By Ron Covell

Some of the most eye-catching vehicles at the recent Grand National Roadster Show (GNRS) in Pomona were in competition for the Al Slonaker award—the contest for all vehicles not eligible for the headlining America’s Most Beautiful Roadster award. The winner was the Pat Gauntt 1932 Ford coupe built by Hollywood Hot Rods (HHR) under the direction of Troy Ladd; it took home the ARP custom trophy and the $15,000 check.

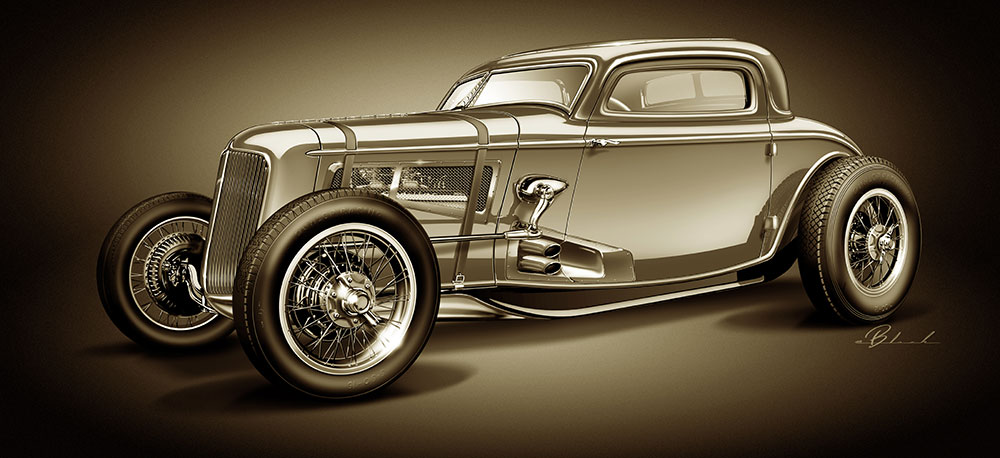

Gauntt had his eye on some of HHR’s past work, but since the car he wanted wasn’t for sale, he commissioned them to build a very special car for him. The concept of this car is rather unique—adapting European sports car elements to a thoroughly American hot rod.

Also check out: How To Build a Bomber Seat With a Speedway Motors kit

This was a multi-year project, and Gauntt gave Ladd free reign to develop the concept to the ultimate extent of his vision. Ladd works closely with designer Eric Black, and they had hatched the concept for a car with this theme several years ago. He built a roadster with a related theme a few years ago, the “Brooklands Special,” and with the green light for the new project from Gauntt, they doubled down and found some creative ways to expand the vision, then quickly commenced with the construction.

Starting with a 1932 Ford 3-window coupe body from Brookville Roadster, the top was chopped 5-1/4 inches in front, 4-½ inches in the rear, and the windshield was laid back 18 degrees. The body was sectioned 1-¼ inches, and a ½-inch section was removed from the doors above the beltline, enlarging the window openings. Ladd decided to split the windshield and angle each pane into a “V” shape. Another unique touch was hinging the glass panes at the top so they can hinge open for ventilation! The roof was left unfilled, and a new insert was fabricated with a “V” shape to match the windshield.

Read More: All about the AMBR-winning 1934 Chevy roadster and its LS Engine.

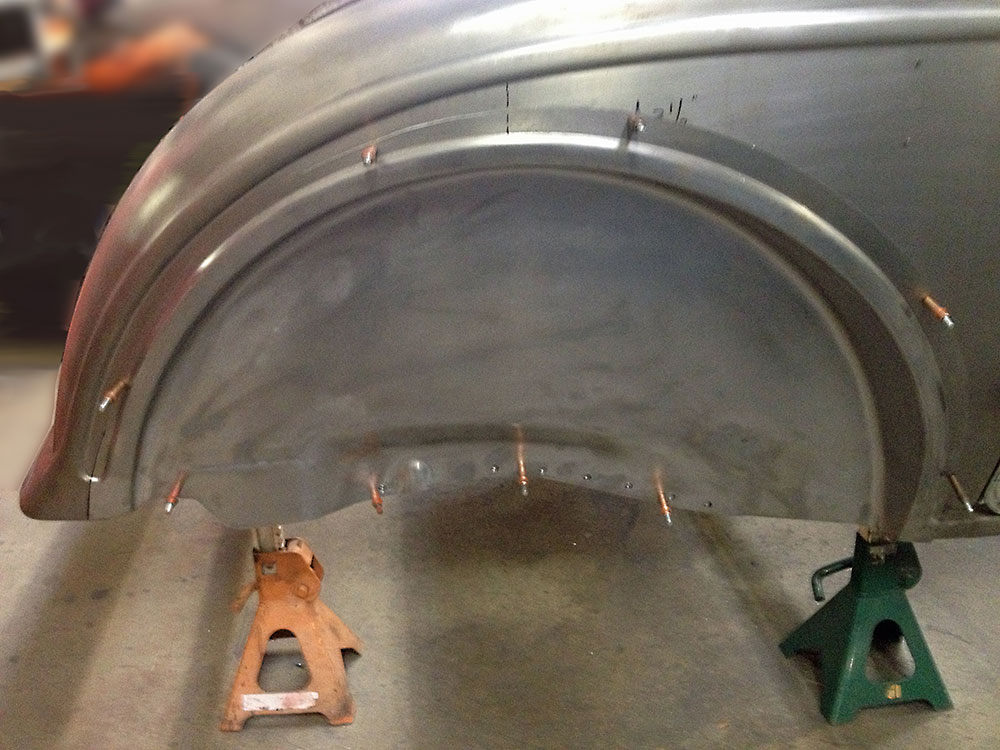

The wheel wells were raised to follow the curvature of the rear tires, the decklid was made smaller (another European touch), and the corners were radiused.

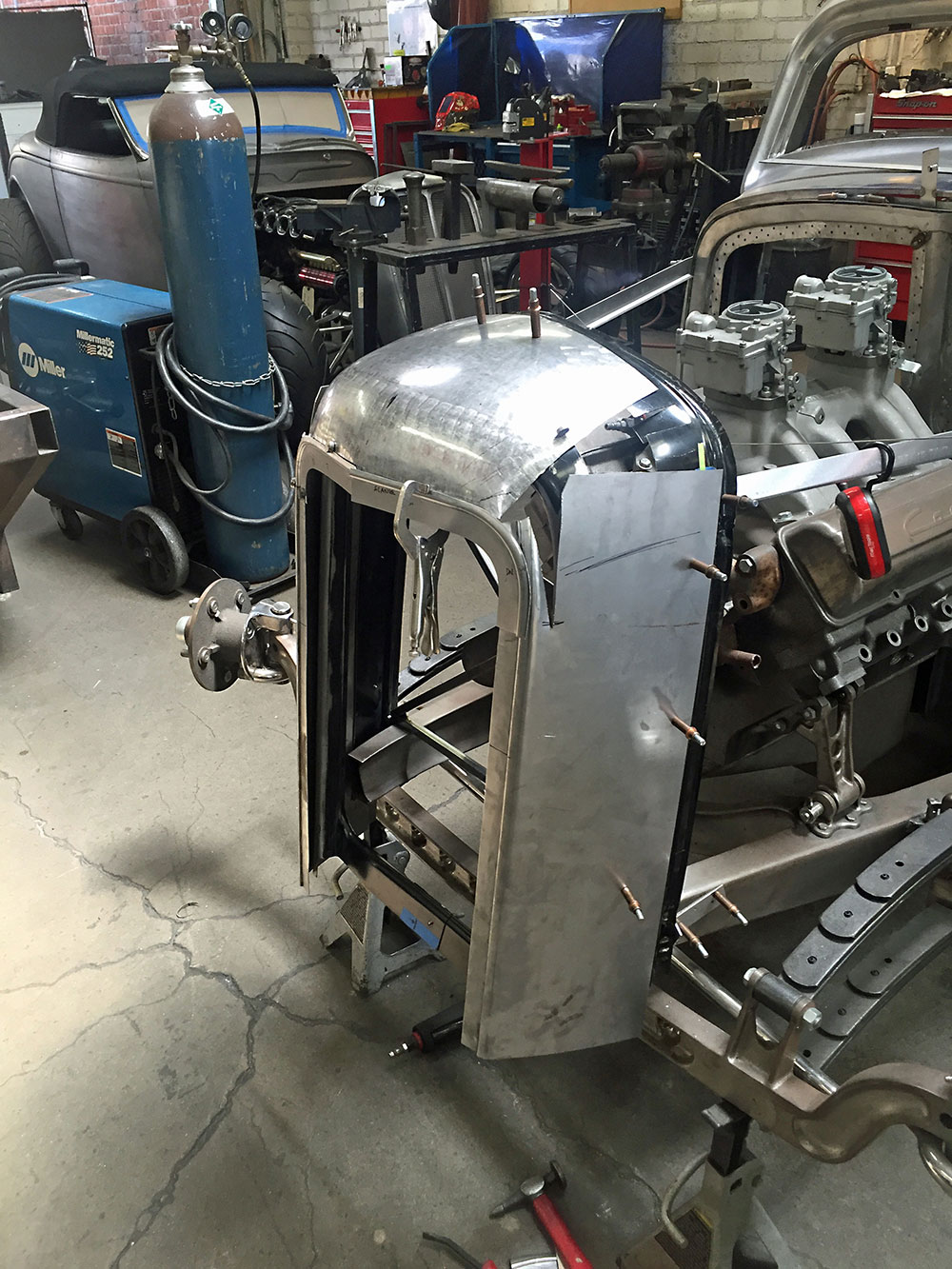

The firewall was completely reconfigured, matching the “V” windshield shape on the cowl top, and following the curve of the doors on the sides. The rear window was split too, and the lower edge positioned so it aligned with the door glass. A grille shell was scratch built from steel and angled to match the firewall. An aluminum rolled pan was formed to hug the rear of the body.

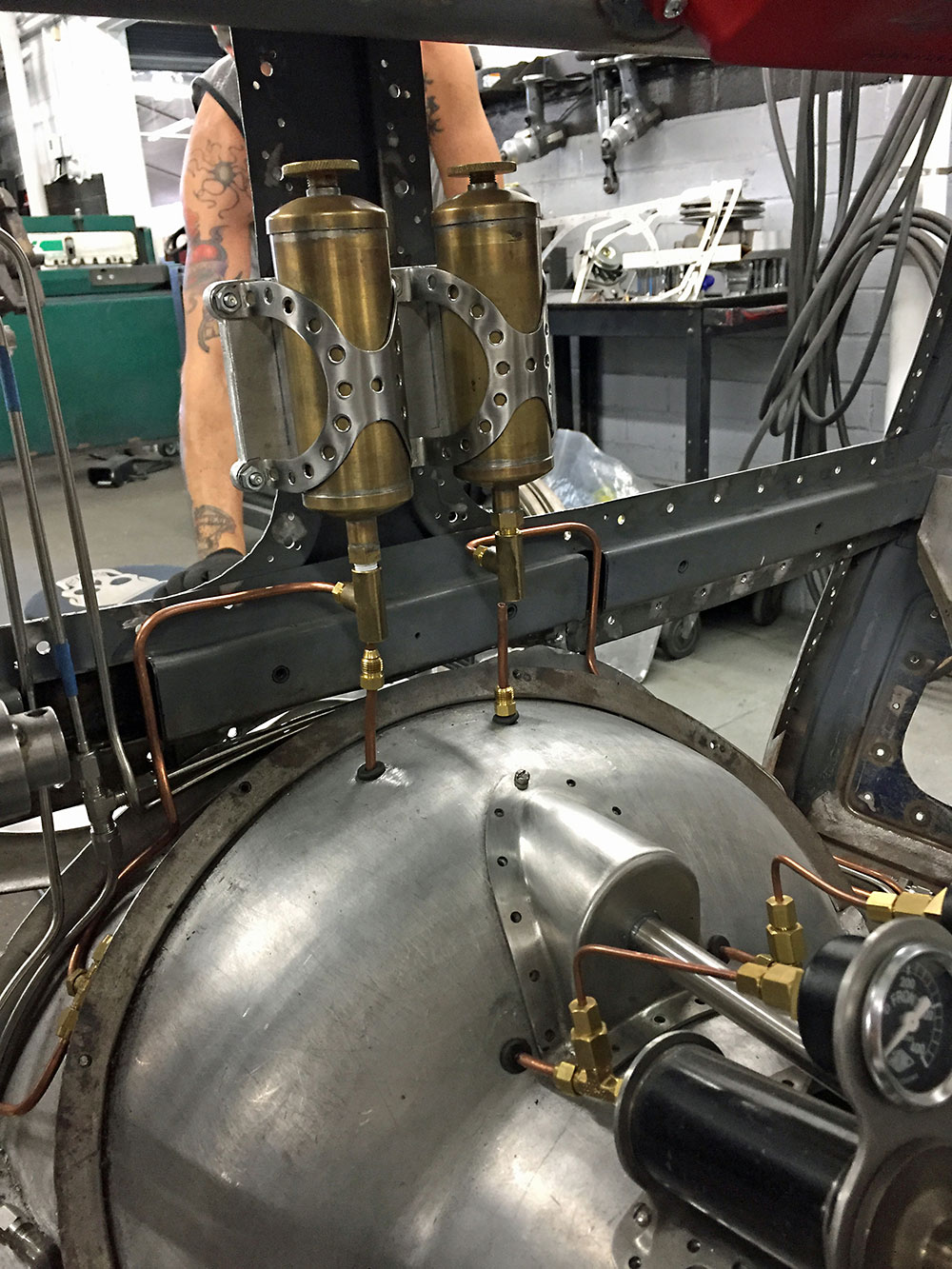

Some of the most demanding work went into the details. Ladd has adopted rules for the work he does, and one of the most important is that everything must be done for a purpose. Another rule is that every “wear point” needs to be protected, usually with a polished stainless trim piece. To continue the theme, all the trim pieces fit into recesses with a sculpted border, adding another finishing touch to the design. Components like the taillights adhere to this rule, too. Troy takes pride that his crew handcrafts every component—nothing is computer designed and CNC machined.

Visit: Above & Beyond a Simple Restoration: 1931 Ford Sedan

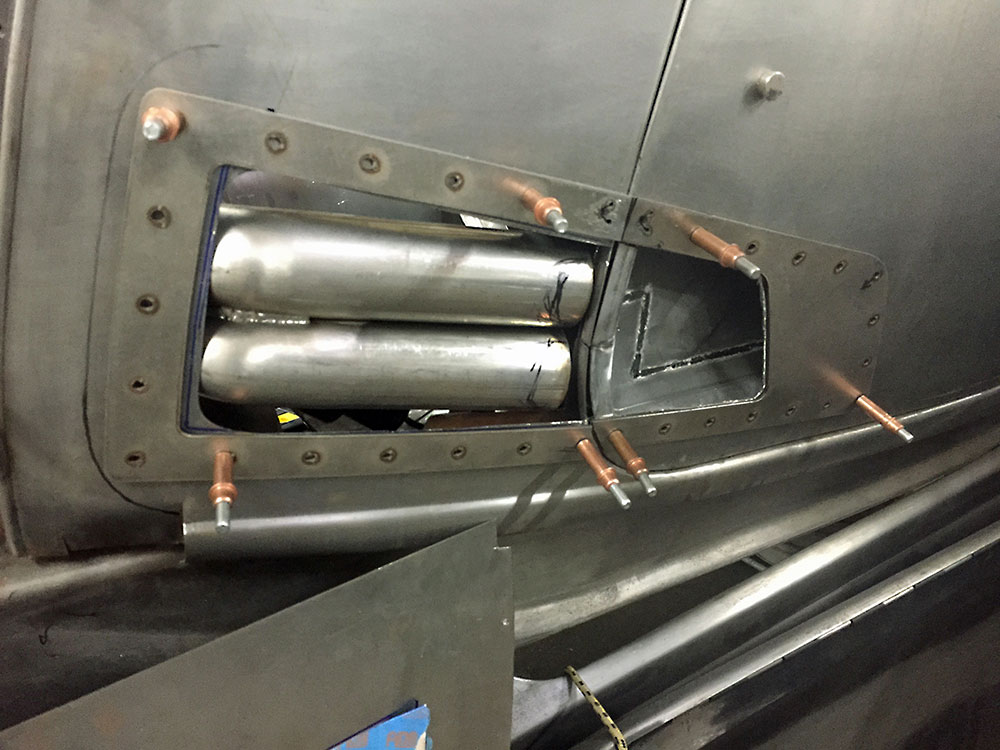

One of the most unique design elements on this car is the cowl exhaust, with a protective stainless trim piece that goes into the doors. There is just enough room in the kick panel area inside the car to house a remotely operated valve, which directs the exhaust to exit through the cowl, or it can be diverted through mufflers carefully fitted under the car. From a side view, you’ll see that the hood vents have a graceful curve that leads into the stainless trim around the exhaust tips.

This car abounds with carefully thought out and perfectly executed details, and you will see much more in the accompanying photos. Gauntt, along with Ladd and his crew, are delighted with the way this car turned out, and they feel like nothing was left “on the table” in terms of design. Apparently, the judges at the GNRS agreed since they bestowed the Al Slonaker award to this one-of-a-kind coupe. MR

Sources

e. Black Design Co

eblackdesign.com

Hollywood Hot Rods

(818) 842-6900

hollywoodhotrods.com