Part 2: Sectioning the Cowl with Gary’s Rods and Restorations

By Ron Covell – Photography by the Author, Michael Christensen & Gary George

While we often enjoy seeing adventurous experimentations with truck styling, this is something that is easily overdone. Sometimes the more subtle modifications produce a better result.

Last month we introduced Jason Souza’s ‘56 F100 project being built at Gary’s Rods and Restorations in Northern California and showed the work done on the floor and firewall. This time we’re going to look at a subtle modification being done to lower the roof—not by chopping but by sectioning the cowl.

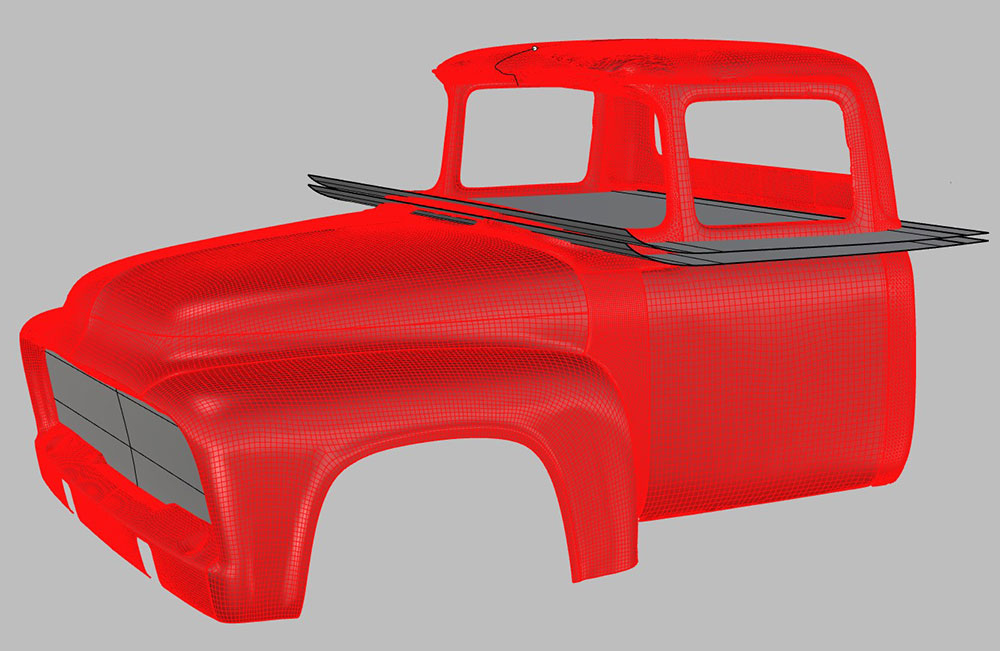

In preparation for the extensive body modifications being planned, Gary had the entire truck digitally scanned. This resulted in a complete surface model, so the body modifications could be tried out, tweaked, and visualized on a computer from all angles before any metal was cut. Gary’s neighbor, Sean Sinnott of DG Collective, was called on to do the scanning and computer modeling.

Part 1: No-Holds-Barred 1956 F100

One of the first major body modifications was sectioning the cowl. While it’s common to chop the top on a custom truck, Souza, the truck’s owner, was very impressed with Chip Foose’s personal project truck where the greenhouse area of the cab was left intact and the roof was lowered by sectioning the cowl. This is a “sneaky” way to lower the profile of the old truck, but the modification doesn’t call a lot of attention to itself. Most people appreciate the improved look without recognizing exactly how it was accomplished. Souza knew from the start that he wanted to incorporate this feature on his project truck, and Gary and his crew were eager to work out the details required for the execution.

One of the beauties of working with a surface model on a computer is being able to quickly make changes to shapes and view them from any angle. After a lot of experimentation, Gary decided that sectioning the cowl 1 1/4 inches in front and 1 inch in back would produce the desired effect.

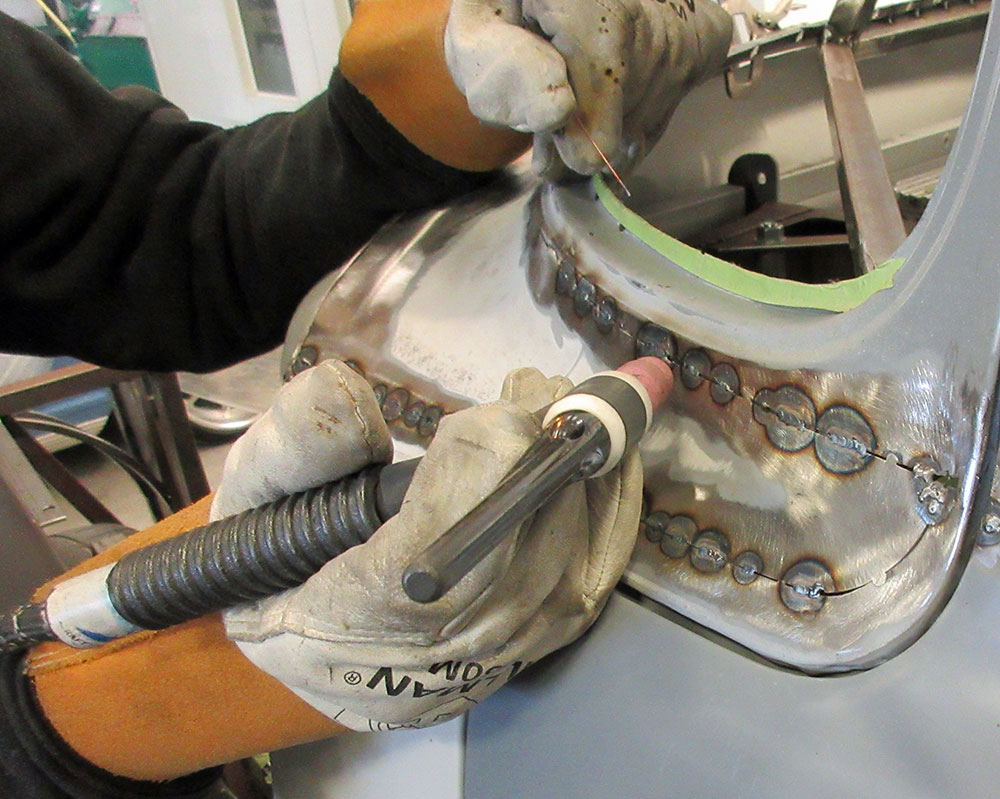

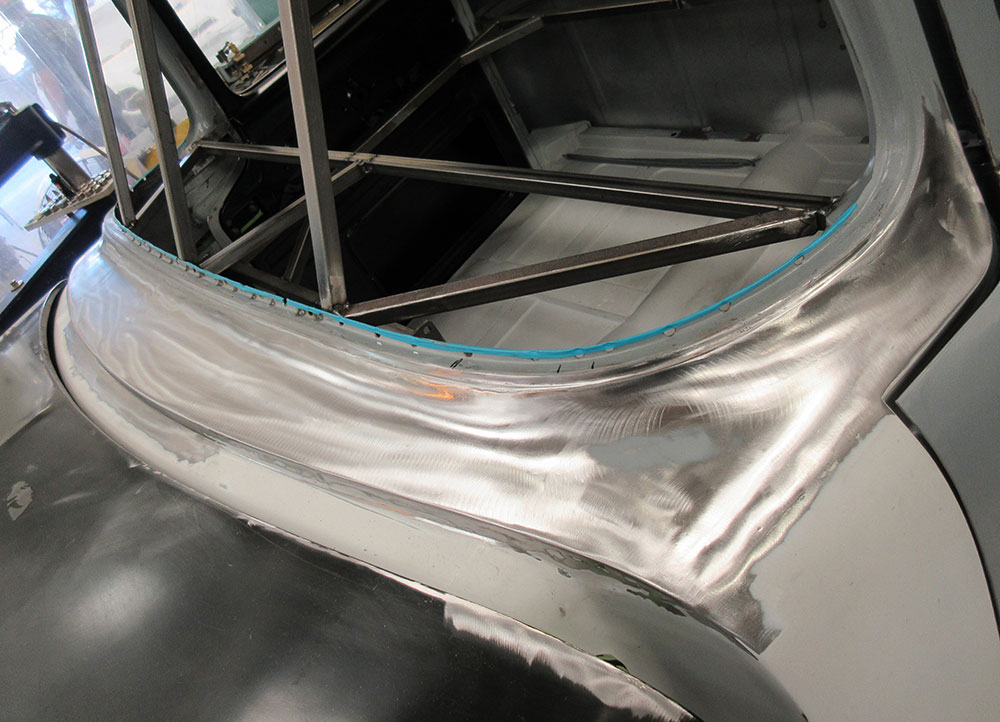

The first step was bracing the cab with tubing so it would retain its shape when the roof was removed. The windshield area on the roof was reinforced, too. The location of the cuts was carefully plotted, striving to provide access to the back side of the welded joints so they could be worked to perfection. The cowl was split from the roof just below the channel for the windshield weatherstrip.

Read More: Alluring Sterling Silver 1956 Ford F100

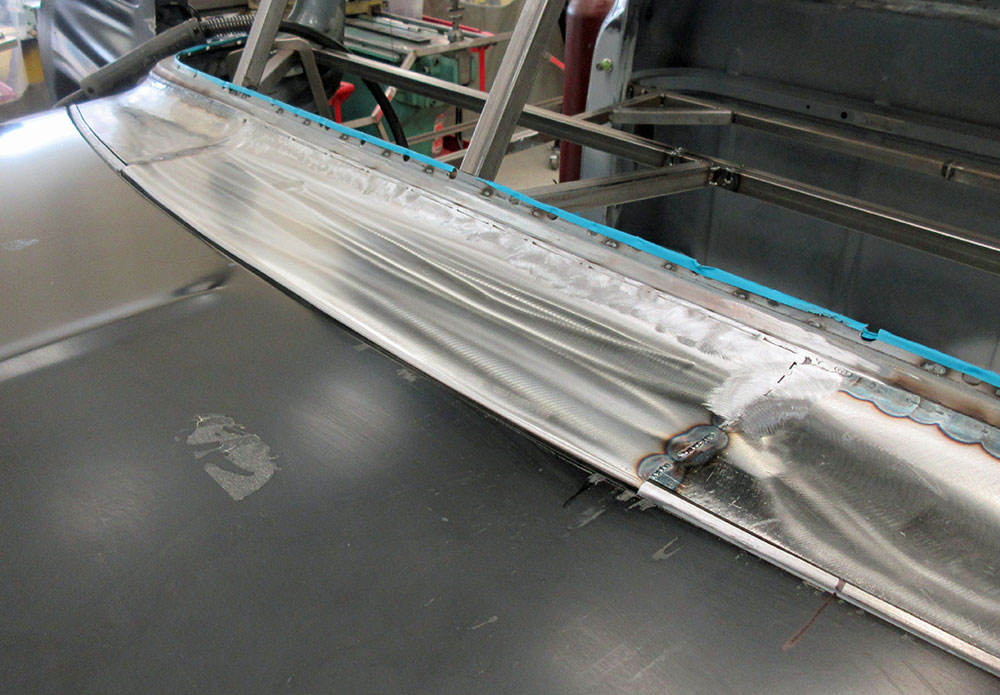

The roof was removed from the cab and a 1-inch strip was cut from the rear cab panel. This portion of the cab is essentially flat, so very little reshaping was required, but welding and smoothing flat panels is a tricky operation. Emilio Belmonte, Gary’s metalworking expert, did a beautiful job with these custom modifications. A section was removed from the door jambs; these were a little more challenging to align because of their taper.

The roof was repositioned in its new location with the front edge lowered 1 1/4 inch. Everything was checked and adjusted as necessary and the joints were carefully tack welded together. The cowl required the most extensive modifications. The sides of the cowl were removed, then the front edges were extended and the back edges were trimmed. The cowl vent was removed and new metal was shaped to fill the void.

The door frame tops were removed, then re-fitted in their new, lower position, ensuring the gaps were uniform. A section of the inner door frame was removed to provide access to the weld on the outer skin, allowing the joint to be worked with a hammer and dolly and metal finish.

Once all the joints were adjusted and the fits were verified, the panels were tacked, finished welded, and metal finished.

Read More: 1960 Ford F100 With Plenty Of Chevy Performance

The accompanying photos show the work in detail, and you can look forward to a series of articles covering the extensive body modifications in store for this outstanding custom truck, including a completely scratch-built bed!

Sources

Gary’s Rods & Restorations

(831) 728-7025

garysrods.com

Sean Sinnott

DG Collective

(831) 464-8088

designergrains.com