By Jeff Smith – Images by the Author

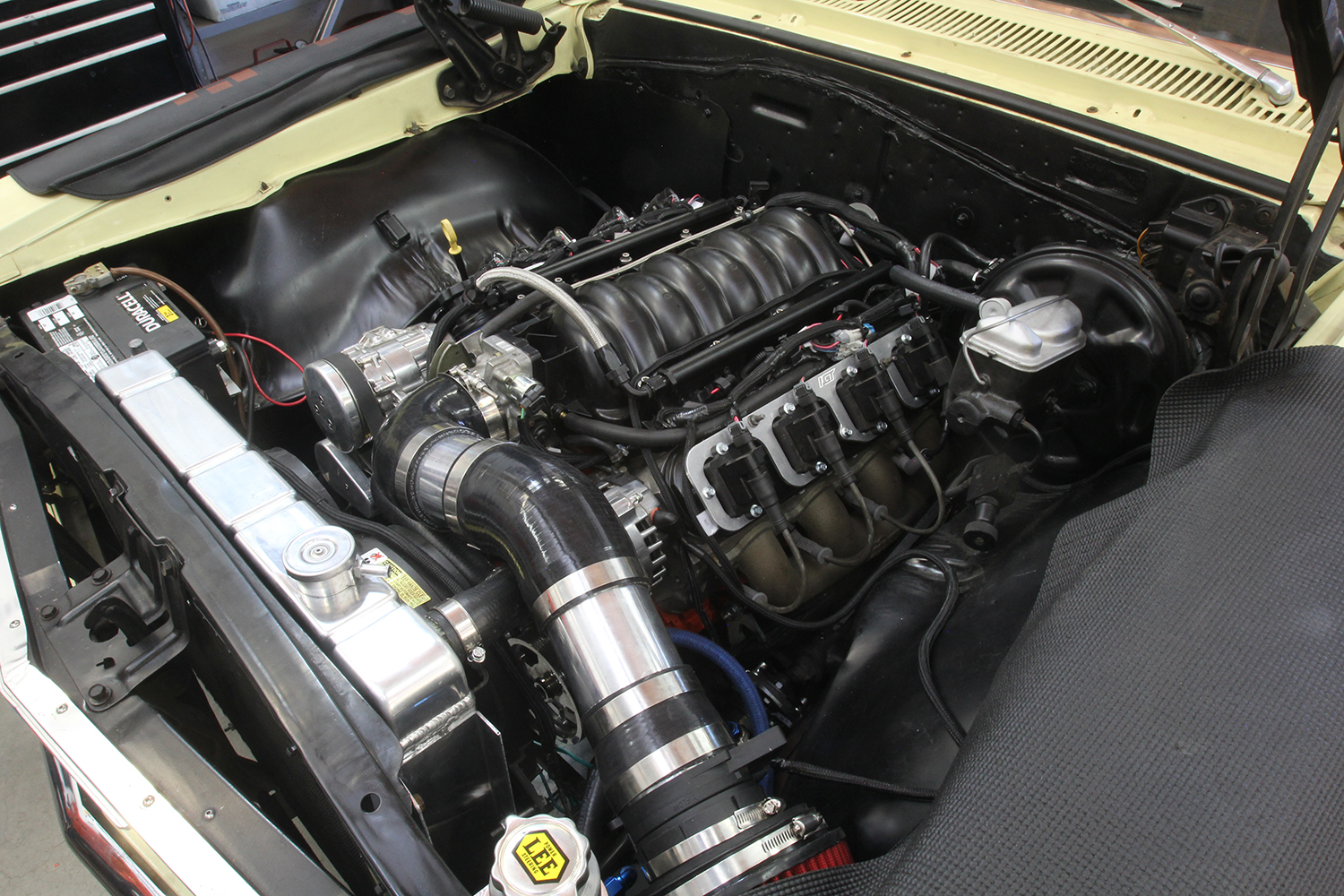

It’s not exactly breaking news that LS engine swapping is a big part of just about any Bowtie horsepower plan. Sure, there are the many traditional small-block Chevy holdouts who just don’t like the LS. But frankly when a near-stock 5.3L LS can make more horsepower than a similarly built 350ci small-block Chevy, why mess with 75-year-old technology?

Also not surprising is the fact that the LS world is changing. Everybody wants big-displacement aluminum block engines, so we’re not going to spend any time on them. It also used to be that you could sidle up to an iron-block 6.0L truck engine on nearly any street corner. Not anymore. That ship, as they say, has sailed.

So, for the budget-oriented car guy who wants an LS engine, the best bet is to search for the smaller displacement iron-block 4.8L and 5.3L engines. These are by far the most prevalent truck engines in the LS series. But even these engines are not all the same and accurately differentiating a 5.3L truck engine from its 4.8L sibling will take a little knowledge and effort.

The first of these littler LS engines appeared in GM trucks in 1999. The 4.8L engine is the smallest at 293 ci—think of it as a longer stroke version of the veteran 283 small-block Chevy. This engine continued until 2014 when it was phased out. The 5.3L is the next step up in the LS displacement chain and is similar in displacement to the old-school 327 with its 325 ci created using a smaller bore and a longer stroke.

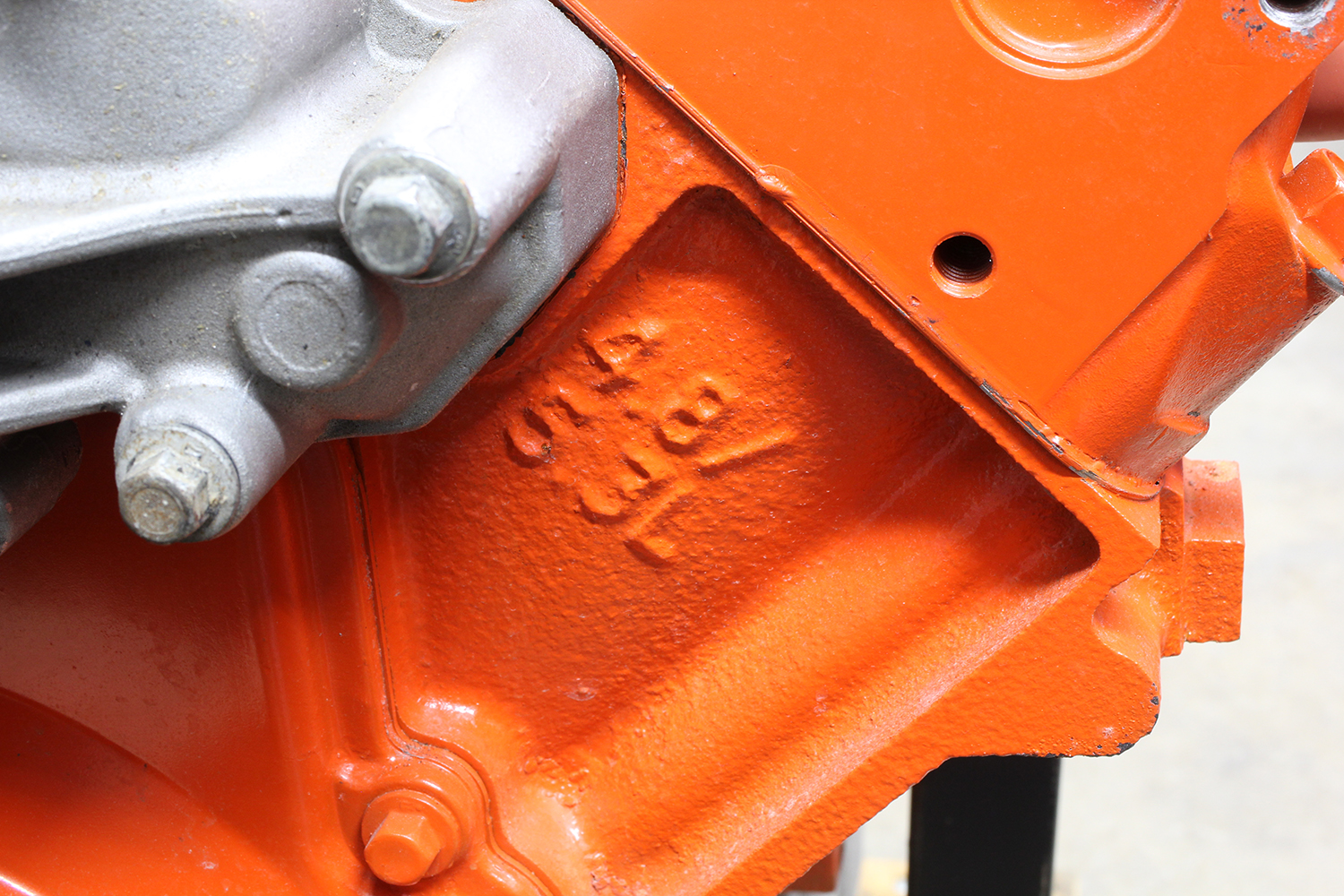

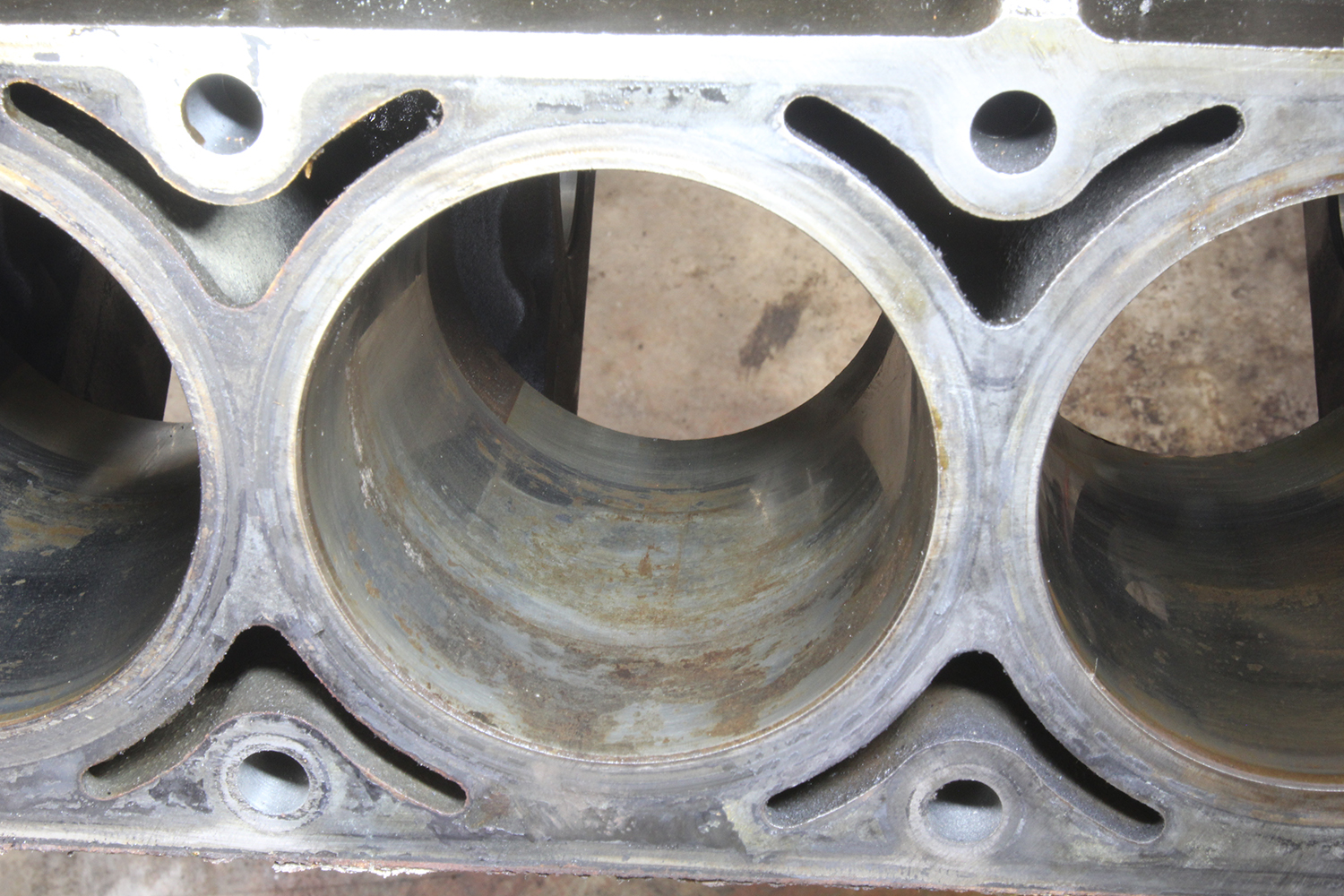

These two Gen III/IV LS engines are nearly impossible to tell apart externally. They both sport a 4.8L/5.3L casting mark on the driver side front of the block. If you find an engine in the junkyard still in the truck, look for engines listed in our RPO chart with a code letter as the eighth spot in the VIN number. Often you will find these engines already removed from the vehicle. The best way to tell a 4.8L from a 5.3 is by peering inside the cylinder to study the piston top.

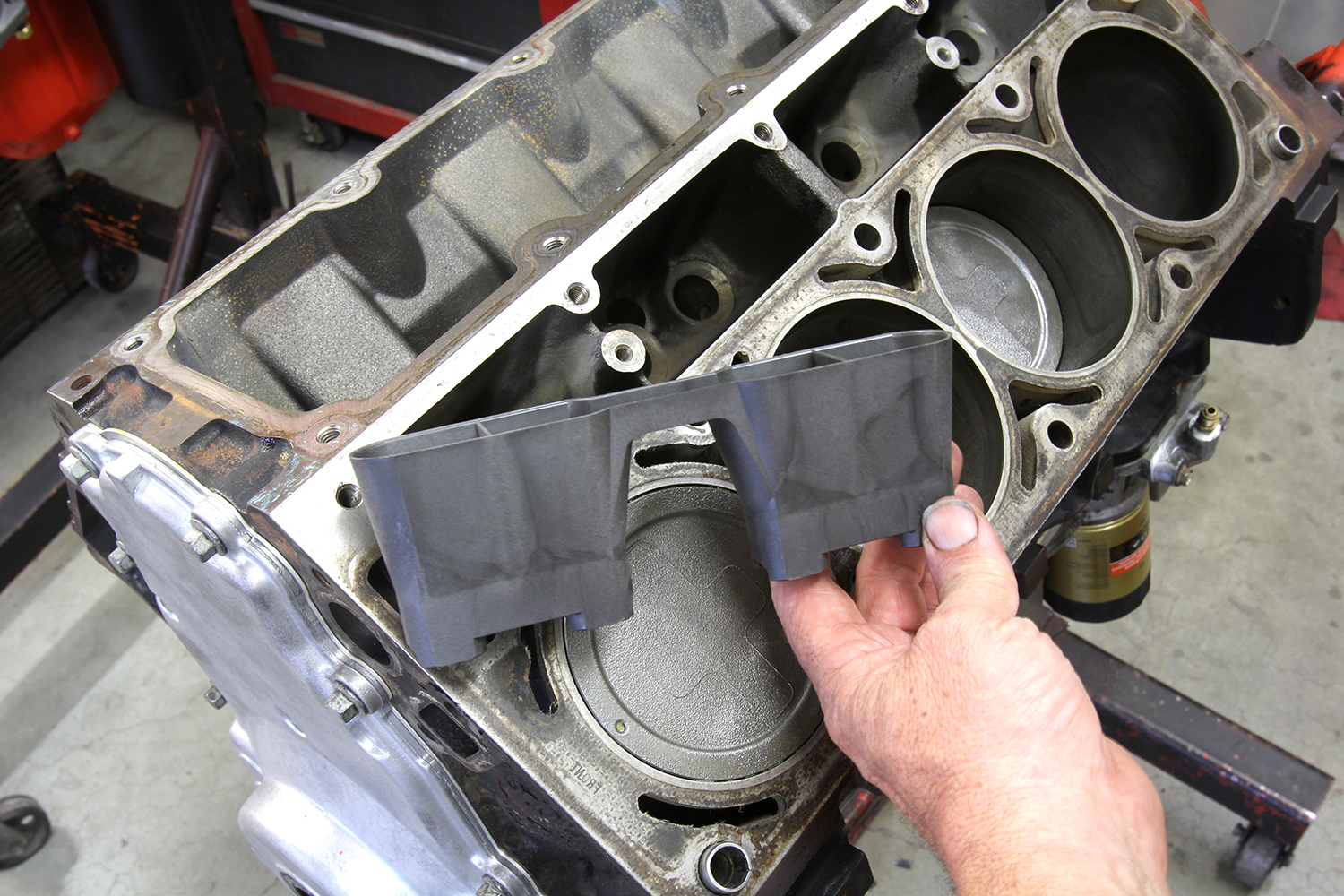

If you can remove a cylinder head, you will know instantly because the 4.8L engine used a flat-top piston while the 5.3L truck engines all employed a dished piston. The one exception to this is the all-aluminum L33 High Output 5.3L engine that used a flat top piston for additional compression. It’s unlikely you will stumble onto one of these engines since they only came in a few 2005-07 trucks, are fairly rare, and will likely command a higher price.

The easiest way to identify a 4.8L from a 5.3L is to remove a spark plug and use a bore scope camera. There are several on the market with the most affordable versions using your own smartphone as the display screen. You might want to look into one of these as a simple way to poke inside the cylinder, but even with these cameras it’s still a chore to pick out a dished piston from a flat top.

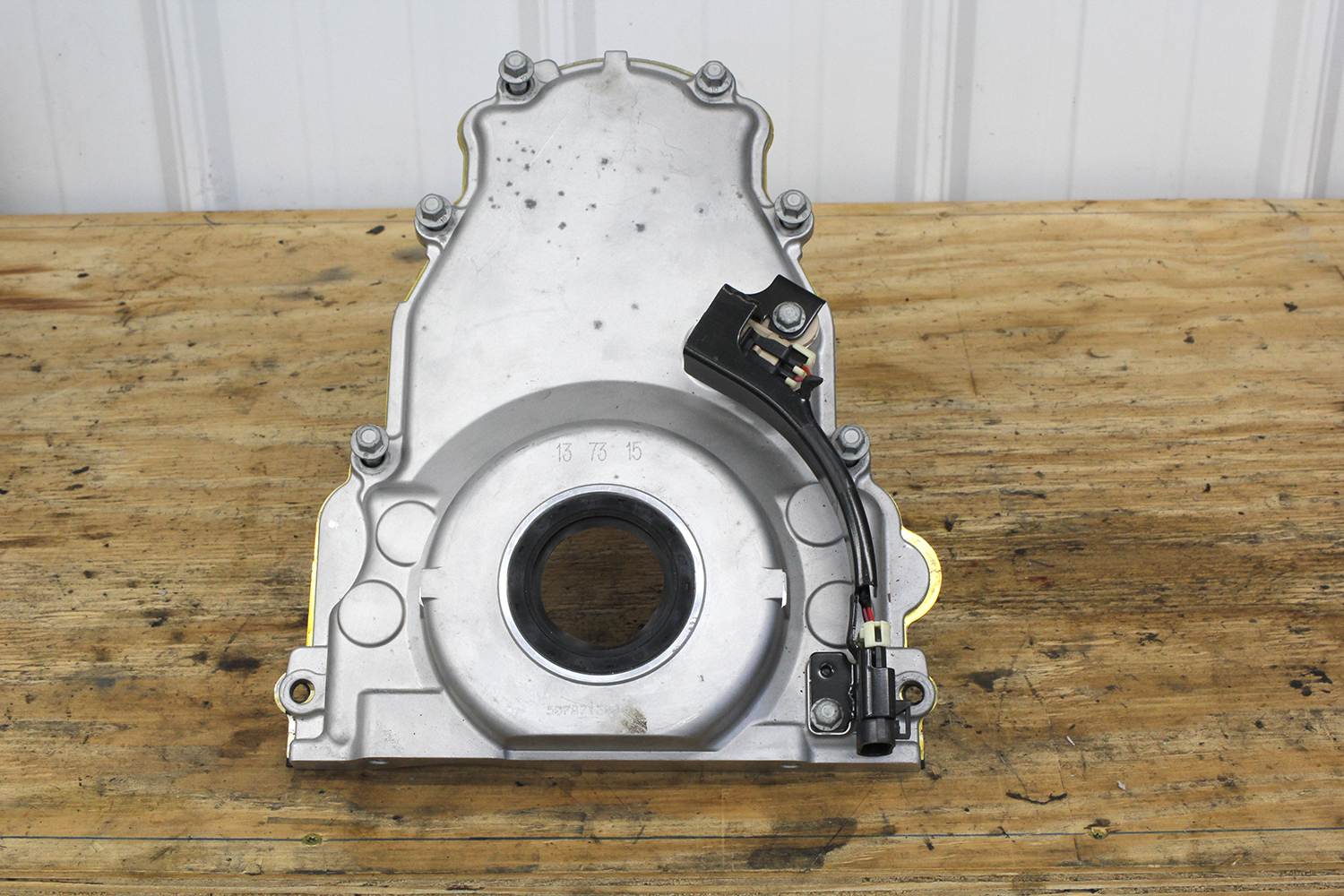

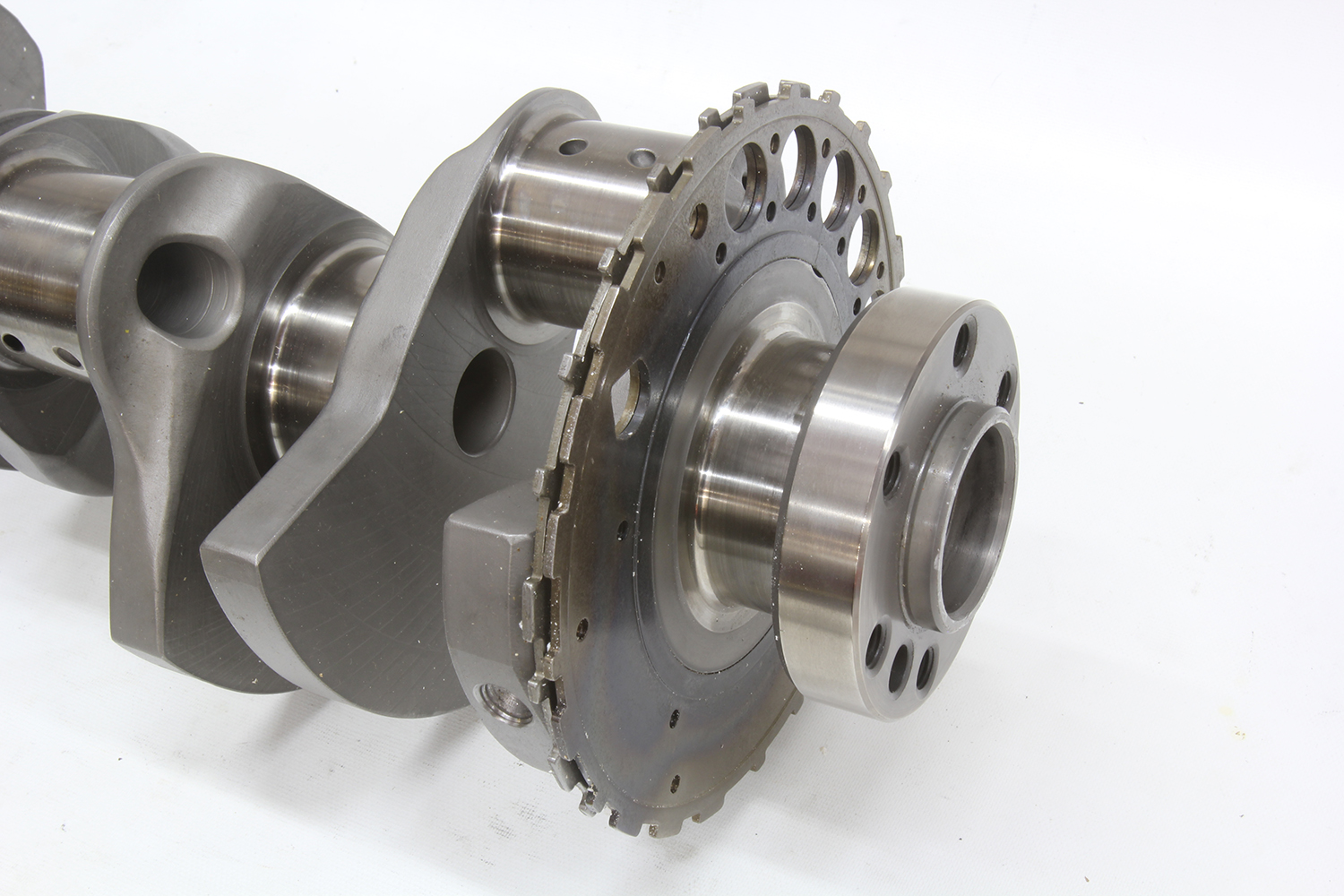

Beyond checking for displacement, there is also the change in configuration that occurred roughly around 2003. The upgrade from the original Gen III to Gen IV brought with it several interior and exterior changes. The main thing that changed was the upgrade from a 24x style reluctor wheel on the Gen III engines to a higher count 58x wheel. The x in these descriptions refer to a missing tooth in the wheel that is the trigger signal for the crank sensor. This change in tooth count was done to allow the ECU to more accurately place the engine position at any one point.

This change to the Gen IV design also moved the cam position sensor from the rear of the block to the front timing chain cover, making it fairly easy to identify an engine as a Gen IV just by looking for the cam sensor position in the timing cover.

Another evolutionary change was that this Gen IV configuration allowed GM engineers to create something called Active Fuel Management (AFM). This is really a displacement on demand configuration where the engine is fitted with lifters that can be disabled to convert the engine from eight operating cylinders to only four during light cruise situations. While Variable Valve Timing (VVT) was used in larger engines, it is not found in the smaller 5.3L Gen IV engines.

Spotting a Gen IV engine equipped with AFM is easiest if the intake is removed by looking at the lifter valley cover. An AFM-equipped engine will have a lifter valley cover with multiple steps or ridges over its entire length while a non-AFM engine valley cover will be smooth. The ridges or steps in the AFM cover indicate the cover is something called a Lifter Oil Manifold Assembly (LOMA). The cover directs oil pressure to the AFM lifters.

Your search for a 5.3L candidate will likely run into one fitted with AFM. For a performance application it’s best to eliminate this AFM feature. There are multiple companies that offer LS-delete packages for these engines. Beyond replacing all 16 lifters in the engine, you will also need a different camshaft as well since the lobes for the AFM cylinders are different from the remaining four cylinders. There are also a few minor modifications to the engine necessary to complete this change, but they are neither difficult nor expensive. We won’t dive into these changes here since there are literally dozens of Internet stories on this conversion.

While the vast majority of these small-displacement engines will be found in trucks and SUVs with iron blocks, it’s worth noting that there are a few—not many—aluminum block 5.3L engines that are worth the search. The most notable is the aforementioned L33 aluminum 5.3L engine used in 2005-07 Silverado and GMC 4WD trucks. The engine was billed as a Vortec 5.3L High Output version with more compression from flat-top pistons, but the most important point was that the block was aluminum rather than iron. We won’t spend more time on these since they are rare, but they are out there in case you spot one.

Most LS swap hopefuls will gravitate toward the 5.3L engine for the obvious displacement advantage. In bone-stock configuration, the 5.3L engines deliver a significant torque advantage because of the added displacement that is roughly worth about 30 lb-ft. But if you are looking at performing a limited budget conversion, the little brother 4.8L can get the job done. We addressed this in a project many years ago trying to do the least-expensive LS swap possible, buying what we thought was a 5.3L engine but discovering later that it was actually a 4.8L.

Despite this subterfuge, we completed the swap and yes the 4.8L motor felt much like its Gen I 283 forerunner because of its weak, low-speed torque. But if fitted with a manual transmission and some decent gears, even these little engines can perform well. As an example, our experience with the Gen I 283 reveals that with pocket ported iron heads and a mild cam, you could expect to make around 275 to 280 hp. It would take some effort with better heads and more compression to make 300 hp with one of these engines.

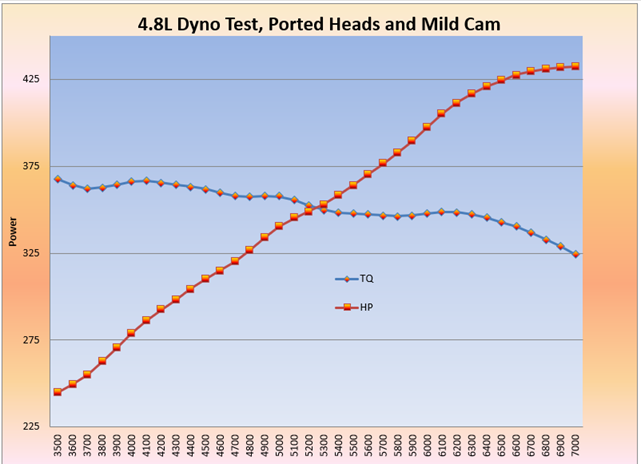

But even with stock 15-degree cathedral port heads on a 4.8L (293ci) Gen III engine, adding a mild cam, carburetor, and intake, and maybe headers you can easily achieve 400 hp. This will, however, demand spinning this engine to 6,800 to 7,000 rpm, but it can easily be done.

Of course, this same approach applies to the 5.3L. Similar modifications with the same mild cam, intake, and headers on a 5.3L engine can push this 325ci engine well into the 430- to perhaps 450hp range. There is a whole separate story on the opportunities available for these affordable small-displacement engines that we will offer in a later issue.

But in the meantime, get out there and start searching for one of these 4.8- or 5.3L pack mules. They may be small, but they offer a bunch of modern improvements over the 1950s technology of the small-block Chevy. You will not be disappointed.

LS Engine Displacement Dimensions

| Engine | Bore | Stroke |

| 4.8L, 293ci | 3.78 | 3.268 |

| 5.3L, 326ci | 3.78 | 3.626 |

| 5.7L, 346ci | 3.898 | 3.626 |

| 6.0L, 365ci | 4.00 | 3.626 |

| 6.2L, 376ci | 4.065 | 3.626 |

4.8L and 5.3L Engine RPO Codes

The RPO codes help identify these variations of the different 4.8- and 5.3L engines. Find the eighth digit in the VIN number to identify the engine that is still in the vehicle.

| Gen III | |||

| RPO | Displ. (Liters) | Block Material | VIN Code |

| LM7 | 5.3L | Iron | T |

| LR4 | 4.8L | Iron | V |

| LM4 | 5.3L | Aluminum | P |

| L33 | 5.3L | Aluminum | B |

| L59 | 5.3L | Iron | Z |

| GEN IV | |||

| RPO | Displ. (Liters) | Block Material | VIN |

| L20 | 4.8L | Iron | A |

| LY2 | 4.8L | Iron | C |

| LMG | 5.3L | Iron | 0 |

| LMF | 5.3L | Iron | 4 |

| LY5 | 5.3L | Iron | J |

| LS4 | 5.3L | Aluminum | C |

| LH6 | 5.3L | Aluminum | M |

| LC9 | 5.3L | Aluminum | 3 or 7 |

| LH8 | 5.3L | Aluminum | L |

| LH9 | 5.3L | Aluminum | P |

| 4.8L and 5.3L Cathedral Head Specs | |

| Casting Number | 852 and 706 |

| Valve Angle | 15 degrees |

| Chamber Size | 61cc |

| Intake Valve Dia. | 1.89 |

| Exhaust Valve Dia. | 1.55 |

Check out this story in our digital edition here.