We Test Multiple Holley LS Intake Manifolds on the Dyno to Find Out What Works Best for Your Application

By Jeff Huneycutt – Photography by the Author

The great things about the LS engine are the aftermarket has fully embraced it as a performance engine and there are tons of options for your next build.

The bad things about the LS engine are the aftermarket has fully embraced it as a performance engine and it can be frustratingly difficult to separate the wheat from the chaff when it comes to determining the best components for your next build.

Don’t worry. We’re here for you.

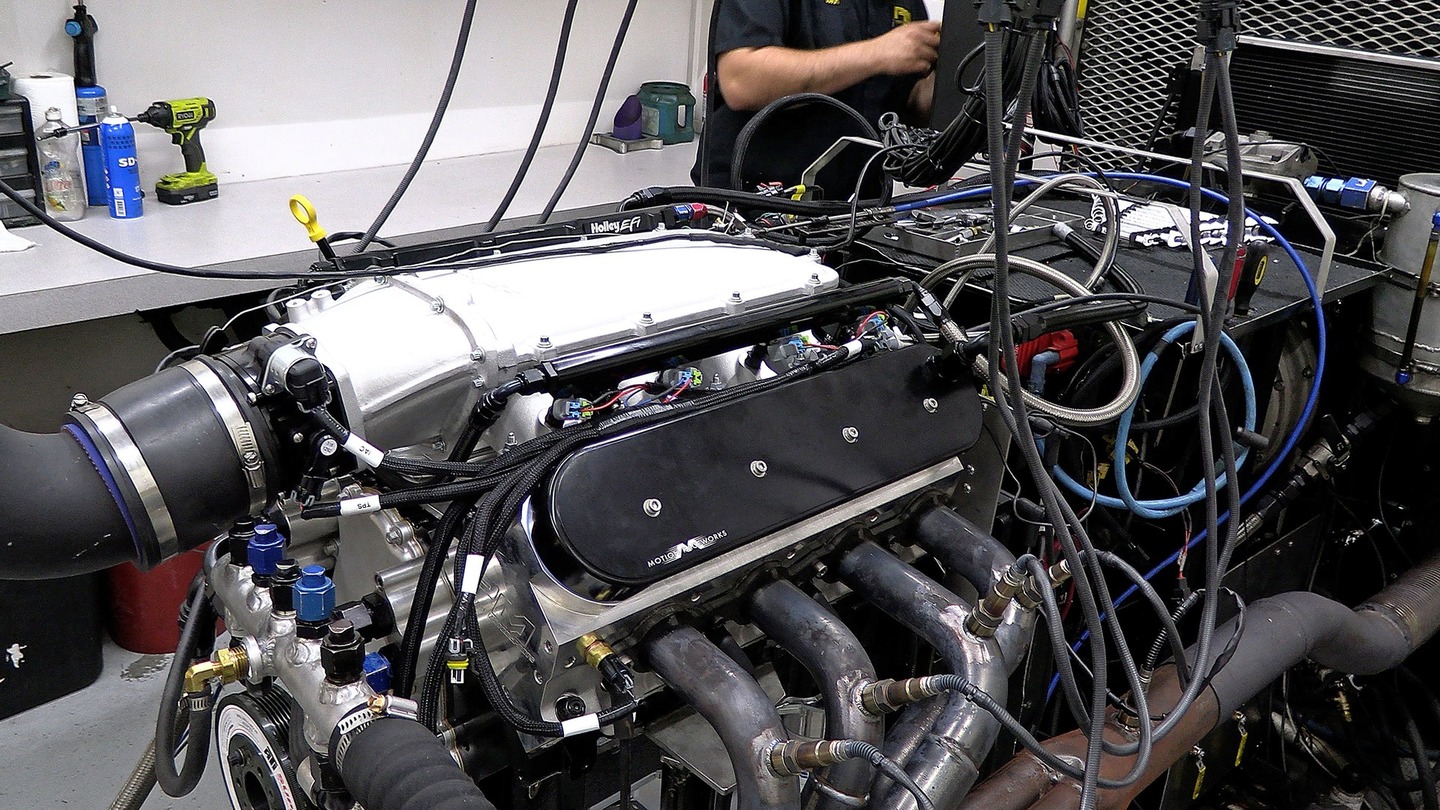

We recently spent two days in the dyno cell with the engine builders at Prestige Motorsports testing just LS intake manifolds from Holley. Our entire purpose was to find out how Holley’s different intake manifold options affect how (and where) the engine makes power. And boy, the results were enlightening.

We’ve done stories with the mad scientists at Prestige Motorsports before because, unlike many engine builders, they are always testing new combos. This is actually pretty rare because dyno time costs money—not only in terms of wear and tear on your equipment, but every hour spent testing is an hour spent not building engines for customers that you can sell. But Prestige feels that continuous testing is vital for keeping ahead of the competition, and they always welcome us to tag along.

Prestige has a strong relationship with Holley and uses many of their products whenever possible. So, Prestige has a lot of familiarity with the Holley lineup of intakes for the LS engine, but this is the first time we’ve seen such a wide variety of intakes run one after another on the same engine.

The engine that we’re using for a test mule is a big-inch 427 with LS3-style cylinder heads. The bore is 4.125 inches with a 4.000-inch stroke. The heads are Prestige’s own LS3 castings with an 11-degree valve angle, 255cc intake ports, and 69cc combustion chambers. The compression ratio is a healthy 11.3:1.

The cam is a hydraulic roller from Comp Cams. It is ground with 243 degrees of duration for the intakes at 0.050-inch lift and 248 for the exhausts. Net valve lift is approximately 0.650 inch. The exhaust headers are a set of four-into-ones with 1 7/8-inch primaries expanding to 2-inch secondaries.

Read More: X vs. H Pipes – The Exhausting Facts

For all the pulls we’ll be using a 102mm throttle body. Also, because even fuel injectors that have the same flow rating can vary slightly, we’re not only swapping out the same set of injectors for every intake, we’re making sure they go into the same holes each time. All the engine controls are handled by a Holley Dominator ECU.

Finally, one last note before we get to the fun stuff. The goal of the testing is to determine which intake manifold designs will work best for different scenarios. There are no losers here. Of course, this isn’t the same as a preschool soccer game where no one keeps score and all the kids are declared winners while they eat their after-game orange slices. The losers—otherwise known as the off-shore, no-name knockoffs with poor casting quality and wild machining tolerances–have already been weeded out. What we’re testing here are four different intakes in a few different configurations that we know are quality to see how they influence power production in the rpm band.

Holley Ultra Lo-Ram

It is obvious that the Ultra Lo-Ram is designed for applications where you have a really low hood line and don’t want to cut a hole into or otherwise modify your hood. And the Ultra Lo-Ram is so short the plenum top doesn’t even extend above the fuel rails. Holley says that this will fit the C6 Corvette without any changes to the stock hood, so if it can make power over stock that’s a good deal.

Besides the ridiculously low 6.86-inch front height, thanks to the flat plenum top, we also wondered if the short runners would help this be a decent option for high-rpm applications. Remember, short runners typically help move the peak power higher in the engine’s rpm range, while longer runners help develop torque and power right off the hit.

On the dyno, we documented runs for every intake from 4,000 to 6,900 rpm. The Ultra Lo-Ram, as you might expect, did make good power higher in the upper-rpm range. Torque peaked at 543.8 lb-ft at 5,700 rpm and 639.6 hp at 6,700. Meanwhile, the averages across the range were 515.0 and 535.6.

Check it out: Consistent Cranking – Tips on Choosing and Installing a Starter

When it comes to horsepower, both the peak and average numbers actually turned out to be quite good. They were the best we found until we got to the Hi-Ram intakes, which are more for all-out competition than street use. The torque also wasn’t far off the other intake manifolds, although it did lag through most of the pull. Still, if you are building a sleeper and want to keep everything nice and out of sight behind a stock hood, the Ultra Lo-Ram is probably exactly what you are looking for.

Holley Mid-Rise

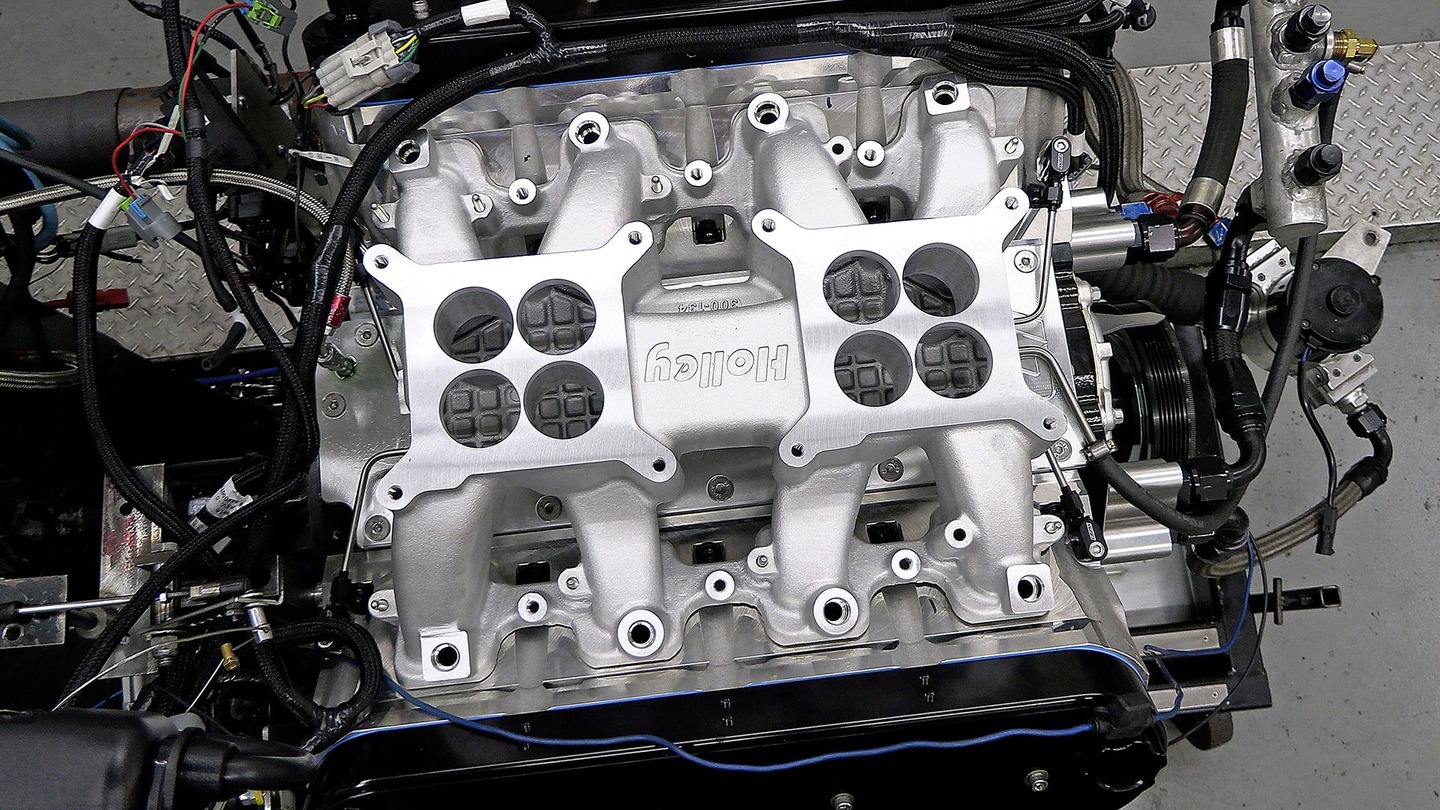

This is definitely the odd ball of the group. All the other intakes we are testing have a large open plenum feeding eight equal-length runners. This is what you probably would call the standard LS EFI configuration. But the Mid-Rise is more like at old-school dual-plane intake.

The Mid-Rise uses a base from Holley’s LS 2×4 intake manifold that is designed for two carburetors or twin four-barrel throttle bodies, but the top is replaced with a similar front breather manifold top as the other intakes and the lower section splits the intake into two distinct sections with only a few shared runners. The runners are also on two different levels, and the result is some very long runner lengths. This truly is a very unique intake design when it comes to EFI engines.

On the dyno the results were quite interesting. For the health of the dyno mule we only began the pull at 4,000 rpm (engine dynos can actually be damaging to the pistons and bearings in an engine if you begin the pull too low because it holds the engine rpm low against the spiking pressure of combustion), but we think this manifold shines even lower.

Although it didn’t lead the pack in any of the peak numbers, this intake set itself apart because of how effectively it made torque up to 4,800 rpm or so. From the beginning of the pull up to 4,500 rpm it made the most torque overall, and until 5,500 it was only bested by the two Hi-Ram intakes we tested.

The key to remember with the Mid-Rise is we don’t race engine dynos. Yes, if you want to bench race and compare dyno numbers, the Mid-Rise will get lost in the pack. But the guys at Prestige said for the regular guy driving his hot rod on the street, if you put the different intakes on his LS and let him drive his car without knowing what was under the hood, he’d choose this intake 8 times out of 10. No, it doesn’t make the most power, but it’s big torque as soon as you touch the throttle and can make a car or truck a real blast to drive.

Holley Lo-Ram

The Lo-Ram intake shares the short runner lengths of the Ultra Lo-Ram but uses the same high-flowing plenum top and throttle body mount as the Hi-Ram. This raises the front height to a manageable 9.25 inches. This combo should still be able to fit underneath the hood of plenty of vehicles. One of the strengths of the Lo-Ram is it can accept an intercooler between the two sections to help cool the incoming air charge in boosted applications without getting too tall.

On the dyno the Lo-Ram performed well all-around. Peak numbers were 542 lb-ft of torque at 5,700 rpm and 627.9 hp at 6,700. Averages across the range were 512.8 on the torque and 532.6 hp.

Holley Lo-Ram with 1-Inch Spacer

In this test we kept the same Lo-Ram intake manifold but the guys at Prestige wanted to test it with a 1-inch aftermarket spacer beneath the lower section and the plenum top. Not that this is not a Holley component. In the good-old days of carburetors, adding a plenum spacer between the carburetor and the intake manifold was often a good way to squeeze out a few extra ponies.

We suppose a few manufacturers are making spacers like this with the idea that more plenum area will help high-rpm power like with the carb spacers. But on the dyno we really didn’t see any benefit. We saw an increase of 2.3 lb-ft of torque but lost 4.3 hp. Overall, the two lines on the dyno graph basically followed the same path.

The conclusion we drew is that the engineers at Holley really did their homework and came up with an optimized product with the Lo-Ram. Maybe there is more of a difference in boosted applications, but if you are running your engine naturally aspirated, keep your money.

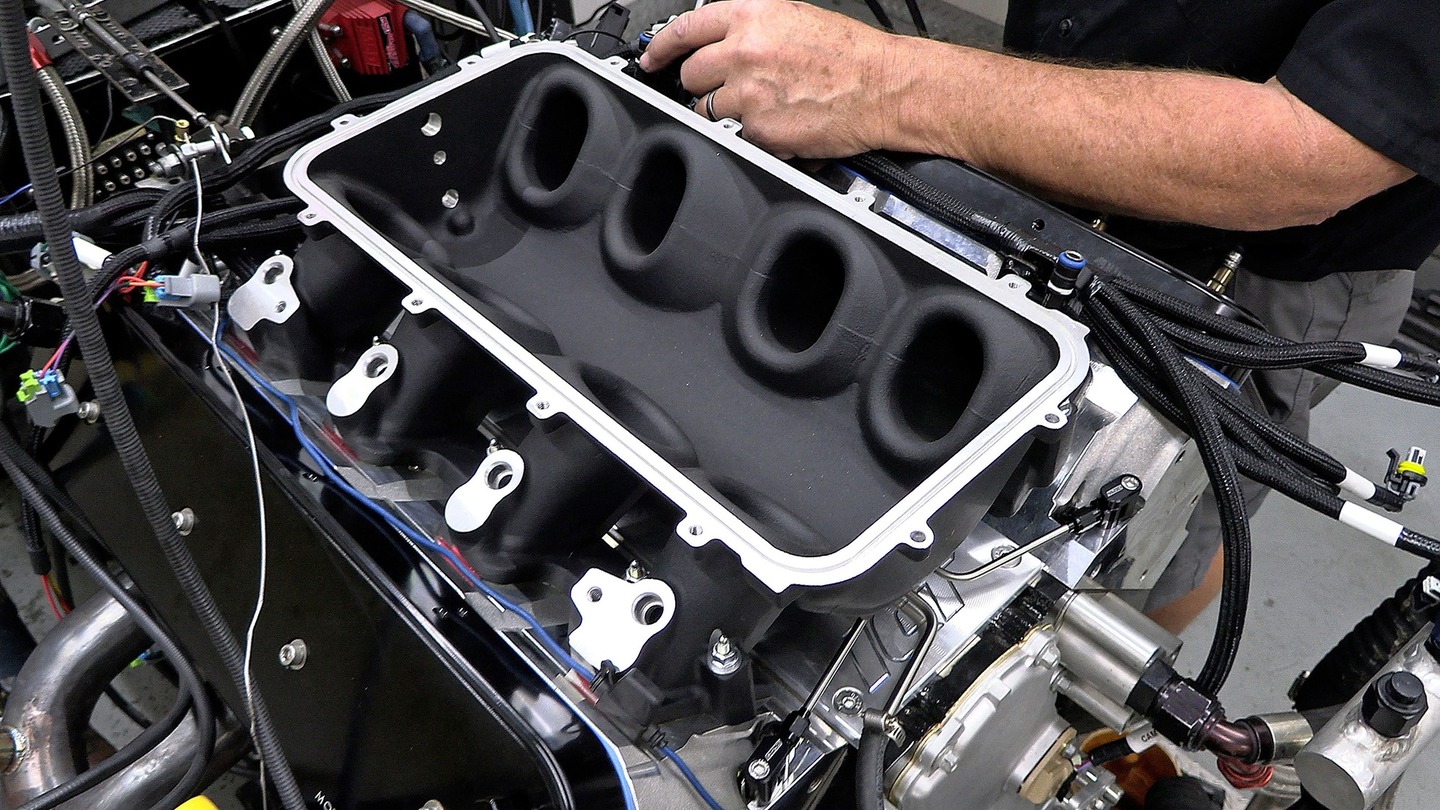

Holley Hi-Ram

With a 12.32-inch height, the Hi-Ram definitely lives up to its name. So, hood clearance was obviously not a consideration in its design.

No, the Hi-Ram is all about producing power, and this intake does that in spades. Even with the longer runners, the Hi-Ram loves to operate in the upper-rpm range. It turns out the Hi-Ram provides the best of both worlds. Peak torque jumped up 8.6 from our previous best with the Mid-Rise and horsepower increased 1.9 from the Ultra Lo-Ram. And the averages across the range were even better with improvements over our previous bests of 13.6 and 14.5 respectively to get 530.5 lb-ft of torque and 550.1 hp. Those kinds of improvements across the range are pretty hard to come by. No wonder the Hi-Ram is such a popular option when it comes to big-power engine packages.

Ported Holley Hi-Ram

Like the 1-inch spacer, this test is another throw-in for a little additional insight. Prestige CNC ports its cylinder head castings and has developed a CNC porting program for the Hi-Ram for a big-power engine being built. Since we had that on hand, we decided to try it, too. The plenum top was the same, only the runners had been ported.

This time around the ported intake runners did probably what you would expect. In the lower rpm range the larger runners caused the engine to lag the stock Hi-Ram a bit until the upper-rpm range when the engine needed even more airflow. By 6,300 rpm the CNC Hi-Ram took over and never looked back. But, let’s be honest, how often do you need power beyond 6,300 rpm if you are driving on the street. The CNC-ported Hi-Ram definitely has its place, but it’s on the big-power, high-rpm screamers that will see most of their time on the dragstrip.

So, what did we learn? There are no losers here. Just like in a good mechanic’s toolbox, there is a correct tool for every job. The key is to be honest about what you are looking for in your ride and find the correct intake manifold that will increase your enjoyment and give you the most bang for your buck.

Sources

Holley Performance

(866) 464-655

holley.com

Prestige Motorsports

(704) 782-7170

prestigemoto.com