By Brian Brennan – Photography & Videography By John Jackson

Joe and Josh Bailey, a father and son team, are no strangers to hot rods of any make or year; when it comes to Chevys, especially Tri-Fives, these boys “stand tall.” Over the years they have built a number of them. Back in 2015 Joe’s 1956 Chevrolet 210 took home the Tri-Five of the Year honors at the American Tri-Five Association’s inaugural event in Bowling Green.

The 1956 was Joe’s dream, so this time around it was Josh’s turn to have his dream come true—a 1957 Chevrolet 210. He’s always thought of this specific Tri-Five Chevy (nickname for 1955, 1956, and 1957 Chevy sedans) as his favorite. Back when Josh was 9, Joe bought three 1957 Chevrolet 150 two-door sedans and over the course of time sold two but kept one for Josh. To listen to Josh tell the story, “Well, that car had been set up for a

427 big block, but our friend Bobby Alloway told him I needed a ‘training motor’ to start with. It ended up having a 327 engine with a TH350 Transmission. This is the black and turquoise 150 Utility Sedan I still own today.”

The Baileys’ day jobs are working at Alloway’s Hot Rod Shop. While the two of them perform a myriad of jobs, most days you can find Joe in the paint and detailing area working his magic while Josh is fabricating on a fresh build. Night, and all other free time, is spent working on their own projects. Turns out building a Tri-Five Chevy is the perfect father/son project and now that sufficient time had passed it was Josh’s turn to have his dream 1957 Chevy 210 Delray sedan. This time the “training motor” was kicked to the corner of the garage and in went the MacDaddy of all big-block Chevy: the L88, or at least their adaptation.

Check Out Another Tri-Five: A 1955 Chevy Gasser that Spits Flames

All of us car types know that the L88 is the Chevy engine of mythical proportions. There were only 216 of these motors built for Corvettes between 1967 and 1969. (Although many motors/blocks were sold over the counter.) Horsepower rating from the factory was 430 but the real truth lies somewhere between 540 and 580. Mind you this was the ’60s and it could move a new Corvette through the quarter-mile in the 11s. That was epic performance for the day.

Before we delve into the story on the Baileys’ 210, let’s get a little background on where the “210” nameplate came from—as it plays into this story. The Chevy 210 was the midrange model of the Chevrolet car from 1953 to 1957. The “210” was arrived at by taking the production series number (2100) and dropping the last digit. Back in the early ’50s there was a trend in Detroit to use numbers in model names. The Chevy 210 took the place of the “Styleline DeLuxe” model that came before. The Chevy 210 stuck around until 1958 when the “Biscayne” took its place.

Josh also wanted to draw attention to the fact the car is a Chevy 210. The license plate is obvious but look closely at the rear quarter-panels. Story has it a dealer in the south made the “Two-Ten” emblems and then installed them on the front fenders. Josh has seen photos from 1958 showing a 1957 with these emblems. A friend found a pair online, and while many people think they were for the 1953 or 1954 Chevy 210 because of the logo similarity, the fact is they are not. Josh put them on the rear quarters in place of the factory emblems and it generates lots of conversations.

When any hot rodder embarks on a build it’s known it will be a long haul, especially when it’s your reputation for excellence that’s on the line—cutting corners isn’t an option. Time becomes the expendable component—it’s finished when it’s finished. To get Josh through 4-1/2 years of building he would often gain strength by looking at a particular photo on his garage wall.

The photo on the wall: Smokey Yunick is revered within the world of racing, southern lore, and pretty much everyone who wants to one-up those in charge. Joe once had Yunick autograph a picture to the two of them of his famed 1966 Chevelle that never saw the light of a NASCAR race day. (Ah, the innovative and creative mind of the man from The Best Damn Garage in Town.) The photo was autographed to the Baileys and oftentimes provides the required “kick in the seat of the pants” boost for the added inspiration and motivation to get the job done.

Speaking of The Best Damn Garage in Town, one only has to look at the decklid to see a similar reverence in the “Bailey Built Garage … Best Detail in Town.” The Baileys pride themselves on quality of workmanship for sure but it’s their attention-to-detail that truly sets their cars apart. Before any bodywork was completed all trim and bumpers were fitted for tight clearance, and all door, trunk, and hood gaps were tailored.

The PPG Surf Green basecoat/clearcoat was sprayed on by Joe while the two of them performed the hours of prerequisite bodywork to make the paintjob look as picture-perfect as it is. It should be mentioned that the entire build took place in the Baileys’ garage, never leaving for other work. The color was an idea that they tried on a 1955 Chevy pickup. Seeing how well it was received they opted to try the color once more, but this time a smidgen more green was added to tone down the “white” look when in the sun.

Check Out This Interesting Story of a Mark IV 427-cubic inch Big-Block Engine

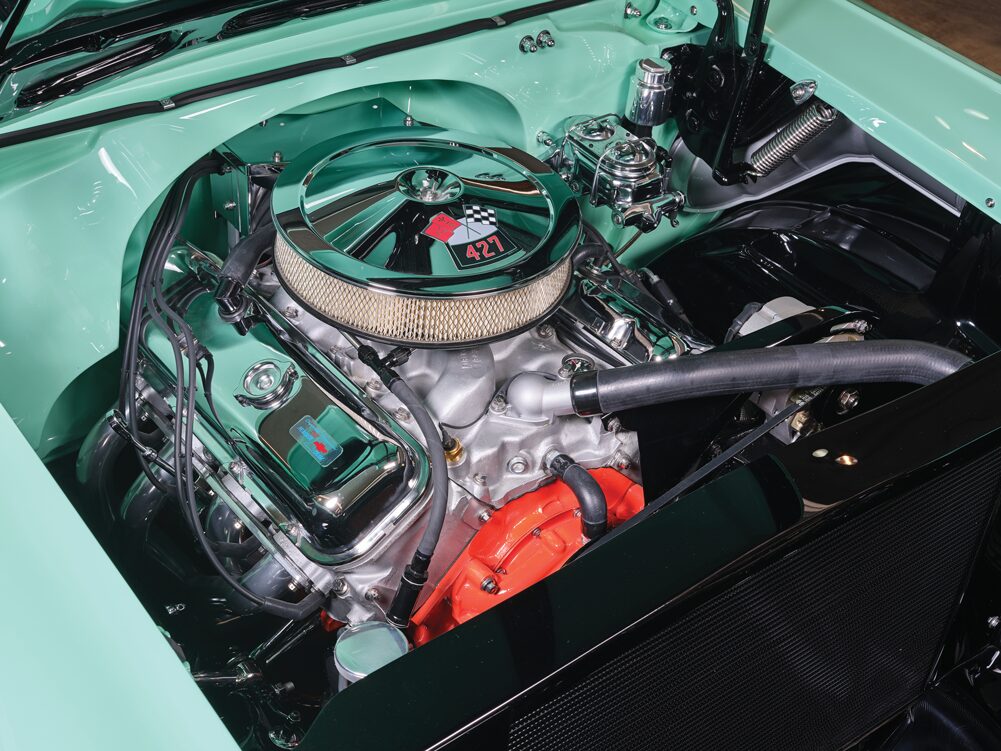

L88 motors aren’t readily available at your local wrecking yard much less your local Chevrolet Performance dealer. If you want an L88 you will pay dearly for an outtake from one of the 216 produced, or one from an earlier over-the-counter motor/block sold, or you make your own. The Baileys opted to pay homage to the iconic L88 and build their own. The 1970 iron block came with four-bolt mains and was furnished with many of the correct L88 parts to complete the build. B&B Performance Engine handled the machine work, boring it 0.060 inch while the assembly was handled by Roger Huffstetler. From here the iron block was armed with the correct crank, a Comp Cams custom grind hydraulic roller, and aluminum heads with the correct Winters L88 casting numbers (3946074) then covered with a pair of 1970 Corvette chromed valve covers. (We checked, it’s the correct head casting number.) ARP stainless head studs are used (along with every other bolt on the engine) to secure the heads.

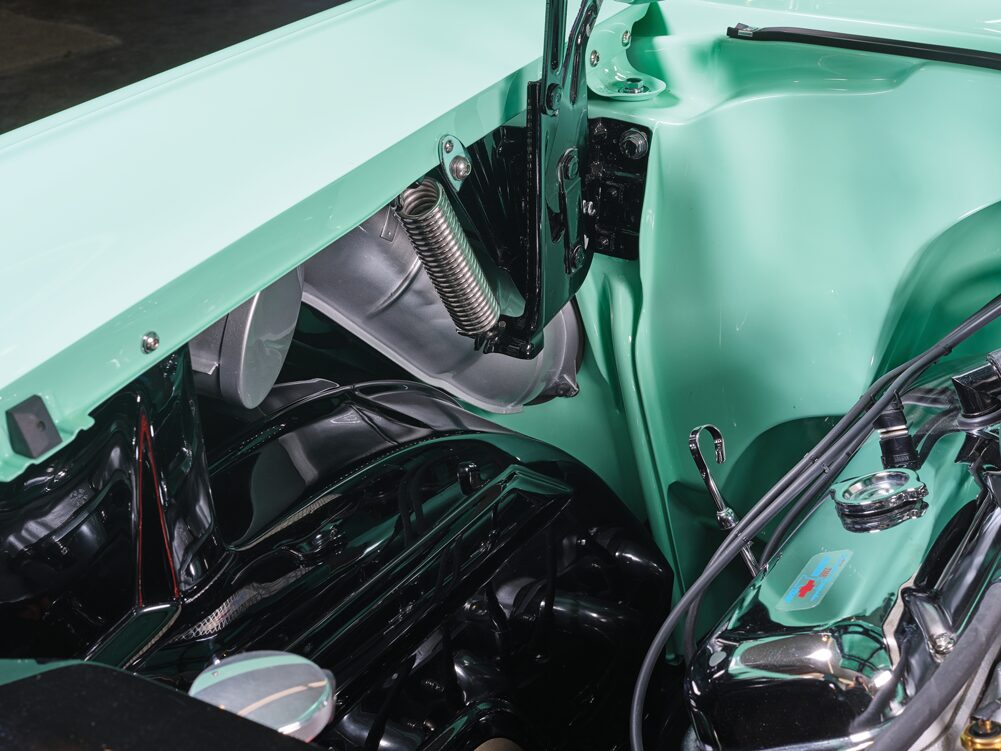

The motor is an accurate 12.5:1 compression ratio, keeping its L88 heritage intact. (It was mid-year 1969 that the compression was dropped 12.5:1 to 12:1.) A GM aluminum single four-barrel intake manifold, again bolted in place with ARP hardware, is topped with a Quick Fuel 850 double-pumper carb (and a 1970 Corvette air cleaner) teamed with a Quick Fuel mechanical fuel pump. The oil pan had its capacity expanded to 8 quarts to provide for ample lubrication and cooling efficiencies. Josh also built a custom core support for the Walker crossflow radiator that’s matted to a pair of Cooling Components electric fans, and a Flow Kooler water pump to maintain the L88’s cool. More engine accessories include the MSD distributor, 6AL box, Blaster coil, Moroso primary wires, and the trunk-mounted AC Delco battery.

The exhaust system is highlighted by a Borla 3-inch stainless steel mandrel kit and a pair of XR1 oval multicore 3-inch mufflers and modified Patriot full-length headers with 1-7/8-inch primary tubes. From here Josh fabricated his own exhaust, including an X-pipe, which really enhances the mellow tunes. In an effort to gain under body room, Josh raised the trunk floor several inches, thereby changing its slope for the 3-inch exhaust to have sufficient space to travel up and over the rearend.

An American Powertrain (AP) kit is used to link the tribute L88 to the TREMEC TKO 600 five-speed manual transmission, which includes the transmission cross member and the hydraulic throwout bearing and a Wilwood hydraulic clutch master cylinder. The shifter is an AP White Lightning model while AP also supplied the steel flywheel, clutch disc, and pressure plate. An AP driveshaft is also part of the kit while Josh opted for an old-school Ansen scatter shield used for its safety benefit but mostly to depict its period feel.

The body also received “unseen” mods, such as the 3-inch widened rear wheeltubs to allow for the 9-1/2-inch rear wheels to fit neatly, and at the same time this area is used to provide room for the custom-length sway bar. One of the endearing features of the 1957 Chevy 210 is its tailfin gas filler location.

Josh realized that by overfilling the tank, gas would backflow out of the original filler cap and onto the driver taillight. To combat this, he solved the problem with an independent vent system and changed to an O-ring sealed cap. Speaking of fuel, note that you will find it hard to see the brake and/or the fuel lines. Josh wanted to keep these lines away from any heat source, which might affect the fluid’s efficiency. The fuel line is run through a tunnel that passes by a header as heat is deflected and keeps the line away from the idler arm and draglink. There’s also a heat sleeve on any line or wire that may be exposed to engine or exhaust heat. Josh isn’t a fan of the stock mechanical emergency brake so he opted for an E-Stopp push-button system that’s mounted inside the trunk along with other electric components while the actuator button is on the lower left side of the dash.

Inside the stock-appearing interior PPG Surf Green and 1955 Neptune Green paint was used. The stock dash does feature “delete” plates for the radio, heater control, and clock. Josh rebuilt the stock gauge cluster and to this he incorporated a 1966 Chevelle “knee knocker” tach.

Using a Painless Performance Products fuse panel Josh handled all of the wiring. The steering wheel is an interesting piece as it sits on top of an ididit replacement column. Josh constructed it using an original centersection, with the “Two-Ten” logo, and then combined it with a 1965 Impala outer ring and painted it in the two-tone greens. Ciadella Interiors provided the original-style patterns and colors for the headliner, door panels, carpeting, and seating. The headliner is a perforated light green, the carpeting is an original Daytona weave in dark green, while the vinyl seat material is in Green Inca fitted over the stock front and rear bench seats in the 210 Delray pattern. The trunk is trimmed like the interior in its colors and materials. The car’s glass is factory green tint, giving it an even deeper green look.

The stock frame was highly modified by Josh, performing such tasks as welding up all holes that weren’t required, open areas were boxed, and then the frame was slicked. The IFS is based on narrowed Heidts control arms with their 2-inch drop spindles, coilover shocks, and a Heidts sway bar modified by Josh. The OE steering is replaced with a Borgeson Delphi 600 box with a 12.7:1 ratio. Front braking is based on GM S-10 drilled-and-slotted rotors with Wilwood GM replacement calipers while the rears are the Currie large drum brake kit. Pressing the brakes into service is a Classic Performance Products Corvette-style master cylinder with OE pedal assembly.

The rear suspension is based on a polished aluminum Currie 9-inch housing with the pumpkin packed with 4.56 TrueTrac limited-slip gears and 31-spline axles. Holding up this mean-looking Tri-Five Chevy is a set of wheels made by Wheel Smith—steelies in front and aluminum in the rear to achieve the correct backspacing. The ventless wheels look correct for 1957 and they are able to accommodate the original “dog dish” hubcaps. The fronts measure 16×8 and the rears are 17×9.5 with 225/60R16 and 275/60R17 General radial rubber.

Need More Tri-Fives? Check Out: Project X-Tra 1957 Chevy

It’s pretty hard to beat this combination of a 1957 Chevy 210 packed with a tribute L88 and a five-speed. This is what a hot rod Tri-Five should look like. MR