By Ron Ceridono – Images by the Author and Courtesy of the Manufacturers

There’s nothing cooler than taking your hot rod out for a cruise. On the other hand, there’s nothing worse than driving a hot rod with one eye on the road and the other on the temperature gauge as it climbs up the scale. That’s because overheating an engine always comes with consequences—it may be as simple as having to clean up the mess from dumping coolant out the overflow to substantial engine damage. Severe overheating can cause pistons to expand enough to scuff or even seize in the cylinders, rings can lose tension, stick, or literally weld bits of themselves to the cylinder walls, exhaust valves may stick in their guides, heads can warp, head gaskets can develop compression and water leaks, and blocks and heads can crack. In short, a good engine can become an even better boat anchor if it gets too hot. But thanks to a number of experts on the subject, we’re going to help you keep your hot rod cool.

How Hot is Too Hot?

It’s a lousy pun but engine operating temperature really is a hot topic. Although the hotter an engine runs the more efficient it becomes, there is a practical limit, primarily because the internal components can only tolerate so much heat. Due to the composition of today’s fuels, 180 degrees is considered the minimum operating temperature for efficient combustion even for vintage engines on the street. Most experts agree that 190 degrees is a safe operating temperature for modern engines and for contemporary fuel-injected crate engines, 195 to 220 degrees is considered the norm.

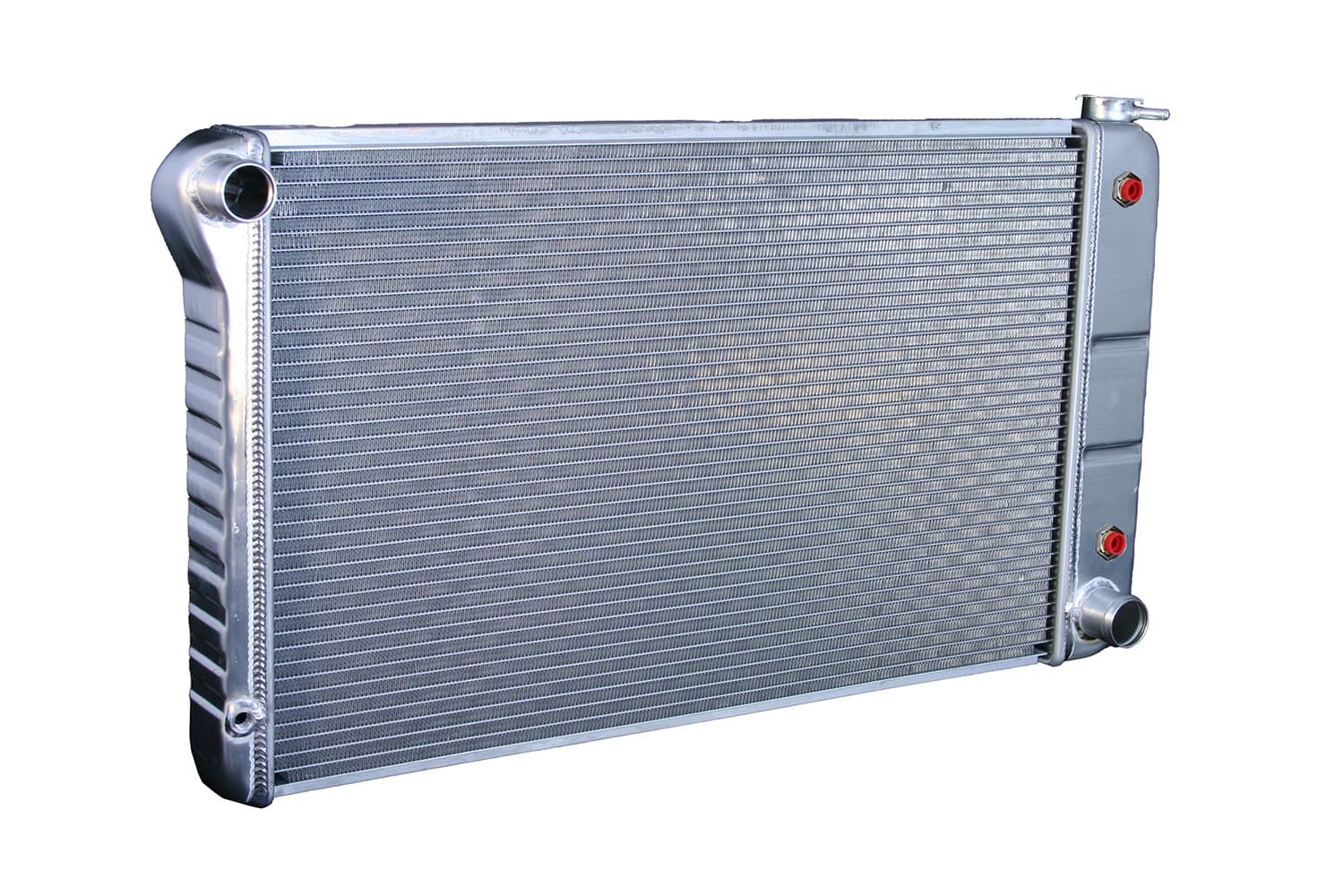

Radiator Types

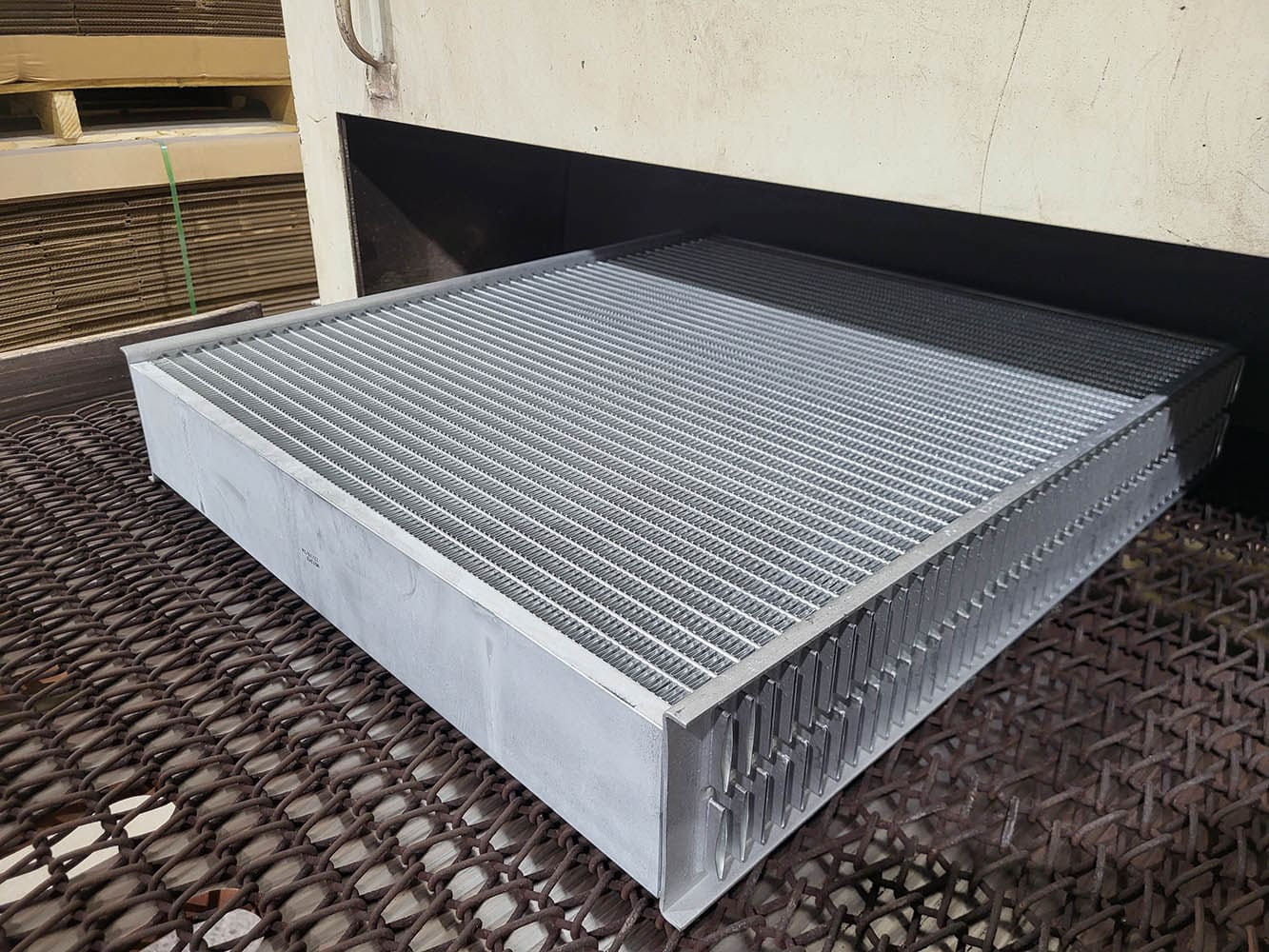

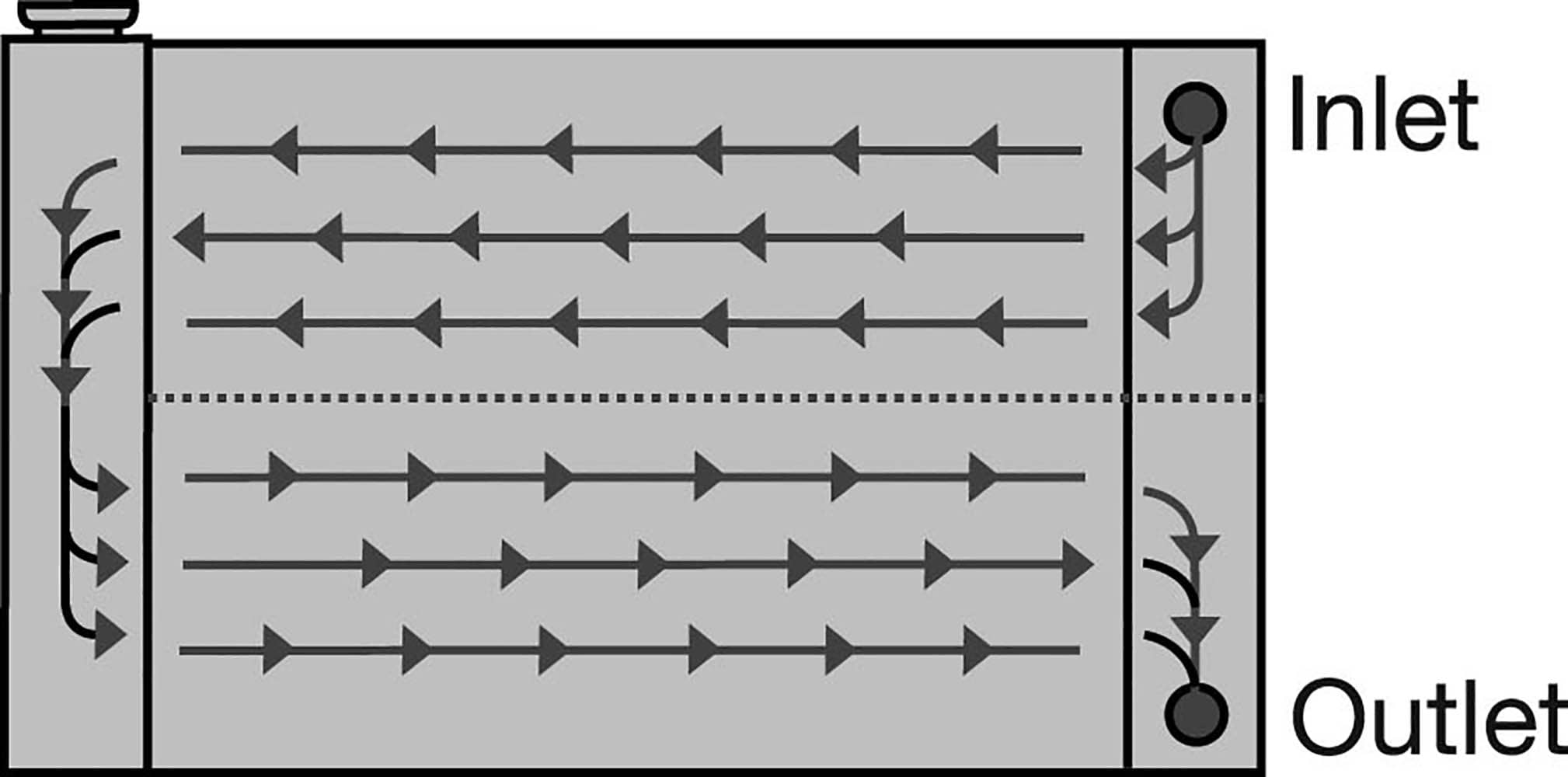

All radiators share the same basic parts, a pair of tanks, a core that consists of tubes that connect the tanks, and the fins between the tubes. For years downflow radiators were used, as they had the tanks at the top and bottom of the cores with vertical tubes connecting them; these radiators were taller than they were wide. As automotive styling dictated lower hood profiles, less height was available for a radiator, which led to the introduction of the crossflow design that is wider than it is tall. By placing the tanks on the sides of the radiator the horizontal tubes could be long enough to provide adequate cooling. All things being equal (tube length and fin count) downflow and crossflow, radiators are the same in their ability to cool.

A relatively new development in radiator technology is the multi-pass configuration. By placing baffles in the tanks, the core is “divided” and coolant is redirected to make two, or in some cases three, passes through the core. Double-pass radiators are often used for LS swaps, so both the inlet and outlet can be on the same side of the radiator.

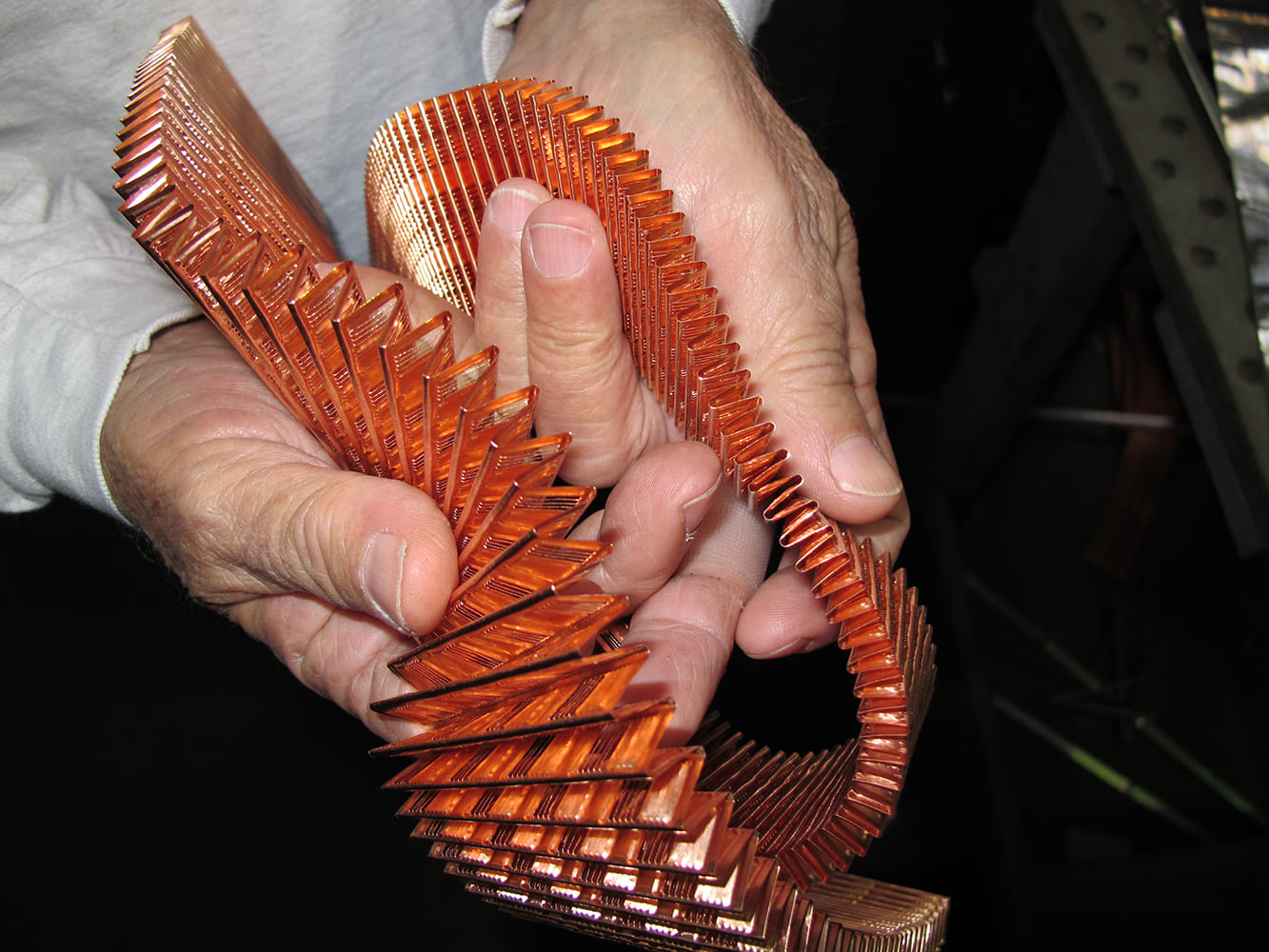

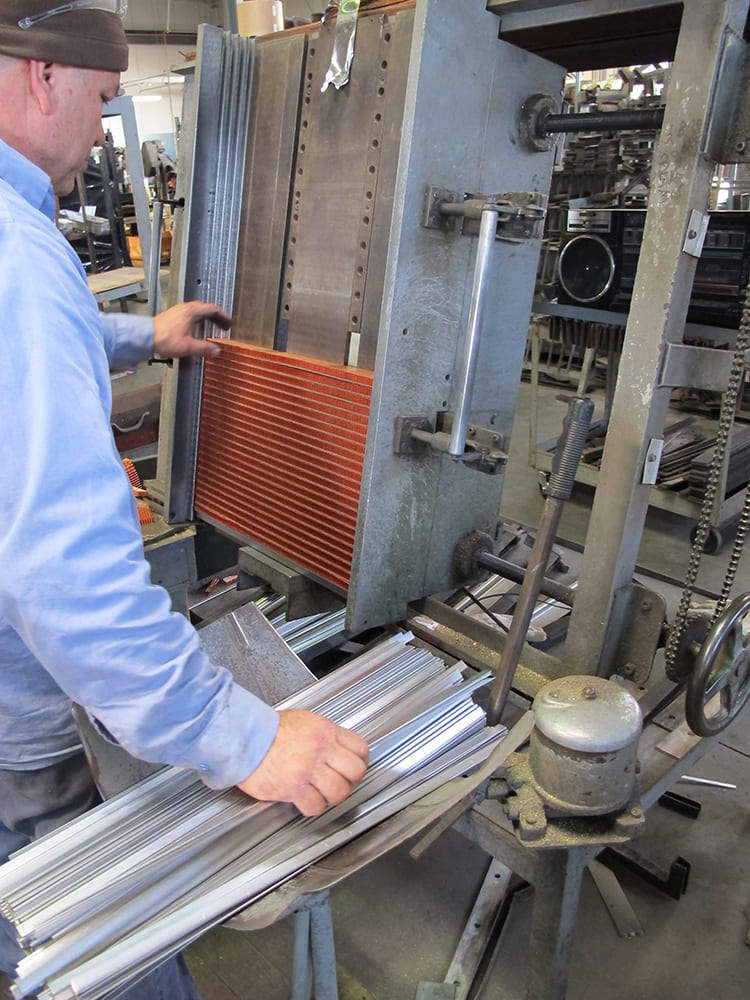

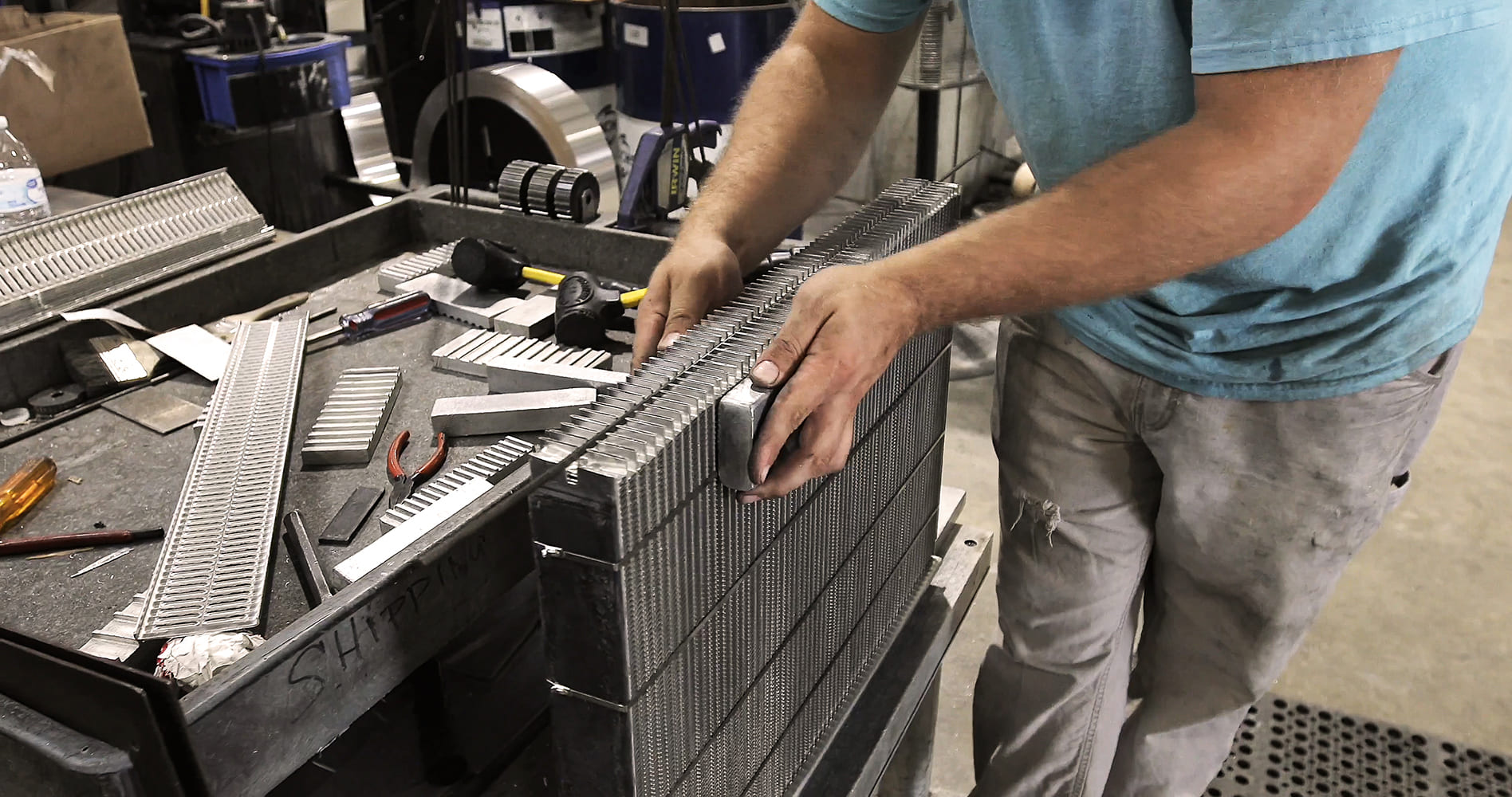

The Aluminum vs. Copper/Brass Debate

There has been considerable discussion concerning the effectiveness of copper/brass radiators (copper is used for the fins and brass is used for the tanks) and aluminum radiators. When comparing the thermal conductivity of the two materials (measured in [BTU/hr.ft degrees F], copper is rated at 231, aluminum 136, which means copper conducts heat better than aluminum. That being said, there is an equalizing factor; the lead solder used to attach the copper fins to the tubes is a very poor conductor of heat, so some efficiency of a copper core is lost. Aluminum radiator cores have the tubes brazed to the tubes with aluminum so there is no impediment to heat transfer.

Basically, the situation is this: the advantage of a copper core is offset by the solder that holds everything together, so manufacturers try to minimize its impact by carefully controlling the amount applied. On the other hand, aluminum radiator manufacturers use larger tubes that result in fewer gaps between the fins to increase the efficiency of aluminum cores. We’ve used both with excellent results, so the choice most often comes down to personal preference, appearance, and price point.

Tube Size & Fin Count

While all radiator cores appear to be similar in design, the size of the tubes and the number of fins per inch varies. Modern copper/brass radiators usually have 1/2-inch tubes, while aluminum radiators use 1-, 1-1/4-, or 1-1/2-inch tubes. Copper/brass radiators typically have three or four rows of tubes, while aluminum radiators typically have two.

Another important factor that figures in radiator efficiency is the number of fins per inch count. A higher fin count will increase the ability of a radiator to cool, but only up to a point. If the fin spacing is too close, airflow may be restricted, which will reduce cooling capacity. For all-around driving, 14 to 16 fins per is commonly used.

LS Steam Ports

LS engine swaps are certainly popular, but there is a cooling system issue that must be addressed. Unlike the venerable small-block Chevy that had the thermostat high up in the intake manifold, the LS thermostat is in the water pump housing, which is located low on the engine. As a result, air can get trapped in the system, which disrupts the flow of coolant, which in turn can cause overheating. To cure the problem, GM provided ports that connect to the radiator allowing the air to escape. As LS swaps are so popular, most radiator manufacturers offer radiators with steam connections for the same purpose.

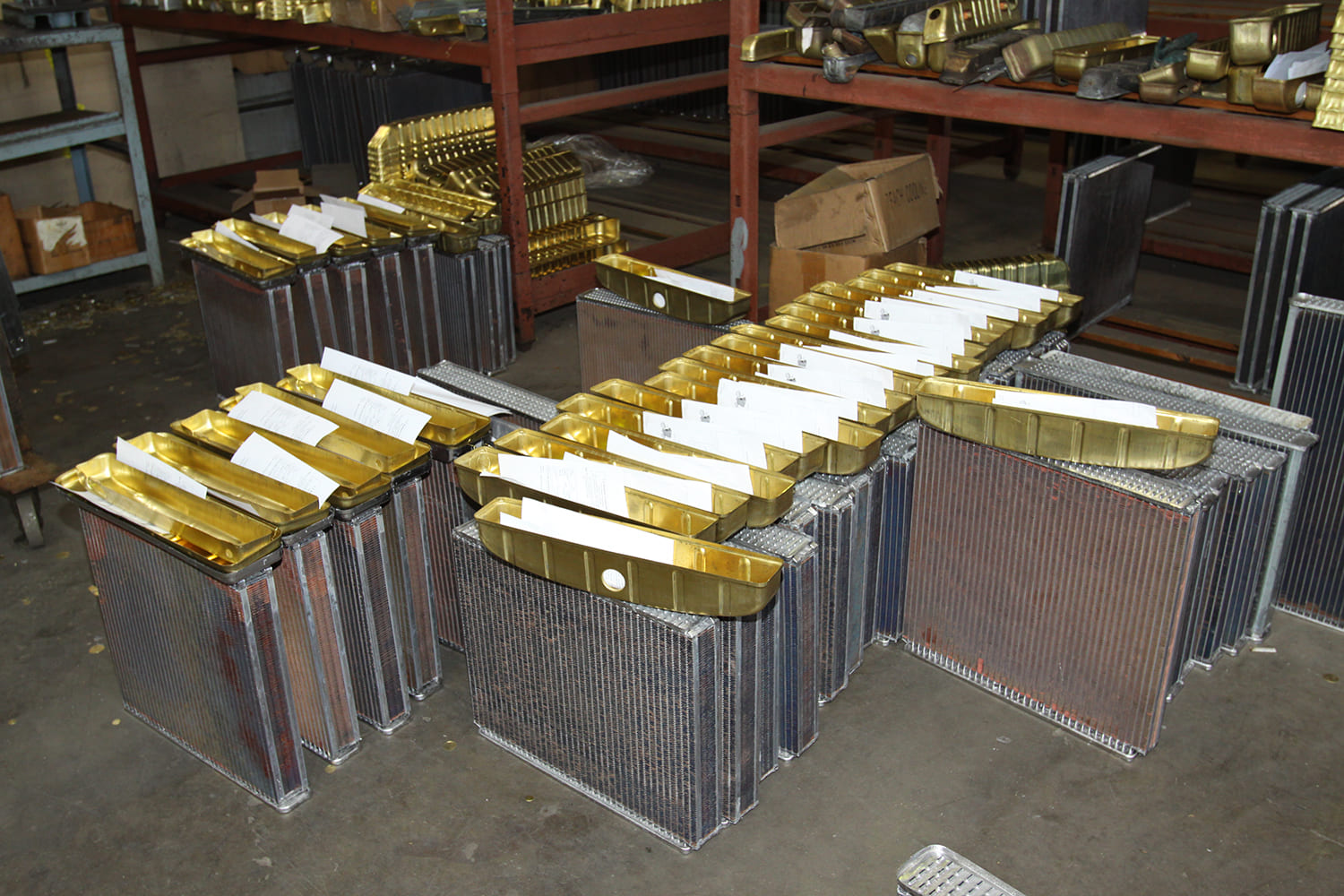

Choosing a Radiator

There are a number of considerations to be made when choosing a radiator. For restorations, exact replacements are available, which in most cases are an improvement over the OEM design. For restomods, radiators that look like the original but have additional cooling capacity are also available. For high-performance applications the basic rule of thumb is this: get the biggest most efficient radiator you can fit in the space available as you’ll never regret having more cooling capacity than necessary.

We’ve just scratched the surface on the subject of cooling systems, so if we haven’t answered all your questions, stick around, there’s more to come.

Check out this story in our digital edition here.

Sources

AFCO Racing

(800) 632-2320

afcoracing.com

DeWitts

(517) 548-0600

dewitts.com

Johnson’s Radiator Works

(256) 399-9925

johnsonsradiatorworks.com

Speedway Motors

(800) 979-0122

speedwaymotors.com

U.S Radiator

(800) 223-4299

usradiator.com