By Brian Brennan & Rob Fortier – Images by NotStock Photography

When it comes to stealth hot rods (subtle yet menacing), to me, nothing is more iconic than black-on-black (with red accent) ’60s-70s Chevy muscle car with the proper stance, and, of course, some mean motivation underhood. Typically, that describes many a Chevelle, Camaro, and even Nova. But in this case, it only begins to describe Mark Deatley’s 1972 Chevrolet C10, built by none other than Hot Rods by Dean (Livermore).

When you take a long, hard look at Mark’s Fleetside, you start to see many non-stock features, from front to back, top to bottom. Now, since my elder partner in magazine crime, Brian Brennan, spends almost as much time at Dean’s shop as most of his workers, thus he was present throughout the build, I asked him if he’d care to share some insight on just what it took to make the Deatley C10 so unique in its styling:

“When I asked Dean Livermore about the sheetmetal changes made to this 1972 Chevy C10, he chuckled and replied, ‘What wasn’t changed?’ The modifications start at the front with significant reconfigurations to the cowl and firewall. Everything from the dashboard forward has been custom made to ensure the cowl fits snugly at the back of the hood, allowing it to close properly while clearing the doors and fenders. The side markers have been filled and the entire grille area, including surrounds, is custom built with backlit Chevrolet emblems crafted from acrylic framed-in steel. Additionally, all turn signal indicators and buckets are 3-D-printed. The fender openings have undergone extensive alterations, as well. The top of the front wheel openings was lowered by ½ inch, while the front and rear edges were pulled closer together by 3 inches and dropped approximately 2 inches. This creates a more-aggressive look compared to the stock openings. The top of the cab was chopped by 3 inches, and the center crown was reduced by 2 inches, resulting in a flatter roof profile.

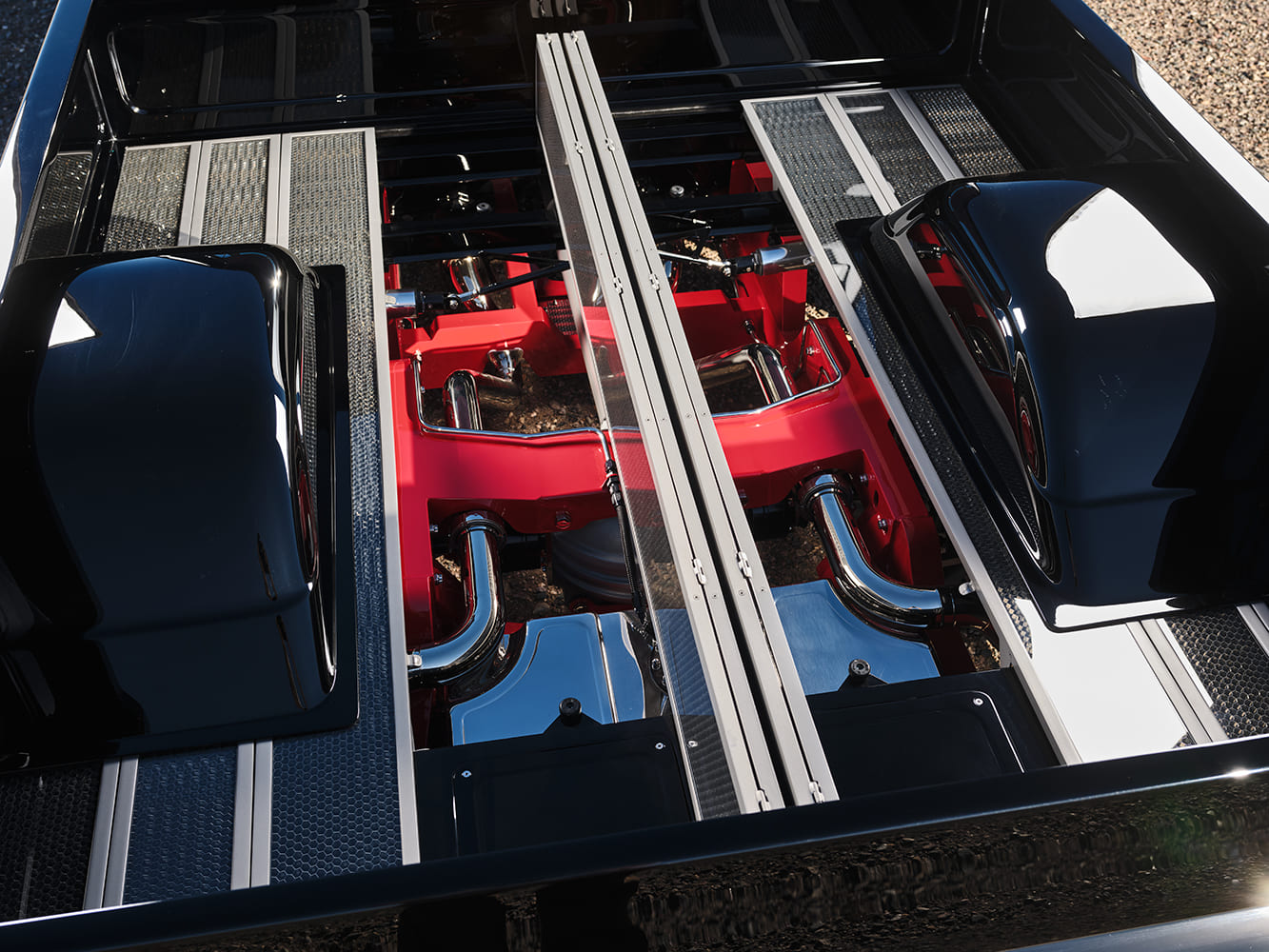

“On the bed, side markers were removed and filled, with reshaped wheel openings mirroring the front modifications. The tailgate features a ‘soft open’ mechanism, akin to modern trucks, with the latch relocated inside for a cleaner exterior. Despite tailgate access panels for its inner components, most of the tailgate’s sheetmetal remains stock. The custom taillights, crafted from scratch, integrate 3-D printing and LED lighting.

One standout feature of the bed is its accordion-style floor, which opens up to reveal the suspension, underbody, and chassis components. These trifold panels are constructed from stainless steel framing with an aircraft-grade honeycomb core, finished with acrylic glass for enhanced visibility.

“A quick glance at the truck profile reveals a seamless, stock-like appearance. The factory windwings are intact, the A-pillars retain their upright position, and the front and rear glass are flush-mounted. The windows are now powered, replacing the original hand-crank operation. The body is painted in sleek PPG black with eye-catching red accents, and an impressive 800 hours were dedicated to painting, cutting, and buffing, not including the bodywork. All bumpers and trim are custom made, with gray trim treated with Cerakote at Hot Rods by Dean.

“Stitchwurx contributed by utilizing 3-D printing for all internal panels. These panels, routed out of a single block, are secured without screws—using magnets instead. The seating resembles a bench yet functions as individual bucket seats, featuring a center armrest that converts into a console. The interior (including the armrest/console) is finished in red leather with black and gray accents. An Ididit steering column is paired with a SPARC steering wheel featuring a flat bottom for added leg clearance. Above the wheel, the driver gazes at a full set of Classic Instruments AutoCross Series gauges, providing essential information.”

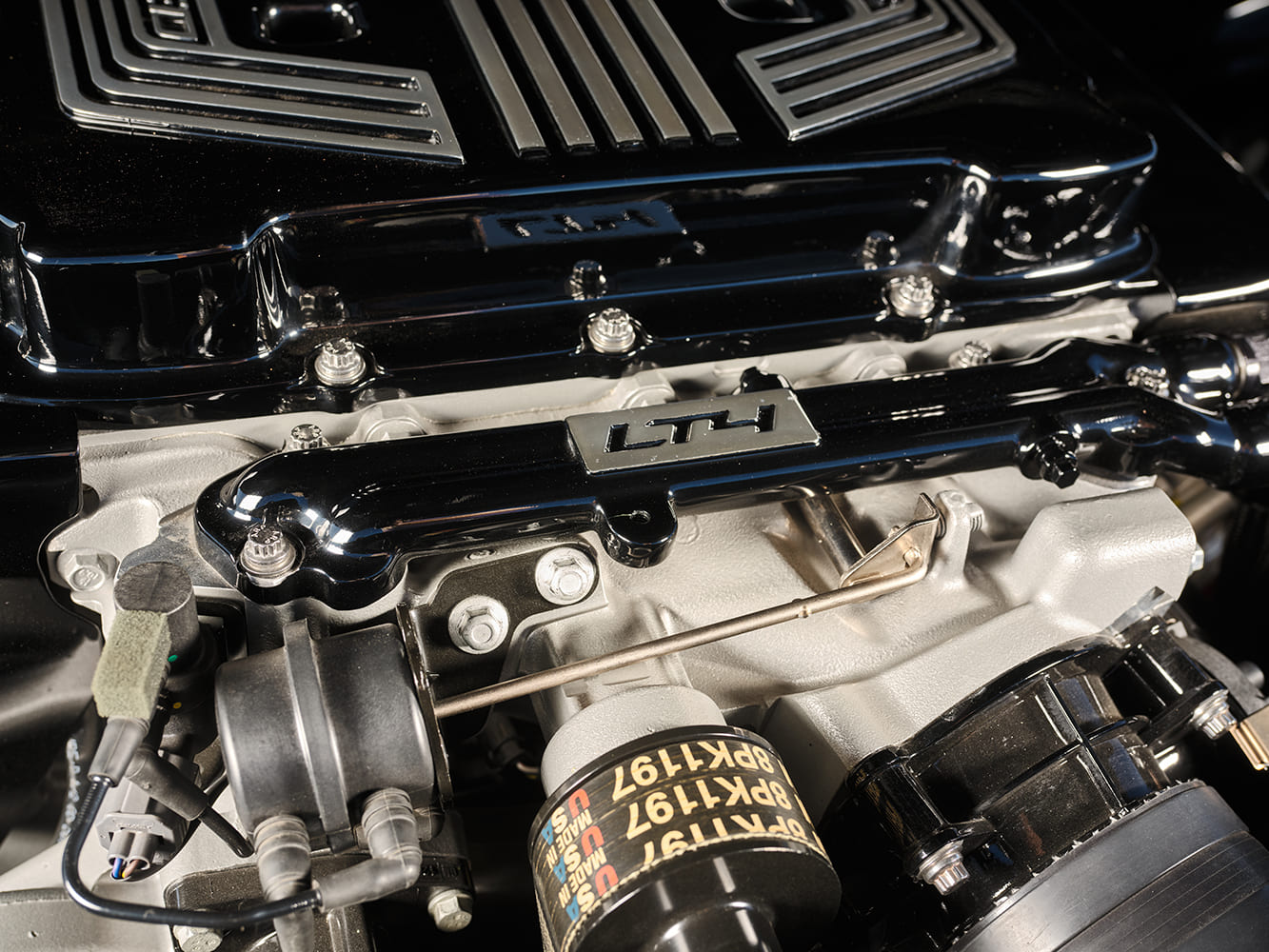

Beneath that aforementioned styling work lies a Roadster Shop Fast Track Stage III chassis with independent front and rear suspensions, a Strange Engineering centersection, and RS-Penske dual-adjustable coilover shocks. All hardware has been replaced with high-quality ARP components, including many custom-made nuts and bolts to fit the modified chassis specifications. Braking is comprised of a CPP HydraStop system controlled by a Kugel pedal assembly powering Baer Claw Extreme/Pro calipers situated behind Schott’s Mod 5 d.concaves in 18- and 20-inch hoop sizes with Michelin Pilot Super Sport radials. Finally, powering the ’72 is a Connect and Cruise system from Chevrolet Performance, featuring an LT4 engine that produces 650 hp and 650 lb-ft of torque, mated to a 4L75E transmission with a factory 2800 stall speed converter. The custom exhaust system, including headers and tips, was fabricated in-house at Hot Rods by Dean.

The effort to make Mark’s C10 unique is staggering, totaling nearly 9,000 hours for the build. Within those hours, there are 800 hours allocated for painting, cutting, and buffing (no bodywork is accounted for); a year spent sourcing parts; and an additional 3-1/2 years to complete the project. This Chevy pickup is a testament to a Herculean effort.

Check out this story in our digital edition here.