Heidts IFS for ’50s Ford F-100s

By Ron Ceridono – Photography by the Author

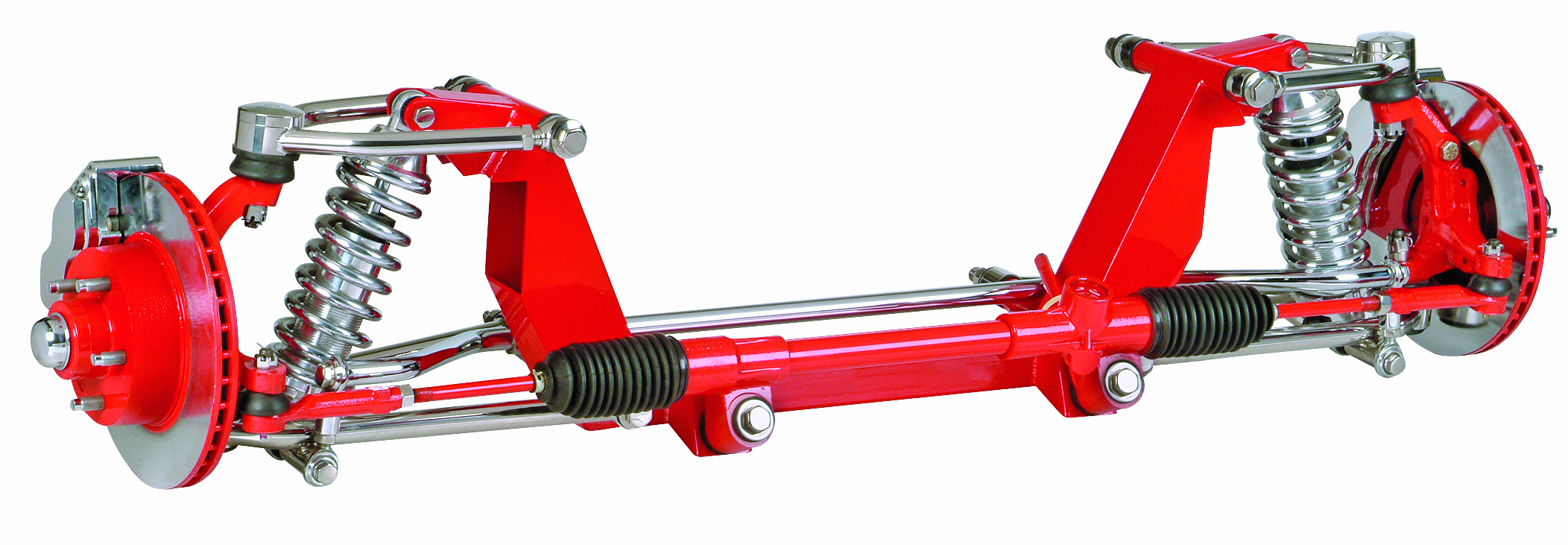

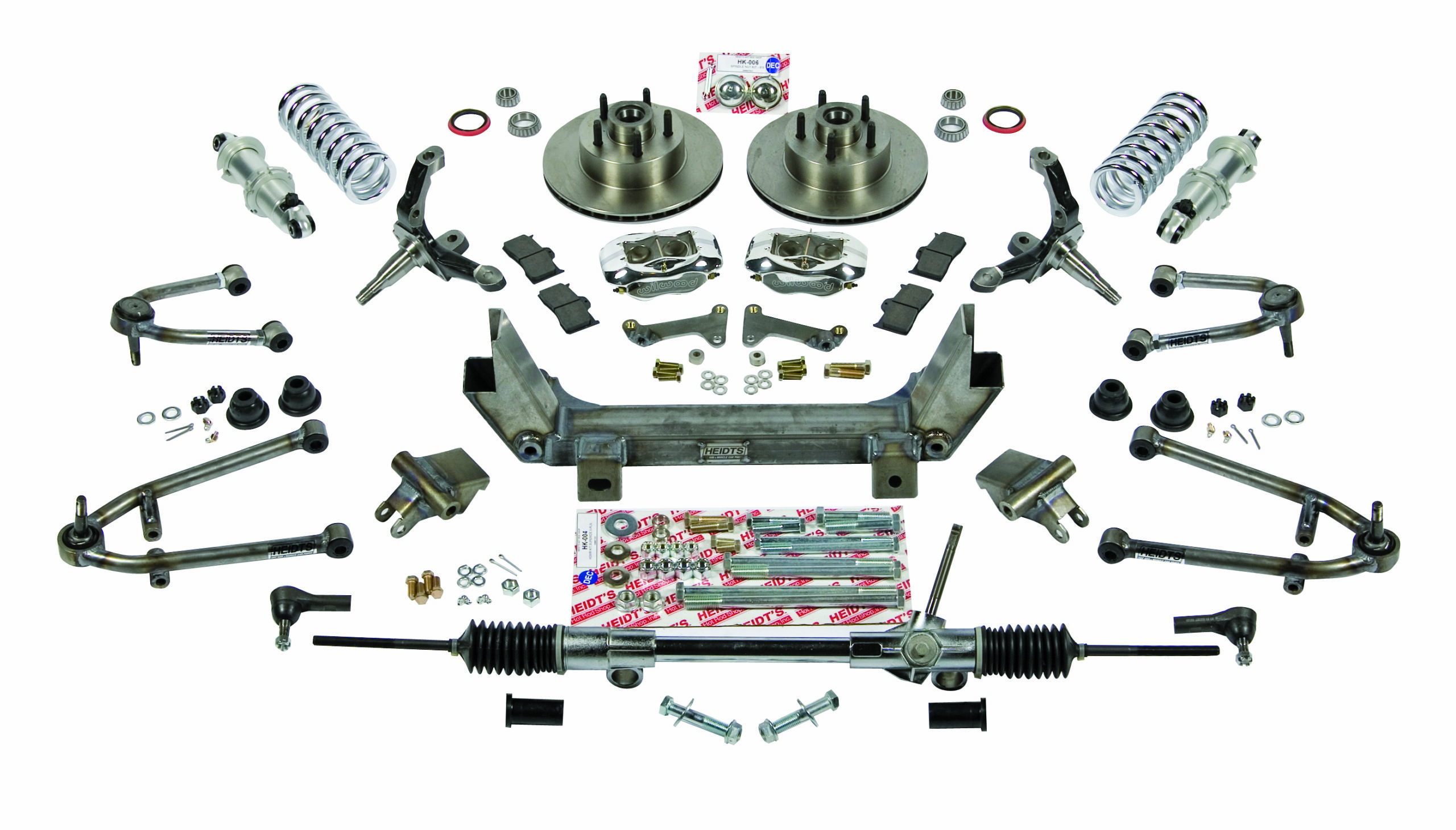

Of all the products that have been offered to improve the overall performance of hot rods and classic trucks, arguably, Mustang II–based independent front suspension kits have to be high up on the list. Simple, affordable, and effective, these suspension packages make it easy to transform a rough-riding, solid-axle truck into a smooth-riding, better-handling version of itself. In addition to the advantages IFS offers compared to a solid front axle, there are a few other perks, such as the modern disc brakes and rack-and-pinion steering, that are also part of the package. The suspension swap shown here was done on a 1955 Ford F-100, but the procedure is virtually the same for any solid-axle pickup. We chose a Heidts PX-105-E-K IFS kit that uses coil springs, power rack-and-pinion steering, and disc brakes.

One of the best known names in the suspension business today is Heidts, but like many of the giants in the aftermarket industry the company had a modest beginning. Gary Heidt started manufacturing parts in a 700-square-foot garage in 1985. How things have changed. Today Heidts occupies a 50,000-square-foot facility full of state-of-the-art equipment with production capacity that allows them to ship most orders within 24 hours.

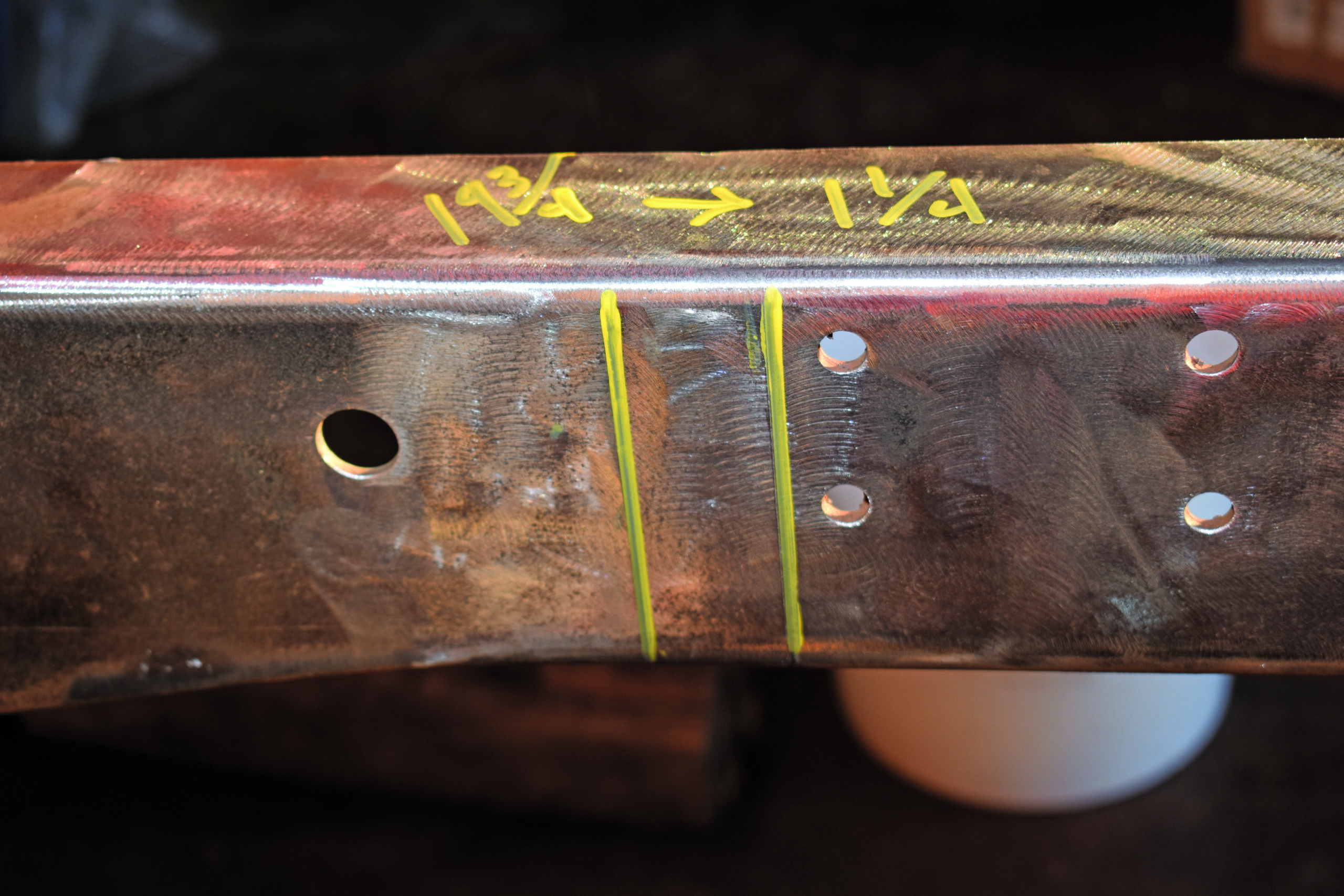

With the stock steering and suspension removed, the first steps in our truck’s transformation were to place it on jackstands and then level it side-to-side with the front of the frame slightly lower than the rear (approximately a 2 1/2-degree rake). Following Heidts’ instructions we measured back from the center of the front shackle holes 19 3/4 inches and made a mark (check the photos for a little trick to make this easier). This would be the center line of the front wheels and crossmember.

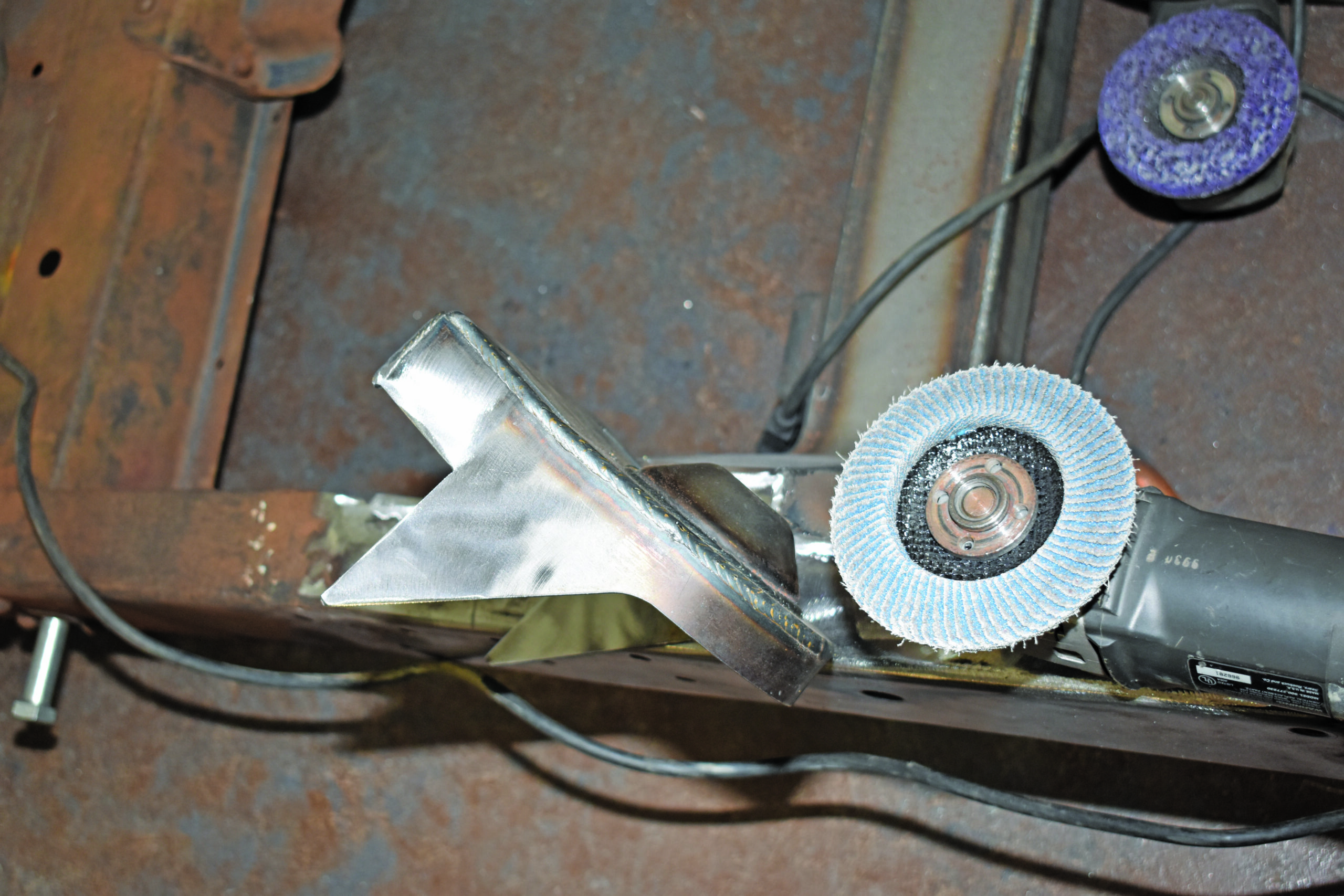

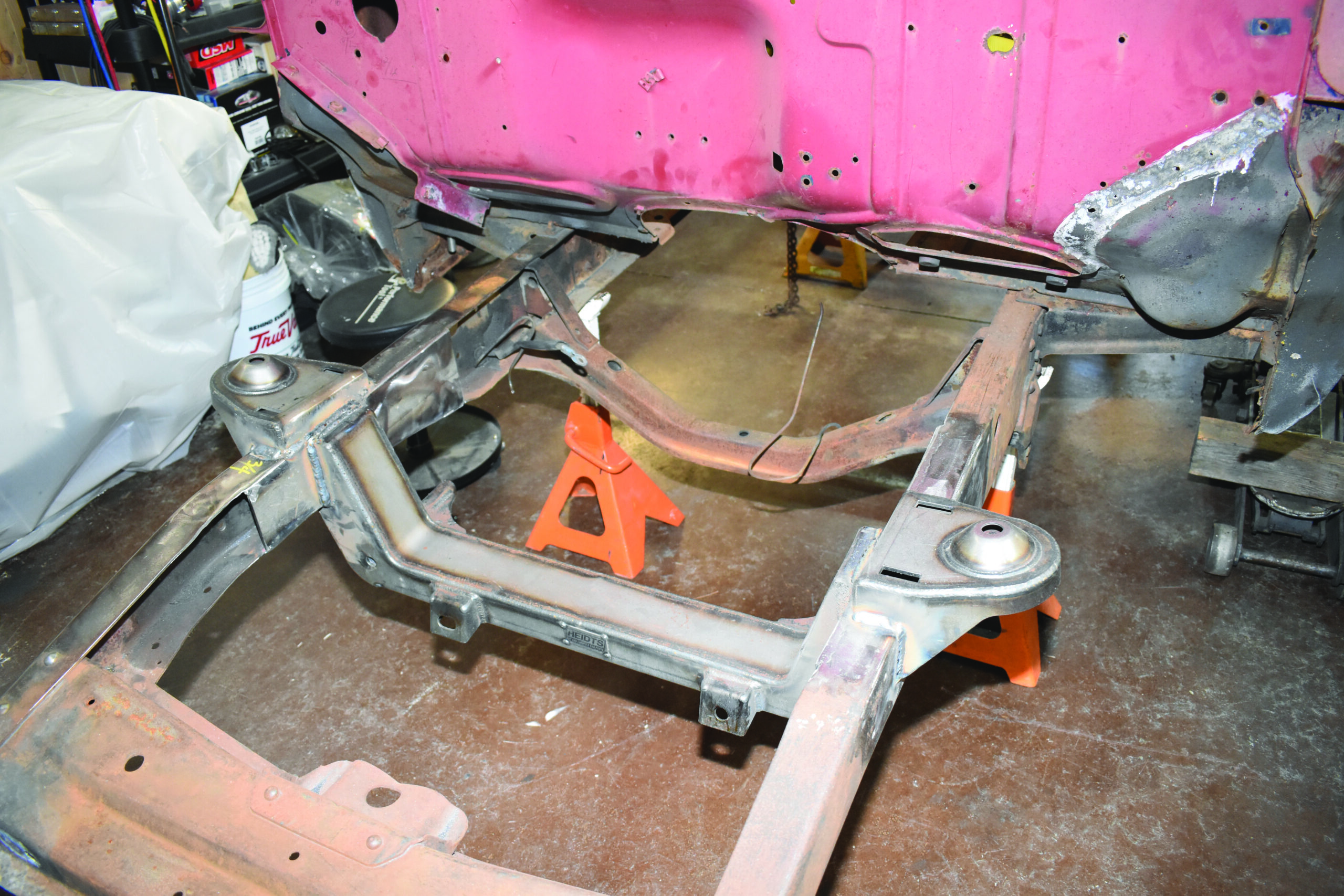

While Heidts’ location of the front crossmember puts the wheels in the original location, 1953-1956 Ford pickups have a slight peculiarity in this regard. In stock form the front wheels are slightly to the rear in the fender openings. Some sticklers for accuracy prefer them that way, however we elected to move the crossmember forward 1 1/4 inches to move the tires closer to the front of the fenderwell. With the crossmember located and centered side to side it was welded in place. The next step was the installation of the spring towers. Be aware there is a left and right—the built-in angle in the towers provides antidive geometry that keeps the nose of the truck from diving under braking.

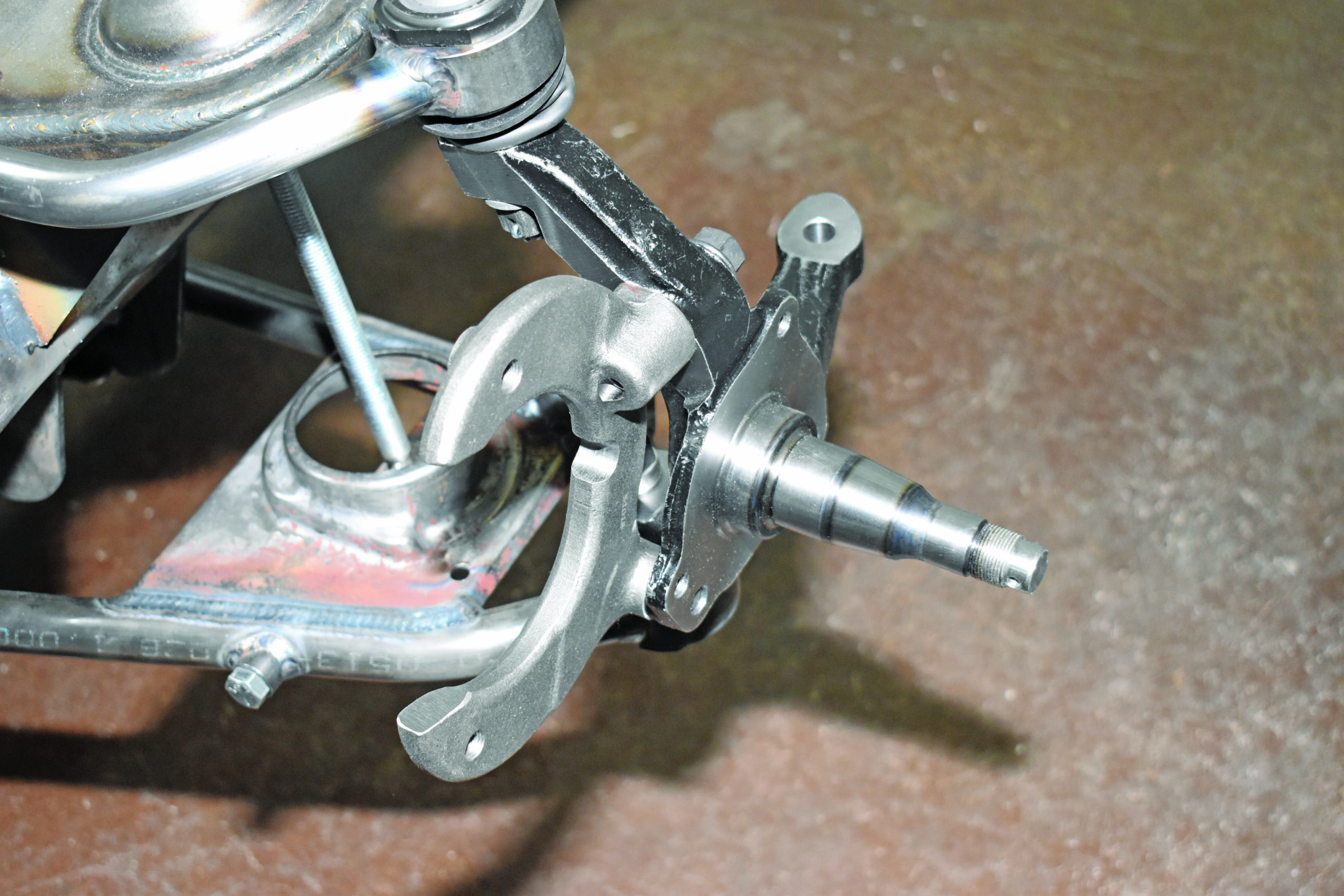

Installing the control arms and spindles is straight forward but in our case we elected not to install the coil springs and shocks just yet. As the engine and transmission have yet to be installed, the coil springs would not only be difficult to compress due to the lack of weight on them but the shocks could possibly be damaged by prolonged overextension (especially bouncing up and down on a trailer on its way home). To hold the suspension at the proper ride height we fabricated a pair of struts from threaded rod and tubing.

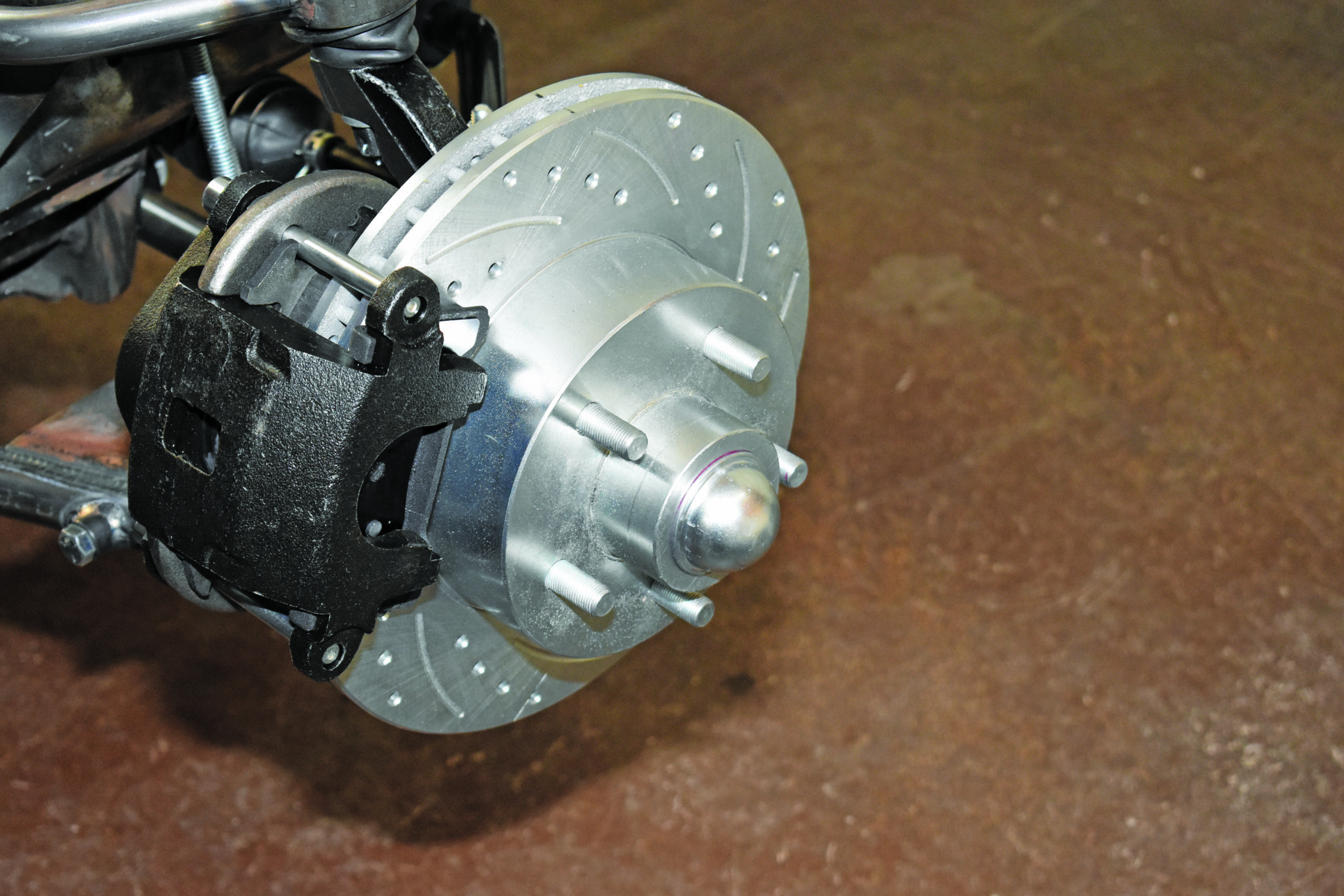

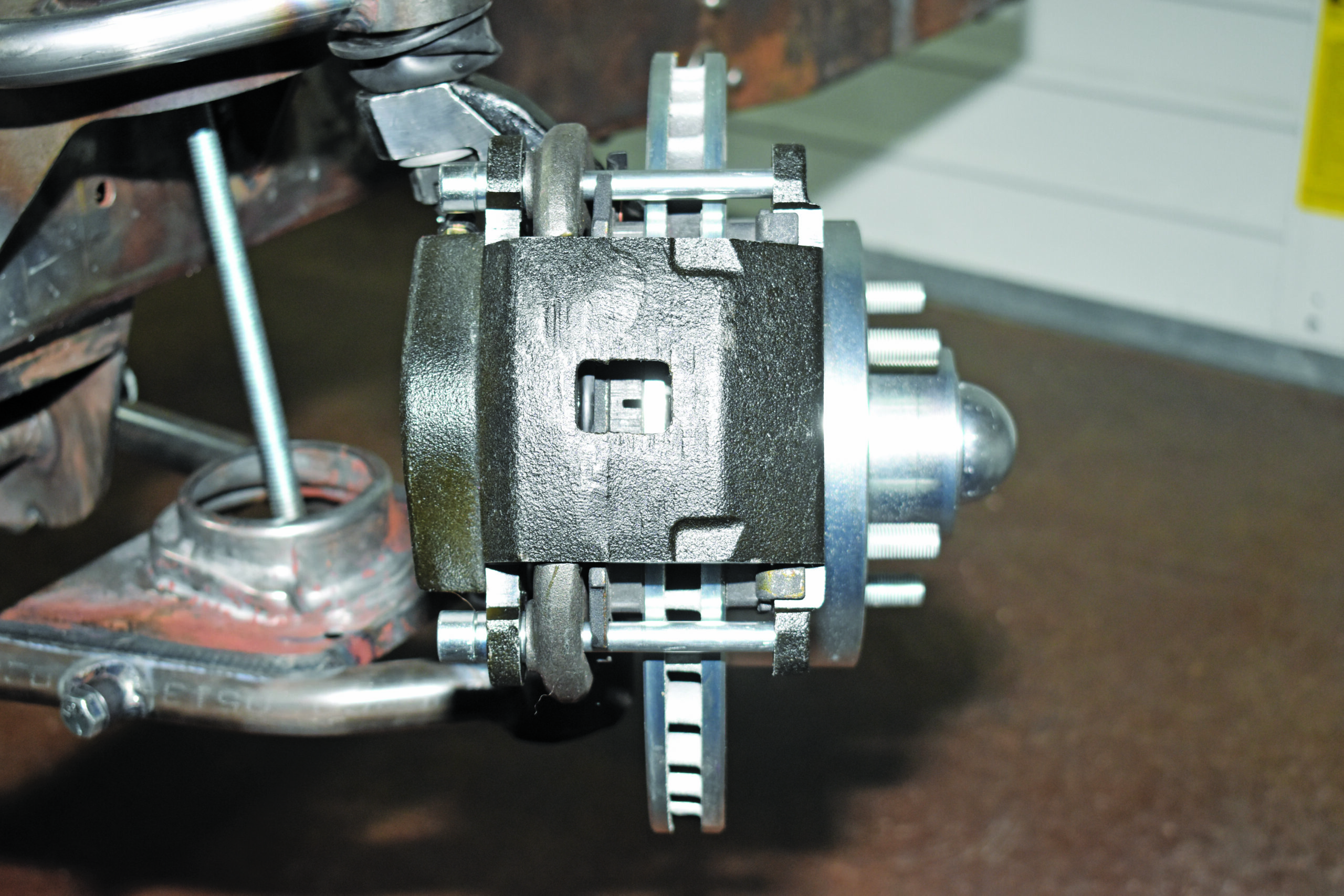

If the Mustang II front suspension had a shortcoming it was the 9 1/4-inch-diameter brake rotors and small-bore calipers. For beefier brakes we can count on, we used 11-inch drilled-and-slotted rotors, GM calipers, and custom brackets to attach them to the Mustang II–style spindle. One last step in our IFS installation was the addition of 2-inch extensions on each side of the steering rack, as F-100s have a 4-inch-wider track than a Mustang II.

With the new suspension system in place, the first trip the truck will make under its own power will be to an alignment shop. Alignment specifications are: caster 1 degree positive, camber 1/2 degree positive, toe 1/8 plus or minus. Then it will be time to forget the buggy suspension and enjoy all the benefits an IFS with disc brakes and power rack-and-pinion steering have to offer.

Sources:

Heidts Hot Rod & Muscle Car Parts

(800) 841-8188

www.heidts.com

Speedway Motors

(800) 979-0122

www.speedwaymotors.com