Hot Rods by Dean’s Easier Method For Chopping On 1933 Ford DeLuxe coupe

By Chris Shelton – Photography By Brian Brennan

The world really doesn’t need yet another top chop story—or so I thought. Then ol’ Editor Brian Brennan visited Dean Livermore at Hot Rods by Dean and brought home these photos of the chopping of a 1933 Ford DeLuxe coupe.

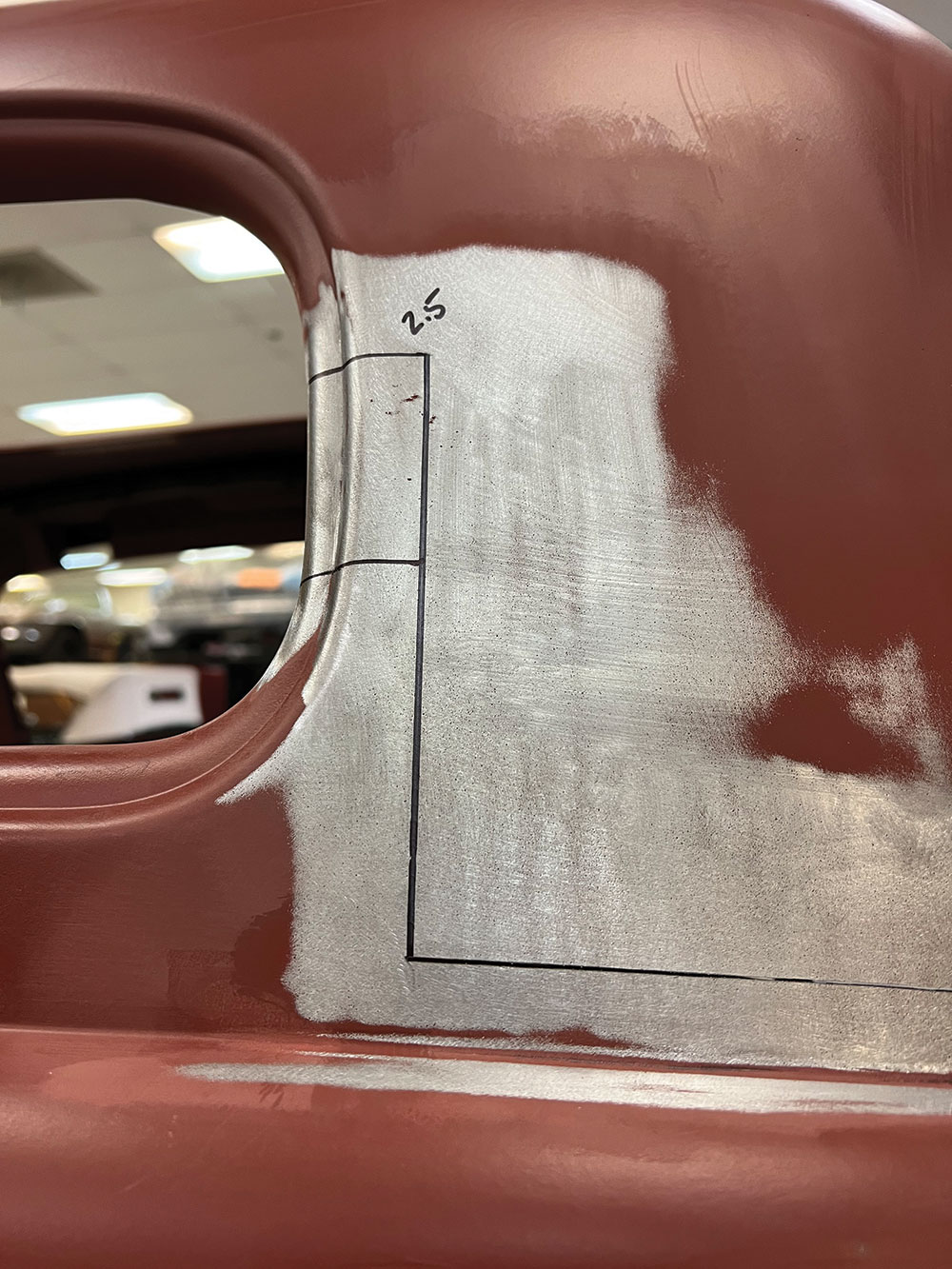

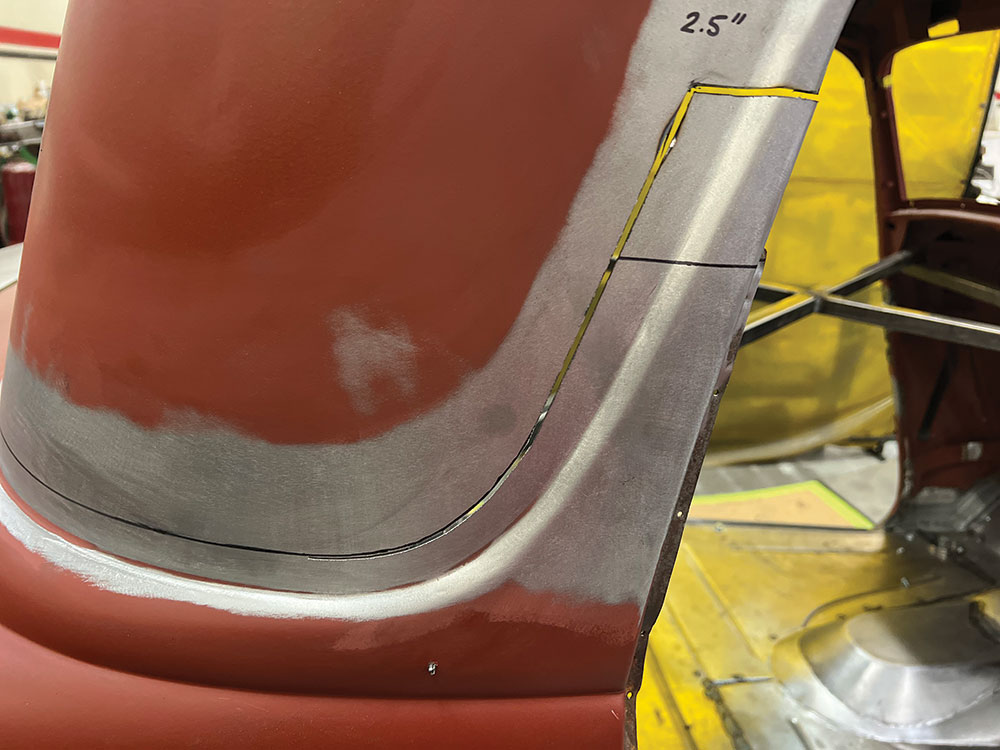

It wasn’t the chop itself that caught my attention—it’s a moderate cut (2-1/2 inches) on a somewhat common car. Rather, it was the way Nick Sinioris plotted his cut lines to minimize effort and maximize accuracy that stood out.

Welding Technique

Welding—specifically the preparation for welding—really eats up time. Strong welds that don’t distort favor tight, consistent gaps. While nearly anyone can get such a gap along a short run, it takes a fair amount of skill and time to get that kind of gap over, say…a foot or two. To get those tight, consistent gaps over that large area usually requires cutting a little wide of the scribe lines then creeping up on them with snips and files. And that kind of fit up usually requires making tabs to support the panels during the trimming process. The fit, trim, and repeat cycle takes a long time.

Read More: Function and Form: The Art Of Channeling a Hot Rod

Chopping The Top

In oversimplified terms, Sinioris cut the top off, slid it down until the base overlapped the top, drilled through the overlapped area for temporary panel fasteners, then pinned everything together. That lets the lid fasten to the body without separate tabs or brackets.

Sinioris’ method

Though neat, the ability for the top to serve as its own fixture is a secondary benefit to Sinioris’ method. The cut edge of the overlapping panel doubles as a guide for scribing and/or trimming the underlying panel. Cut right on that guide or cut through both panels simultaneously and you’ll get a panel gap that measures exactly the width of the cutting blade. Close up that gap for GTAW/TIG process as Sinioris did or leave it open for GMAW/MIG.

Correcting Method #1

Because the top tapers toward its crown, the pillars misalign when chopped (the top emerges too short, lengthwise). One correction method extends the lid part of the top lengthwise to realign the posts. That maintains the windshield angle, which preserves the windshield’s seal.

Correcting Method #2 Bonneville Chop

The other method leans the windshield posts back. Doing that streamlines the windshield, which made it a popular technique in landspeed racing in the middle of the last century (see the Spalding Brothers’ and SO CAL Speed Shop’s coupes for examples). You’ll sometimes hear people refer to it as a Bonneville chop, and it’s how Sinioris chopped this top.

Techniques To Improve The Chop’s Integrity

Along the way you’ll see a few other techniques that improve a chop’s integrity. For example, Sinioris uses a fixture to preserve hinge-pin alignment during reassembly, something that ensures that the doors will open and shut without binding. He also fabricated a lot of internal structural elements, like a tubular support that bridges the door jambs and ties them into the top and inner fender wells.

Read More: How To Custom Build and Upholster Custom Seat Cushions

Though some techniques are specific to 40 Model Ford Coupes, most of the process translates to other makes and models of the period, if only because they’re built largely the same way.

I still stand by my assertion that the world has enough top chopping stories. But as I’ve learned, for every rule there’s an exception. And so long as fabricators find those ways to improve the process and reduce the effort, we’re all eyes. MR

Ready for Part 2? Check it out here: How To Chop A Top With Minimal Effort and Maximum Accuracy Part 2

Sources

Hot Rods by Dean

(623) 581-1932

hotrodsbydean.com

Woodn’ Carr

(562) 498-8730

woodncarr.net

Leading Edge Machine and Design

(402) 660-8289

leadingedgemad.com