By Jeff Huneycutt – Images by the Author

In the 1960s, many of Lola Cars’ most successful racing machines were powered by Chevrolet small- and big-block V-8 engines. Company founder Eric Broadley recognized early on the advantages of building his lightweight British racers around potent, reliable American V-8s. Despite being a relatively young constructor, Lola quickly earned a winning reputation, thanks in large part to the performance of its Chevy-powered cars.

The Lola T70, introduced in 1965, was designed from the outset to accept large American V-8 power. In 1966, driving a Chevy-powered T70 Spyder, John Surtees captured the inaugural Can-Am championship, winning all but one race that season. Lola T70s claimed five of the six Can-Am races that year in a dominant showing against rivals like McLaren and Chaparral. These machines also proved their endurance capabilities; a Team Penske Lola T70 Mk3B, backed by a 5.0L Chevrolet, scored a celebrated overall victory at the 1969 24 Hours of Daytona. Throughout the late ’60s, Chevy-powered Lolas regularly challenged factory teams, such as Porsche, Ferrari, and Ford, underscoring Lola’s ability to blend British engineering with American horsepower.

By the end of the 1960s, the success of Chevy-powered Lola cars had firmly entrenched the company among racing’s elite constructors. Although they did experience greater success in the U.S. than Europe, the big, high-compression engines struggled with the poorer fuels over there but were allowed to burn Avgas in the States. Models like the thundering Lola T70 sports racer and the versatile Lola T142 formula car demonstrated Lola’s knack for pairing British chassis ingenuity with American V-8 muscle. Plus, the cars were just beautiful. There’s something magical about the silhouettes in sports cars from the ’60s.

Of course, any original Lola T70 MkIII you come across will probably be in an automotive museum but just like with the Shelby Cobra there is a healthy replica industry that can replicate the look and feel of these beautiful cars without the million-dollar budget it would take to acquire an original. That’s exactly what this big-block engine build is all about. Prestige Motorsports, out of Concord, North Carolina, got the call to build an engine for a customer’s 1969 Lola T70 Mk3B replica build from Replica Race Cars out of Fraser, Michigan.

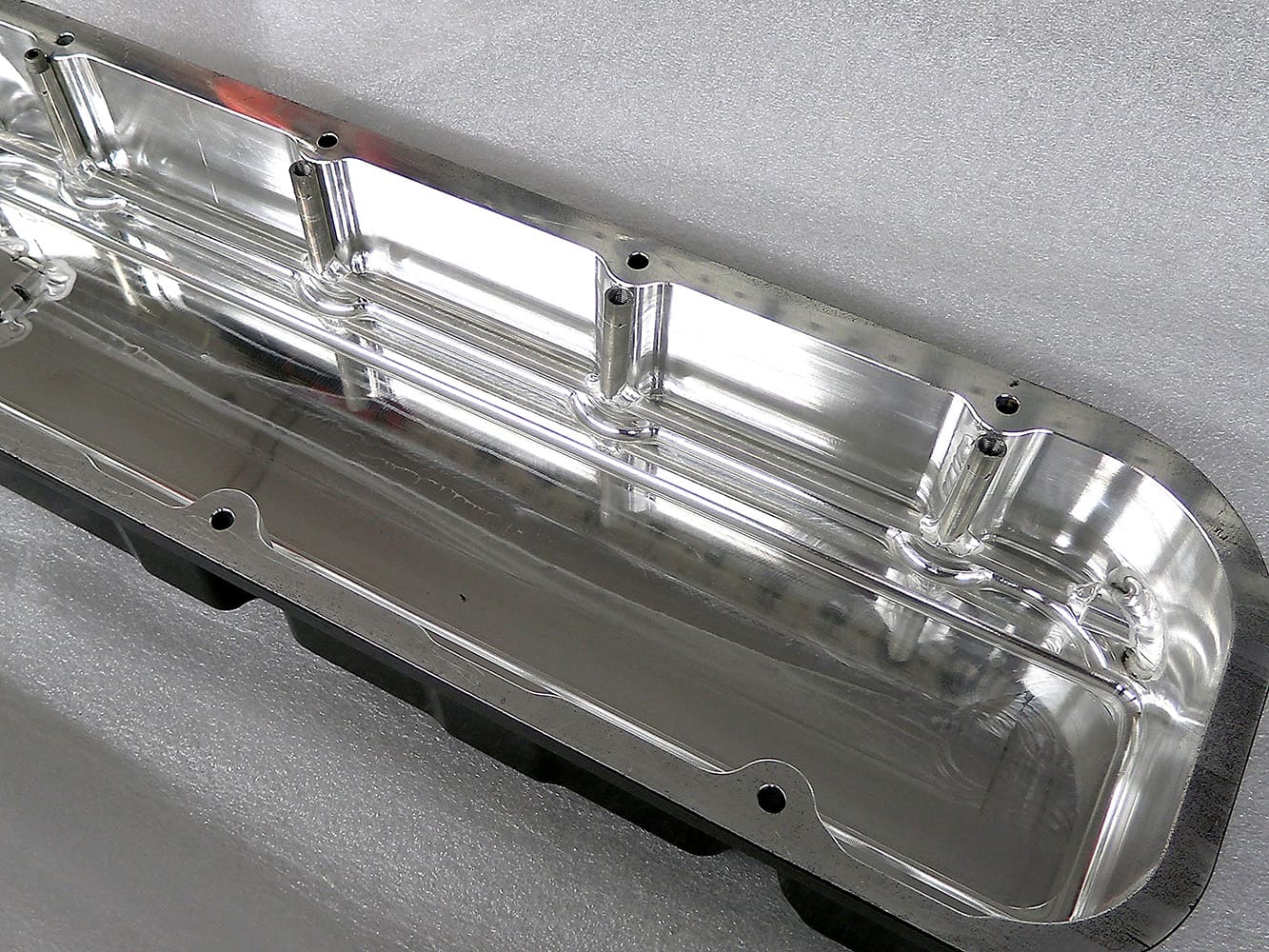

Obviously, going into a car that celebrates the heritage of one of the great race cars from the golden age of sports car racing the engine could be no lightweight when it came to horsepower. But it also absolutely had to be a lightweight when it came to … weight. Even if it made tons of horsepower, a cast-iron pig that would make the Lola wallow through the turns just wasn’t acceptable.

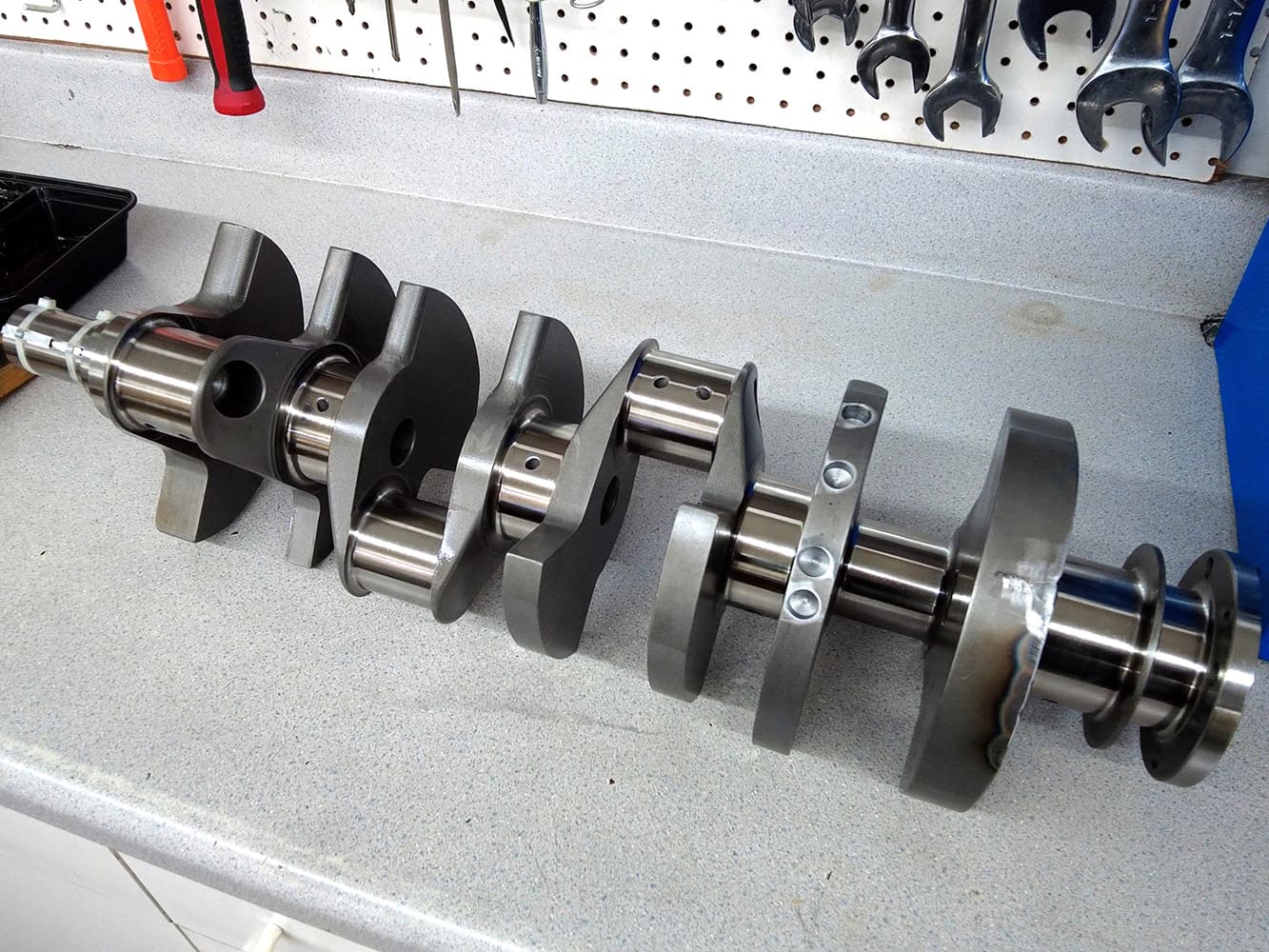

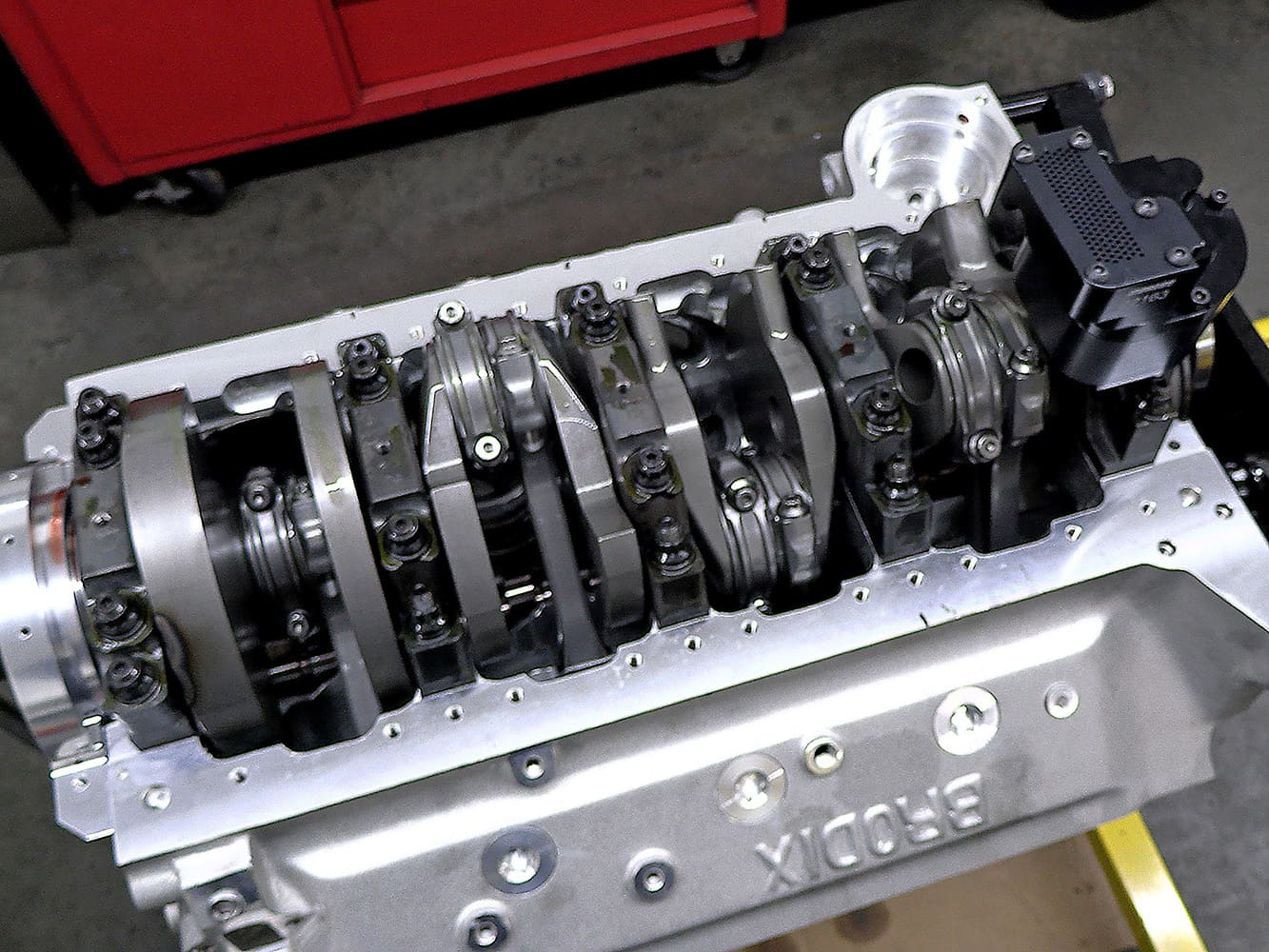

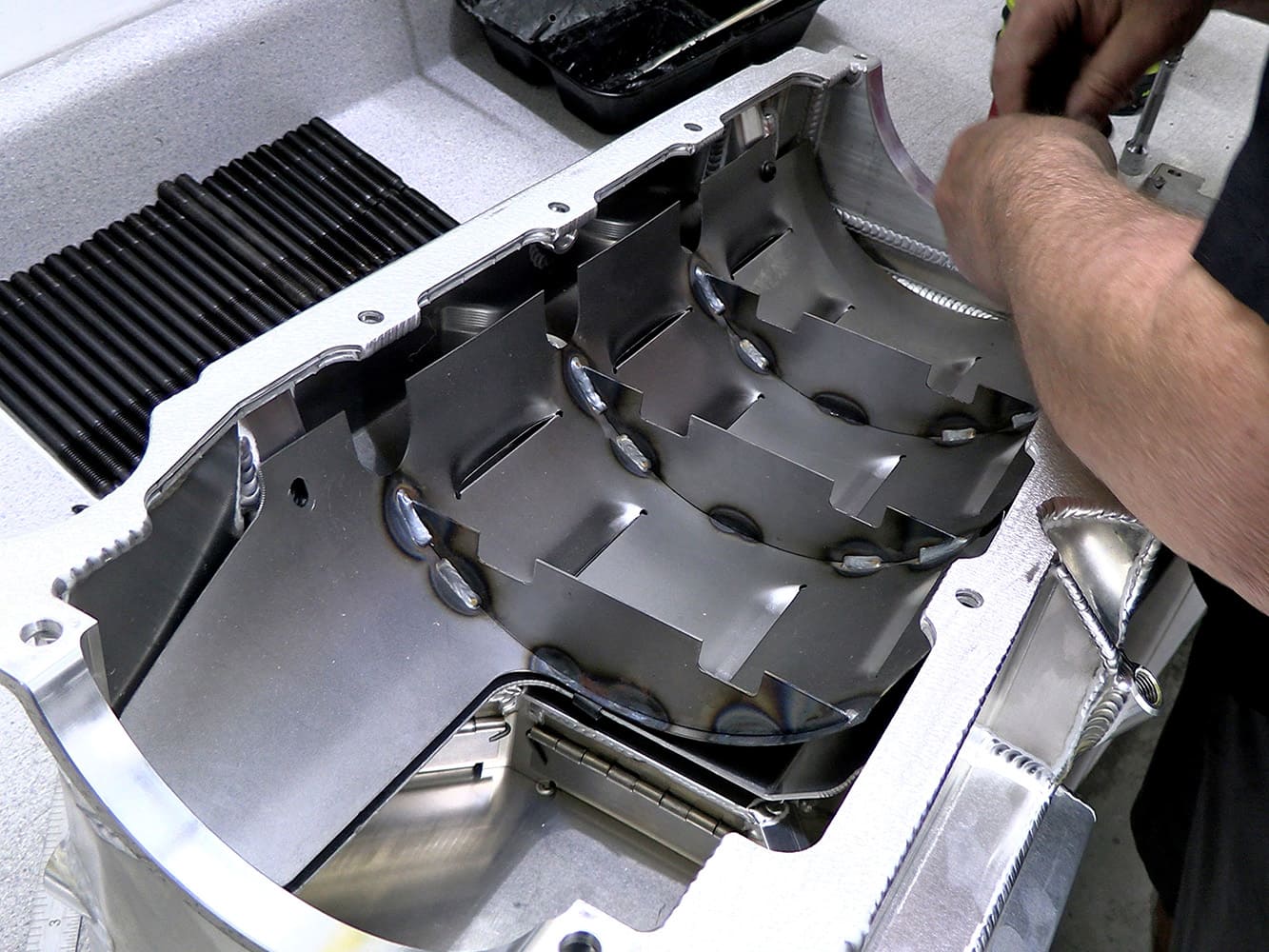

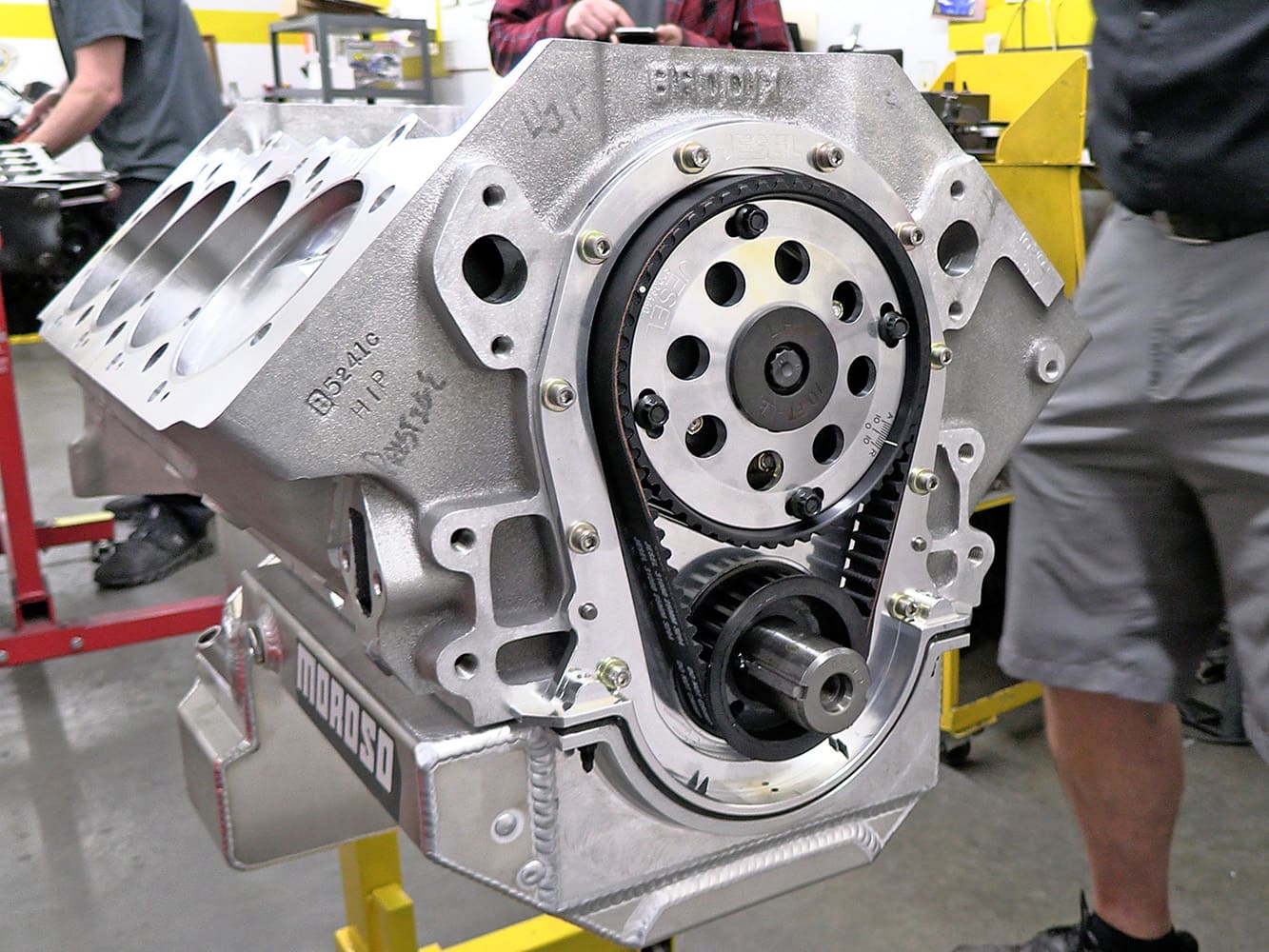

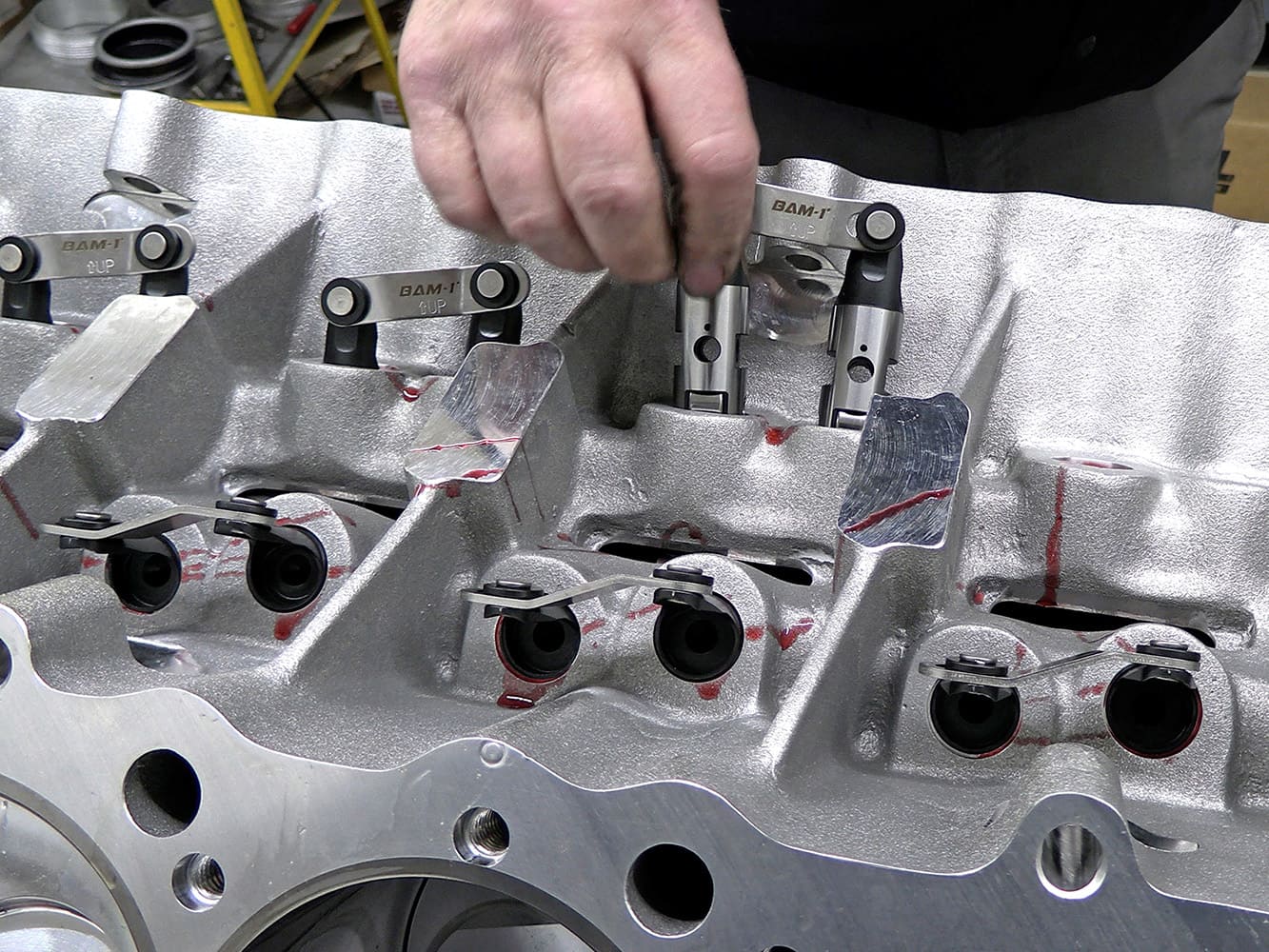

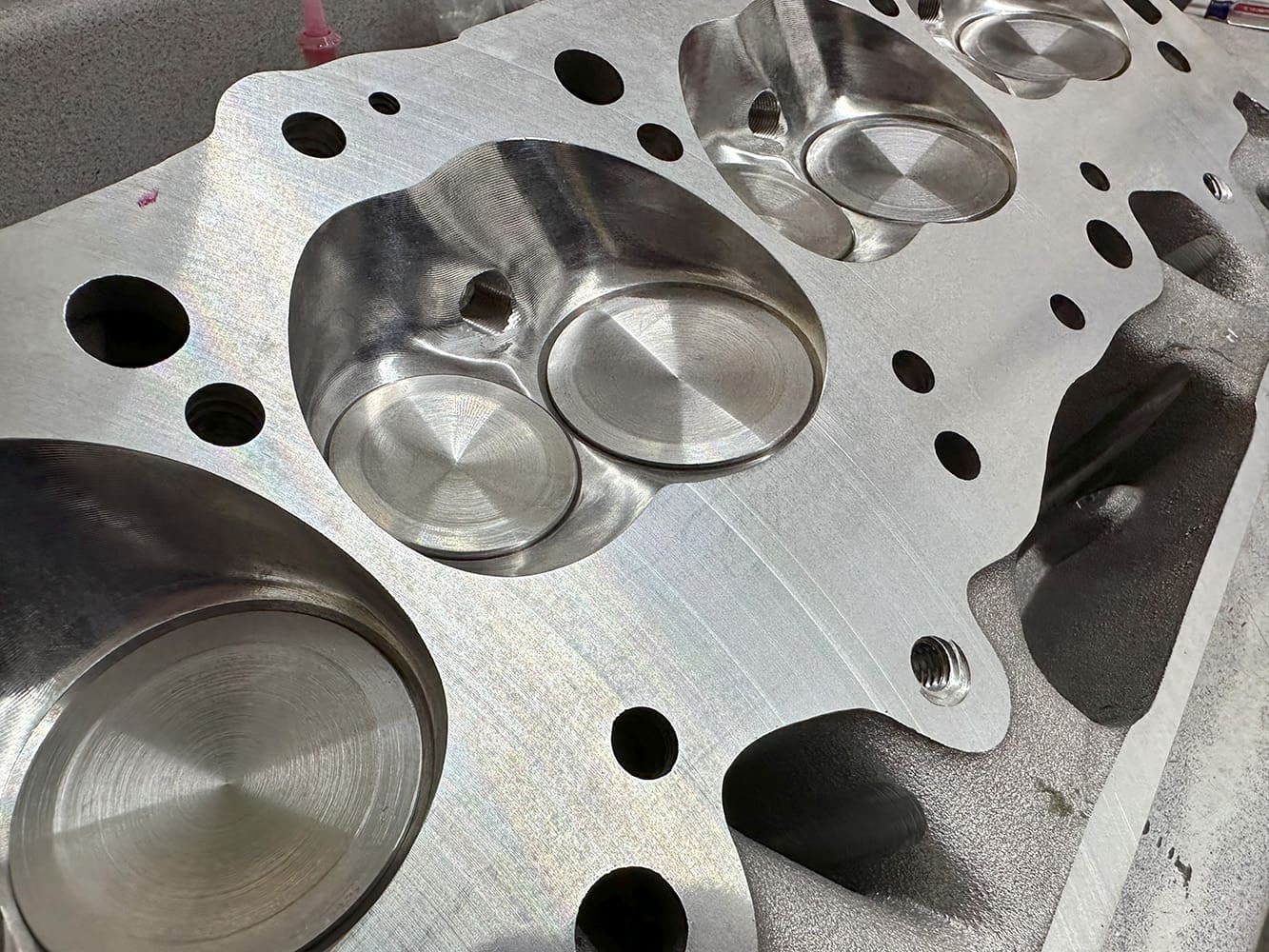

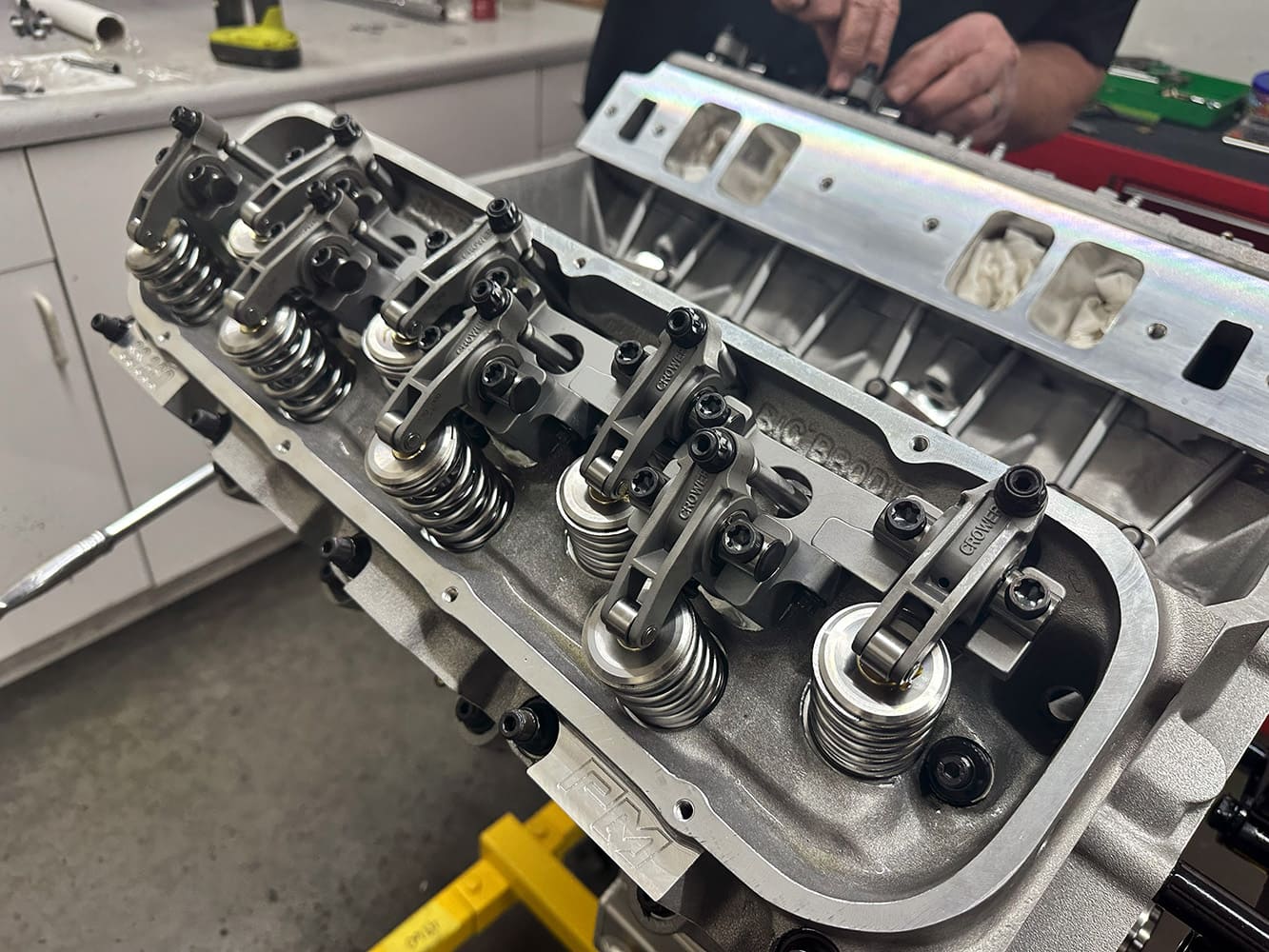

So, Prestige came up with a plan to build an all-aluminum, 582ci big-block that pumps out 900 hp (on pump gas!) without adding any extra pounds to the fiberglass-bodied car. Oh, and it has to keep that old-school vibe.

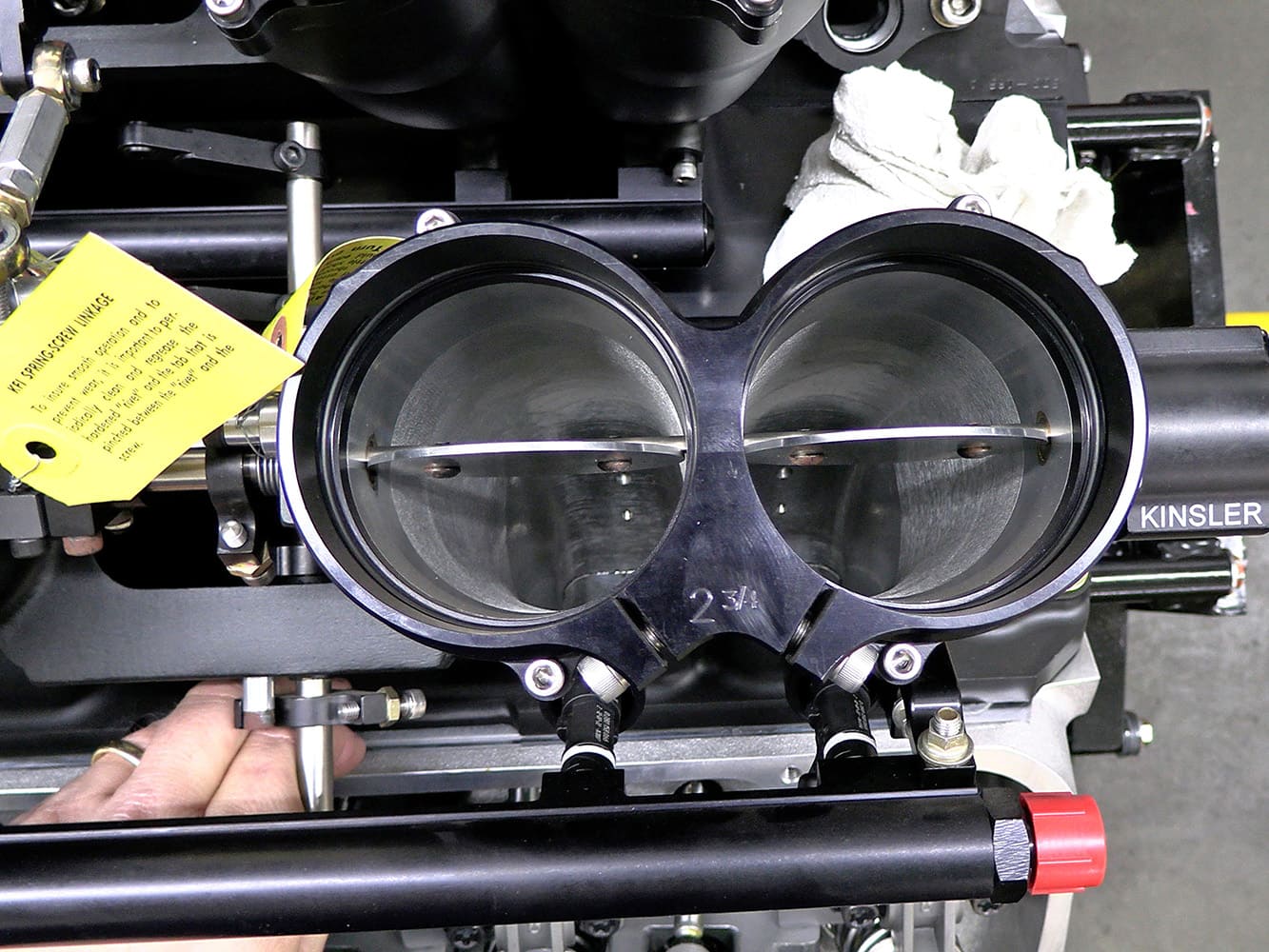

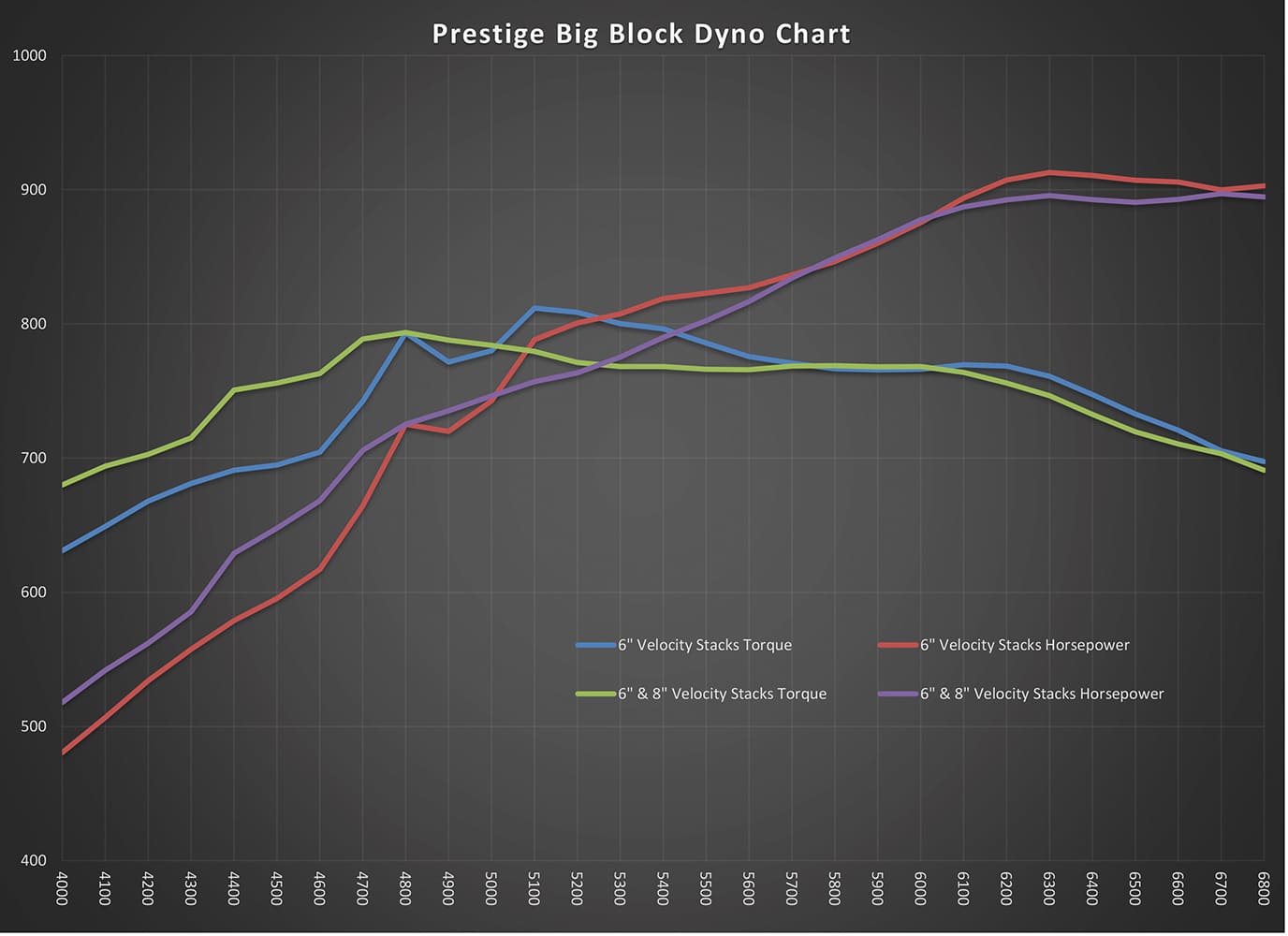

The crown jewels of this build are the very tall velocity stacks from Kinsler Fuel Injection. This is not a mechanical fuel injection setup like Kinsler is famous for with Sprint Car racing but instead is an EFI port injection system with a Holley ECU controlling everything. What’s interesting is Kinsler’s engineers gave the engine builders at Prestige the heads up that running all eight velocity stacks the same height could result in dips in power along the rpm band. (Something about harmonics of air pressure/flow or something that’s way above our heads.)

And that’s exactly what we saw on the engine dyno. With the 6-inch velocity stacks on the individual runner fuel injection we saw an aggressive dip in power between 4,800 and 5,100 rpm. But the guys at Prestige expected it and swapped in four 8-inch-long velocity stacks on cylinders 2, 3, 7, and 6 and ran it again. The mixed lengths of the velocity stacks not only looked cool but actually did a great job of fixing the problem. Power delivery was smooth across the pull and low-end power actually increased (although we did lose power from 5,000 to 5,700 rpm). Overall, average torque and horsepower still went up by 6.1 and 3.1, respectively. So, the mix is not only an incredible look, it’s also the better way to go in this application. That’s a win-win in our book.

Check out this story in our digital edition here.

Sources

Brodix

(479) 394-1075

brodix.com

–

Callies

(419) 435-2711

callies.com

–

Comp Cams

(800) 999-0853

compcams.com

–

Crower

(619) 661-6477

crower.com

–

Holley

(866) 464-6553

holley.com

–

JE Pistons

(714) 898-9763

jepistons.com

–

Jesel Valvetrain

(732) 901-1800

jesel.com

–

Kinsler Fuel Injection

(248) 362-1145

kinsler.com

–

Manley Performance

(732) 905-3366

manleyperformance.com

–

Moroso Performance Products

(203) 453-6571

moroso.com

–

Prestige Motorsports

(704) 782-7170

prestigemoto.com

–

Race Car Replicas

(586) 329-1573

race-car-replicas.com