Experts Weigh In

By Jeff Huneycutt – Photography by the Author

These days, thanks to modern engine controls, it’s easier than ever to add boost either to a new or existing build. But just because it is easier than ever doesn’t mean that throwing boost on a build is foolproof. No, there are still lots of things that can jump up and bite you when you least expect it. And the results can run from mild, like less horsepower than you’d hoped for, to wild, like a dreaded blown engine.

To help you avoid those pitfalls, we surveyed several of the most trusted manufacturers in the industry, asking them what problems they see most often, and how they help guide car guys and gals through those issues. Their answers ran the gamut, and they were all great. In fact, we feel they will be quite helpful to many of our readers.

So, without further ado, here’s what they said:

Don’t Miss Out on This: We put FiTech’s Ultimate LS System to the Test on the Dyno

Big Boost May Require a Total Package Rethink

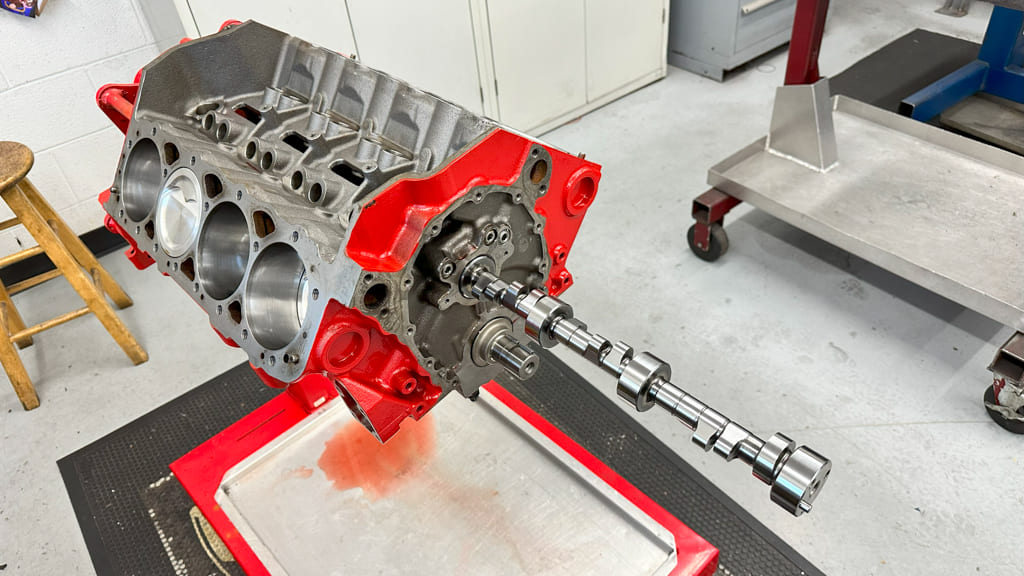

Mark Campbell – Comp Cams

The problems I see the most on boosted engines are incorrect camshafts and incorrect torque converters. Both of these things can have a dramatic effect on how quickly an engine makes boost and how efficient it is when doing so.

This applies to turbo engines more dramatically, but it’s certainly very important on supercharged engines as well. Not only having the right camshaft, but having the correct combination of compression ratio, bore and stroke, and camshaft event timing is critical to how the engine runs. On a basic combination, if you are just adding 10 psi or under, it is less of a factor. But as you are trying to make big power with a turbo or supercharger, the engine combination, and more importantly the torque converter, become more critical in getting the power to the ground.

Boost Pressure is an Indicator of Restriction, Not Power

Jimmy Martz – Vortech Superchargers

Customers will often call and ask, “What pulley do I need to make X pounds of boost?”

This is an easy question to answer if a baseline has been established or the customer is using one of our complete kits. It is as simple as changing the pulley diameter 0.100 inch up or down as that will change boost pressure 1 psi. On a custom application, it gets a little trickier.

Often, customers will not understand that boost pressure is a measure of restriction of air waiting to get into the engine, and there are many factors that can affect it. If a customer makes an exhaust change that flows more, the boost number will go down due to the efficiency of the engine being able to remove exhaust gases more efficiently. If a custom inlet is installed that is too small, that will lower the boost number. In general terms, any time an engine modification is made that increases horsepower the boost number will go down. Our team can get a customer close, but it is very difficult to get an exact number given all the possible variables.

Turbo-Specific Camshafts

Brian Nutter – Summit Racing

We’ve developed our own lines of camshafts, and one thing we’ve run into is people thinking boost from a turbo or from a supercharger would use the same type of cam. They don’t. We have cams designed for each type of boost as they are completely different.

Since it is driven off the crankshaft, the supercharger isn’t sensitive to reversion, so the cam is very similar to the naturally aspirated camshaft. But a turbocharger, because it is driven by exhaust gases, can make the engine very sensitive to reversion and the cam should be different. By their nature, turbos create exhaust backpressure between the turbo and the cylinder head—it’s called “turbine inlet pressure.” You may be making 15 pounds of boost, but even on a good turbo that may be creating 15 or as much as 45 pounds of backpressure.

So, if you have 15 pounds going into the engine and 45 pounds sitting on the back of the exhaust valves trying to push its way back in, and the cam, by virtue of it having too much overlap allows it to backflow, it will pop head gaskets. That’s all exhaust gas, so it’s also way too much heat for the pistons to be able to deal with. That heat has nowhere to go. So, you may melt a piston, or more likely, butt the piston rings.

When that happens you may blame the engine, thinking the head gasket and the piston and rings just couldn’t handle that level of boost, but the truth is it was the camshaft that caused the damage.

So, we’ve got various cams that have different overlap, mostly to save a turbo engine from destruction while still able make a lot of power. Many people don’t know that a turbo really needs a cam that limits the valve overlap in many cases. We have several different cam grinds specifically for different turbo combinations. For a street combination, as an example, when designing a cam, we start with when we want to activate both the intake and exhaust valves. For our smaller turbo cams, the intake and exhaust valve opening events are exactly the same as our naturally aspirated cam grinds. The event that we change is the exhaust closing point, and that is what actually limits the amount of overlap in the cam.

Be Smart at the Pump

Karen Orlandi – ProCharger Superchargers

The ProCharger staff doesn’t really associate the word “boost” with the word “problems” because supercharging is still the best bang for the buck and the best way to add big power. However, there are aspects to education.

For example, one of the things we see folks struggle with the most is understanding that not all pump gas is created equal. Just because someone made a power number on Florida 93 doesn’t mean California 91 will support that same power. The same applies to understanding that winter and summer fuels are different and how much power E85 can support and why.

Give Your ECU Quality Data

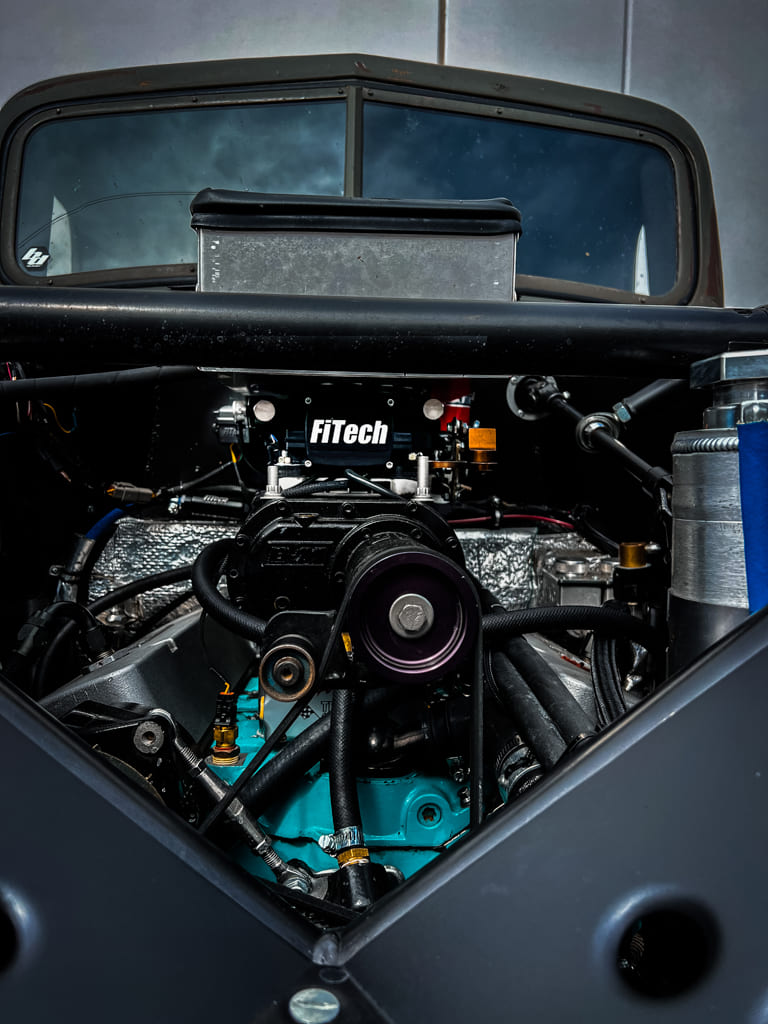

Bryce Cegielski – FiTech Fuel Injection

One of the more common issues we have customers run into in boosted applications is how to provide a proper signal to the ECU to read vacuum and boost. Our throttle body EFI systems have MAP sensors built directly into them, and depending on if the system is used on a draw-through (roots-style supercharger) or blow-through (Procharger/turbo) application, the system needs to get a vacuum reading from different locations.

On a draw-through supercharger configuration, the MAP sensor reading needs to be pulled from underneath the supercharger. If this rerouting does not happen, the EFI system will read from above the supercharger. This will result in the EFI system not seeing any of the boost and will not be able to compensate. Ultimately, when it comes to the MAP sensor we want it to be able to see vacuum and boost so that it can provide a good signal to the EFI system. That way the ECU has good data to be able to accurately compensate for the additional air getting into the engine.

Check it out: Get a Grip, Single vs. Dual Clutches

Do I Need an Intercooler?

Jimmy Martz – Vortech Superchargers

Most applications will benefit from an intercooler. An intercooler, or charge cooler, will allow for cooler, denser air to enter the engine, which in turn can make more horsepower. You can also get more aggressive with ignition timing, which can result in more horsepower.

If a customer is using E85 or methanol injection, they can sometimes omit the charge cooler. By doing so, you remove the pressure drop across the cooler, which can mean more boost and more horsepower.

Direct Injection Issues

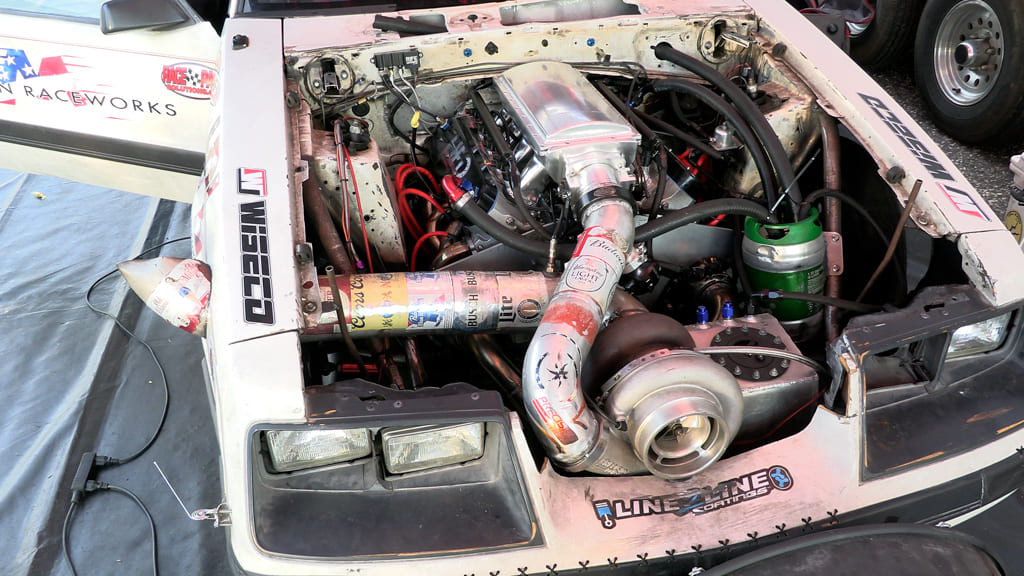

John Urist – Hellion Turbo

The way I think about it is we have to continually make ourselves available to help educate a new customer who may not know that they need something. The way that the Internet is now, you can kind of get an answer to practically anything due to the amount of information out there. But, if someone is new to making horsepower and engines, it’s also easy to get overloaded or get some bad info.

Plus, sometimes they may initially purchase the wrong product because they’ve gotten bad info from who knows where, or they didn’t consider all the variables. So, we try to communicate with the customer to make sure that we’re getting them all the pieces they need to meet their goals. I mean, we get calls from people who want 5 pounds of boost and the next call will be from someone who wants 35 pounds of boost, and there’s a real difference in the system they are going to need. So, what do you want to do? Where’s it going? What’s your budget?

We get that information and work from there. An example of that is making sure we understand the vehicle you are going to be working with. If you have a new Camaro with the LT engine, you can make good power, but you have to understand that you are going to run into different issues than somebody with an LS engine. You’re going to run into a fuel system restriction with the direct injection, and you’re going to have to address the fuel delivery side. That can be more involved than a lot of people expect if they don’t know, but we do have solutions for all the issues you might run into.

Boost Requires More Fuel than an Equivalent Naturally Aspirated Engine

Joe Granatelli – Granatelli Motor Sports

When you are running fuel injection naturally aspirated, your BSFC (brake specific fuel consumption) really needs to be 0.5. A supercharged engine will need to be 0.6 because heat and pressure require more fuel. That means a properly tuned, 500hp supercharged engine will eat more fuel than a naturally aspirated engine at the same horsepower.

As an example, let’s take an LSA engine and compare that to a 505hp Z06 engine in a C6 Corvette. But let’s add long-tube headers so we’ve upped the horsepower to 550 and the two cars are pretty close. If you drive them down the highway like a grandma then whoever has the best tune will get the best mileage because that LSA is never in boost. But now you take both engines and you drive them wide open for 1 mile, I will promise you at the end of that mile, the LSA has used probably 15 percent more fuel than the Z06 due to it not being as efficient.

That’s because you can run a naturally aspirated engine at like 0.45 to 0.5 BSFC, but a supercharged engine is best between 0.55 and 0.62. You have to run a forced induction engine richer. I have a brand-new Hellcat and it goes down the road at 14.7:1 air/fuel ratio, which is stoichiometric, but when I step on the gas, it goes straight to 10:1.

Now if you went 10:1 with a naturally aspirated Corvette, or your suburban, or your pickup truck, you’d have two black trails of smoke coming out of the tailpipes. You can’t run a naturally aspirated engine at 10:1, it’s just way too rich and the fuel would be pouring out the exhaust.

If you are adding boost to a naturally aspirated engine, you have to be able to plan for the extra fuel consumption requirements so you can properly size the fuel injectors. Let’s say you’re running an LS3, right? They have one injector per cylinder, so it’s really very simple.

Selecting Starters: Which One is Right for You, Gear Reduction or Direct Drive?

Start with the amount of horsepower you want to make. Let’s assume you are adding a supercharger and you want to make 700 hp with your LS engine. Divide 700 by 8 injectors, and that’s 87 hp each injector has to feed. Then multiply that by your BSFC factor of 0.6, and that comes out to a little over 52. So, you would need a minimum of 55-lb/hr injectors.

But that’s at 100 percent duty cycle, and you don’t want to run your injectors at 100 percent. So now you take the 55-lb/hr injector rating and you tack on 30 percent. That’s 55 times 1.3, and you get 71.5. So, you need a 71.5-lb/hr injector.

Do you know what size injector comes stock from the factory in a supercharged C7 Z06? That’s 73 lb/hr, so that tells you my math is correct because the factory is running the factory engine at 70 percent duty cycle. So, the lesson here is when you add forced induction, it requires even more fuel than a naturally aspirated engine at that same improved power level. It’s not linear.

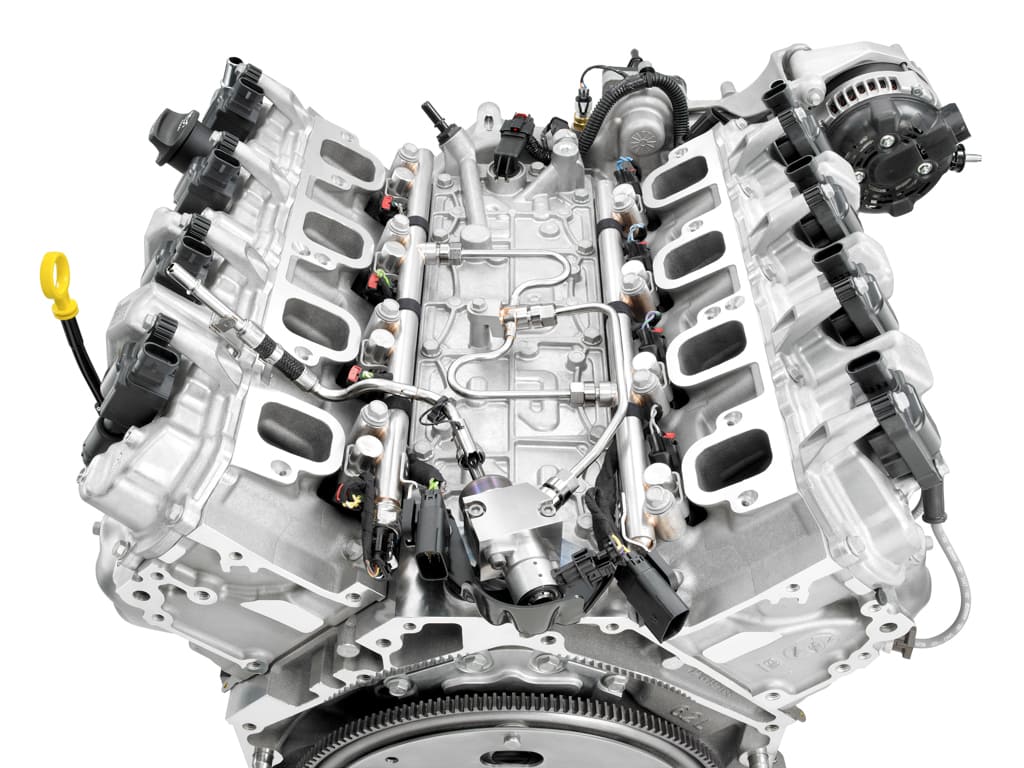

LS is Still the Hot Rodder’s Go-To

Bradley Richardson – Precision Turbo & Engine

The LT1 engine is nice, and it has a lot of great features, but you must be careful with it if you are planning to add a turbo. If done correctly, they are plenty capable of holding 700 or 800 hp no problem. Plus, they are basically all aluminum, so there’s a weight savings over the old 4.8- and 5.3L engines.

But they do have their drawbacks if you are trying to add big boost. For one, the ring gaps are pretty tight, so you really need to pull them apart and open up the ring gaps a bit so you don’t butt a ring once you add boost.

And the big one is they are all direct injection. It can get pretty expensive once you get above the 700hp mark because you can only supply so much fuel to the engine with those injectors.

So, it’s a little tricky, which is why I don’t think they’re going to, at least for now, be the mainstream like the standard LS engine. It’s just as easy to work on it. Which is what I’ve seen most of the guys doing with the LTs; just adding port fuel injection in addition to the direct injection or plugging the direct injection entirely and just going with port fuel injection. But that means you’ll have to make a manifold change plus run a new fuel system. It gets expensive real quick—upwards of $2,000 from what I’ve seen. Now, I’ve seen people have a lot of success with that; you just need to be aware you may run into some extra costs versus the old LSX. That’s why I think the LT engines still aren’t hitting the mainstream when it comes to engine swaps like the LS engines are famous for.

Fix the Flex Joints

Brian Nutter – Summit Racing

One thing that a lot of people have been burnt by is a bad flex joint. Well, not bad really, but they use the standard exhaust flex joints instead of upgraded ones for turbo systems. They can come apart inside and those wires will go right through their turbo and cause a lot of damage. At first you might think it would just be limited to the turbo itself, but if you’ve ever locked up the turbine side of a turbo, the impeller side will smack the housing and then send shrapnel through the cold side and right into the intake manifold. That’s when things can get very expensive.

Some guys have had that experience and won’t use flex joints at all anymore. They will only use a bellows system. But if it is easier for you to keep the flex couplings, we do have our own line of couplings that are turbo-rated and designed so that they won’t come apart internally and send garbage through your turbo. So, make sure to use either a bellows system or a turbo-rated flex coupling to protect yourself and don’t try to just get by with a standard flex coupling. That can cause big problems you never saw coming.

Bigger Isn’t Always Better

Jimmy Martz – Vortech Superchargers

Sometimes customers do not realize you can have a supercharger that is, in fact, too big. If the supercharger is not sized properly, you can have a very lazy boost curve and not realize the engine combination’s full potential.

At Vortech, we use our SAE J1723 dyno cell to produce compressor maps for all of our superchargers. This allows us to properly size a supercharger for a given engine combination to make sure the customer achieves the most horsepower and best driving characteristics possible. Bigger is not always better.

Sources

Comp Cams

(800) 999-0853

compcams.com

FiTech Fuel Injection

(951) 340-2624

fitechefi.com

Granatelli Motor Sports

(805) 486-6644

granatellimotorsports.com

Hellion Turbo

(505) 873-4670

hellionturbo.com

Precision Turbo & Engine

(855) 996-7832

precisionturbo.net

ProCcharger Superchargers

(913) 338-2886

procharger.com

Summit Racing

(800) 230-3030

summitracing.com

Vortech Superchargers

(805) 247-0226

vortechsuperchargers.com

Click on this issue’s cover to see the enhanced digital version of Boosted Advice.