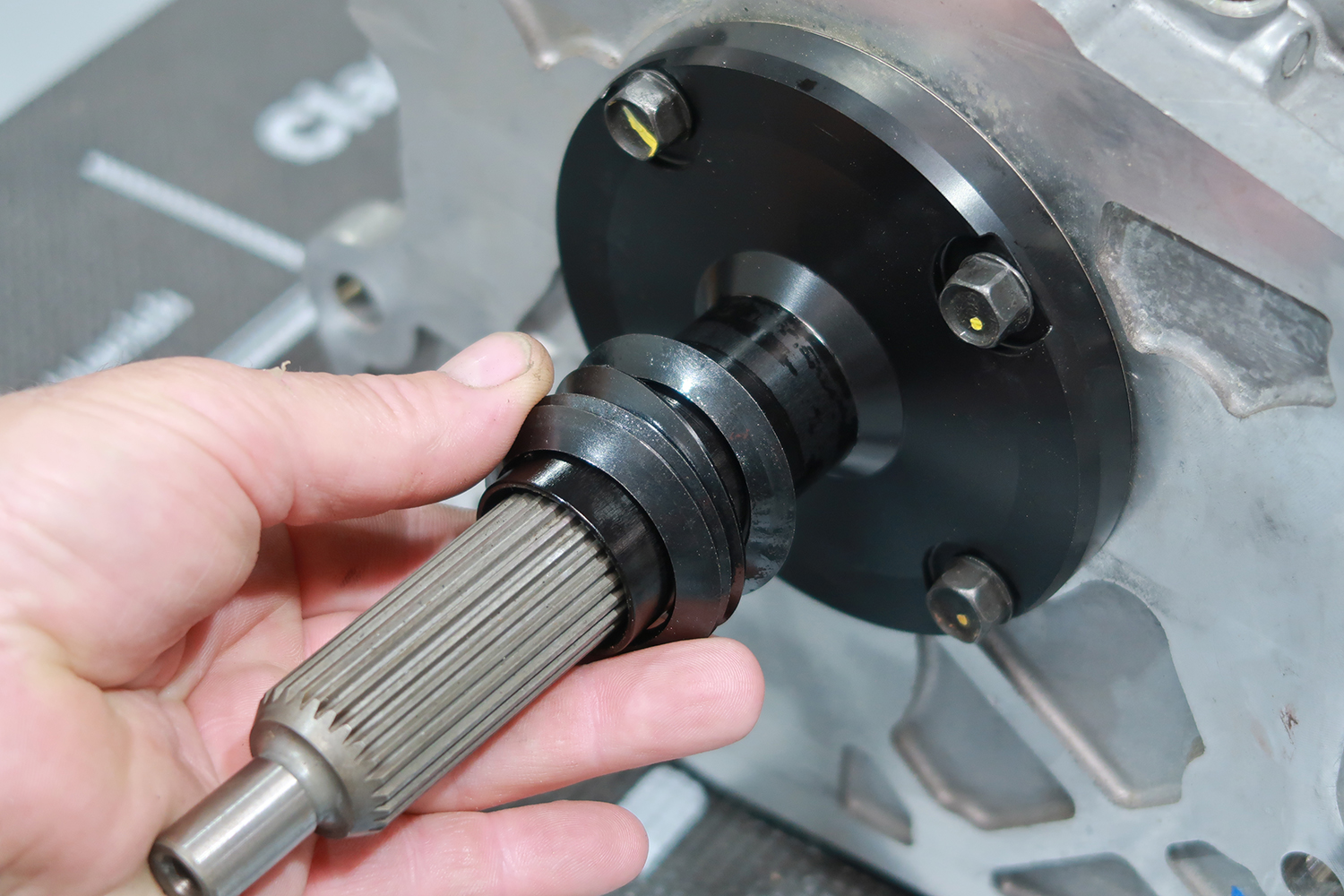

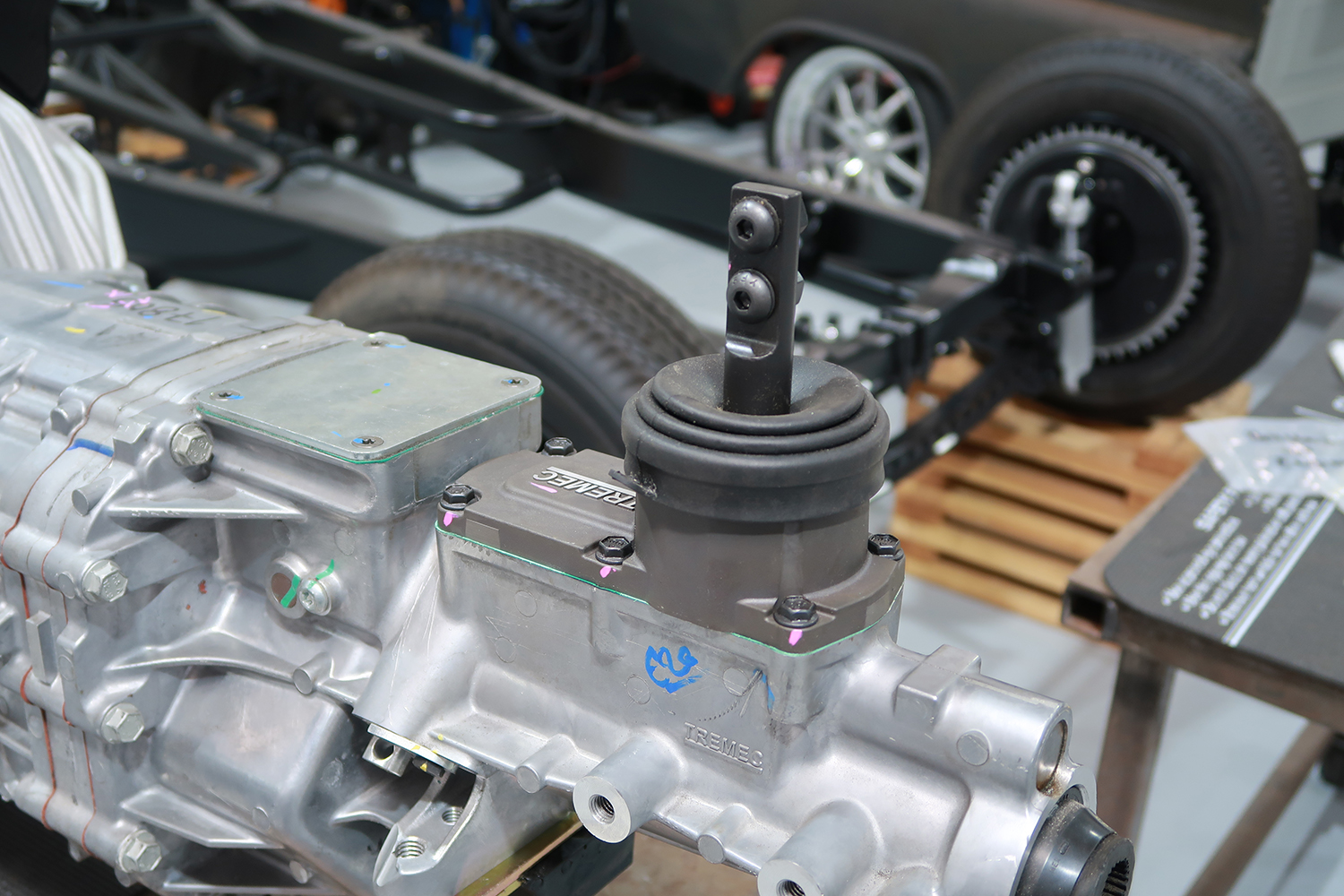

TREMEC offers the TKX five-speed manual transmission for GM and Ford applications. The slimmest five-speed on the market, the TKX will fit most transmission tunnels without floor modifications, and three locations are available to optimize the shifter location. From a strength standpoint, the TKX is rated as 600 lb-ft of torque, can handle engine speeds of 8,000 rpm, and shifts at 7,500 rpm. All gears and shafts are made from special grade steel (ASTM 4615), and smooth shifting is due to the multi-cone synchronizers with hybrid synchronizer rings made of sintered bronze and carbon. The input shaft diameter is 1.125 with 26 splines; the output shaft has 31 splines and accepts a GM slip yoke.

To make the most of any combination of engine and rear gears, the TKX offers three gear set combinations:

| First | Second | Third | Fourth | Fifth |

| 3.27:1 | 1.98:1 | 1.34:1 | 1.00:1 | 0.072:1 |

| 2.87:1 | 1.89:1 | 1.28:1 | 1.00:1 | 0.081:1 |

| 2.87:1 | 1.89:1 | 1.28:1 | 1.00:1 | 0.068:1 |

The TREMEC TKX shown is the GM version, which will bolt up to any standard BorgWarner/Muncie bellhousing. In our case, we used a Lakewood aluminum bellhousing available from Summit (PN LAK-LK4200K). This bellhousing is compatible with an 11-inch- or smaller-diameter clutch.

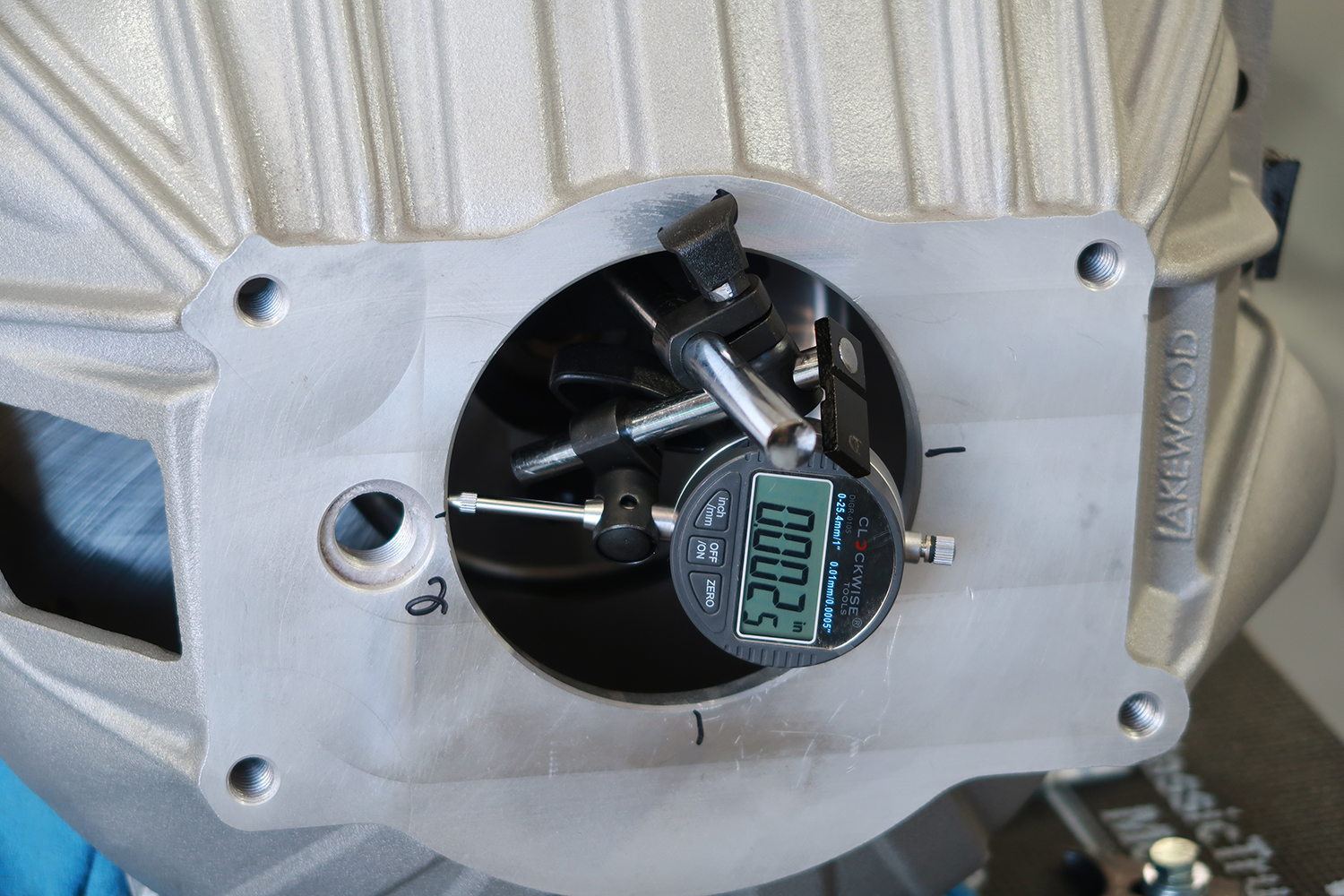

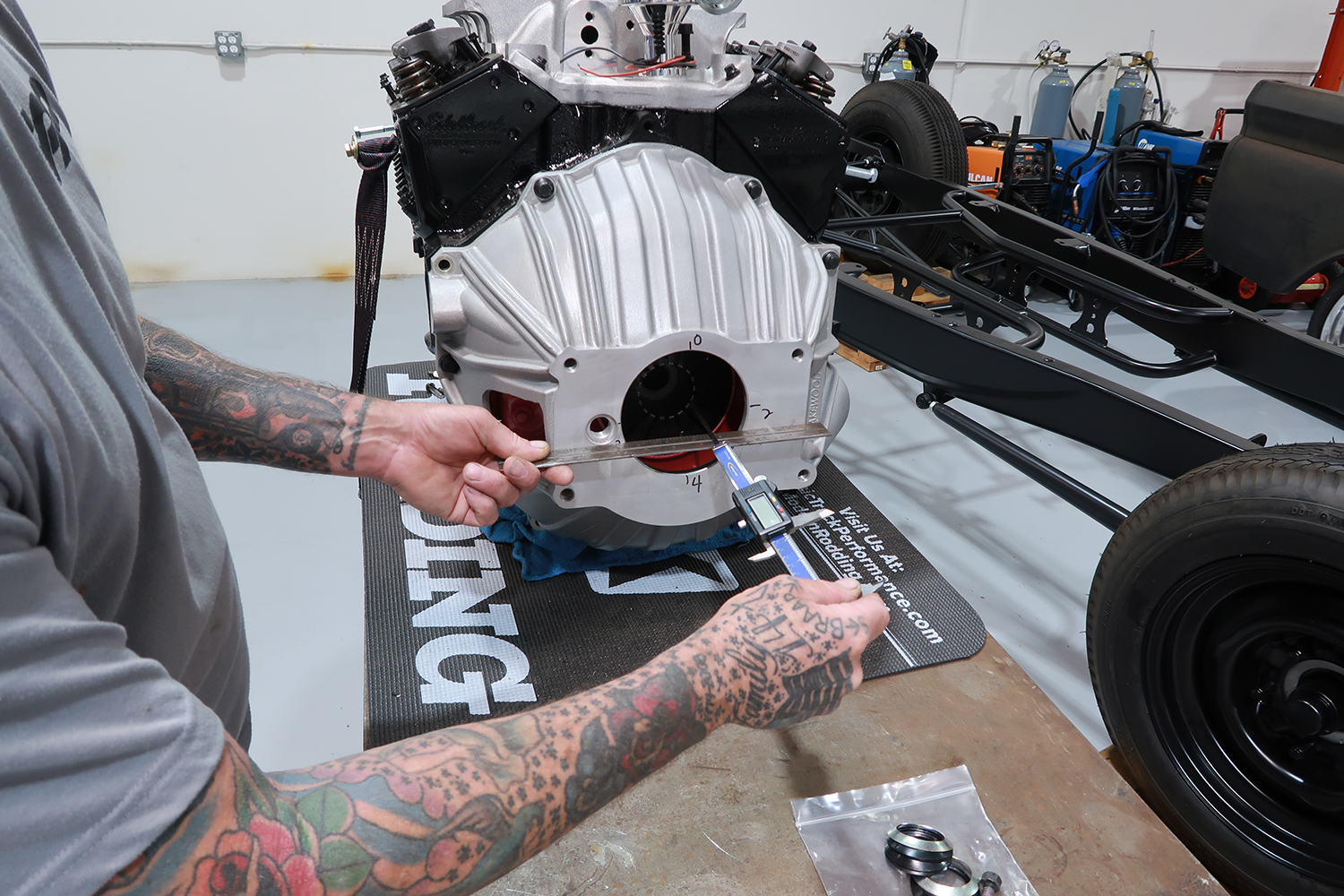

Whenever a bellhousing is installed, it’s always a good idea to check the centerline alignment with the crankshaft using a dial indicator. A misaligned bellhousing can cause difficult shifting and premature transmission wear. In this case, the bellhousing bolted on with the alignment well within specs.

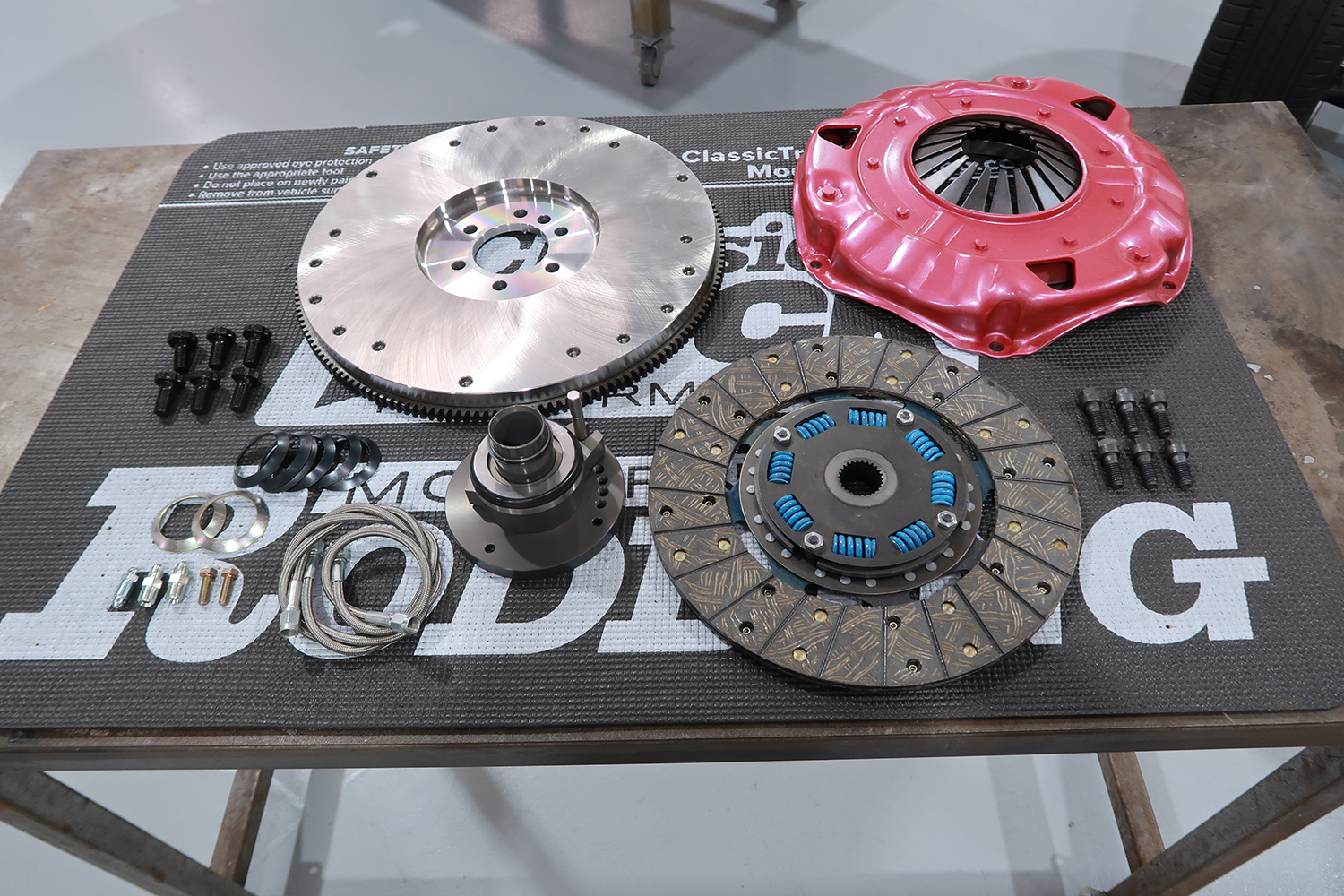

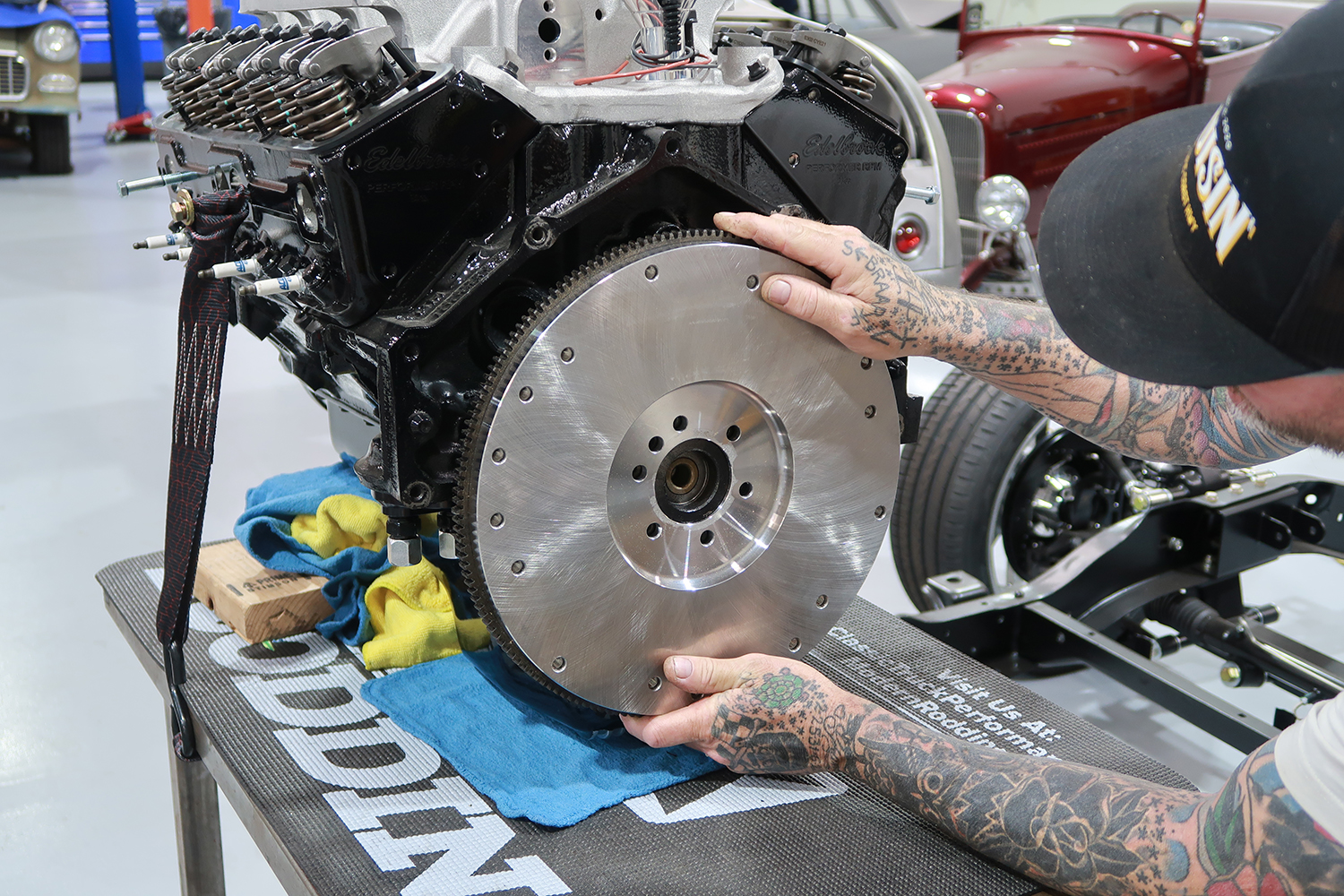

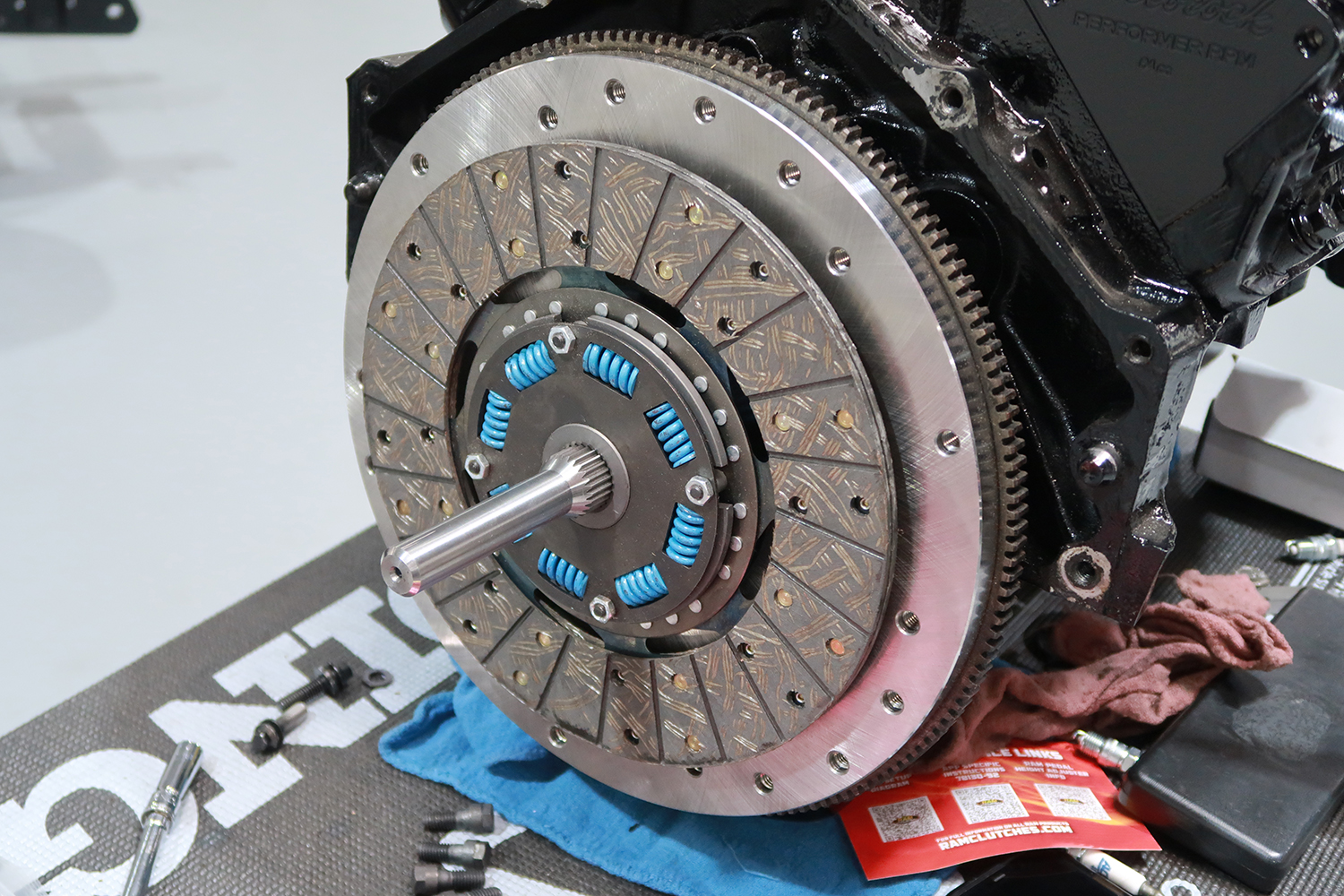

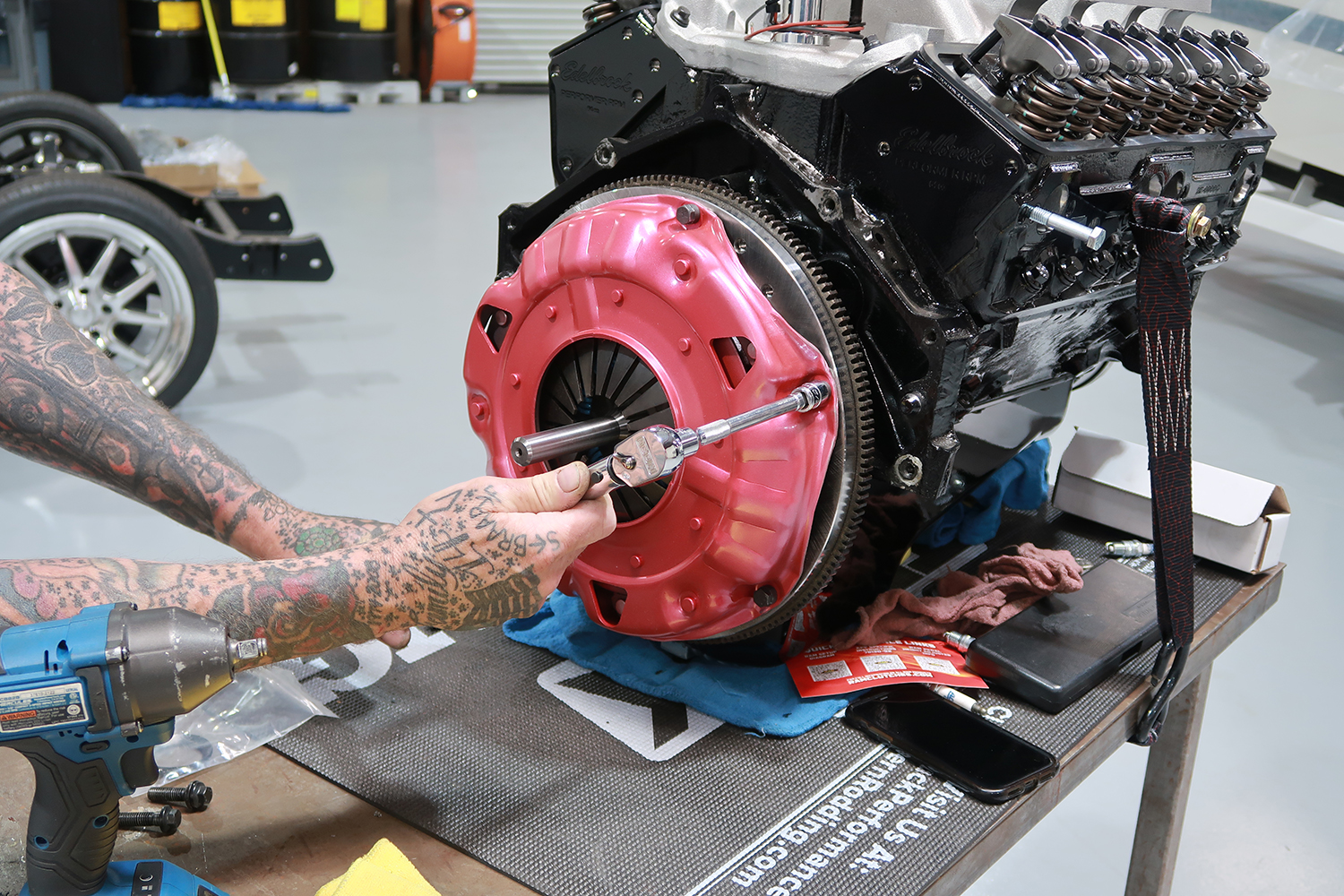

Scudellari ordered Summit’s clutch, flywheel, and mounting hardware Pro Pack (PN CMB 13-0000) for the additional components needed for the transmission installation. It came with a RAM billet steel flywheel for two-piece rear main seal engines (flywheels for one-piece seals and LS applications are available). Also included were a RAM 11-inch clutch disc and a diaphragm-style pressure plate for good clamping capacity without excessive pedal pressure, a hydraulic throwout bearing kit, attaching hardware, and even a clutch disc alignment tool.

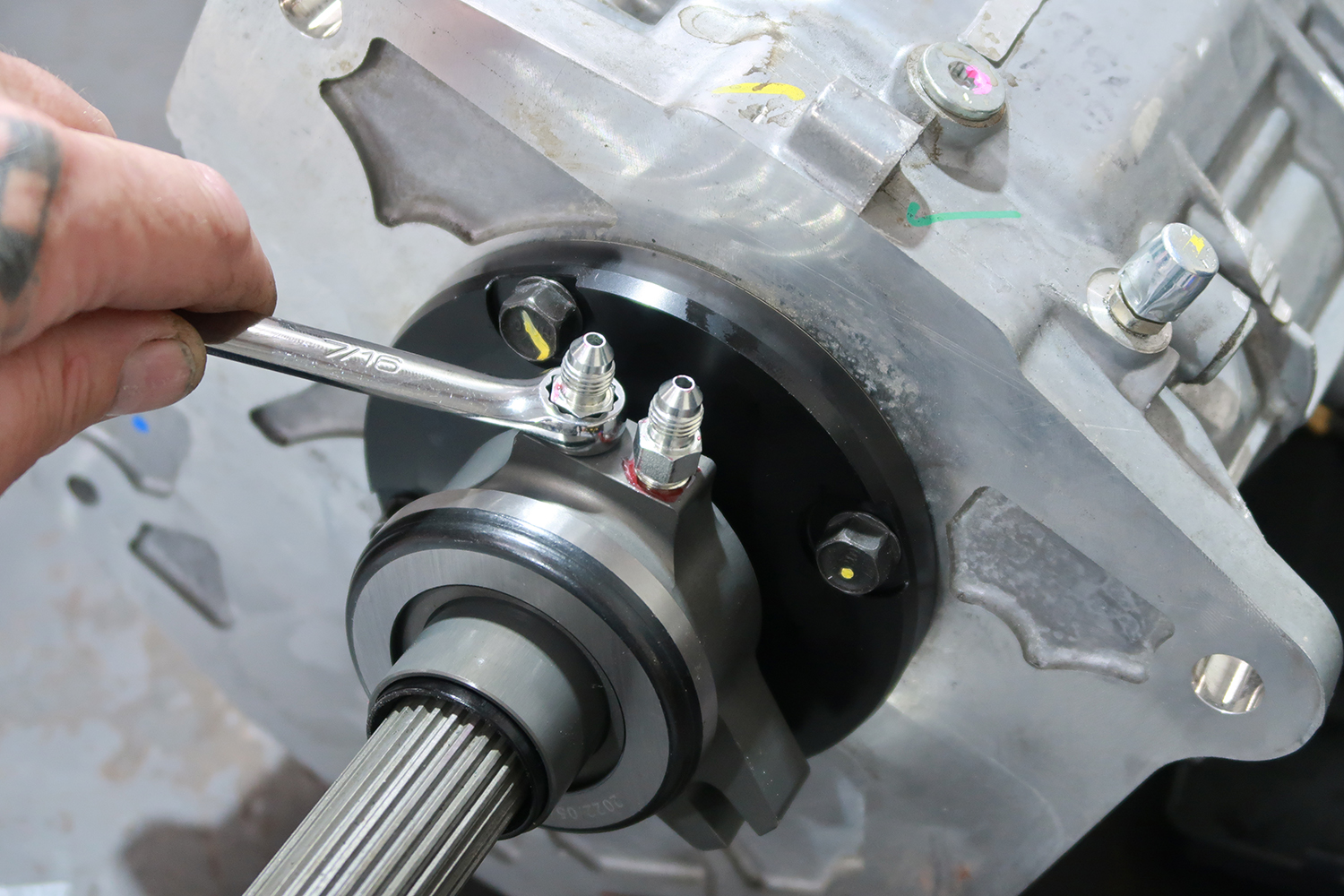

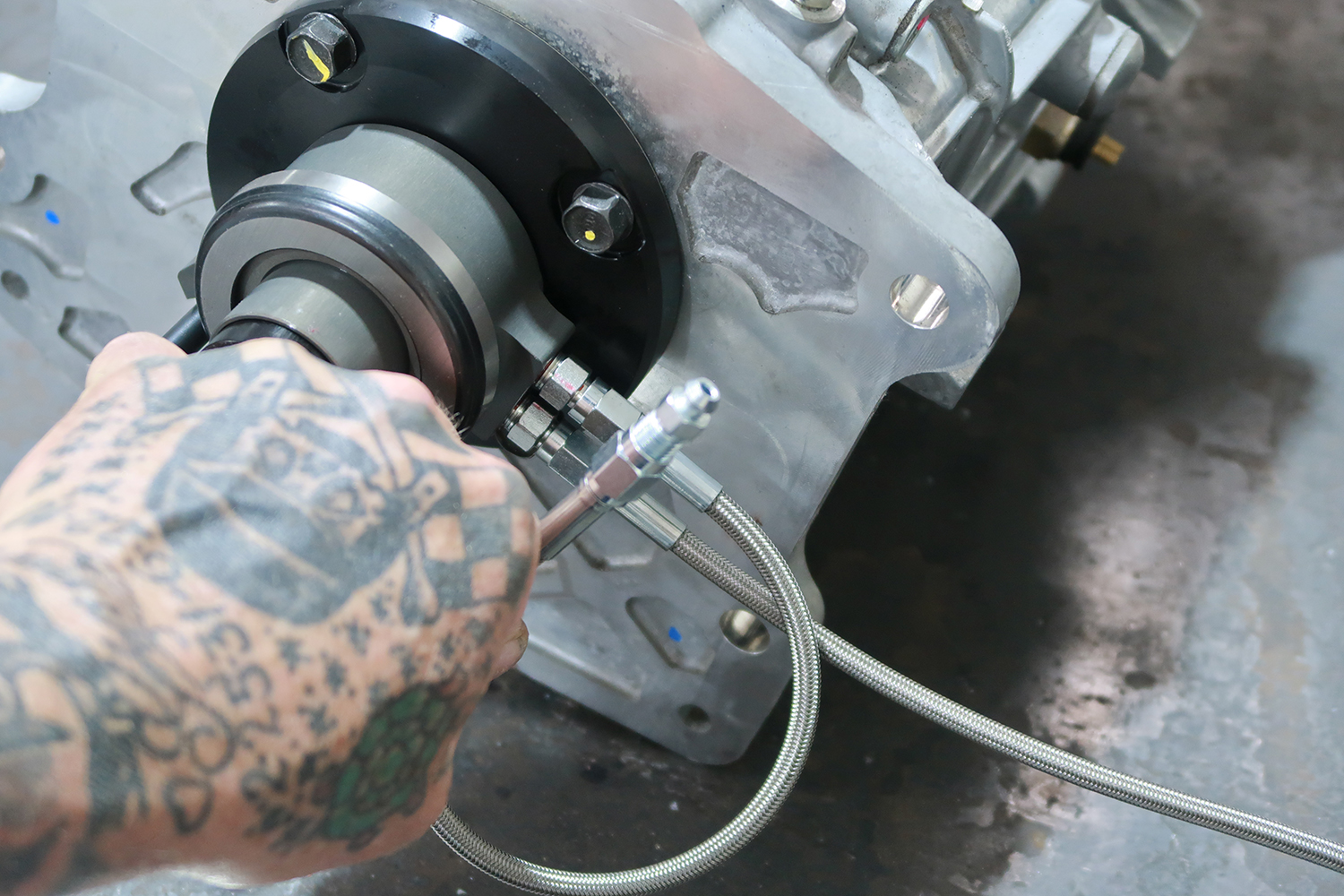

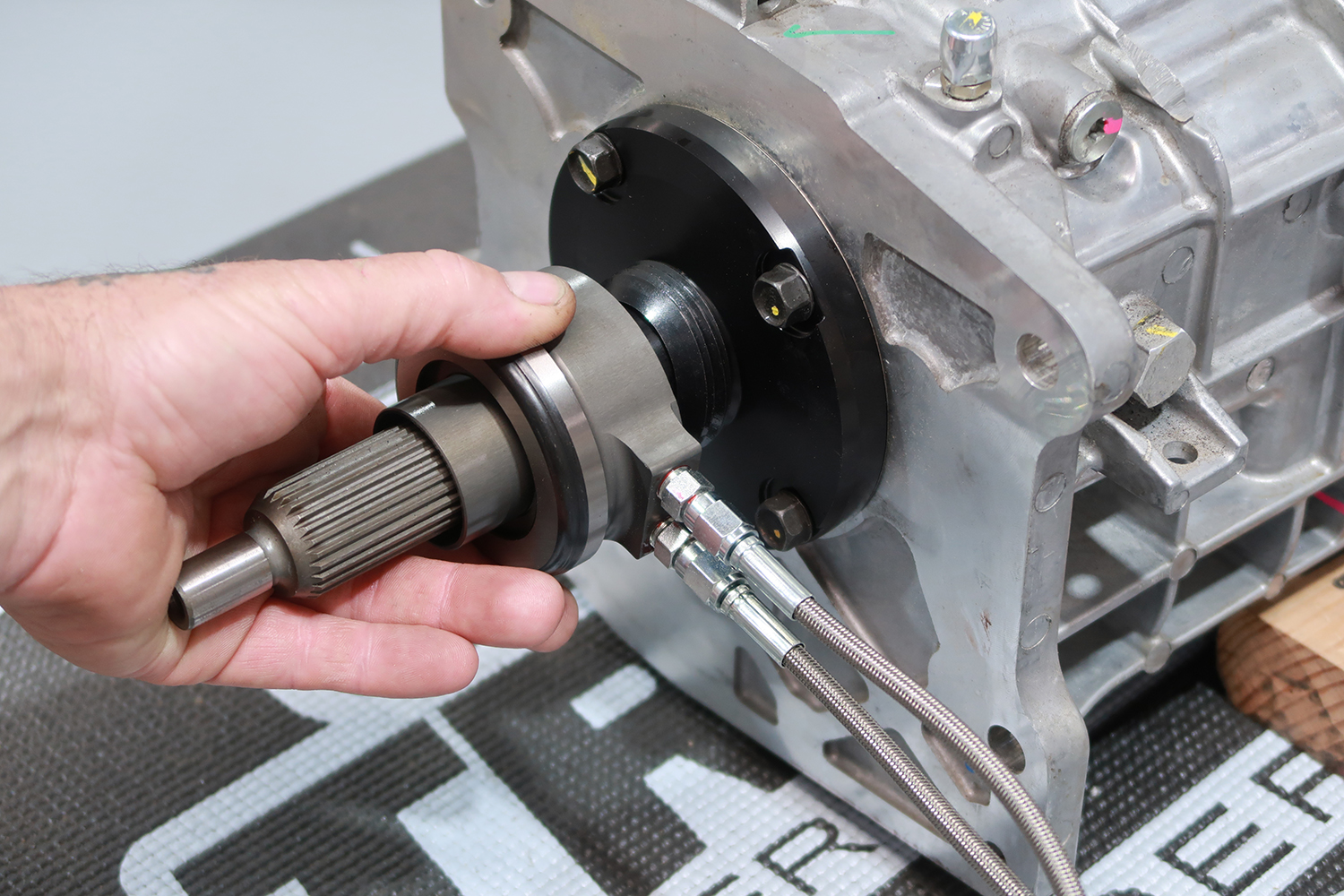

The RAM hydraulic throwout bearing included in the Summit kit has several advantages over a mechanical system. First and foremost, hydraulics provide a softer-feeling pedal; in addition, the movement is more consistent, providing smoother clutch engagement, and, finally, there are fewer moving parts.

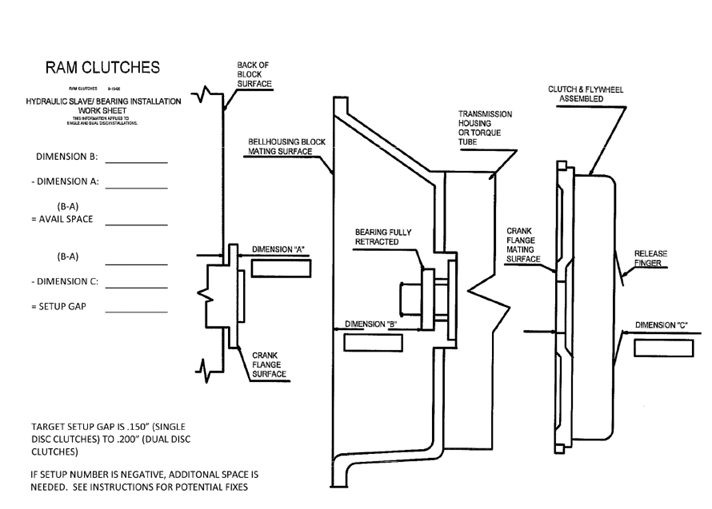

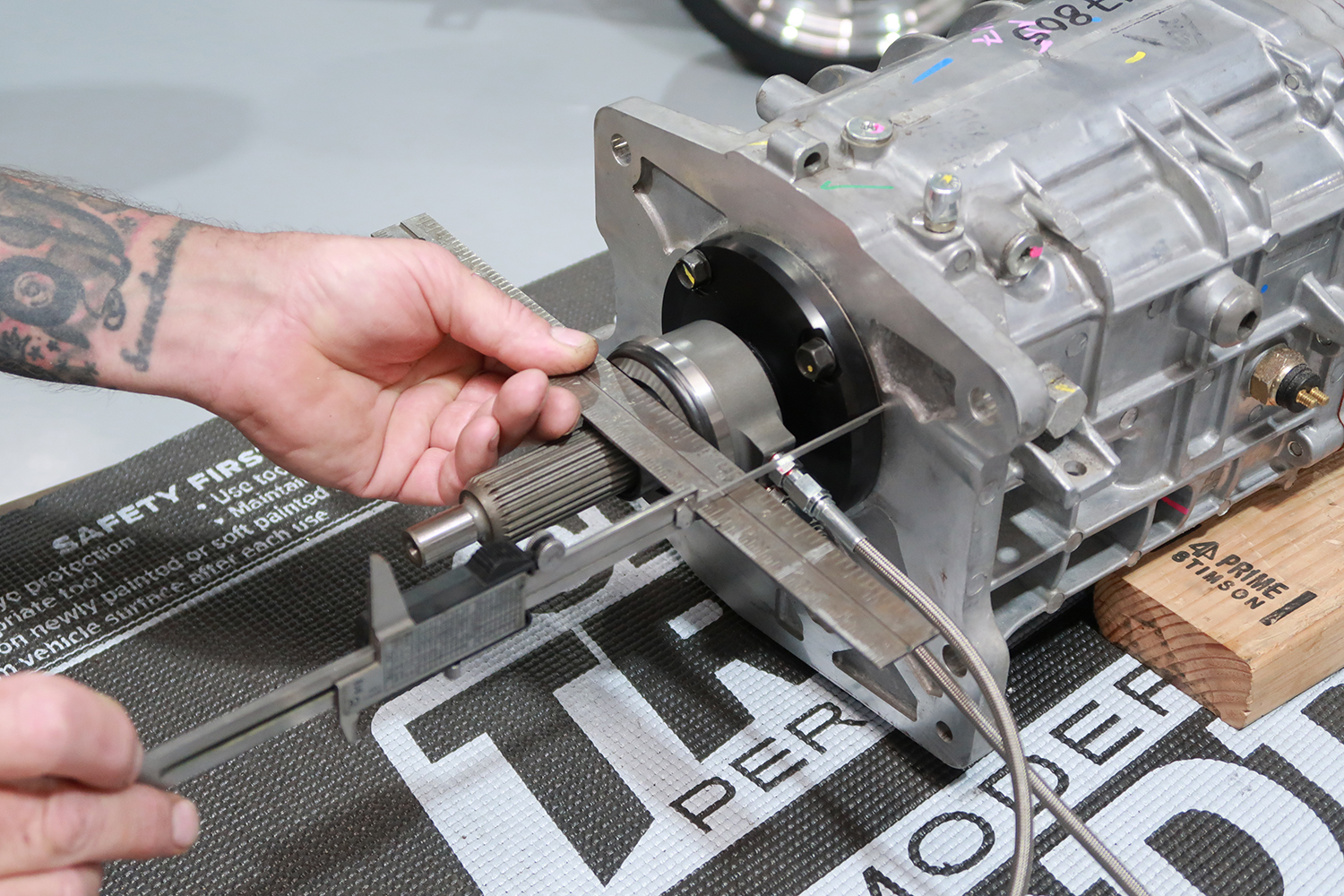

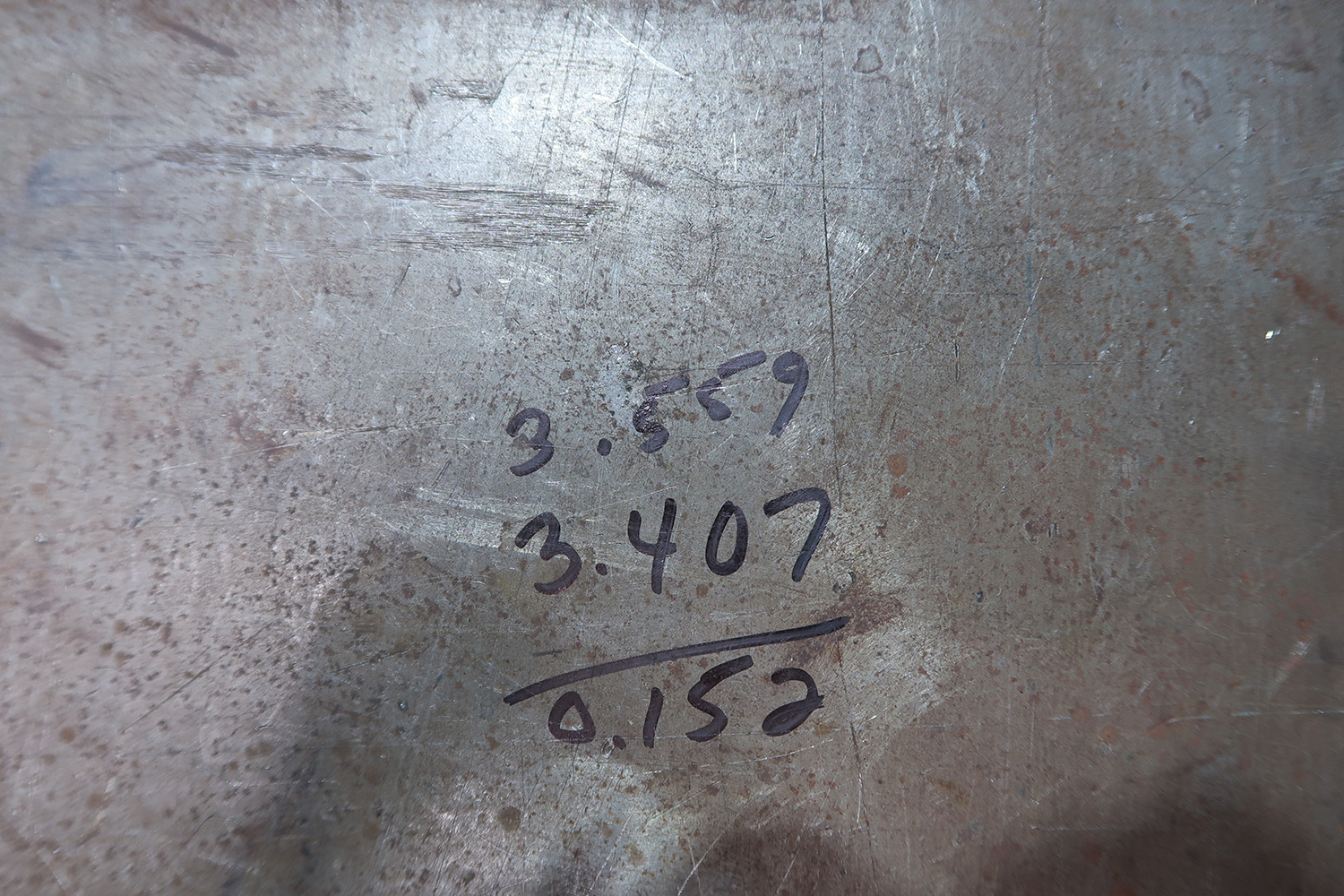

Installing a RAM hydraulic throwout bearing requires measurements to ensure clearance between the bearing and pressure plate fingers when the clutch is released. Also, there must be sufficient travel to allow the throwout bearing to release the clutch when the pedal is depressed completely. Although taking these measurements seems complicated, RAM provides the following worksheet to make it easy; just filling in the blanks and doing some simple math is what’s required.

For gearheads, a few things provide the pure joy that driving a hot rod and going through the gears of a TREMEC TKX five-speed transmission can provide. The gear ratio spread offers impressive performance from a standing start and up through the gears with overdrive ratios that provide comfortable cruising at highway speeds. TREMEC’s rail shifting system provides short-throw and precise gear changes, and the ribbed, three-piece aluminum housing reduces noise and vibration. All things considered we’re willing to bet the TKX would be Tuco approved.

Check out this story in our digital edition here.

Sources

HB Hot Rod

(714) 476-0629

hbhotrodshop@gmail.com

Summit Racing Equipment

(800) 230-3030

summitracing.com