In Part 1 of our series on engine cooling (Volume 5, Issue 54) we began looking at cooling system components starting with radiators. This time around we look at another critical component: engine cooling fans.

For a cooling system to be effective there are three basic necessities: a proper water pump, an efficient radiator, and adequate airflow through the radiator core. In many cases, once a vehicle is moving at speed, 30 mph or so, the flow of air through the radiator is sufficient to keep the engine cool. But when your car is moving slowly, or worse yet when it’s stationary, an effective fan may be the difference between the cooling system maintaining a safe operating temperature and steam coming out of the engine compartment and a river of coolant running down the street.

When it comes to selecting a fan there is a variety to choose from:

Mechanical Fans

Engine-driven mechanical fans are simple, cheap, effective, and have been used since the dawn of the automobile. Early on, two-blade fans were common, but as engines became more powerful and the demands on the cooling system were greater it became necessary to increase airflow, so more fan blades with greater pitch were added. While markedly more efficient when it comes to moving air, the drawbacks to more aggressive fans are the increased power it takes to drive them and the noise they make. On the plus side, when it comes to moving lots of air, an engine-driven fan is hard to beat.

A variation on the mechanical fan is the flex fan. Those of us who were around in 1962 may remember the green fiberglass flex fans that were introduced that year. Today flex fans are made from stainless steel, steel, or plastic but the idea is the same. The extreme pitch of the flex fan’s blades will pull lots of air at low speeds then flatten out at higher speeds for less drag.

Clutch fans are found on many OEM applications. They use a rigid fan attached to a clutch that slips under specific circumstances. There are three types of clutch fans commonly found: the viscous/torque type have some slip all the time that limits their speed to a percentage of the water pump speed, the viscous/temperature-controlled type slip less as temperature rises, increasing fan speed, and the viscous thermostatic type that turns on and off at a predetermined temperature. With this style of clutch, the fan “idles” and doesn’t run at engine speed until needed.

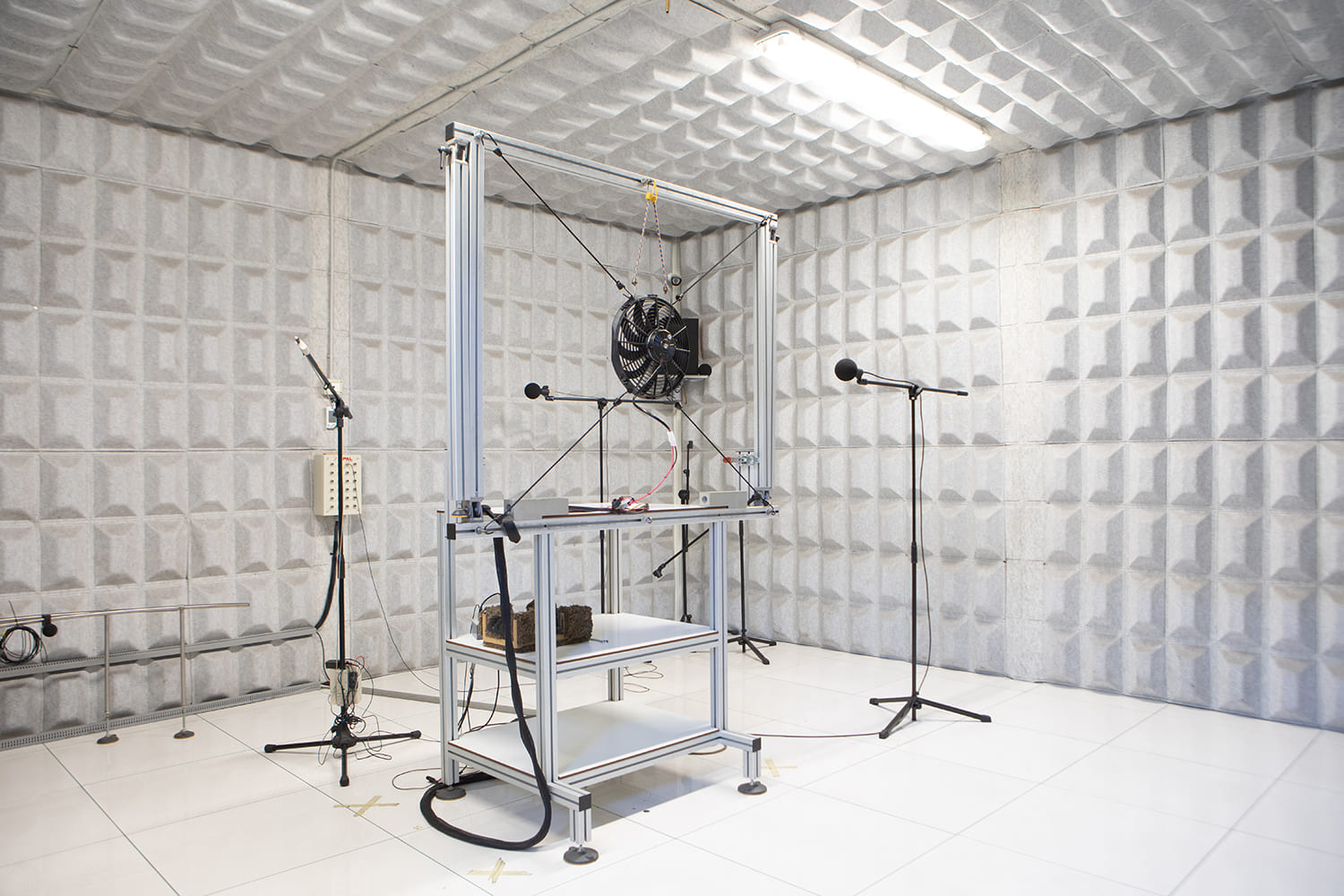

When a mechanical fan is used there should be at least 1 inch from the blades to the core and the blades should never extend past the core (unless a shroud is used). The difference between the lower static pressure at the core and the higher static pressure behind the tanks can cause the fan blade to flex forward. That may result in a weird pulsating sound or damage to the fan and radiator (see the accompanying photos for graphic proof).

Fan Spacers

To properly locate a mechanical fan in relationship to a radiator or shroud it’s often necessary to use a fan spacer, but not all spacers are created equal. Some cheap spacers are not very accurate, which may cause the fan not to run true, resulting in vibration and premature water pump wear. If a spacer is necessary, use a machined aluminum spacer and limit its length to 3 inches.

Electric Fans

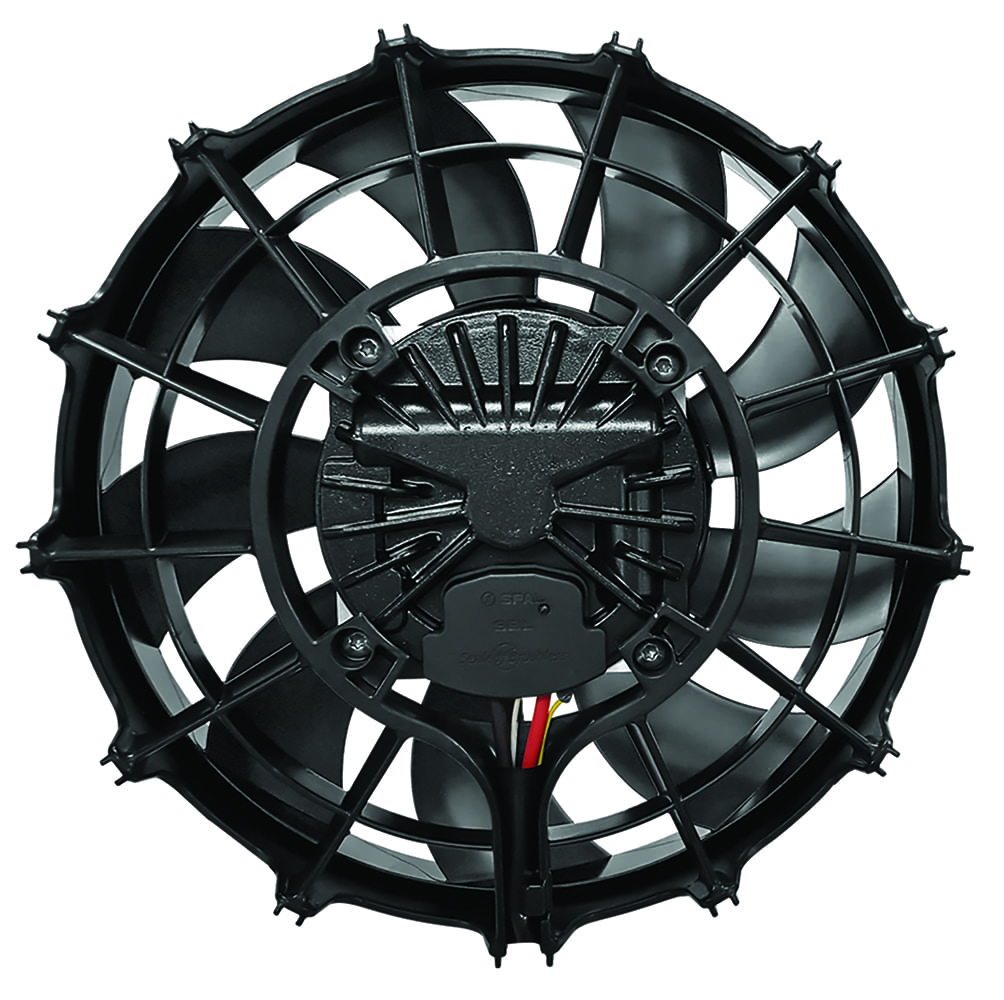

Electric fans are found as “pushers” to be mounted in front of the radiator and “pullers” to be mounted on the engine side of the radiator. Tom Longo of SPAL recommends a puller for most applications when there is room for them to fit on the engine side of the radiator. This is especially true in vehicle applications where ram air is strong enough to cool the engine at speed. Rear-mounted puller fans don’t block any natural “through radiator” airflow and can therefore generally turn off at highway speed, saving power.

When comparing fans Ryan Salata, of Proform, points out electric fans have several advantages over the mechanical type in terms of performance. Salata adds, “Mechanical fans are belt-driven, so the fan’s performance is tied to the engine’s rpm and horsepower that would otherwise be transmitted to the wheels is instead going to the fan. Additionally, in low-rpm situations, such as sitting at a traffic light, a mechanical fan may not generate enough airflow for the required cooling.”

When choosing an electric fan there are several considerations, and one of the most often used for comparison is cubic feet per minute (cfm) rating. However, something called static pressure can change that rating dramatically. Salata explains it. “Static pressure is created when something is blocking the air that the fan is trying to pull through. In automotive use, that something is the radiator and any other coolers that are stacked in front of the fan; cfm drops as static pressure increases. At Proform, fans are rated at zero static pressure.”

SPAL’s Tom Longo adds, “Pressure can vary system to system depending on the thickness of the radiator, the fin spacing, and even type of fins. The static pressure of a given system directly relates to how hard the fan must work to move the air. Generally, the higher powered a fan is the more pressure it can overcome. There are a few other factors, such as the shape of the fan blades and the size of the fan that influence the fan’s ability to overcome pressure. But even this varies from application to application.

Another common means of comparing fans is the power of the motor. However, motor power alone doesn’t rate how much air moves. Other factors, such as blade design, speed, and pressure resistance, heavily influence performance. Proform suggests fan performance is better measured by airflow (cfm) and airflow efficiency—the amount of power required to move a certain volume of air represented by the Fan Energy Index (fei) or cfm per watt rather than using the motor’s power as the determining factor.

Other important factors when selecting an electric fan are the diameter of the blades and their design. As much of the radiator core as possible should be covered, and in some cases that may require dual fans. Another consideration is the type of fan blades— they may be straight or curved. In operation, S-blade fans are quieter, whereas straight-blade fans generally move more air. For a normal street rod, SPAL suggests using a curved blade fan. For more high-performance applications, a straight blade fan is recommended.

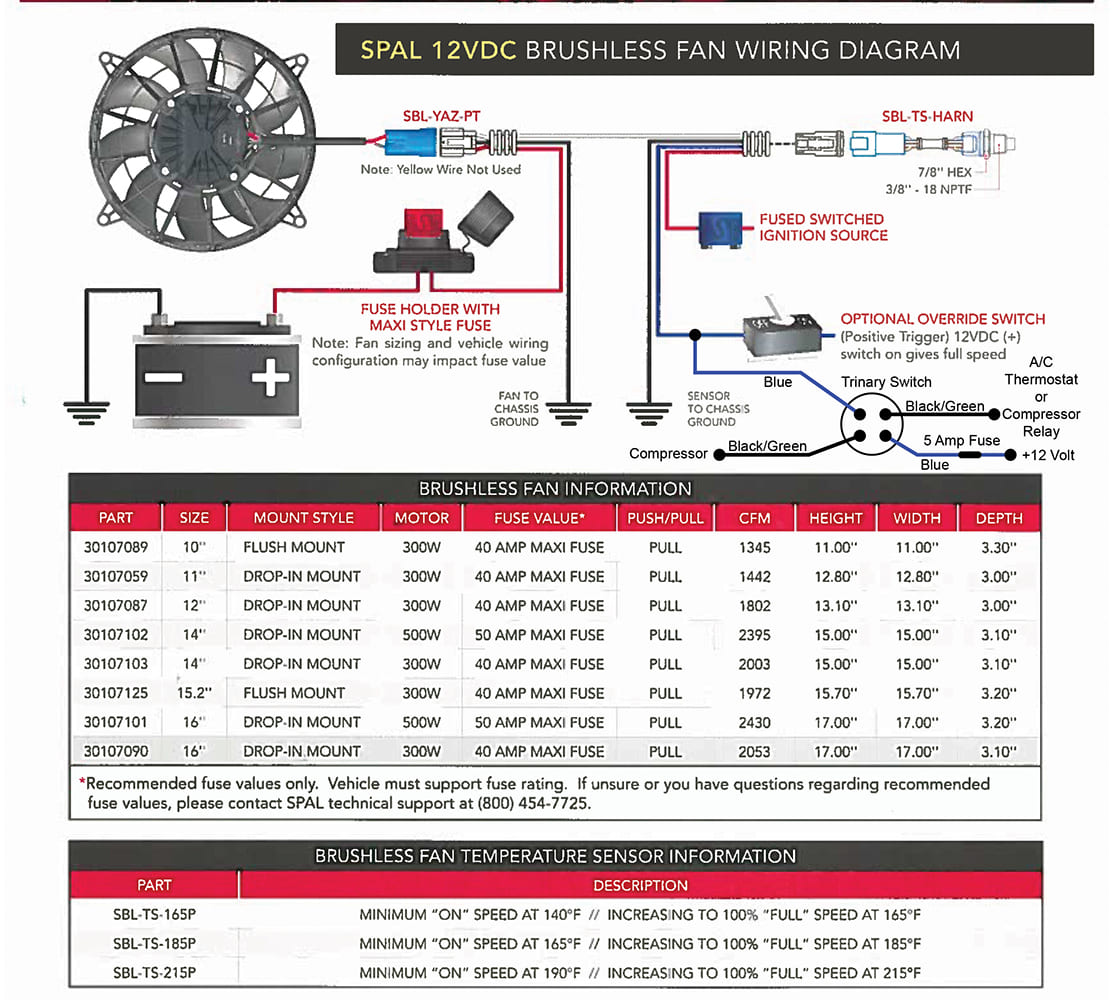

Brushless Fans

A variant of electric engine cooling fans are the brushless designs found on many modern cars. Traditional brushed motors use a stator to create a magnetic field around the rotor, which is the rotating part inside the motor. The rotor has windings that generate a magnetic field when powered, causing the motor to spin. Brushes contact these windings inside the rotor and switch the current, causing the magnets to repel and attract, which in turn causes the rotor to spin. However, the brushes wear out over time due to physical contact. Brushless motors replace mechanical contacts (the brushes) with electronic communication, causing the magnets to attract and repel. With no brush contact, wear and tear is reduced dramatically. No brush contact extends the lifespan of the brushless fan motor and also improves its reliability.

Another advantage to the brushless fan is the “soft start,” or the slow ramp-up in fan speed. That slow start means there is no amp spike from the large initial electrical draw when a brushed fan starts.

To control their operation, brushless motors typically utilize Pulse-Width Modulation (PWM), a type of digital signal that simulates analog signals by switching the output on and off at a very rapid rate. Proform brushless fans eliminate the need for engine-specific controllers by utilizing a built-in, advanced voltage regulation system to control the fan motor speed with a single-wire connection.

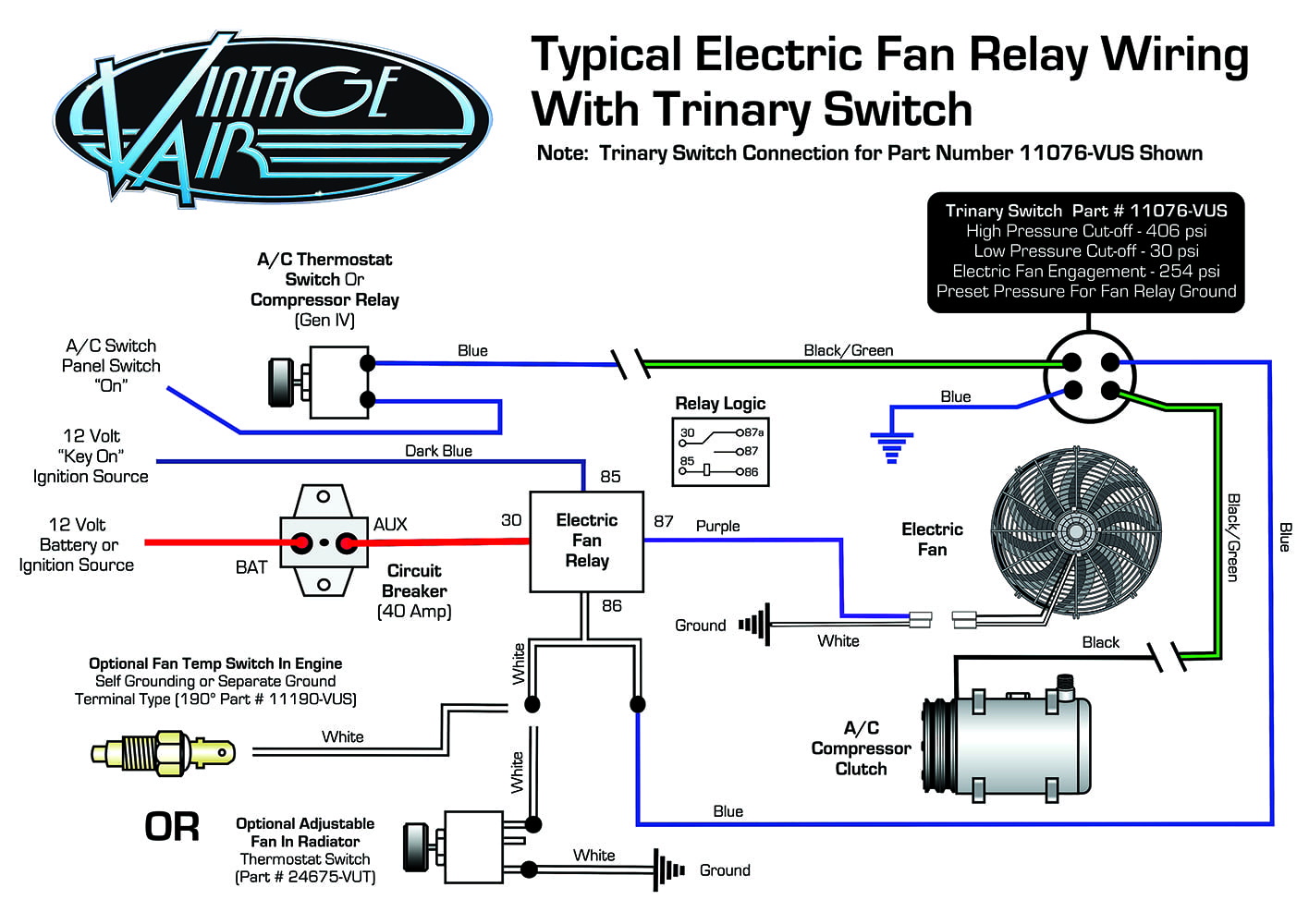

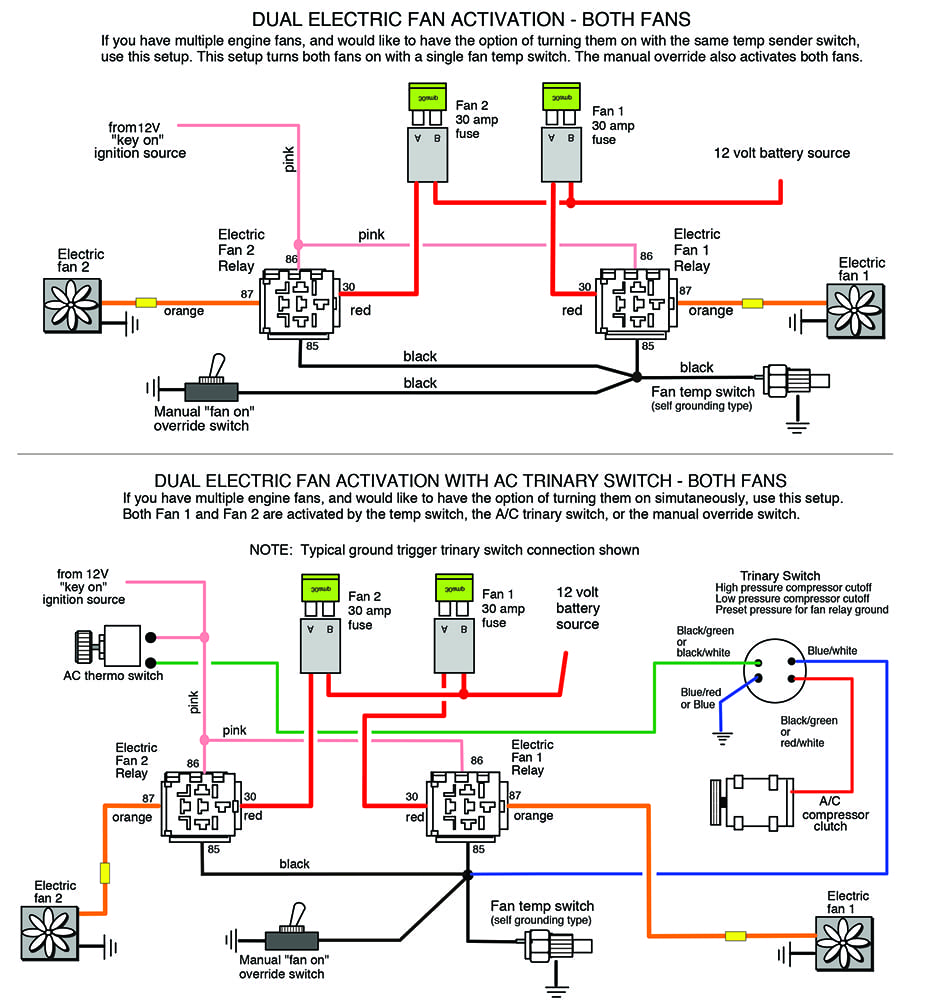

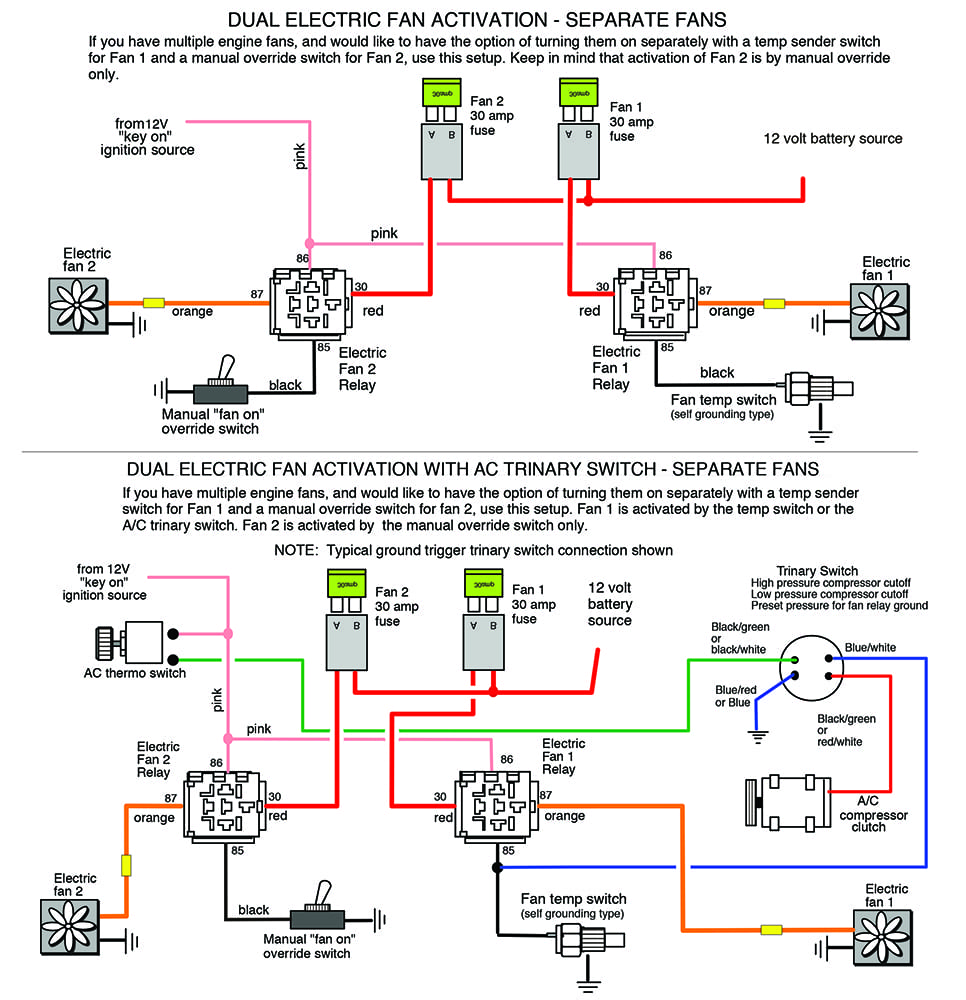

Electric Fan Controllers

There are a wide range of fan controls, from simple to complex. Basic controls use a thermal switch with high and low set points that turn a relay on and off to control the fan. This style switch should turn the fan on approximately 15 to 20 degrees higher than the thermostat’s opening temperature and off around the thermostat’s opening temperature. More complicated controllers have adjustable on and off set points, are capable of controlling variable speed or dual fans, will activate the fan(s) when the A/C is turned on, and will allow the fan(s) to run for a period time after the engine is shut off.

A variation on fan controller design is the PWM (pulse width modulation) type. These controllers use on and off electrical pulses to control the motor. The duration of “on time” is determined by a temperature sensor. In turn, the controller alters the width of the pulse to regulate the speed of the motor as needed. Basically, the longer the on pulse the higher the voltage and the faster the motor spins.

Electrical Considerations

Electric fans can consume anywhere from 4 to 36 amps or more depending on the size of the fan and the efficiency of the motor. Keep in mind that when a brushed electric fan starts the current, draw will spike and be considerably higher for an instant. As a result of the electrical demands from an electric fan it’s important that an adequate alternator is part of the charging system. Check with the fan supplier for their electrical system recommendations.

Shrouds

Regardless of the type of fan installed, a shroud is a wise addition. Without a shroud the fan is only pulling air through an area equal to the size of the blades. A shroud will help pull air across the radiator’s entire core. Shrouds also provide a great way to mount an electric fan to the radiator. It should be noted that shrouds are meant to be used with puller fans, and a proper seal of the shroud to the radiator is important to ensure the greatest benefit from using a shroud.

A unique feature often found on shrouds for electric fans are “flappers” or air vents. At speed, airflow through the radiator may be restricted by the fan (particularly when off). The vents, or flappers, relieve this pressure, allowing more airflow through the radiator.

A Few Final Thoughts

For such a basic device, there are many options when choosing an engine cooling fan, and mechanical and electric fans each have advantages. In most performance applications, the trick is to pull air through as much of the radiator core as possible with the biggest fan that will fit. Add a shroud if possible and you can be confident your Chevy will keep its cool.

Check out this story in our digital edition here.

Sources

Proform

proformparts.com

SPAL USA

spalautomotive.com

Vintage Air

(800) 862-6658

vintageair.com