By Ron Ceridono – Images by the Author

When it comes to tricking out a truck, two common objectives are reducing ride height and improving road manners. At one time those goals were often mutually exclusive. Dropping a truck made it look cool but the lowered stance, often done with heated springs, lowering blocks, and other crude methods, could also reduce suspension travel, resulting in a rough ride and unpredictable handling. It was the price to be paid for looking cool. But today, with suspension components from Detroit Speed & Engineering (DSE), you can have it all; 1967-87 Chevy and GMC pickups can be lowered substantially and have vastly improved ride and handling characteristics.

In the Feb. ’25 issue of Classic Truck Performance we looked at DSE’s Speed Kit and SpeedMAX front suspension kits. This time we’re checking out their QuadraLink rear suspension systems.

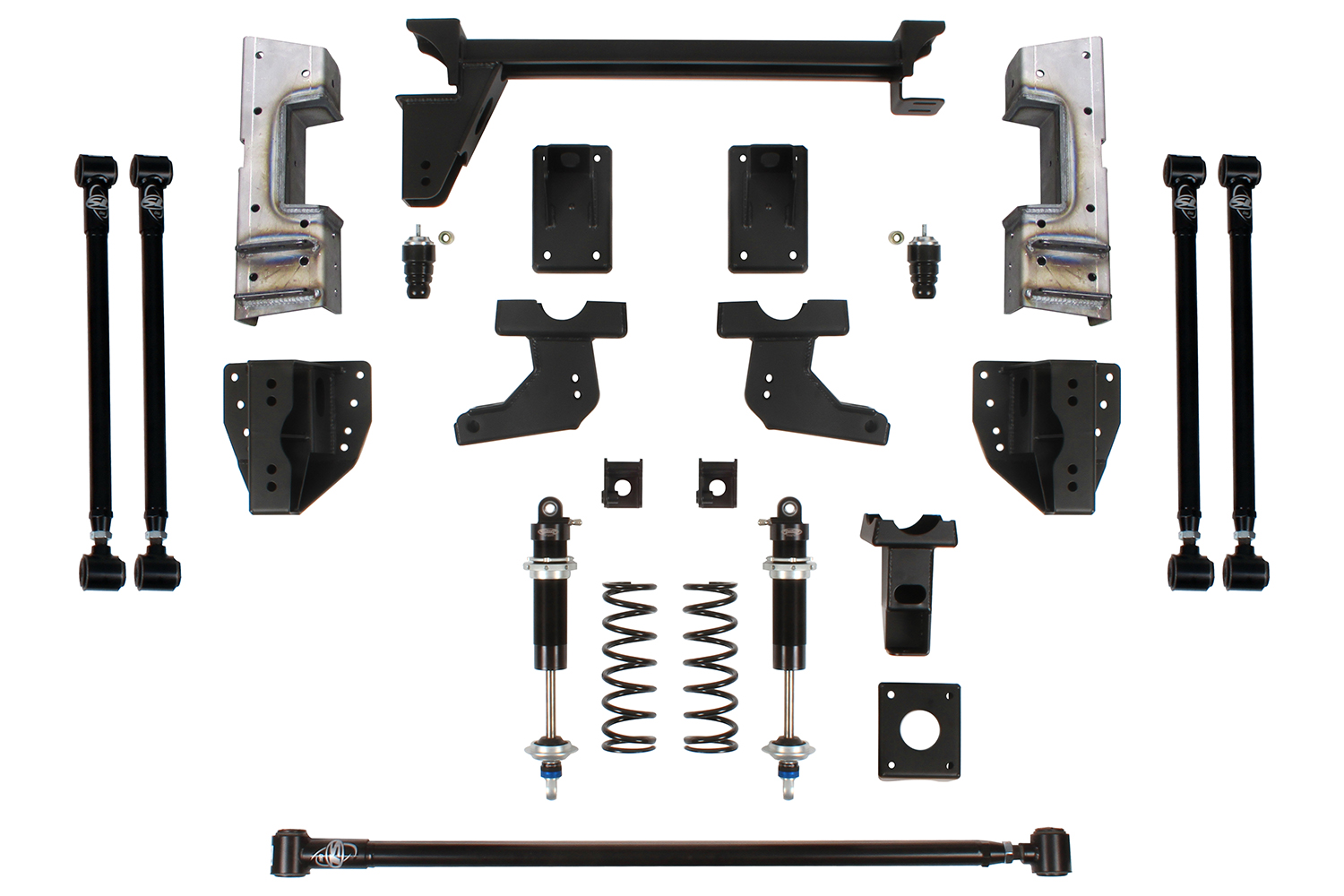

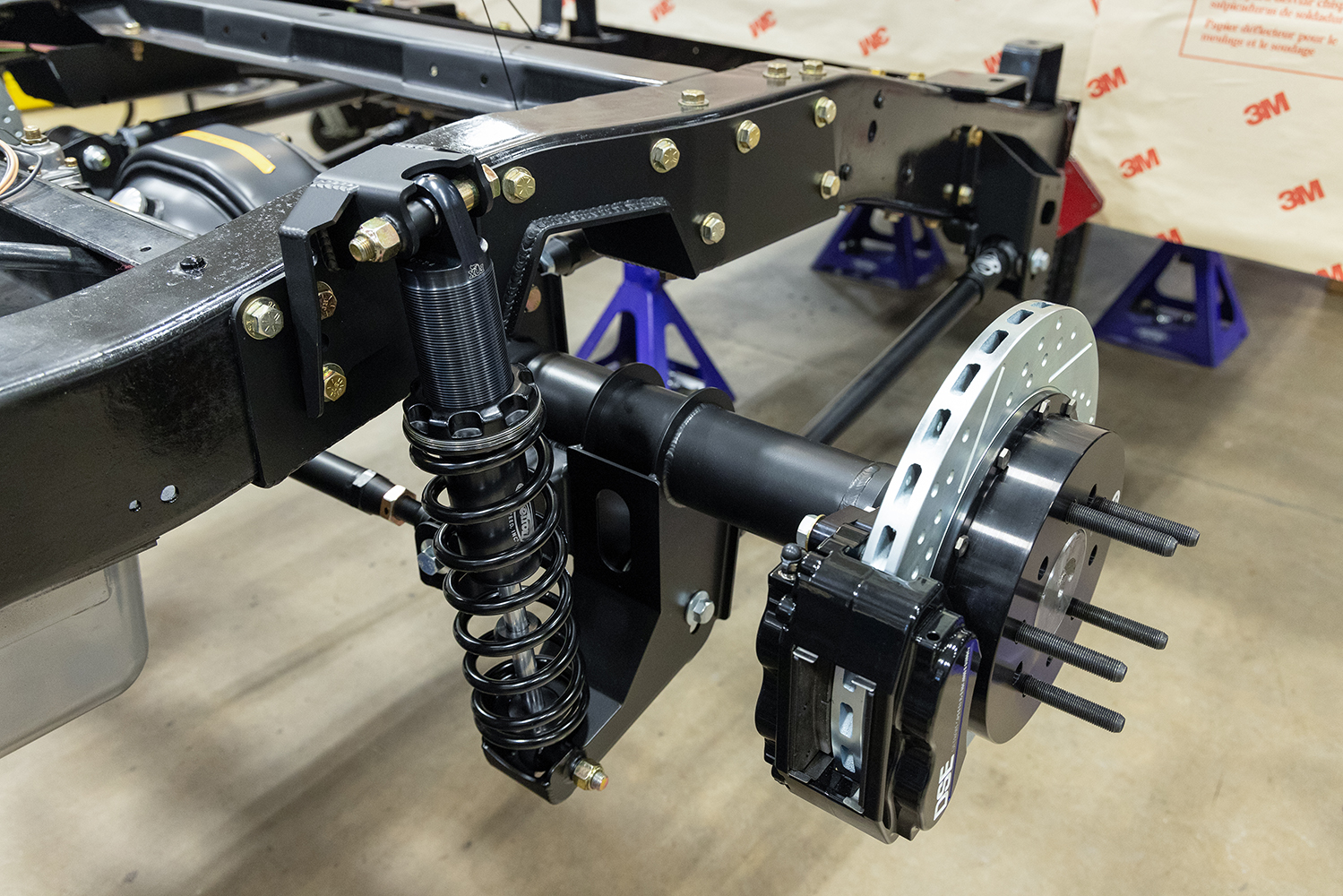

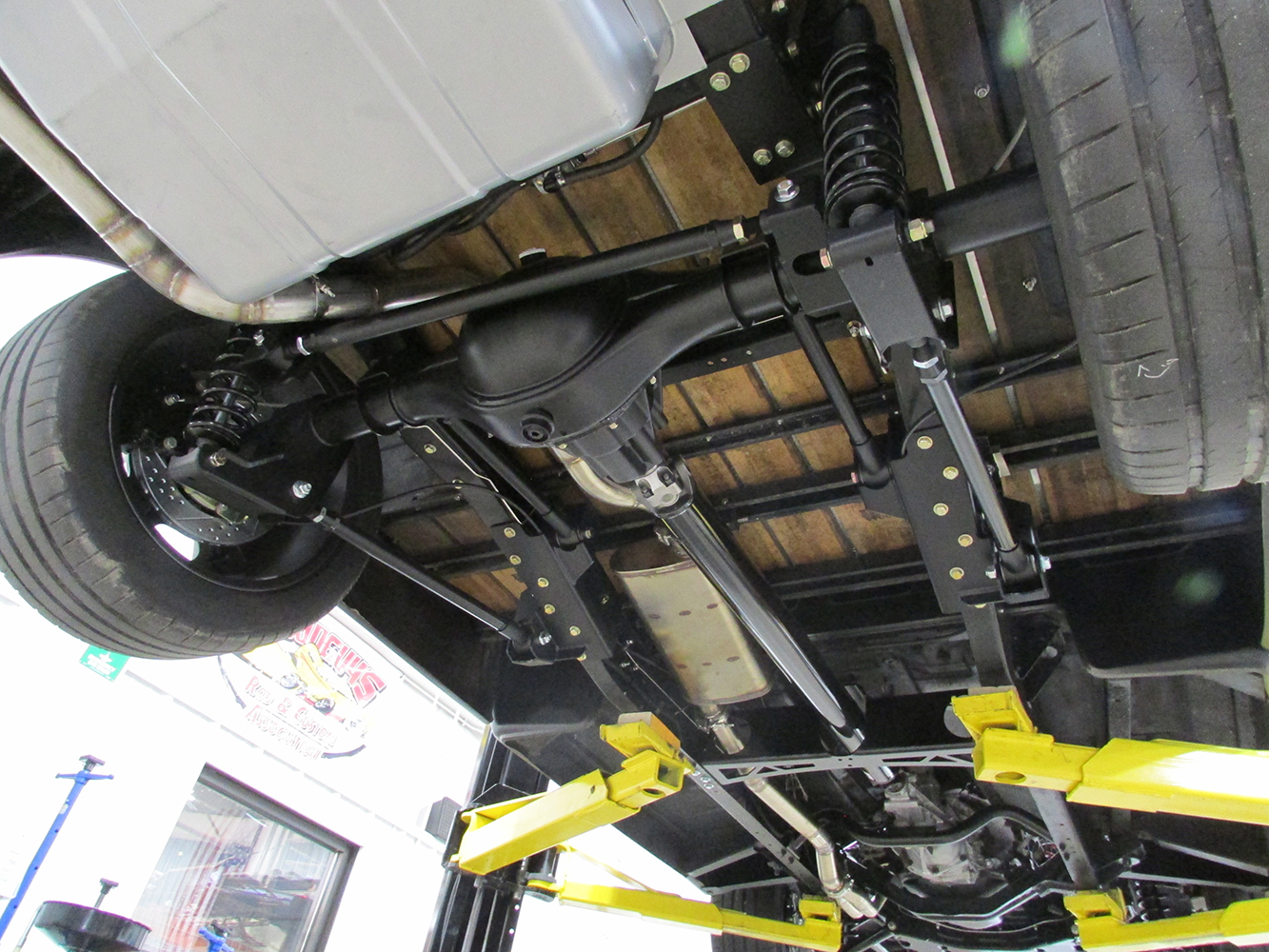

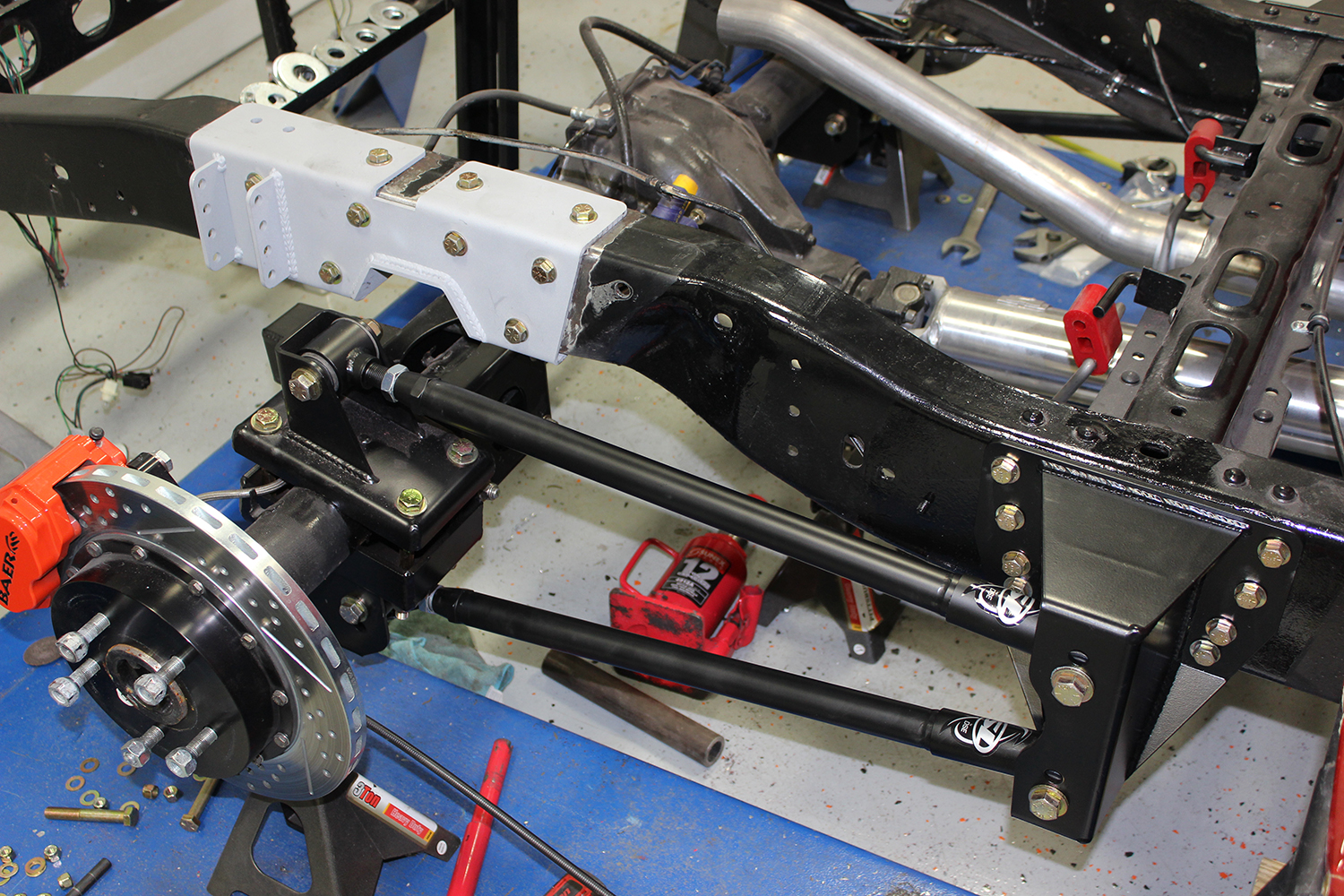

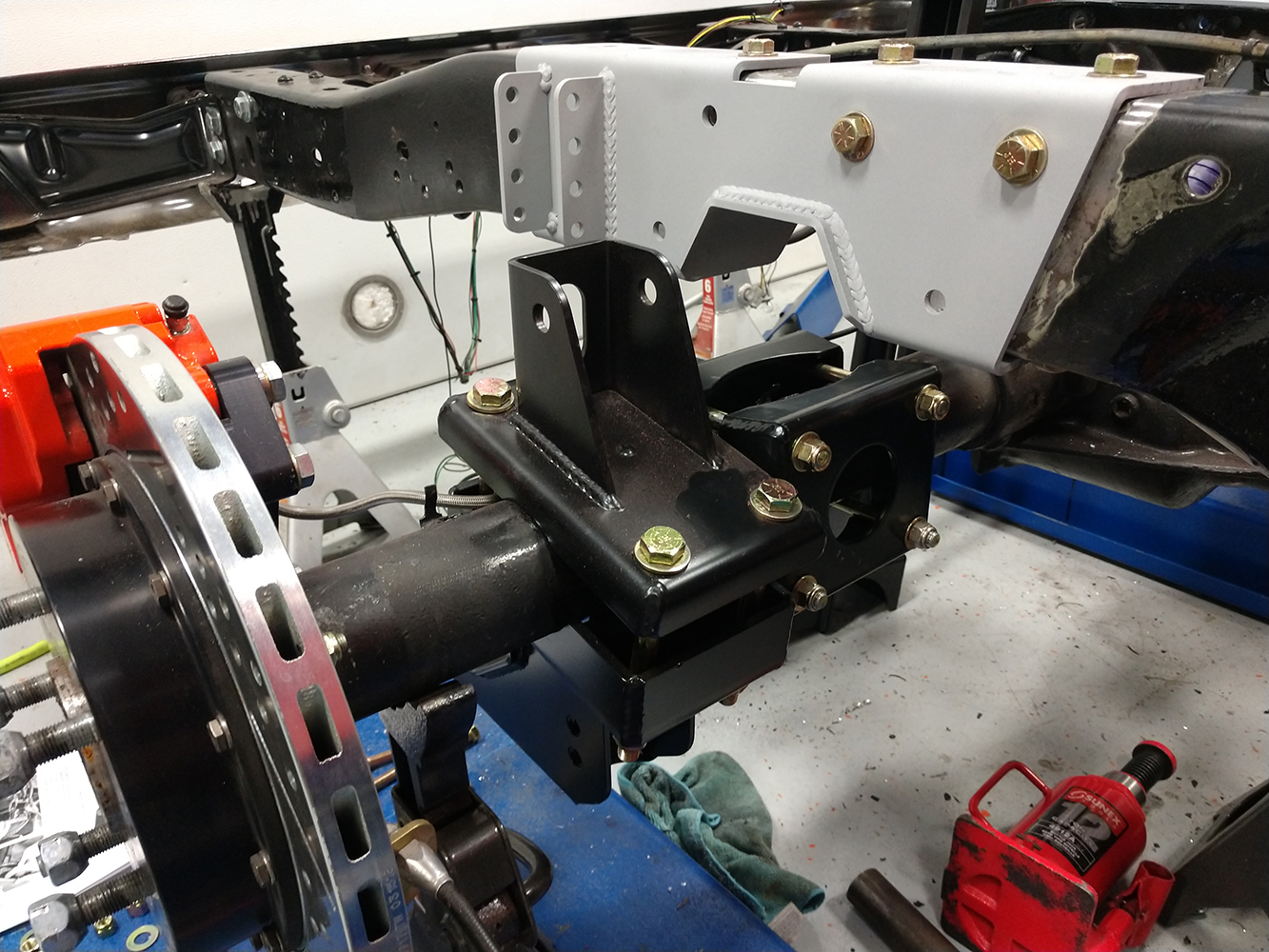

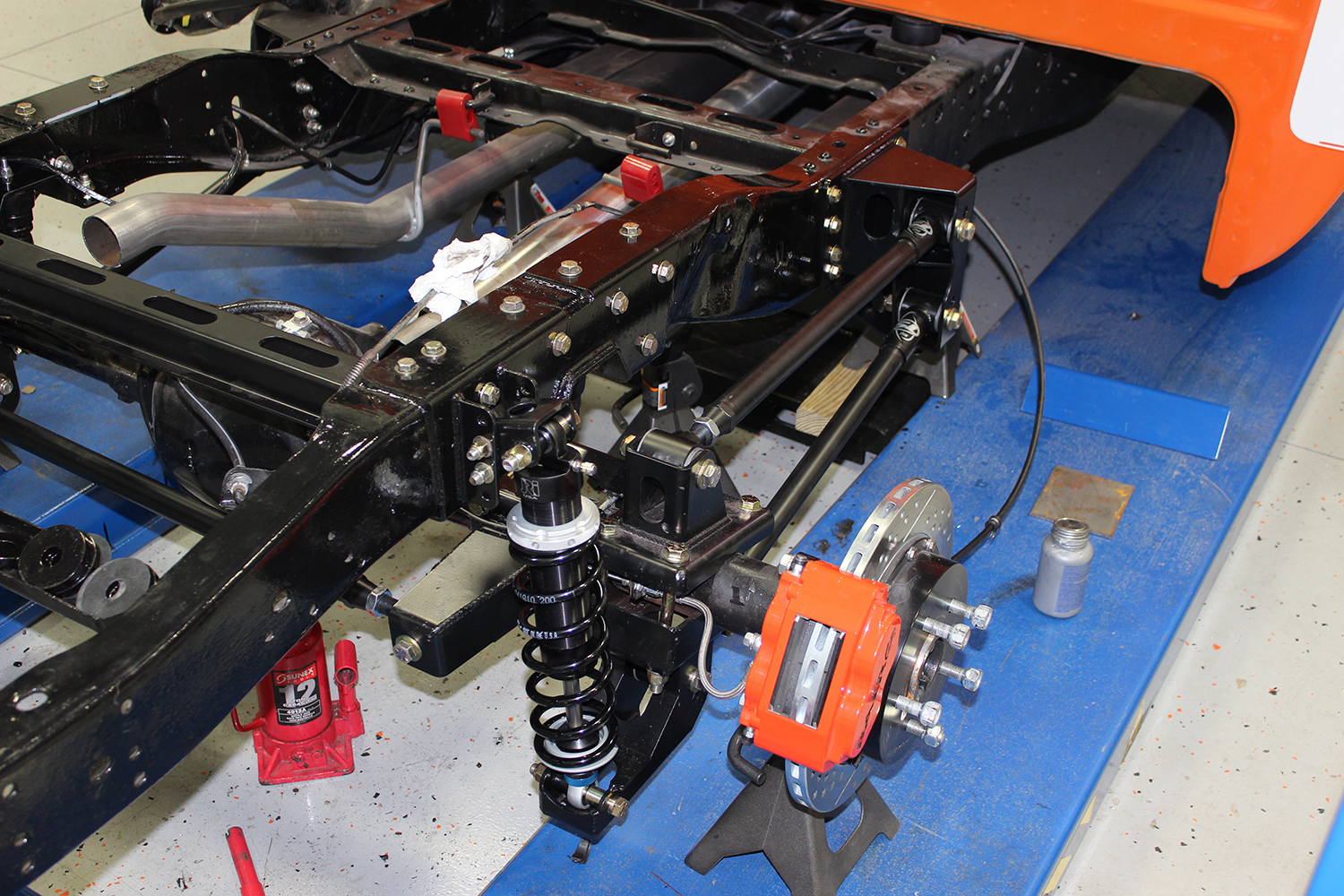

DSE’s GM Quadralink comes in two basic configurations, one for 1967-72 trucks, the other for 1973-87s. While there are differences in the two kits, both use DSE’s exclusive four-link geometry to provide the best ride and handling possible. In the case of the “early” kit the four-links are staggered with the top links inside the framerails while the lower links are on the outside. The “late” kit has all four links outside the framerails. In both cases, the locating links feature patented “Swivellink” technology in combination with tuned high-durometer rubber bushings to allow the suspension to fully articulate smoothly and silently.

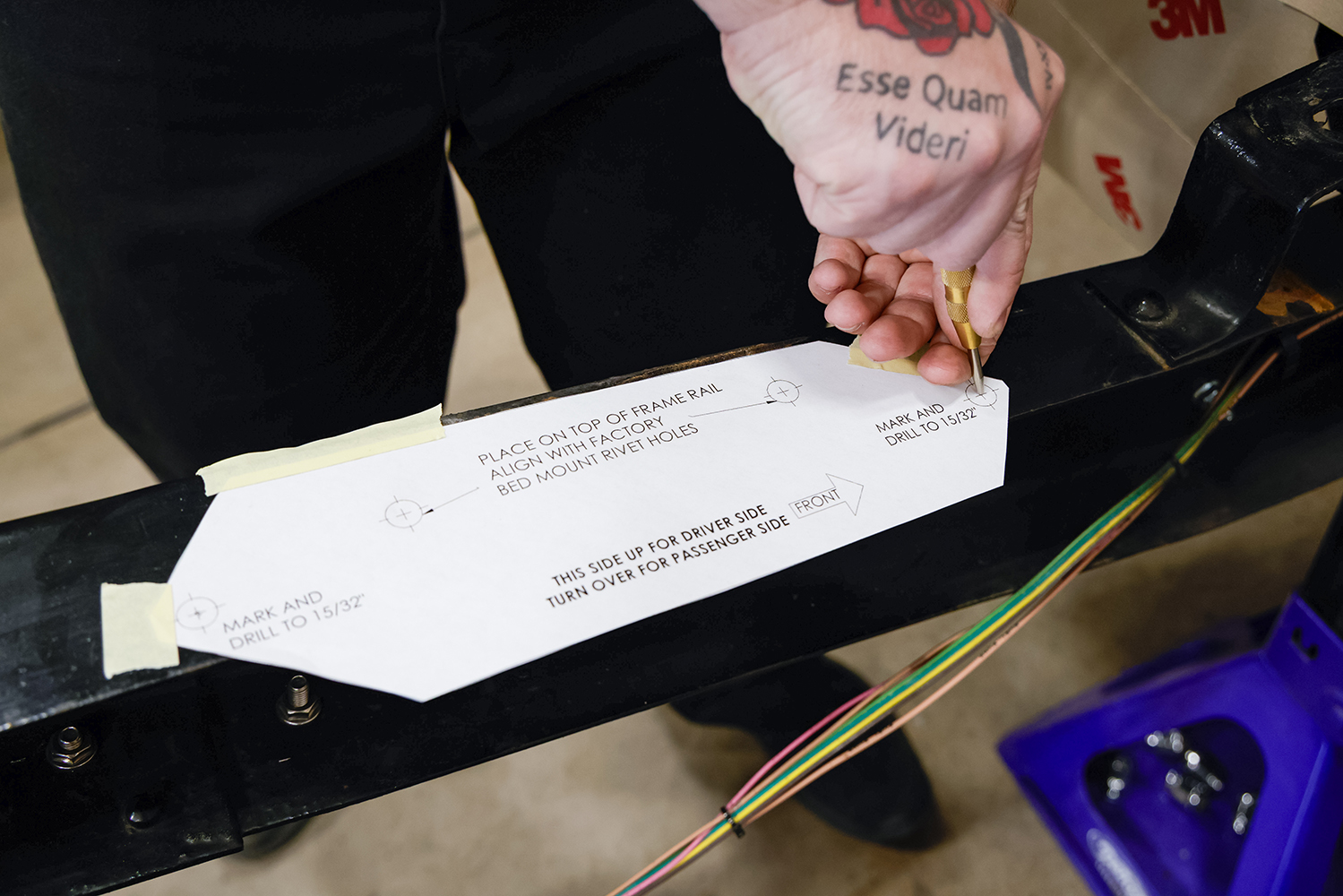

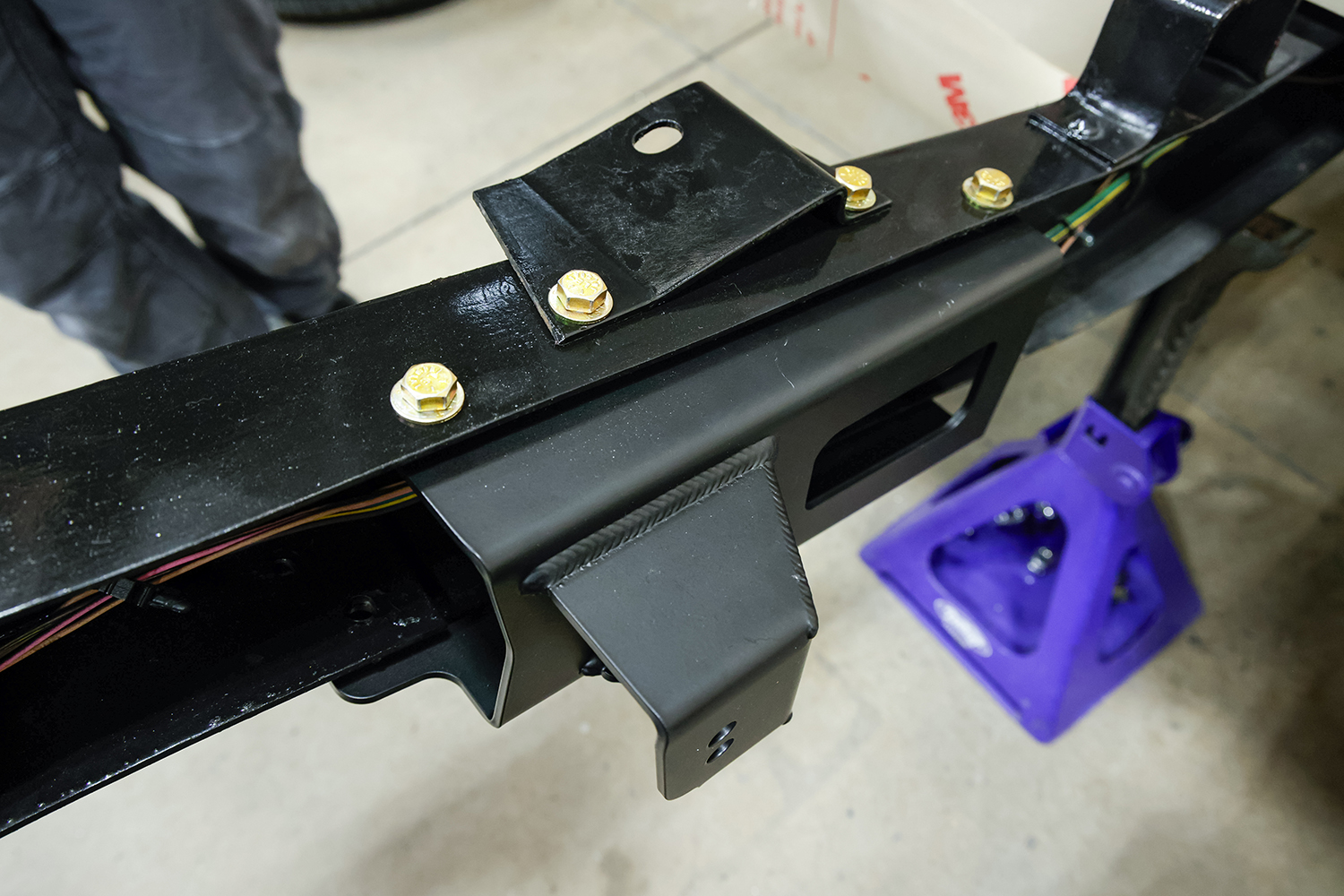

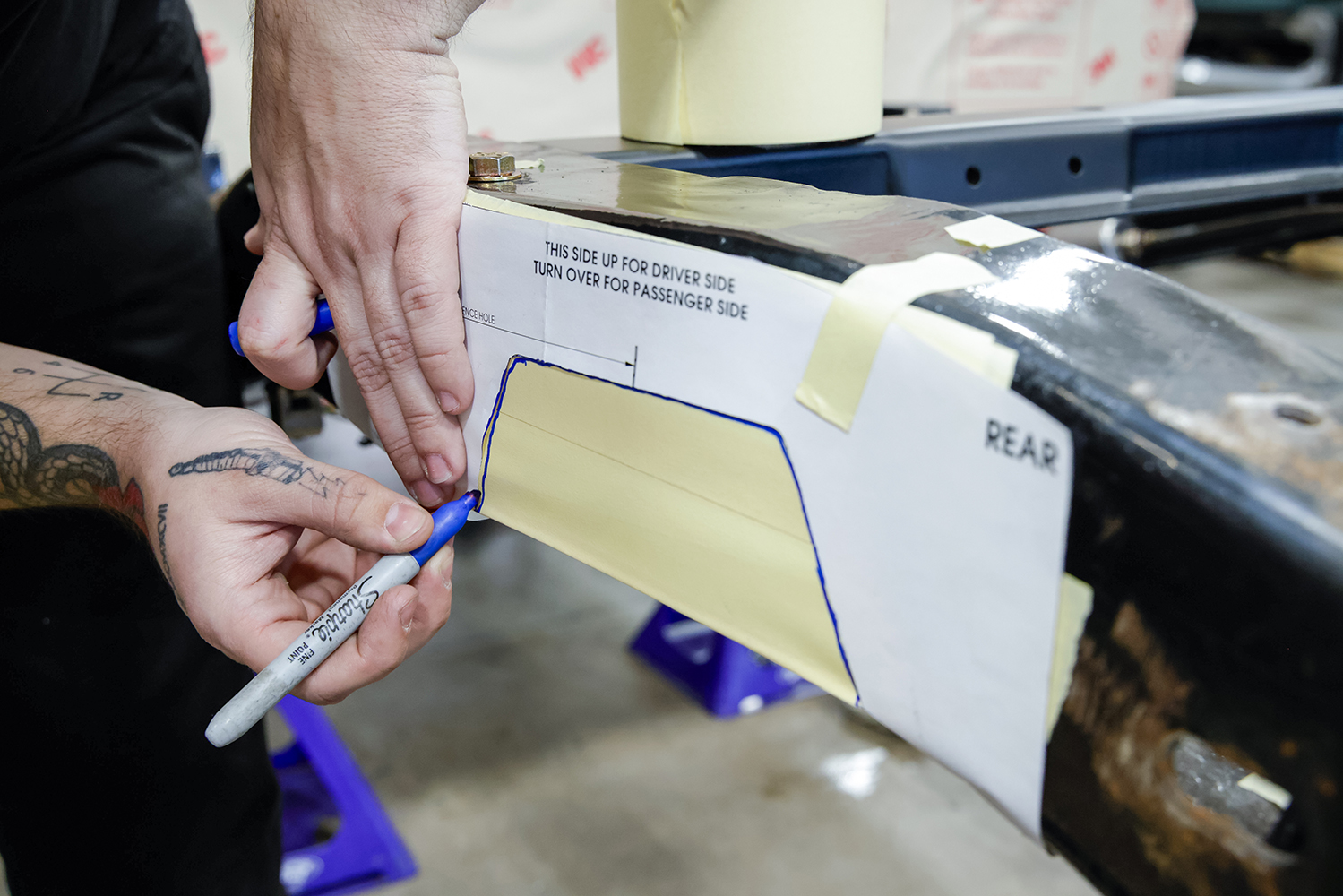

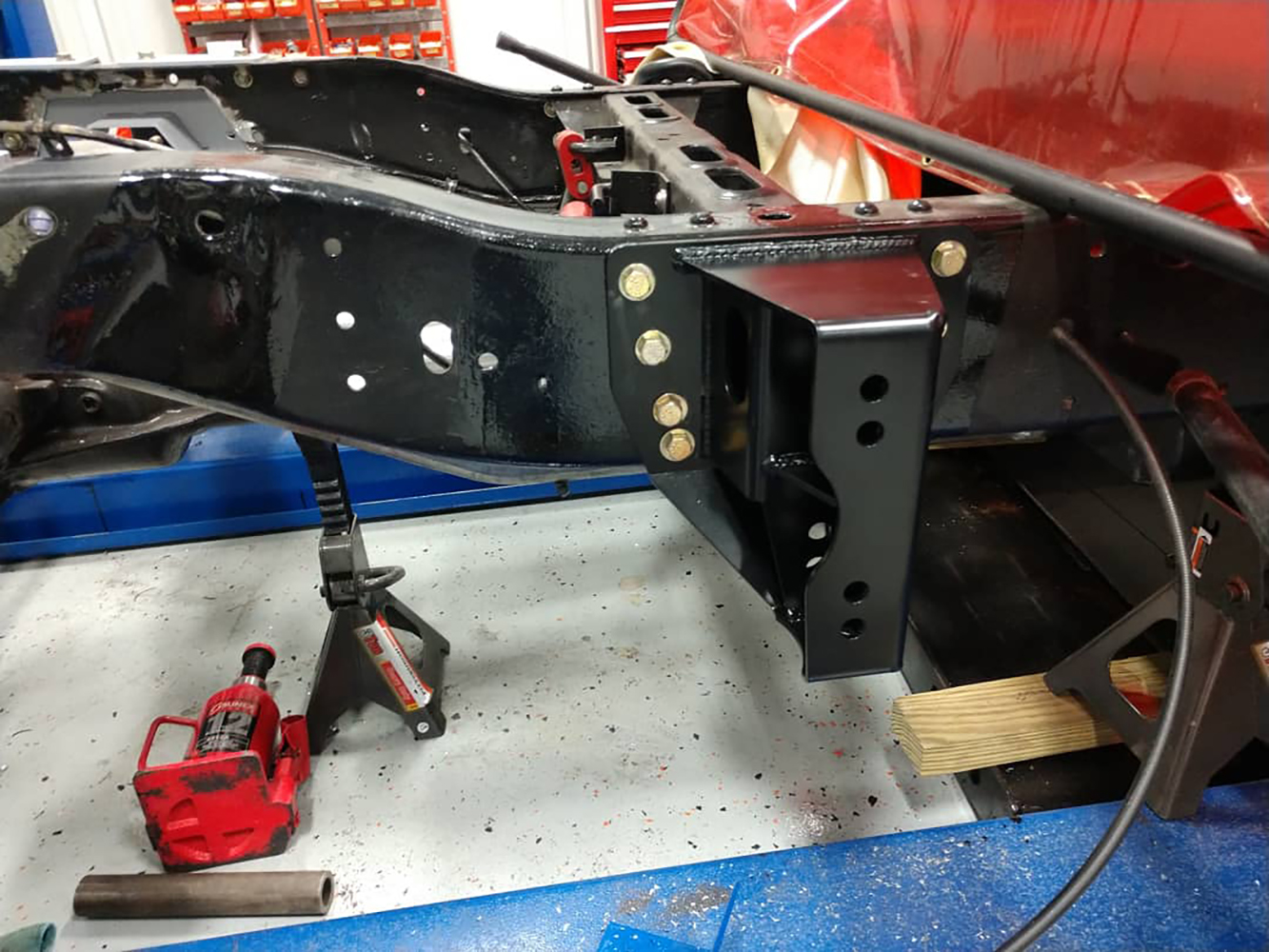

Both the early and late QuadraLink kits feature a horizontal track bar that provides precise and effective rear axle lateral location, although the mounts differ; in both kits the track bar is adjustable to provide the optimum roll center control at various ride heights. These kits also include specific frame notching/reinforcement plates, coilover and track bar mounts, four-link attachment brackets, and all the necessary installation hardware. Once the original rear suspension components are removed, the DSE brackets are bolted in place with only a few additional holes to be drilled.

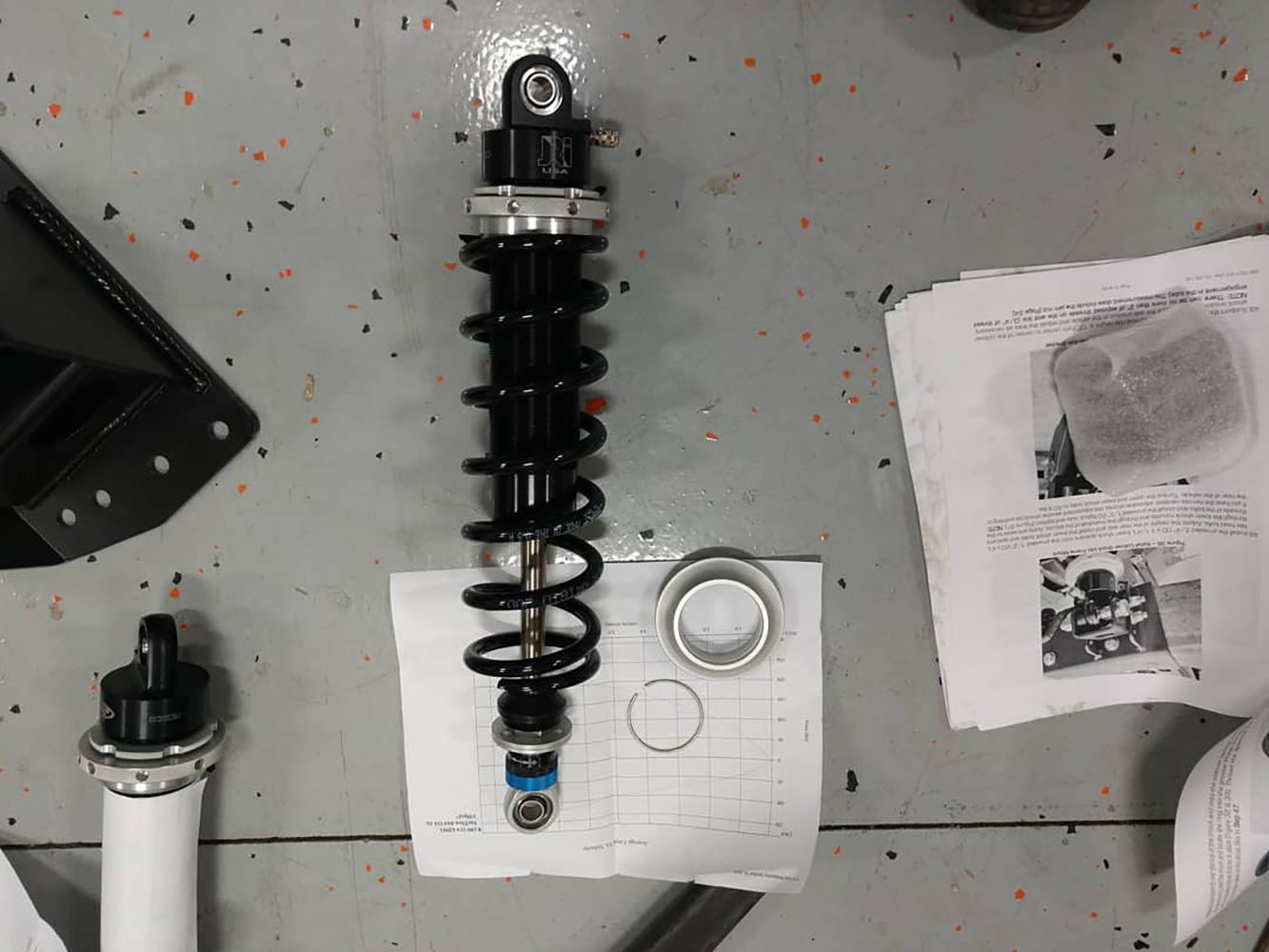

Along with the 1967-72 and 1973-87 QuadraLink frame modification components, DSE offers both bolt-on and weld-on brackets for original GM axle housings, as well as new 9-inch and FN988 axle housings with the brackets welded in place. In addition, there are several coilover options: for 1967-72 applications, non-, single-, or double-adjustable shocks are available; for 1973-87 applications, non-, single-, or remote-canister double–adjustable shocks are available.

There’s nothing cooler looking than a lowered 1967-87 General Motors pickup, be it a Chevy or GMC. What makes these trucks even cooler is when something that was once considered a utility vehicle can carve corners like a performance car. To that end DSE’s suspension components are designed and manufactured to infuse these classic trucks with contemporary technology—and nothing is cooler than that.

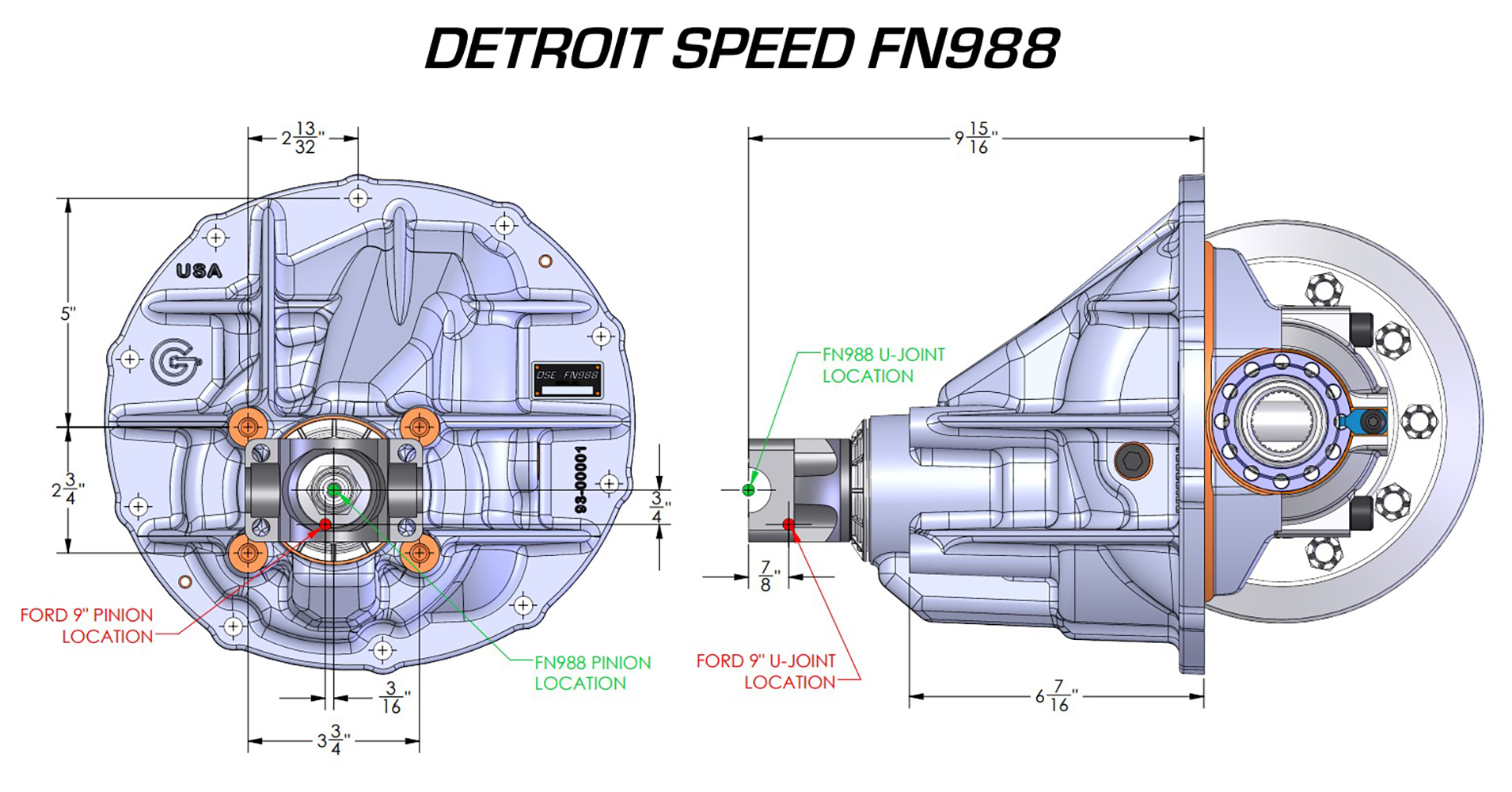

FN988: The DSE Alternative to the 9-inch Ford Rearend

Since its introduction in 1957, Ford’s 9-inch rearend has been the go-to axle assembly for high-performance applications. Produced from 1957-86, the Ford 9-inch is Hotchkiss style, which is the case containing the ring-and-pinion assembly is removable as a unit, making gear changes relatively simple. Of course the real reason for the popularity of the Ford 9-inch is its strength, primarily the result of the relationship of the ring-and-pinion gears. To provide increased tooth contact, the hypoid distance, which is the offset between the ring gear and pinion centerlines, is greater than that found in most rearends. While this greater tooth contact does increase strength, a certain amount of efficiency is lost due to increased friction and gear noise increases noticeably (often referred to as nine-whine).

To replace the venerable 9-inch rearend, Ford introduced the 8.8 axle assembly in 1983 under Ford trucks and most V-8–equipped cars from 1986 on. These rearends are the Salisbury design, which have the third member components mounted in the axle housing with a removeable rear cover on the back side. This style of rearend makes gear changes much more involved, compared to a Hotchkiss. Another difference between the 9-inch and 8.8 is the method of retaining the axles. The 9-inch uses pressed-on bearings and lock rings on the axles, which are held in the housing with retainers bolted to the flanges on the axle tubes. By comparison the Ford 8.8 axles are held in the housing by C-clips inside the differential case. That means a broken axle, along with the wheel and tire, can come completely off the car (there are C-clip eliminator kits that resolve that problem, and rear disc brakes act as retainers, to some extent).

DSE’s hybrid FN988 uses a 9-inch-style Hotchkiss carrier with 8.8 gears, which makes setting up the ring-and-pinion considerably easier than the Salisbury design and makes swapping gearsets easier. In addition, the C-clips are eliminated as the axles are retained the same way as a 9-inch. Thanks to reduced internal friction, the FN988 is more efficient than the 9-inch, which arguably may offer a performance and mileage increase along with a significant reduction in gear noise.

Check out this story in our digital edition here.

Source

Detroit Speed & Engineering

(704) 662-3272

detroitspeed.com