Ford Ranch Wagon Project Part 1: Roadster Shop Chassis & GT500 Powertrain

By Ron Covell – Photography By Rodger Lee

Work continues at Ironworks Speed and Kustom on Danny Schaffer’s 1957 Ford Ranch Wagon. The interior of this car has been completely redesigned—from the custom headliner to the numerous CNC-machined components on the dash, doors, and console that are unique but made to have an OEM character. Rodger Lee, the proprietor of Ironworks Speed and Kustom, wanted to model the interior styling after a 1960 Ford Thunderbird, an idea inspired years ago by Fat Jack Robinson.

Read More: Deuce 5 Window Coupe

While a few Thunderbird components were used, most of the interior was fabricated from scratch, with Tavis Highlander, from Highlander Concept Rendering, making dozens of sketches for details, large and small, before the fabrication commenced. This design utilizes bucket seats both front and back. Ironworks Speed and Kustom makes extensive use of 3D printing to check the fit and style of components before committing to carving them from metal. They will commonly scan a section of the car before the components are designed to ensure precise fitment.

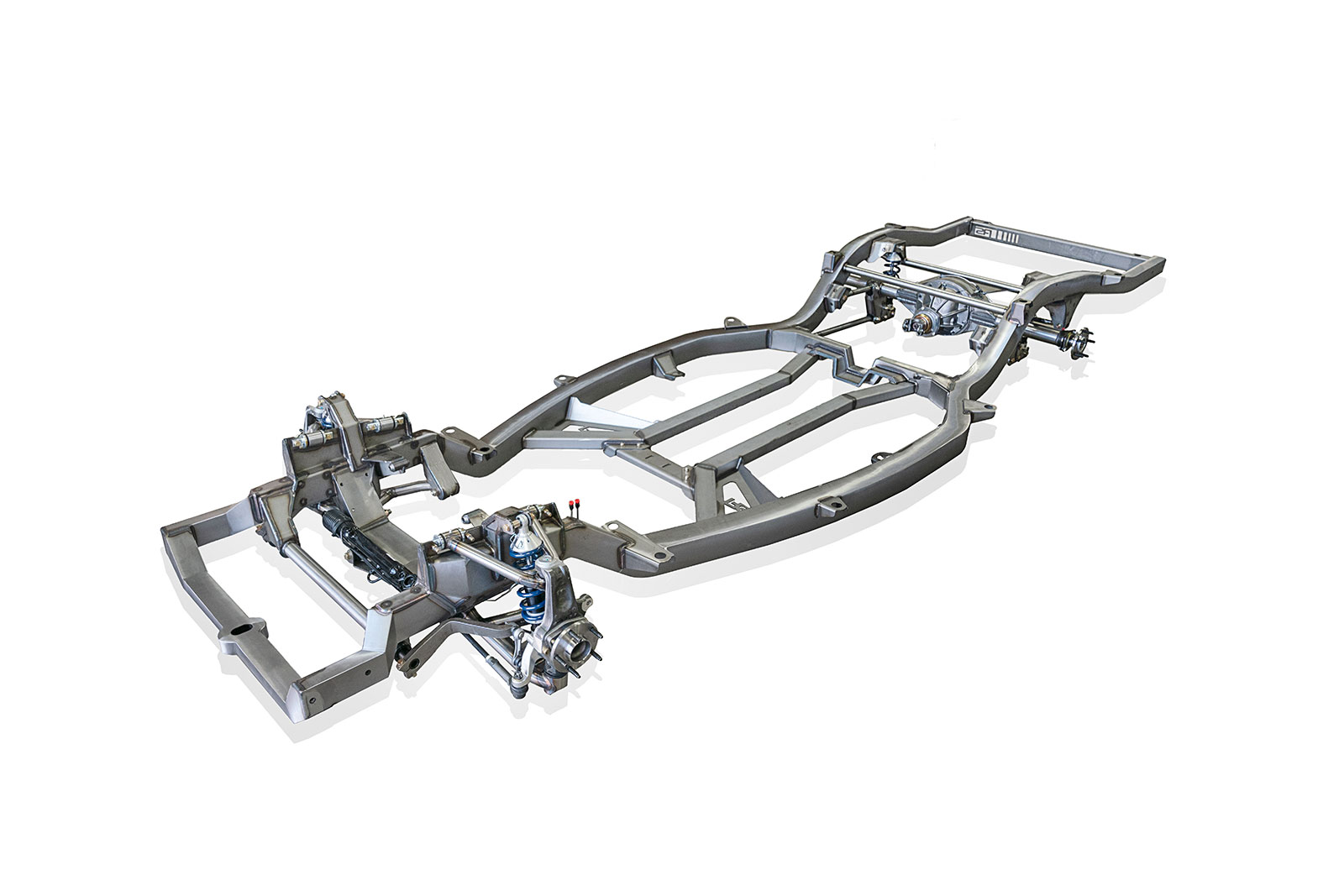

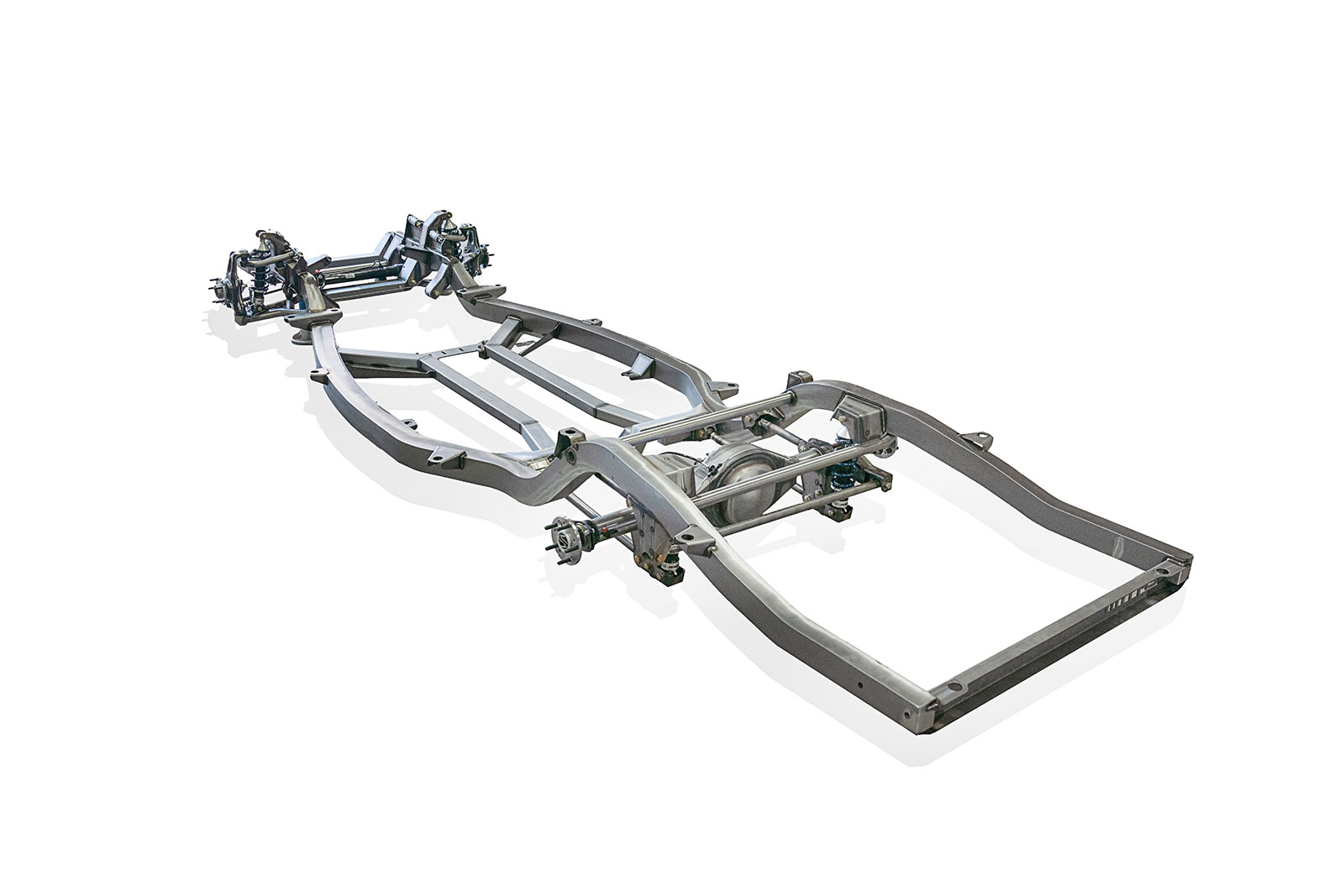

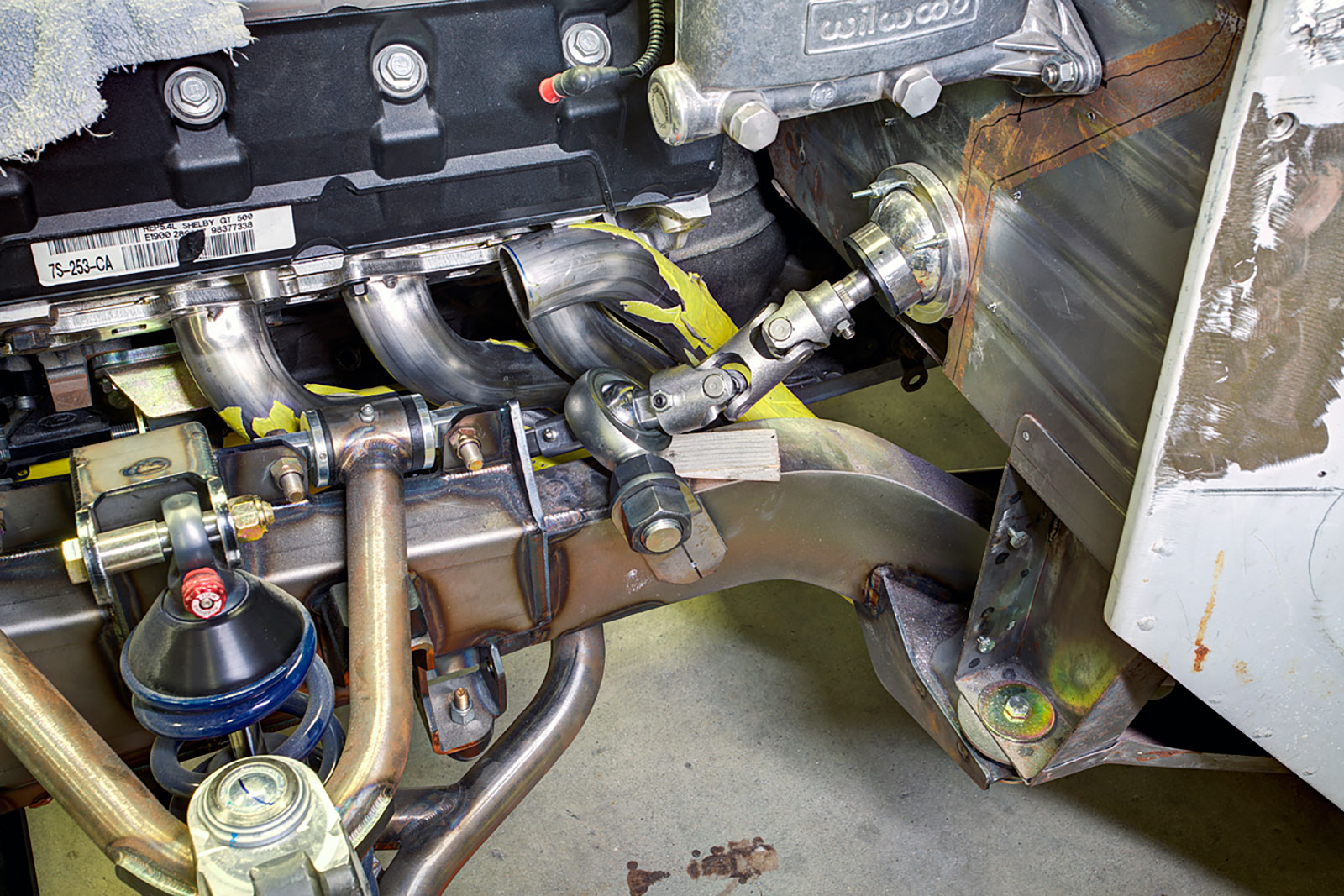

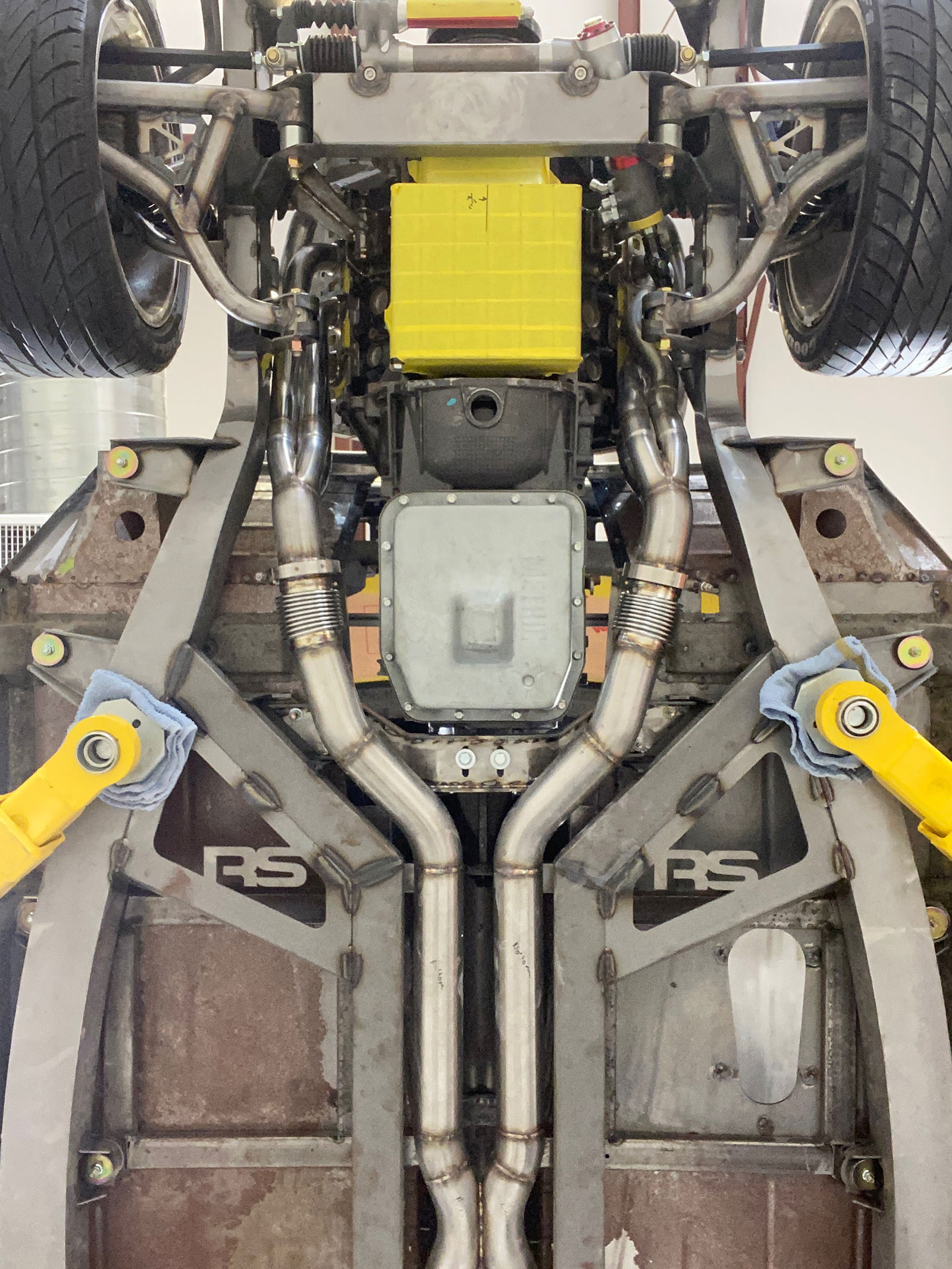

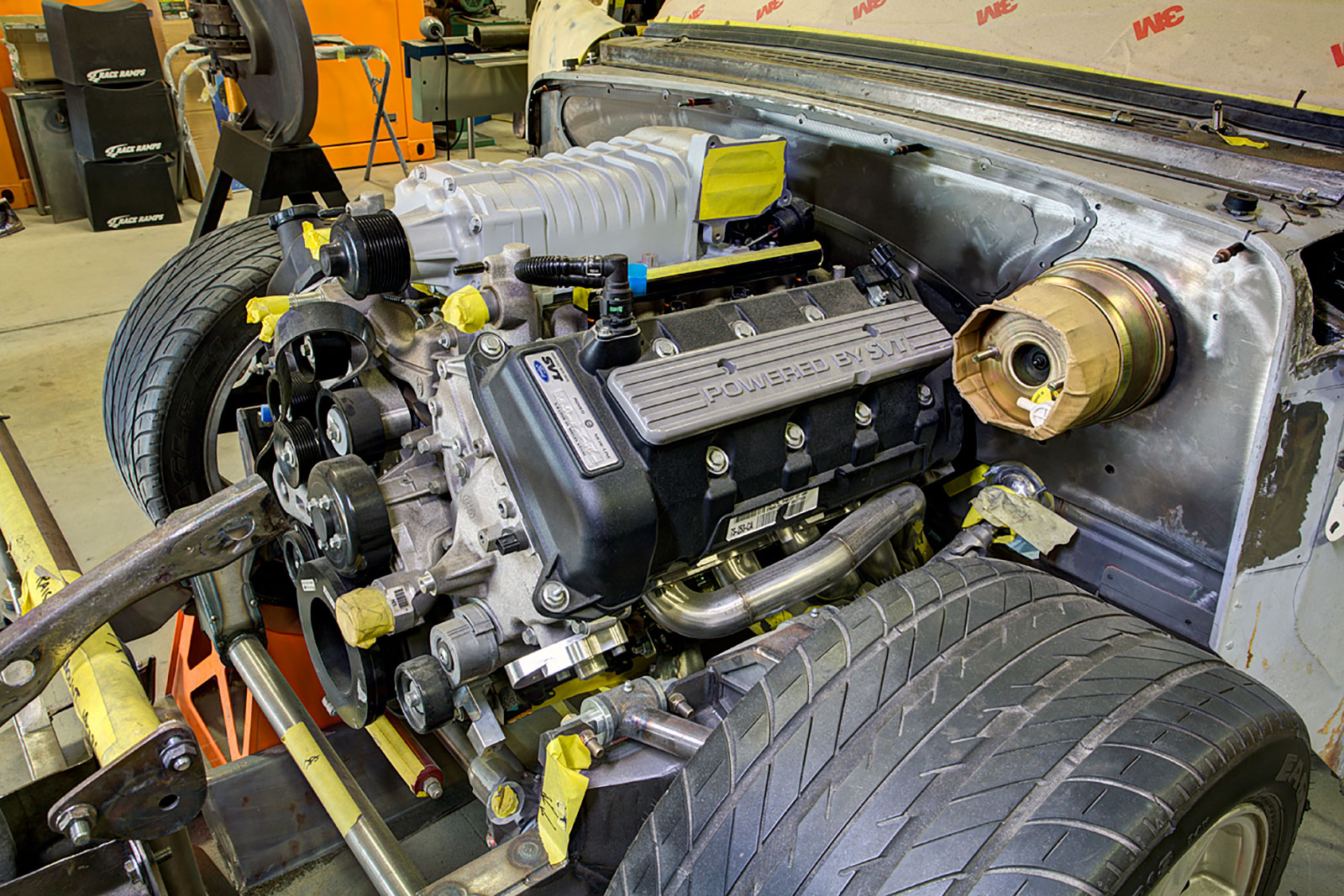

A Roadster Shop chassis was commissioned for the Ranch Wagon, fitted with a Ford 9 inch rear end, a supercharged Ford GT500 5.4 crate engine, and Ford 4R70W transmission. Wilwood brake kit is used, and a Woodward power steering rack complements the Roadster Shop–designed independent front suspension.

They started with a car in very good condition, but on any car that’s over 60 years old you can expect to find some rust damage and minor body damage. The Ironworks Speed and Kustom crew replaced the entire floor, the rocker panels, built a new firewall, and fabricated new patch panels wherever needed. After all the repairs, they straightened every panel to perfection and adjusted the door, hood, and tailgate gaps to precise tolerances.

Read More: Completely Custom 1951 Chevrolet

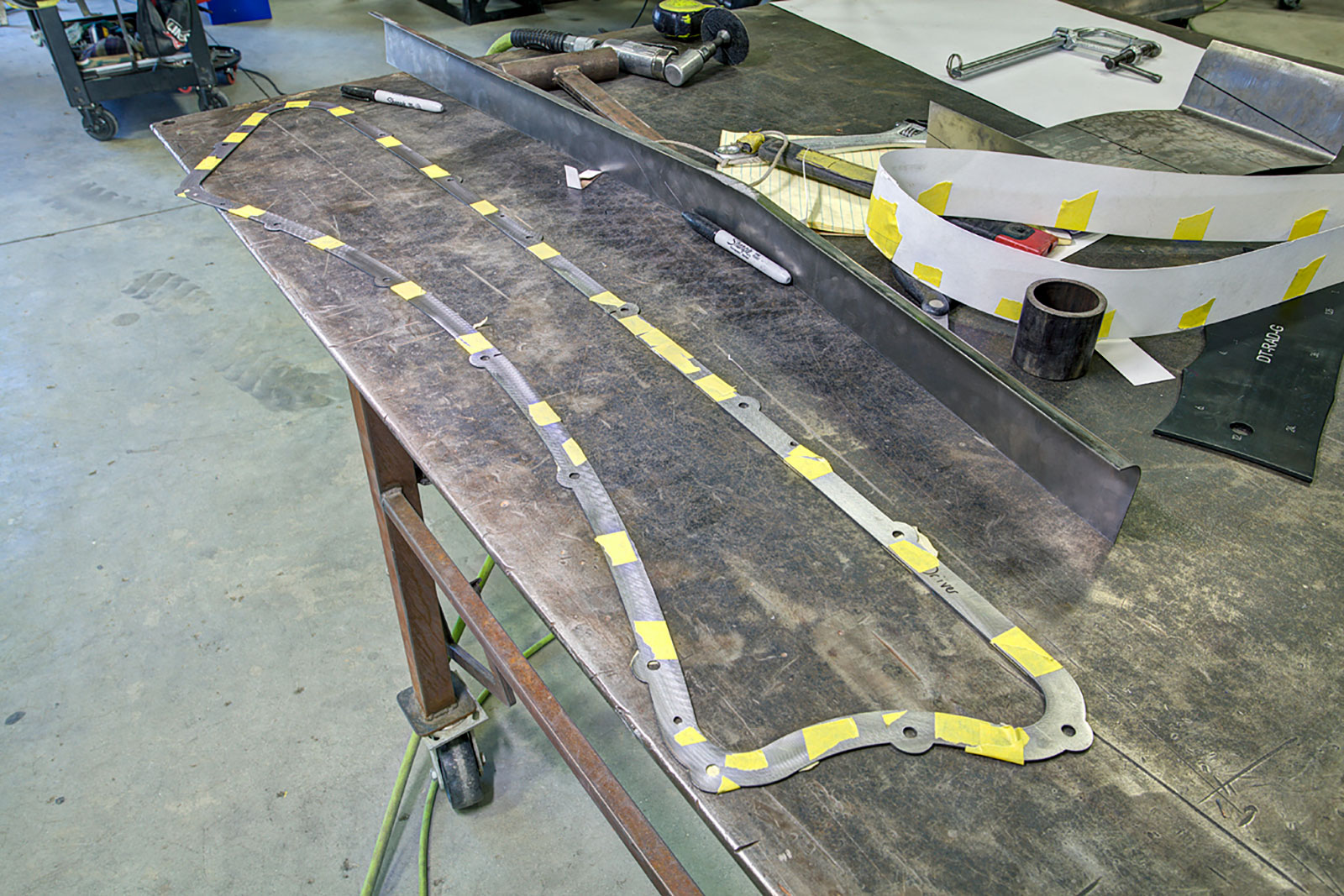

Extensive work was focused on the engine bay, with custom inner fender panels and a scratch-built clearance panel that was fitted to the new flat firewall. A complete stainless exhaust system was built, starting with carefully fitted headers, flowing back to oval mufflers tucked outside the frame rails behind the rear axle. Stainless bellows were incorporated to accommodate engine movement or dimensional changes from heat. Note how well the large-diameter tubes fit inside the contours of the center frame members—a testament to the excellent design of the chassis. At the rear of the chassis, a custom-built 18-gallon stainless fuel tank was built in-house and fitted snugly between the frame rails.

Read More: 1960 Buick LeSabre With Subtle Style

It will take several articles to just scratch the surface of the extensive work being lavished on this project, and we’ll focus primarily on the chassis and underhood area this time. MR

Source

Ironworks Speed and Kustom

(661) 399-8999

ironworksspeedandkustom.com

Click on this issue’s cover to see the enhanced digital version of 1957 Ford Ranch Wagon Gets A Modern Chassis & Powertrain From Ironworks Speed and Kustom.