Customize and Repair Ford Phaeton Bullnose Grille Ornament

By Gerry Burger – Photography By The Author

My latest project is a flathead powered 1936 Ford Phaeton being built as an early ’50s hot rod/custom. Recently we came across the original chrome plated, die-cast grille ornament with the V8 emblem intact, but two holes where a greyhound had once been. We decided to grind down the finned portion of the ornament to a lower profile, to remove the damaged portion, giving us a “semi-bullnose” look. Working with die-cast pot metal can be difficult, but follow along and we’ll show you how to repair, fill, and smooth it for chrome plating.

Building a hot rod of any era is a stream of choices—some big, some small—but they all contribute to the finished package. One thing we learned early on was to pick a theme and make every decision fit that style. Many cars built in the ‘50s blurred the lines between rod and custom, with performance under the hood and some custom details and paint on the outside. That is the very theme for our 1936, with a built Flattie under hood and a conservative custom approach on the outside.

More How To Tips: How To Make Custom Headlights For Your Hot Rod

We’ve been doing the bodywork, and while stacking parts on a shelf (all neatly marked for the memory impaired) we came across the original grille ornament. The die-cast pot metal was in overall good condition, however, two holes drilled in the top finned portion on top told us a greyhound had once adorned it. While greyhound ornaments are cool, in keeping with the theme of the car, we thought a simple Ford bullnose ornament like the 1936 Ford Chrome Radiator Trim Bezel from Speedway Motors would be a quick-and-easy solution. But then we began to think about making our own bullnose piece, with a custom twist that would make it unique.We envisioned removing the V8, and grinding down the finned portion of the ornament to a lower profile, giving us a “semi-bullnose” look.

More How To Tips: This Ford Phaeton Gets Some European Flair

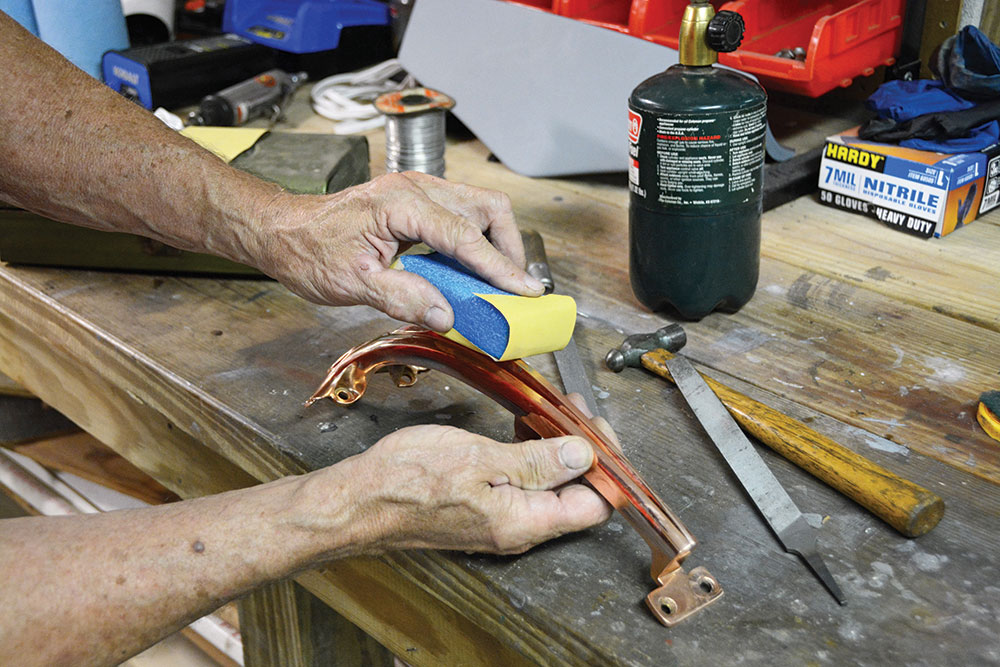

Since the hood ornament is die-cast pot metal, removing metal is easy—so easy you must work carefully not to remove too much material. Some marking with a Sharpie indicated we could trim the piece to eliminate the two holes and achieve our desired lower profile. A die grinder and cut-off wheel took off most of the die-cast piece and we finished shaping with files and sandpaper. We sanded the ornament down to a 400-grit finish and spent some time viewing it from various angles. The piece flowed nicely but we now had the problem of filling the resulting openings caused by removing the V8 emblem and removing the top of the fin.

Working with die-cast white metal is difficult, but working with copper is relatively straight-forward. So, one trick is to convert this die-cast piece into a copper piece by plating it. We spoke to our friends at Advanced Plating about having them copper plating it, then returning it to us where we would solder copper filler pieces in place, before returning it to Advanced Plating for more copper and a final chrome plating. We opted to do this at home for two reasons: One, we enjoy doing these little projects that make a big difference; two, we’re cheap and wanted to save a little money. It should be mentioned that Advanced Plating is fully equipped to do the entire die-cast metal repair and filling process, and this type of repair and modification can be done to virtually any die-cast piece.

More How To Tips: Installing a Universal Fuel Sending Unit and Fuel Tank – 1936 Ford Project

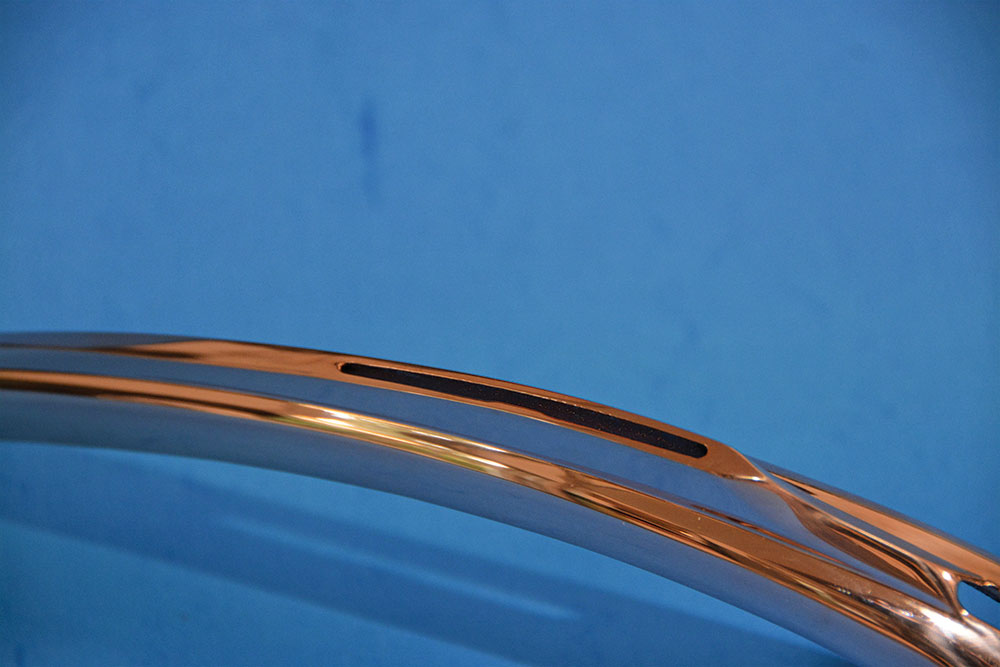

And so, satisfied with our final shaping of the die-cast metal piece, it was carefully boxed up and shipped to Advanced Plating for stripping of what remained of the original chrome plating, followed by copper plating. Remember to plan ahead for chrome plating as all good chrome shops have a backlog of parts to plate. Generally plan on at least a couple months to get chrome done and a simple call to the plating shop will give you an idea of how long it may take to complete your job. Our piece fell into the production line and a couple of months later the grille ornament returned, glistening in all its copper glory. In this drive-thru window, overnight-shipping world, there are still some things that just take time.

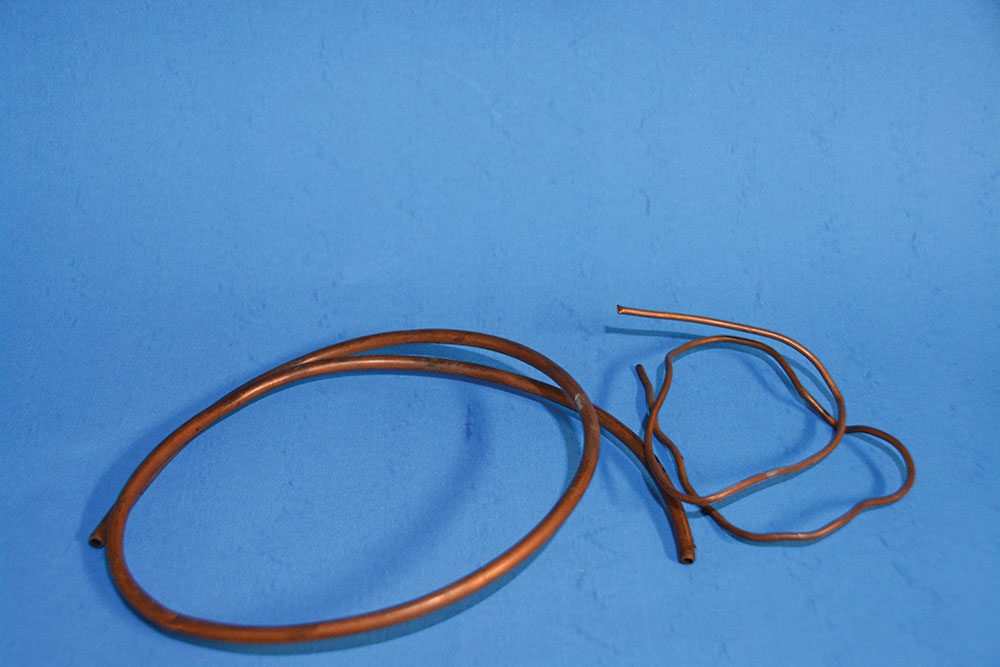

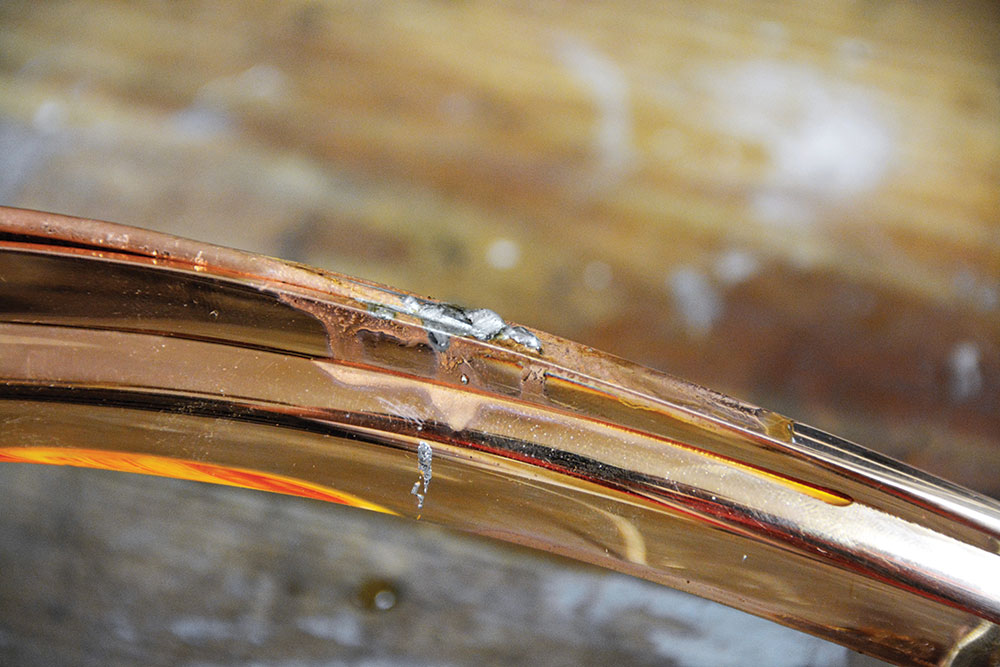

Finding copper material to fill the voids proved to be fairly simple. Since the piece is basically hollow, a simple piece of 1/8-inch copper tubing was gently shaped to fill the long void on top of the ornament. This involved bending it by hand and then squeezing it in a vise to slightly flatten the copper tube. The tubing was fit from the underside to the ornament and then we soldered one end in place; think of this as a “tack-solder,” much like a tack weld. This allowed us to gently tap the copper tube up into the void. The operative word here is GENTLE; die-cast is not known for its strength so you must be careful not to damage the piece. With the tubing fit to the opening it was soldered from the top to fill the seams between the tubing and the hood ornament. Allow the solder to build up above the piece. Since the lead solder is very easy to work, fill it high and then carefully file it down to the proper profile. Once the filing has formed the initial shape, finish the piece with a soft sanding block and sandpaper. We first sanded with 320-grit and finished the work with 400-grit.

The front opening is a bit irregular, but using the same tubing technique (this time we used 1/4-inch tube) we shaped a filler piece and soldered it in place followed by more of the filing and sanding to smooth the piece. Satisfied with the shape and finish of the piece it was returned to Advanced Plating for final finish, copper, and chrome plating. You can use the copper and solder method to repair all sorts of die-cast, chrome plated pot metal trim in this way.

When we received the piece back in finished chrome plating, we were more than pleased. The plating was impeccable but beyond that we were pleased with the overall custom shape of the piece. It will be one of those things that most people may never notice, but such subtle changes are what make a car special and we are pleased knowing our hood ornament is one of one. MR

Sources

Advanced Plating

(615) 227-6900

advancedplating.com

Speedway Motors

(800) 979-0122

speedwaymotors.com