By Jeff Huneycutt – Images courtesy of Jeff Huneycutt

There’s a reason why the LS engine has been by far the most popular option when it comes to engine swaps. Actually, there are many reasons: They make good power, they’re easy to work on, there’s a ton of aftermarket support, they’re durable, and they are compact so they can be made to fit under the hood of a wide variety of different trucks.

And that’s just the beginning. People at car shows gripe about seeing LS engines in too many different kinds of trucks. But those are the people who have never done an engine swap before. Let’s be honest, if you want a good-looking engine that makes good power with minimal headaches, the LS engine family is the way to go.

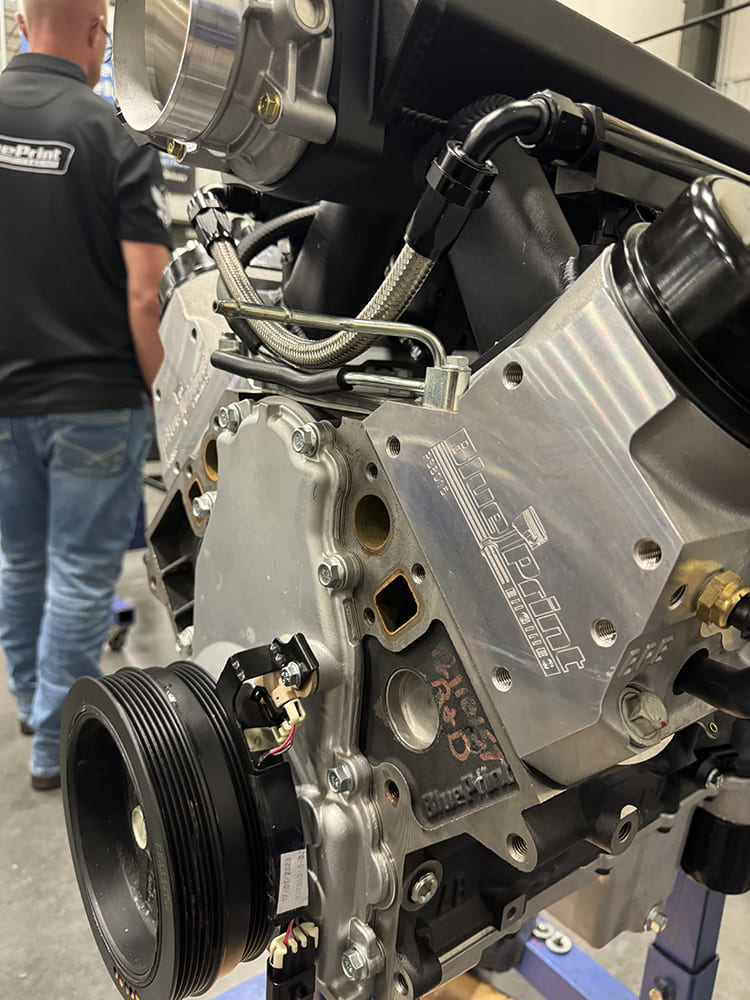

BluePrint Engines is one of the most successful builders of performance crate engines in the United States. Their engine packages are so popular they actually rival the OEM manufacturers in terms of crate engine production. BluePrint constantly does research on market patterns to match supply with upcoming demand and builds engines compatible with Ford, Chevrolet, and Mopar, so when they decided to make a huge investment in their LS engine program we took notice.

One of the most interesting things about BluePrint’s operation is that in order to maximize both quality control and parts availability, the company has many different components manufactured to their specs. They control the design, the quality, and the supply. This includes everything from intake manifolds to oil pans. There are also cylinder heads, main caps, crankshafts, and connecting rods. They even have their own head bolts.

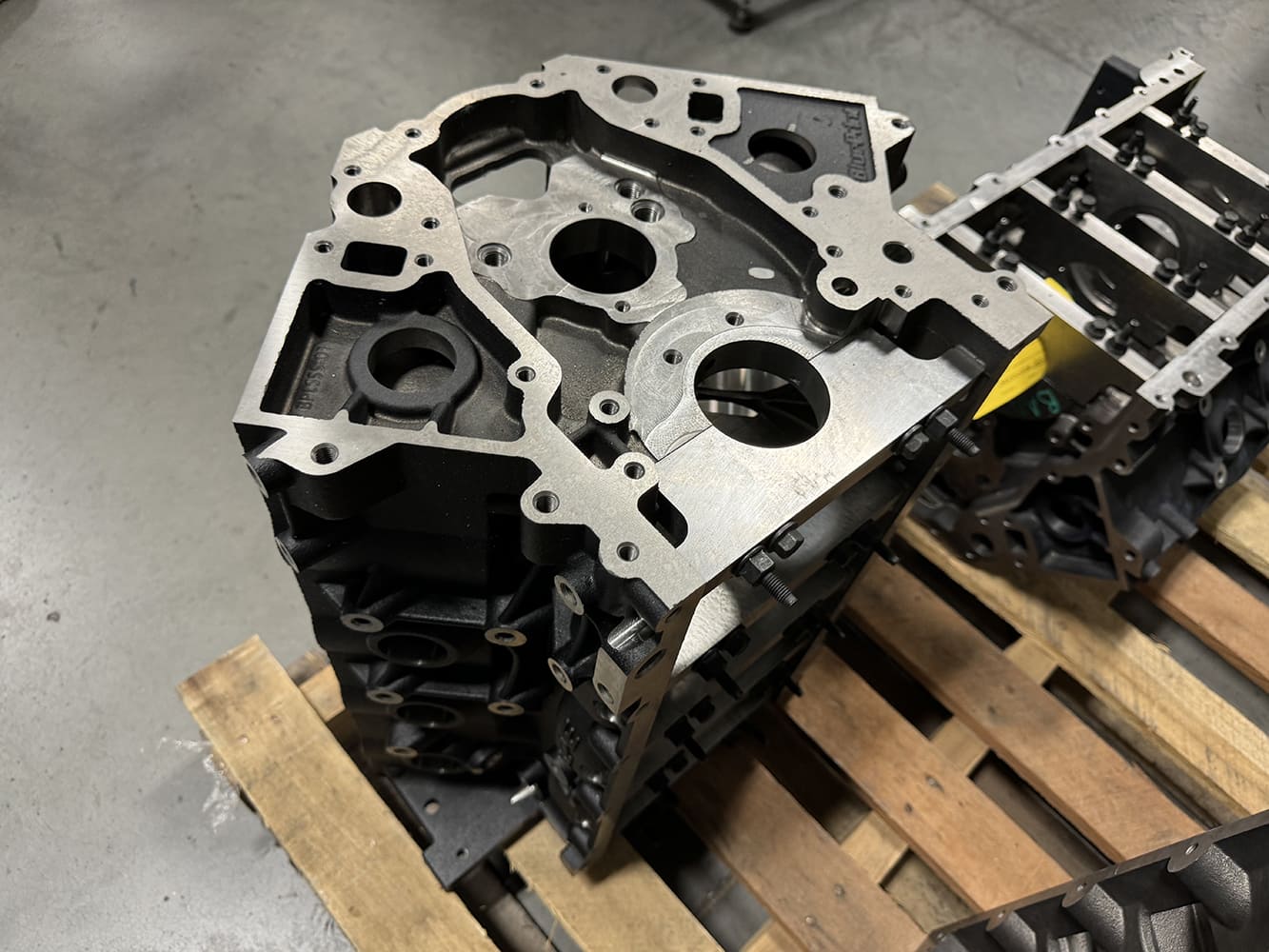

The list is constantly growing. One of the most popular engines that BluePrint builds is the LS. They have many different versions of the LS, displacing either 376 to 427 ci and producing as much as 800 hp. All of them come with a new block casting. Until now all those blocks came from GM, but that’s changing. By the time you read this BluePrint Engines will be shipping all its LS Compatible crate engines complete with their own blocks.

Recently, we had the opportunity to sit down with BluePrint Engines’ director of product development, Chris Larson, to talk about their new LS Compatible block. This isn’t the first time BluePrint has developed their own block casting, they also have their own Chevy Compatible small- and big-blocks. And it turns out there is a lot more to making your own casting than just pouring molten metal.

“There are only so many new blocks out there you can manufacture a new engine with,” he explains. “Obviously, with the volume of engines we are producing for our customer, we have a good idea of where the numbers are trending. The LS platform is incredibly popular and depending on GM to supply the block castings when they have to take care of their own needs isn’t the best way to control your own destiny. So we made the decision to go out and tool up for a block and make sure that we could always offer an LS Compatible block or an LS engine package and not be at the mercy of other suppliers to make sure we could.”

Larson says that the process of coming up with the LS Compatible block requires over two years of work. You probably could do it much more quickly than that if you farmed out the design and took other shortcuts. But when you sell an 800hp crate engine with a 30-month/50,000-mile warranty you definitely want to make sure you eliminate any weak spots.

“We took the opportunity to make changes we felt would benefit in terms of power and durability,” Larson says. “What we did was benchmark against what everyone else was doing with their block designs. So we got in one of all the different performance and OEM blocks on the market for the LS platform to see how they performed. Then we compared that to what we came up with to make sure our design captures what the customer is looking for and stands up well against the best of what the rest of the market has to offer.”

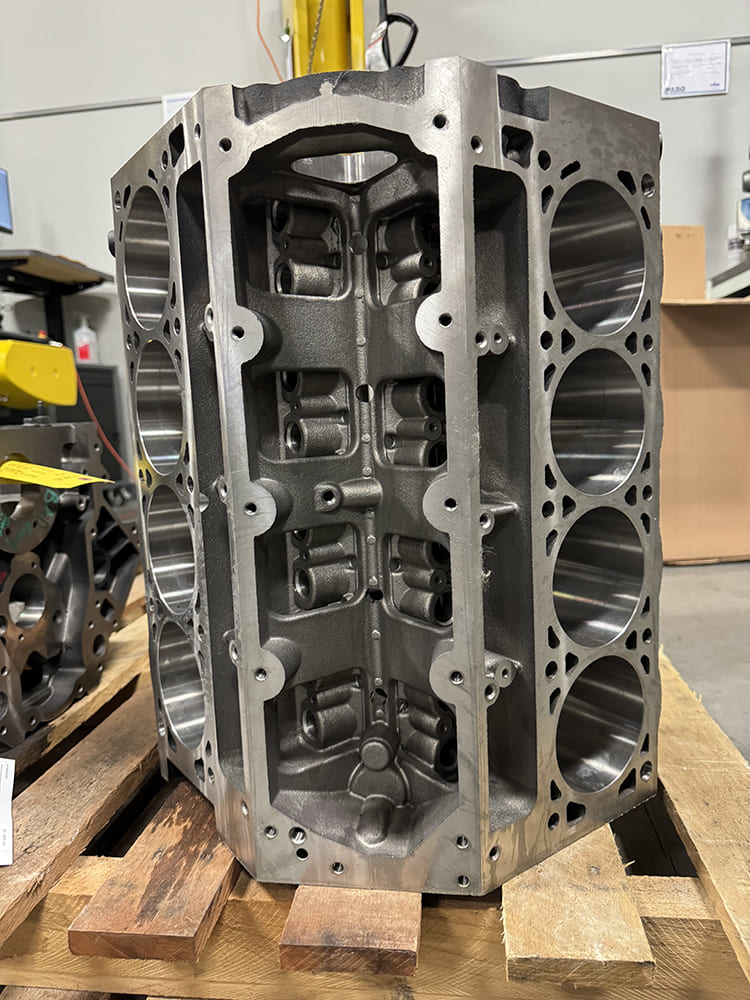

The BluePrint block is a newer-generation LS3-style block with the camshaft position sensor at the front of the engine on the timing cover. The block can, however, accept either a 24- or 58-tooth reluctor on the crankshaft for added flexibility.

But the changes from stock are numerous. “We extended the cylinder skirts,” Larson says. “With the GM LS3 design they are only 5.5 inches long. We extended ours to 5.75 inches. That allows for longer strokes and better piston stability at BDC. We made a wide range of bore sizes to fit a variety of different displacements. We can go from a 4-inch bore all the way up to 4.185. We made it to where we can be a short deck or a tall deck, so I think we can safely go up to 481 ci. And it might be a bit bigger than that.

“We’ve also got the thicker decks and main webbings to be able to withstand boost from either turbos or a supercharger. The water jackets are also improved for better cooling. There were other things we did. For example, for most applications we’ve got traditional press-in freeze plugs. But we’ve got customers who operate in extreme performance markets who want screw-in freeze plugs. So we’ve left enough material around the freeze plug bosses that we can machine them for screw-in plugs. Just more options depending on what our customers want.”

With current environmental regulations, very few castings are produced in the United States anymore. Just about everything automotive has moved to other countries. That’s also true for BluePrint, but instead of going to a location known for depressed wages and bottom-dollar results, they chose to go with a company in Germany known for absolute quality with their casting processes. The raw block castings are then shipped back to the United States where all the machining processes are completed in-house in BluePrint’s facilities in Nebraska.

“Everything’s been really good,” Larson says of the results. “When we go to develop a new product, we do extensive durability testing to make sure everything we put in the market is going to be a high-quality part. This LS Compatible block is no different. We’ve got it in five or six different types of builds. We’ve got them in vehicles. We’ve got durability testing going on that’s extremely extensive that the blocks have got to be able to handle with no sweat before we even launch it.

“We’ve done all that and it did really well. I think people are really going to love this.”

Check out this story in our digital edition here.

Source

BluePrint Engines

(308) 236-1010

blueprintengines.com