We Test to See How Much Power You Can Make Simply by Creating a Vacuum in an Engine’s Crankcase

By Jeff Huneycutt – Photography by the Author

If you are familiar with NASCAR Cup engines, then you are likely aware that they have used their solid-gold R&D budgets to develop dry-sump oiling systems that use a multi-stage pump to do more than just move motor oil around. The engines are actually sealed tight, and the external oil pump also scavenges air along with oil to effectively pull a vacuum inside the crankcase.

Obviously they are doing that because it helps create horsepower. But the Cup system also comes with a lot of complexity and maintenance, and for hobby-level racers dry-sump oiling systems aren’t usually legal. The good news, however, is there is an option for those of us with cubic zirconia budgets that can get us close to the same result.

As an engine is running, some of the combustion gases will sneak past the rings and create pressure in the crankcase, which is called blow-by. Smart drag racers for years have used vacuum pumps to help gain a few extra horsepower at the track by pumping that buildup of gas pressure back out of the crankcase. If you run a common wet-sump oiling system, there is no way to use the internal oil pump to pull a vacuum like the Cup guys.

Too much crankcase pressure from blow-by can cause a multitude of small problems. Not the least of which is ring flutter, which kills power. Extra pressure inside the crankcase also pushes back against the bottom of the piston on the power stroke. The increase in pressure may be small compared to the incredibly high cylinder pressures created by burning air and fuel in the combustion chambers, but every little bit hurts.

You can mitigate much of the effects of blow-by simply by installing a vent in the valve covers. This is standard practice in practically all engines. In street engines it’s the PCV (Positive Crankcase Ventilation) valve, which routes the air back into the intake stream to be burned. In race engines the PCV valve is usually replaced with a simple breather.

But engine builders have found that power can be improved further by actively pulling vacuum in the crankcase with a vacuum pump. By creating negative pressure inside the crankcase (compared to atmospheric pressure), the chances for ring flutter are further reduced, the pressure differential between the top of the piston and the bottom on the power stroke is increased, and even oil foaming is reduced because there is no air to create bubbles in the oil as it gets whipped up by the spinning crankshaft.

So the goal is to create a whole bunch of nothing in the crankcase to help the engine produce power as efficiently as possible. Sounds like fun, huh?

Manufacturers like Moroso have come up with pretty simple and efficient systems for vacuuming as much air out of the engine’s crankcase as possible without creating much of a drag on the engine itself.

Moroso vacuum pumps, as well as some from other performance manufacturers, have an advantage over OEM-style air pumps because they are designed expressly for high-rpm race engines and have a greater life expectancy. Race engines not only see higher rpm than a stock engine, but they often also have more corrosive oil/fuel mixtures pumped through them.

Moroso produces more vacuum pumps for performance applications than anyone, so we called up Thor Schroder, Moroso’s marketing and new product manager for some more info. He says they’ve tested vacuum pumps on all types of applications, from four-bangers to 900-plus cubic inch Pro Mod drag race engines, and they almost always see a power gain of between 2 and 4 percent.

We asked Schroeder exactly how much vacuum an engine needs, and his answer, as with most things when it comes to making horsepower, is “it depends.

“Ultimately, the engine will only make as much vacuum as its condition allows. Vacuum pumps are all consistent in how much air they can flow,” Schroeder says. “So the vacuum value will vary depending on the engine’s ability to seal, prevent blow-by, and the tune-up.

During our conversation, Schroeder also pointed out one phenomenon from using a vacuum pump that many don’t expect: It can actually lower your oil pressure.

But don’t worry, that’s not a fault. It can actually benefit the engine as well.

“Lower oil pressure (with a vacuum pump) is common based on the fact that the oil is being drawn out from between the bearing and journal of both the crankshaft mains and the connecting rods at a higher rate (because of the vacuum),” he explains. “Therefore, the oil pump sees less resistance, thus less pressure.

“But, the oil volume (through the engine and bearings) will increase, and this ultimately protects the components by drawing the heat away from (them). This creates the second issue of having more oil flow, particularly in the top half of the engine. With the vacuum pump pulling (vacuum) up through the middle of the engine, it causes the oil to slow down its return rate to the oil pan.

“We see racers have less oil pressure in the latter part of the run due to an insufficient amount of oil in the pan. In many cases, what would normally be an 8-quart system will now require 9.5 quarts to have a sufficient oil level for the entirety of the run—while still not creating a windage issue.”

That all sounds well and good, but what really matters is how much it helps an engine turn tire rubber into smoke. So we visited the shop of Automotive Specialists, as owner Keith Dorton was putting a small-block drag race engine on the dyno. It just happens to have a vacuum pump plumbed up, and he was willing to test the mouse motor on the dyno both with and without the pump to see the power difference.

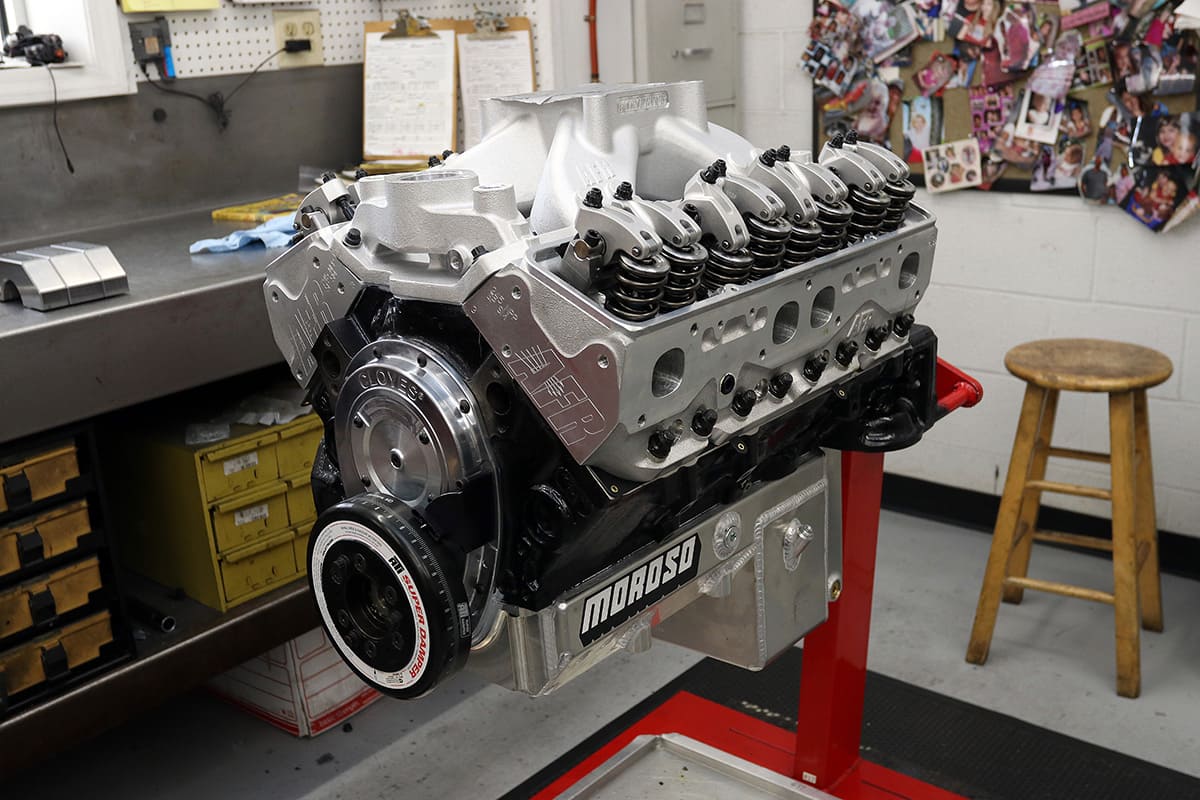

For a small-block, it has a pretty big displacement with a 4.165-inch bore and 4.00-inch stroke, creating 436 ci of displacement. It is outfitted with a Callies crankshaft, Howards Pro 1 connecting rods, Diamond pistons, and coated bearings for the rotating assembly. It is a wet-sump with a Moroso racing pan managing the oil control.

The cylinder heads are a pair of AFR cylinder heads with 2.125/1.600 valves, 70cc chambers, and 245cc intake runners. The compression ratio is 14:1 and it will be burning race fuel.

The cam is a solid roller from Comp Cams, but we won’t get into the specifics of the grind. Finally, air and fuel is supplied through a 950-cfm four-barrel carb from BRE, and the intake manifold is an AFR single-plane Eliminator, but it has been significantly modified by the folks at Automotive Specialists to adapt the airflow to their specs.

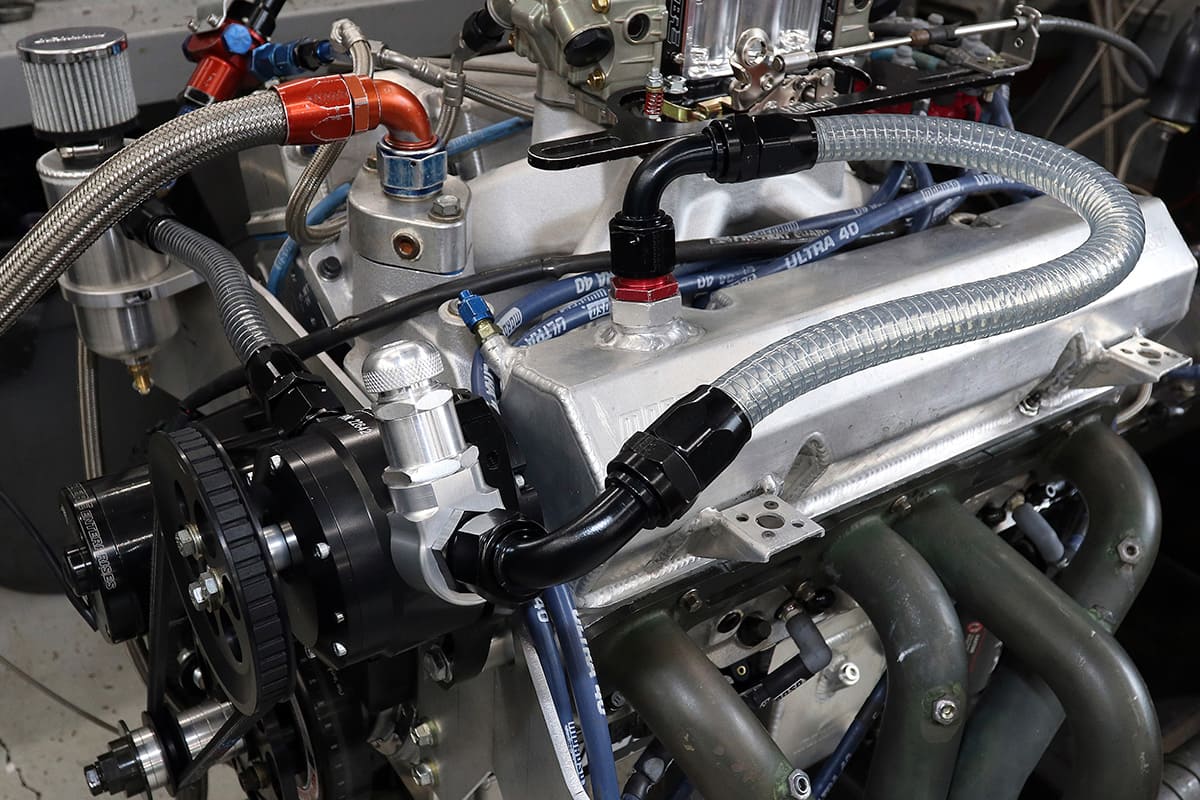

The vacuum pump is a Moroso unit (PN 22642), which is designed to be spun up to 8,000 rpm. There are also lower speed pumps designed for a max rpm of 6,500. Generally, the vacuum pump is run at half the rpm of the engine. Everything Dorton used to plumb up the unit came from Moroso, including a really cool pressure regulator.

By the way, if you noticed that aftermarket vacuum pumps are used almost exclusively on drag race motors; when it seems they could also be a benefit for street engines as well as circle track racing, there’s a reason for that. The pump works by spinning vanes inside of the housing. The vanes are designed to wear rather than damage the housing and they extend out by centrifugal force as the hub is spun. This way as they wear they can extend further out to maintain contact with the housing to create an effective seal. But this means they are usually good for 300 passes before Moroso recommends a rebuild (which the racer can do). This is fine for a drag racing engine that won’t see many laps over a weekend, but for a street or circle track race engine that’s usually a little too short of a lifespan.

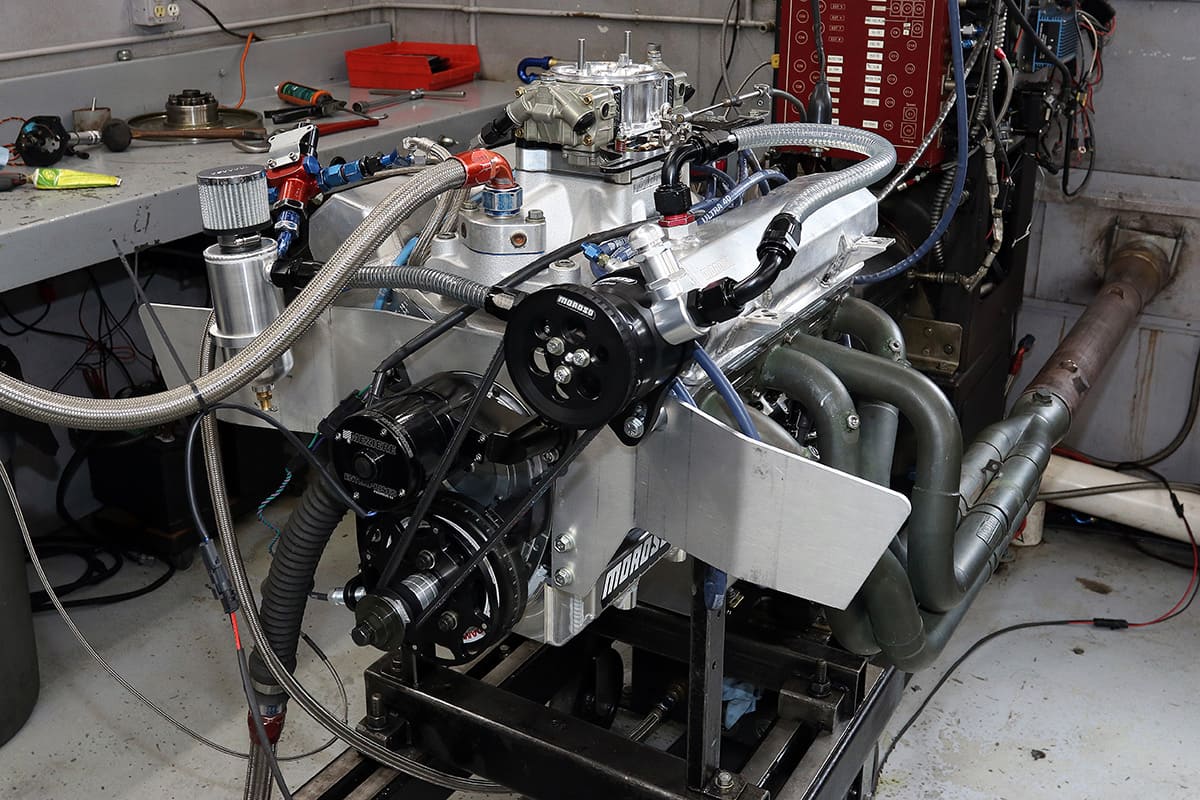

On the engine the vacuum pump was hooked up with the provided Moroso pulleys and belts. The pump pulls air and some oil mist from the valve cover. Moroso recommends that the intake is always placed above the centerline of the crankshaft, and this practically always works best. Plus, attaching the inlet to the valve cover just makes life easier.

Before any air sucked out of the engine can reach the pump, it first flows through a pressure regulator, which is a nice feature. After that it flows through the pump and is pushed into a collector where any oil can flow to the bottom before the air is pushed out through the breather. Everything is up high and out of the way so it is easy to reach, and the hoses are clear so you can see if you have any trash or buildup in there that may be clogging the system.

So how did it do?

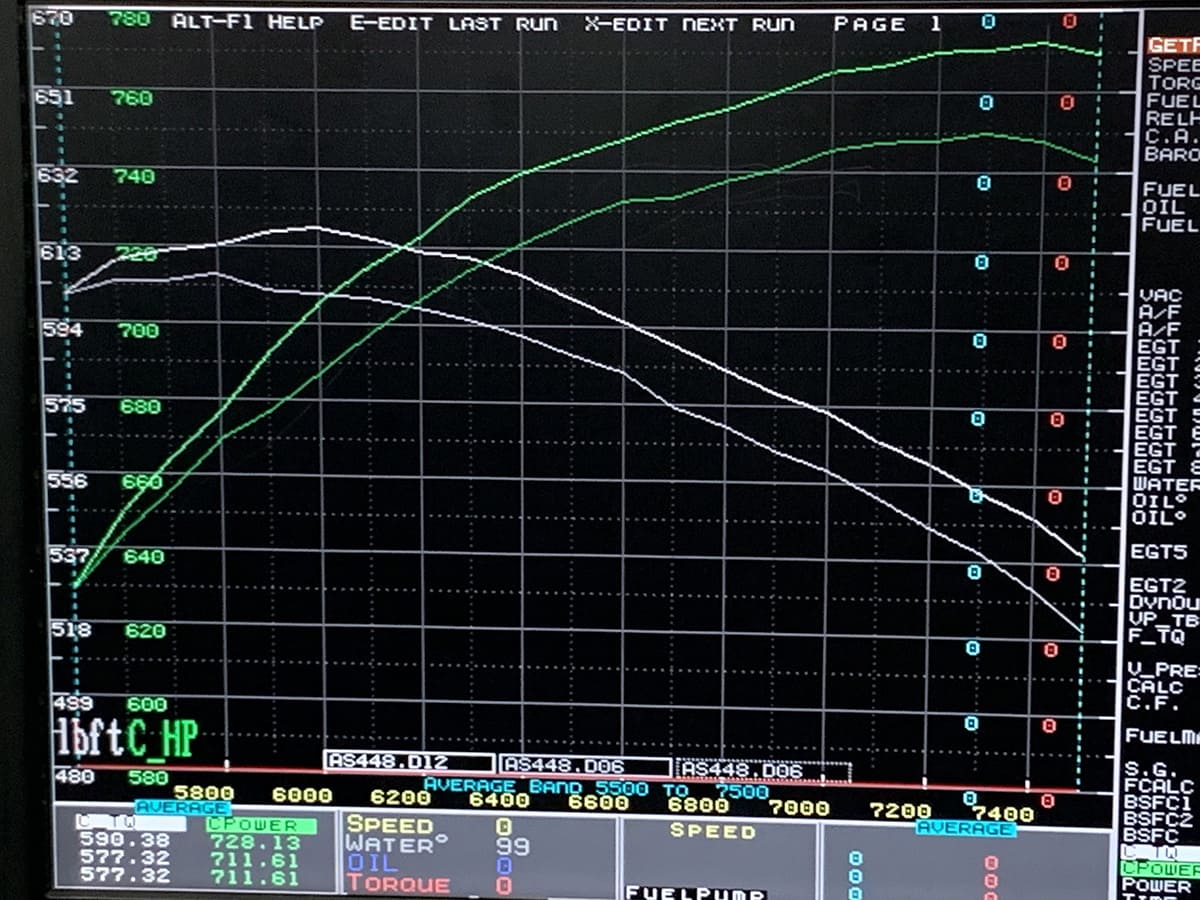

After break-in and tuning on the dyno we disconnected the vacuum pump from the engine. Dorton made sure to pull the belt and not just unhook the pickup hose so we wouldn’t see any horsepower losses from spinning the pump without it doing anything. With 33 degrees of ignition timing all in, we made the pull from 5,500 to 7,500 rpm; on its own this engine is quite strong. We saw peaks of 609 lb-ft of torque at 5,600 rpm and 755.4 hp at 7,300 rpm.

Then we hooked the pump back up with no other changes made to the engine and fired her back up while the oil was still hot. Dorton ran the engine just long enough to match the water and oil temps back up to the same as the previous tests and made a pull.

It is safe to say we were all surprised by just how effective the vacuum pump was. This time around we saw peaks of 617 lb-ft of torque at 6,000 rpm and 771.8 hp at 7,400 rpm. Those are improvements of 8.2 and 16.4, respectively. Better yet, the averages across the pull improved by 9.7 lb-ft of torque and 12.3 hp. That’s definitely nothing to sneeze at and according to a quarter-mile calculator, with a 2,500-pound car it should equate to a reduction in quarter-mile times by a little over 5/10th of a second.

Talk about creating horsepower out of nothing!

Sources

Automotive Specialists

(704) 786-0187

automotivespecialists.com

Moroso

(203) 453-6571

moroso.com

Summit Racing

(800) 230-3030

summitracing.com