Must Know Tips When Preparing Your Next Classic Truck Chassis

By Ron Covell – Photography by the Author

For any project truck, you’ll need to do a lot of sanding and grinding. These processes are so fundamental to metalworking that most people don’t give them a second thought. The more you understand about using these products properly, the more money you can save on materials, with the bonus of getting better results.

The History Of Abrasives

Abrasives have been around for ages–going back to 13th century China when they actually glued sand onto parchment to make sandpaper. The technology has evolved considerably since then, and the abrasive media used for modern-day cutting, grinding, and smoothing has advanced tremendously.

Read More: How To Install 1967-72 C10 Big Brake Kit

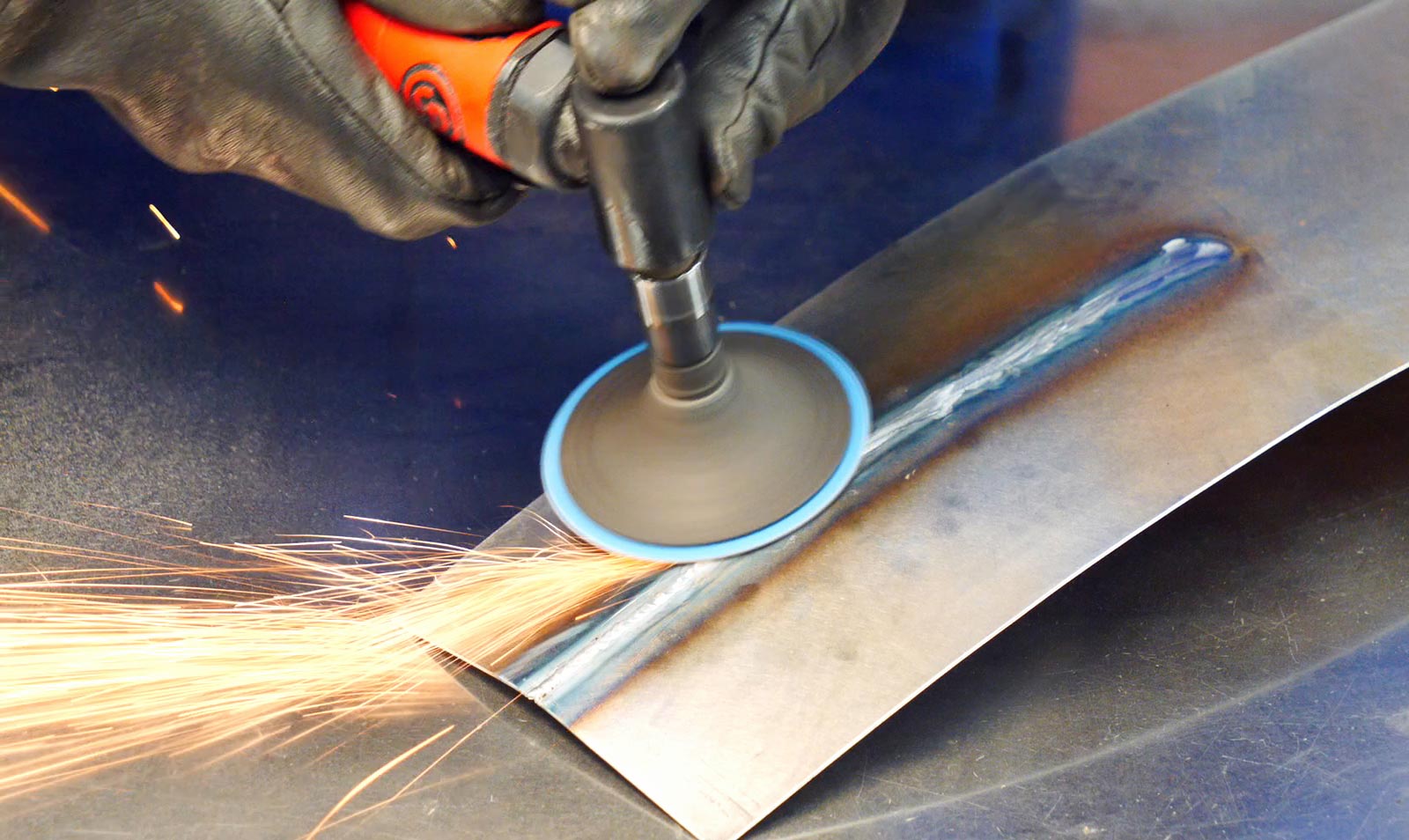

Power Tool Safety

It’s important to keep safety in mind when using abrasives with power tools. A lot of metal can be removed in a hurry, but it comes off as a shower of hot sparks, and it’s essential to protect your eyes, face, and body from injury. A full-face shield is recommended, along with heavy gloves—and be sure to avoid clothing and footwear made from synthetic materials, which can melt and stick to your skin. Hearing protection is highly recommended too, since a grinder working at full song puts out a lot of noise.

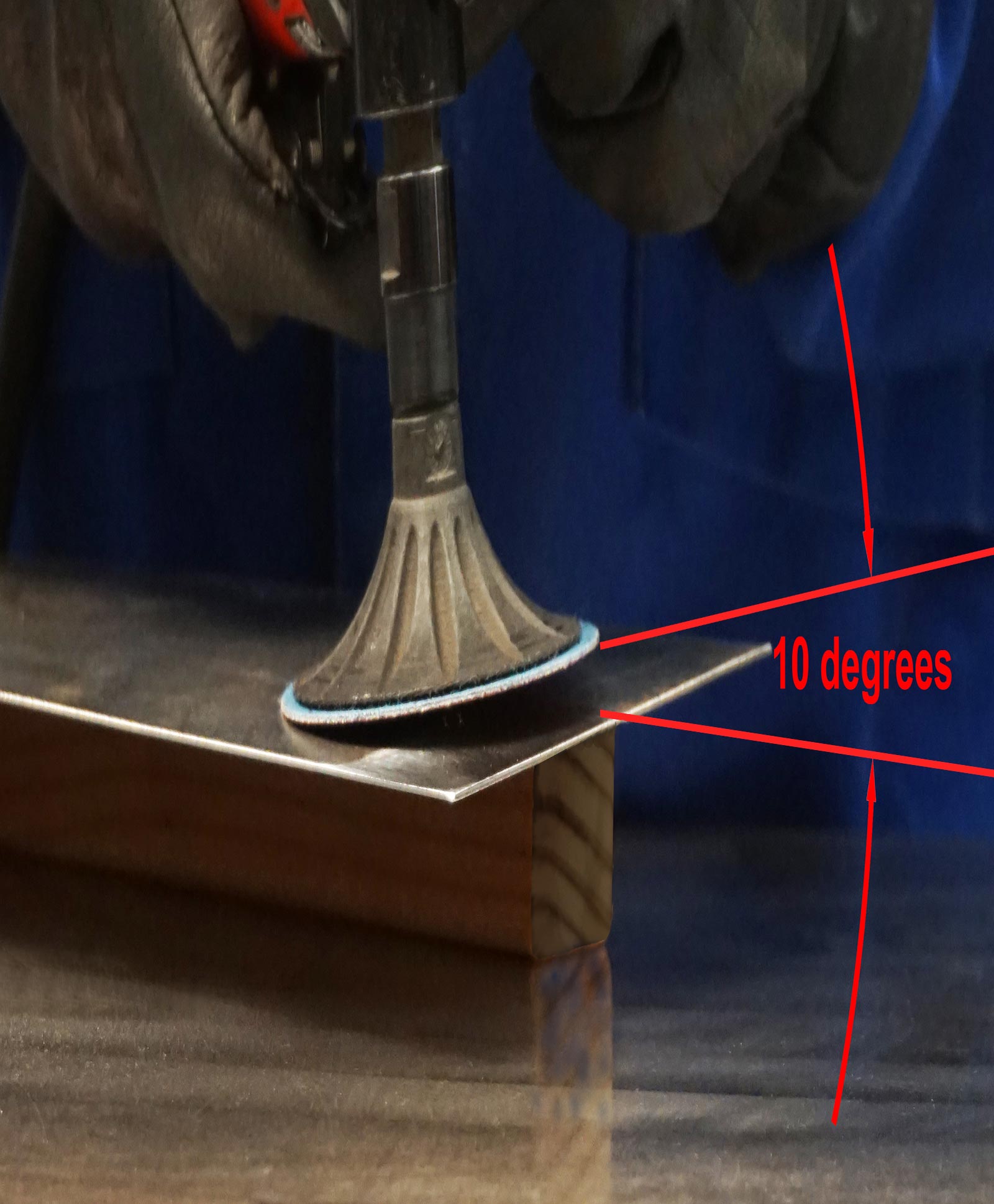

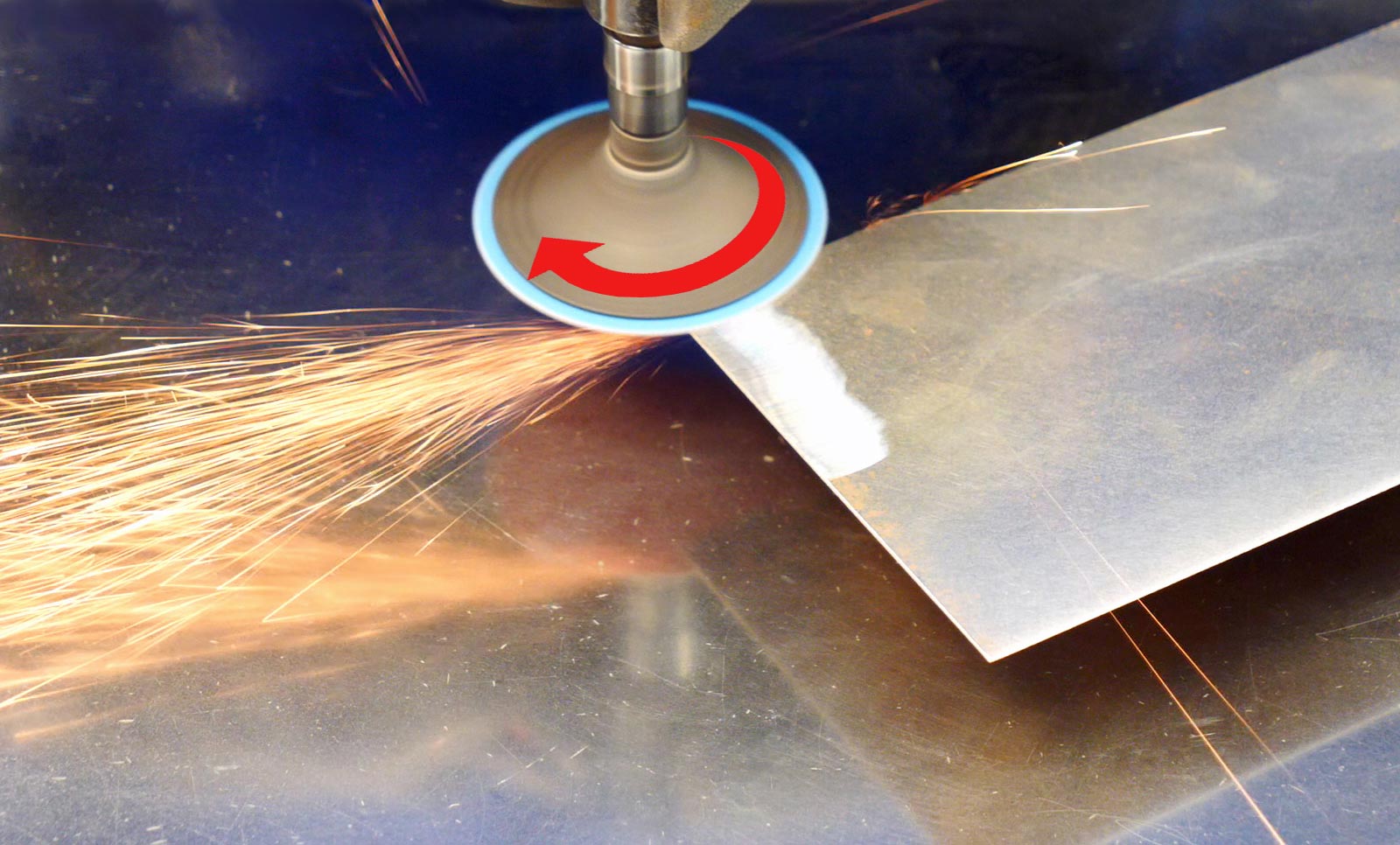

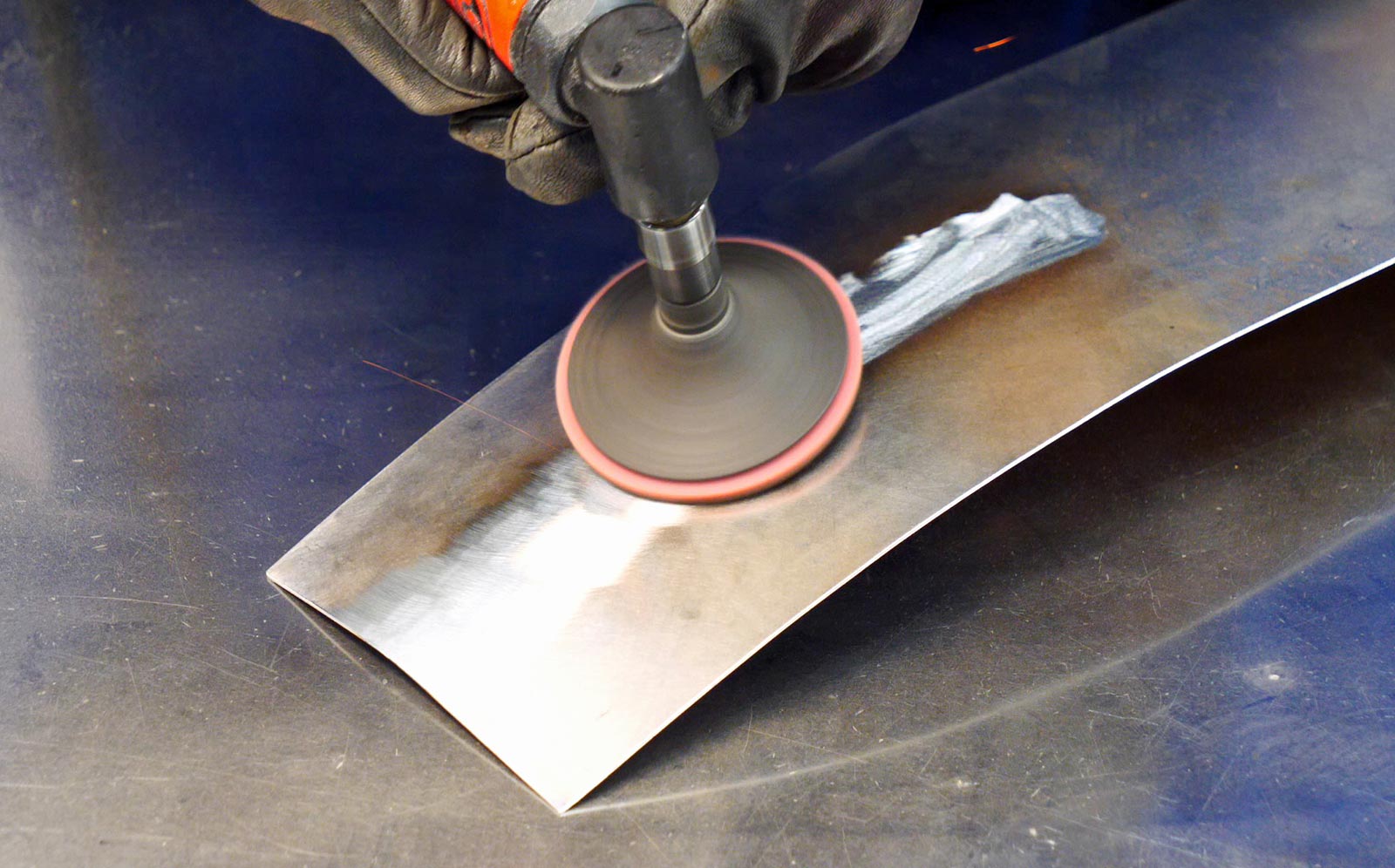

Disc Sander Safety

There are some additional safety issues to consider, as well. When sanding near an edge, it is important to keep the rotation of the disc oriented so it goes OFF the edge, rather than rotating TOWARD the edge. This strategy will help to prevent the edge of the disc from grabbing the metal edge, which can be very dangerous.

Abrasive Cut-Off Wheels

Abrasive cut-off wheels can be used with handheld electric or pneumatic grinders, and they can easily make straight or slightly curved cuts in everything from sheet metal to heavy plate, plus they work well on shapes like rectangular and round tubing and bar, angle iron, and channels. When using a cut-off wheel, it’s important to use a guard that shields the disc, protecting the operator from any flying debris.

Read More: An Award Winning 1958 Ford F100 Built By Revision Rods

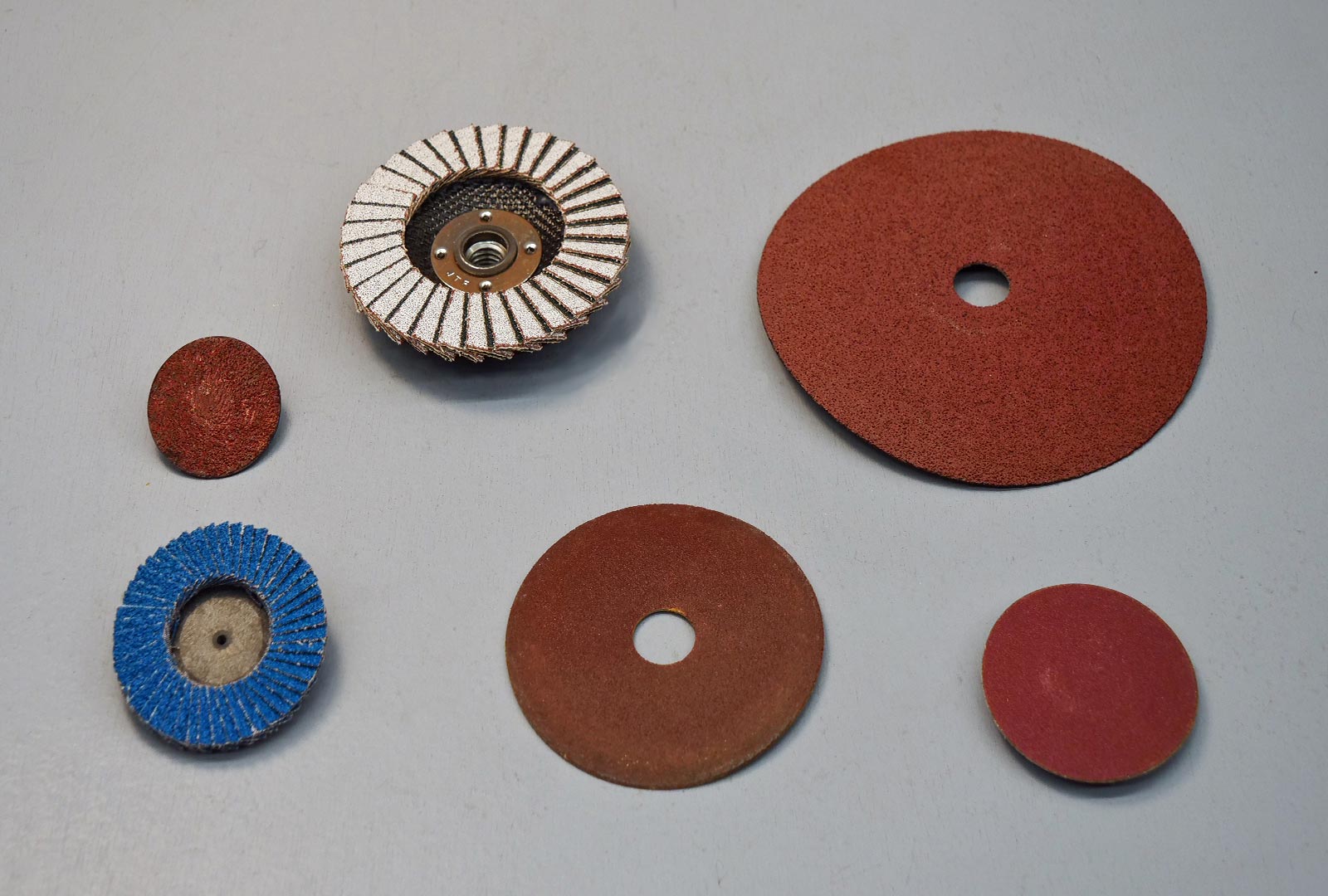

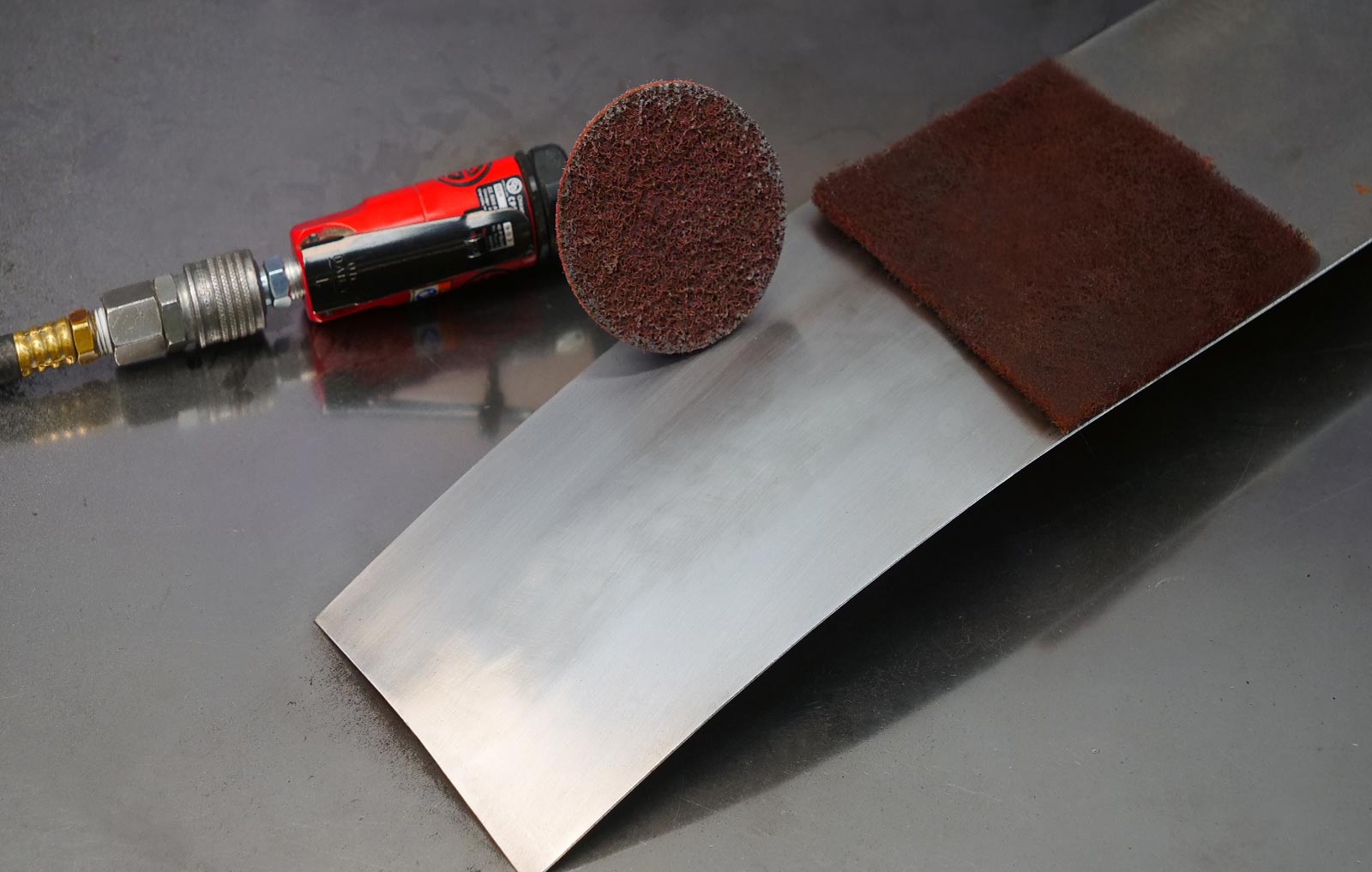

Grinding Discs

Grinding discs are perhaps the most widely used abrasive product, they come in a very broad selection of diameters and grits, and they are engineered for particular applications. While the most common abrasives are designed to work well on mild steel, there are some specialized products that are designed to cope with the particular challenges posed by stainless steel and aluminum.

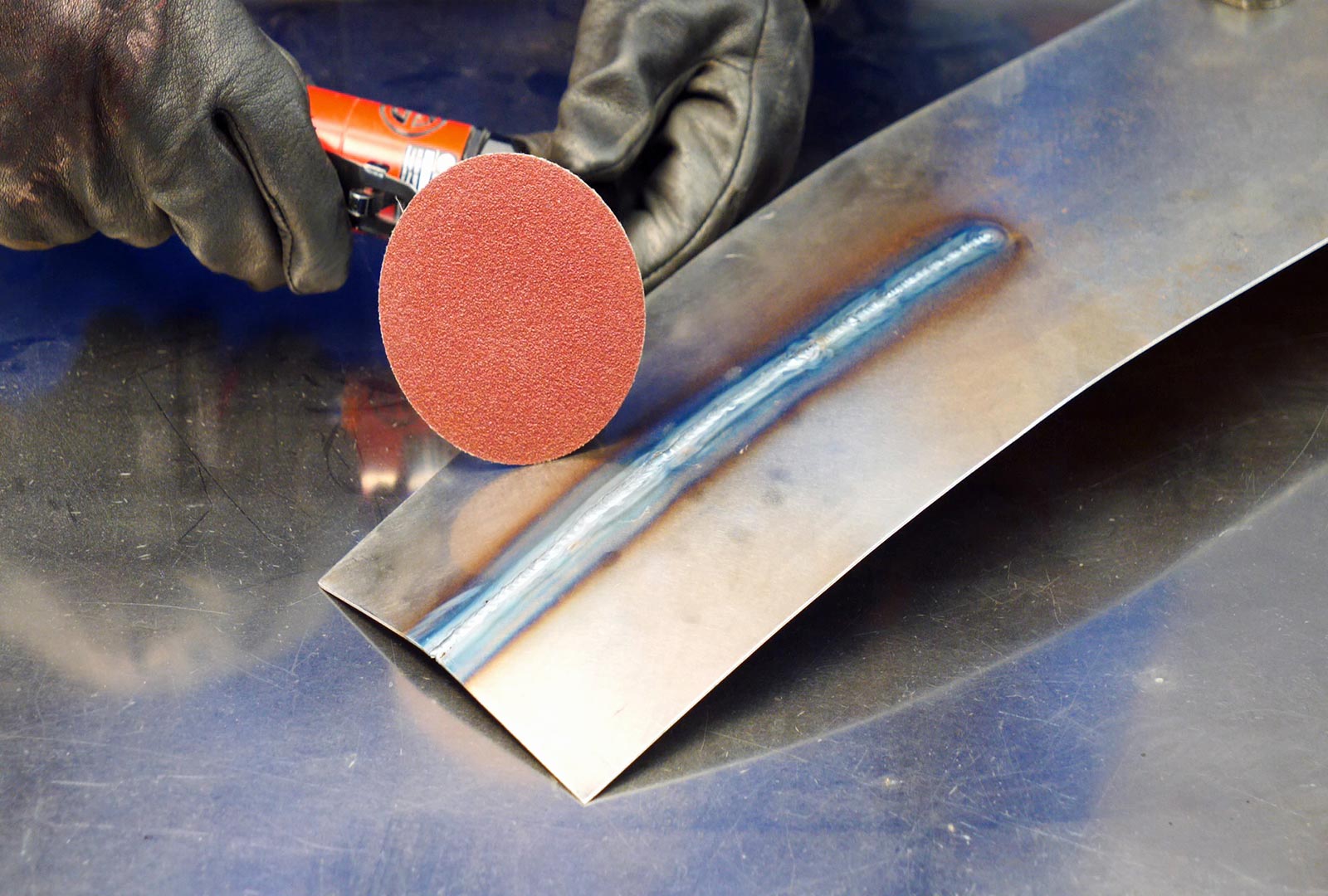

How To Grind Welds Smooth

Pay particular attention to the photos that accompany this article, which show how you can smooth a weld—even on thin sheet metal—without reducing the material thickness significantly. The key is to orient the disc so the grains travel along the length of the weld rather than cut across it. As you’ll see, you can make a weld nearly invisible by using the proper techniques, using only a small number of abrasive products.

Applying Adequate Abrasive Pressure

Another principle that applies to the whole spectrum of abrasives is to let the tool do the work, without forcing it. When you apply excessive pressure, it generates more heat—and unnecessary heat will cause the abrasive medium to break down much more quickly than necessary.

Read More: Replacing the Window and Rear Door Seals on our 1971 Suburban

It’s also important to change abrasive discs when they start to get dull. Using a badly worn disc can cause excessive heat in the workpiece, which can actually distort thin parts like truck body panels.

Source

Weiler Abrasives

(570) 595-7495

weilerabrasives.com