The TCI chassis, Cab Floor & Firewall

By Ron Covell – Photography by the Author, Michael Christensen & Gary George

Gary George, who runs Gary’s Rods and Restorations in Northern California, has a long history of building outstanding vehicles. He was recently approached by Jason Souza to build a showstopping ’56 Ford F100. This will be a “no-holds-barred” project, but they want the truck to have an elegant and refined character rather than going for shock value. Look for future articles that will include sectioning the cowl and the hood, moving the wheel well openings in the front fenders, and scratch building a new bed that matches the shape of the cab.

Careful thought went into laying the foundation of the project. The Total Cost Involved chassis has been extensively modified by Dave McIntyre, George’s chassis guru. He moved the front crossmember forward 4½ inches, built new front and rear frame rails, and made a beefy X-member to further stiffen the frame. He extensively modified the Art Morrison Enterprises independent rear end to allow the truck to be dropped to the ground. Mittler Bros.’ Hydroshox suspension units are used on all four corners, allowing the truck to be radically lowered for shows and then quickly raised to the desired ride height.

Read More: 1954 Ford F-100 G-Comp Independent Front Suspension Upgrade

McIntyre also built an outstanding custom exhaust system and included a custom-fitted set of headers that feed into the Vibrant Performance mufflers and then into gorgeous 2×4-inch oval stainless tailpipes that gracefully snake through the confines of the frame.

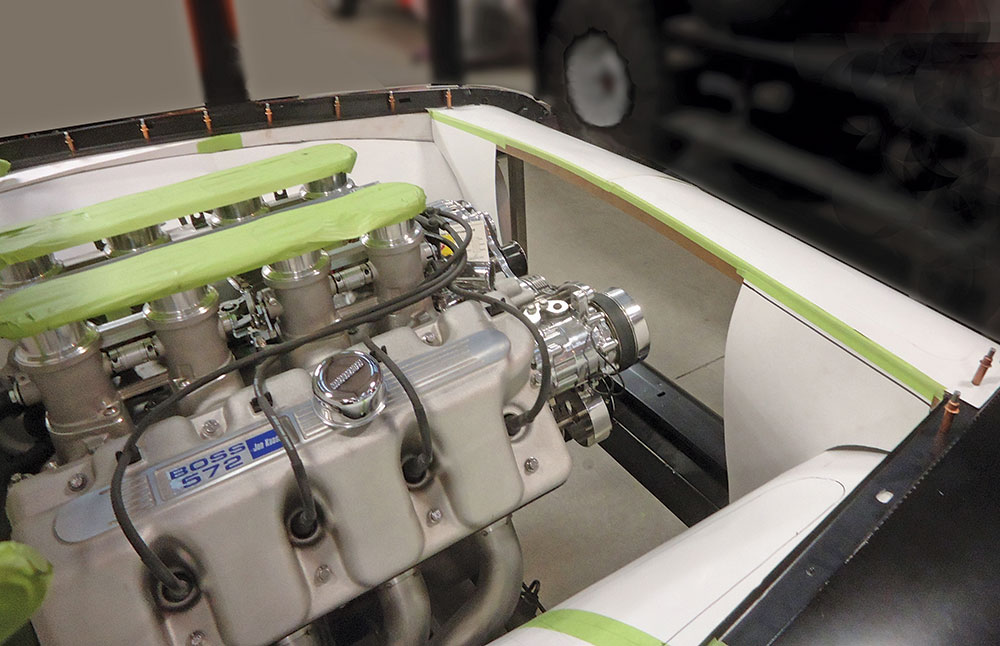

The engine is a Ford Boss 572, fitted with Jon Kaase stack injectors and accessories, backed by a Hughes Performance built 4L85E transmission.

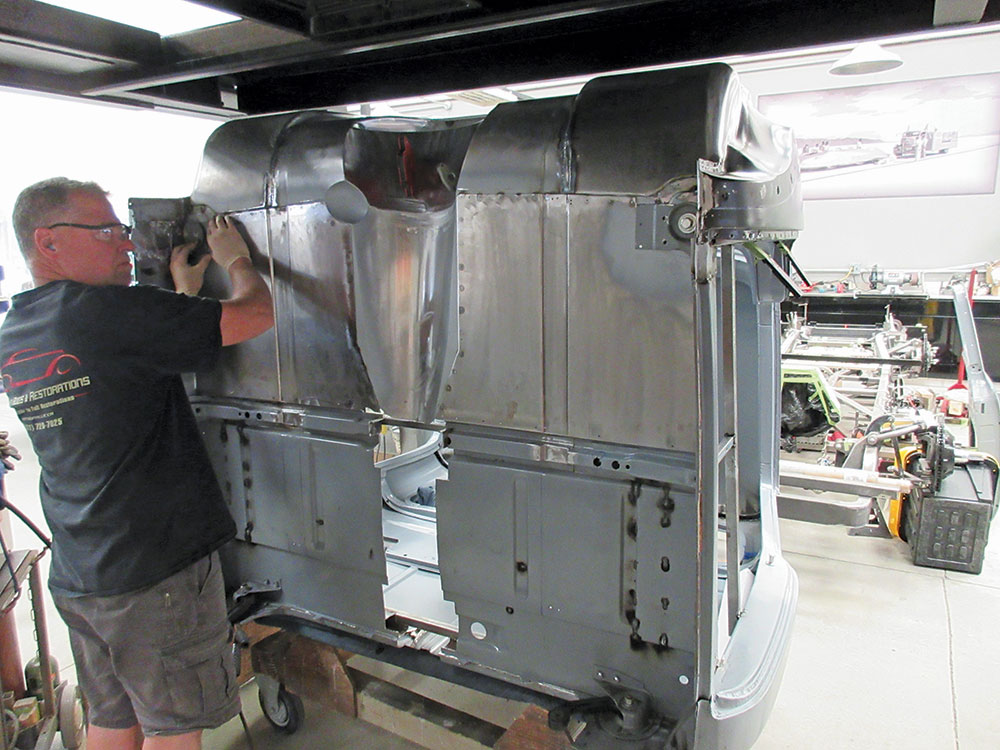

To start the project, George had all the sheet metal panels stripped and powder coated. This ensures that all the nooks and crannies are protected from rusting, inside and out, and will provide a stable foundation for the extensive body modifications to come.

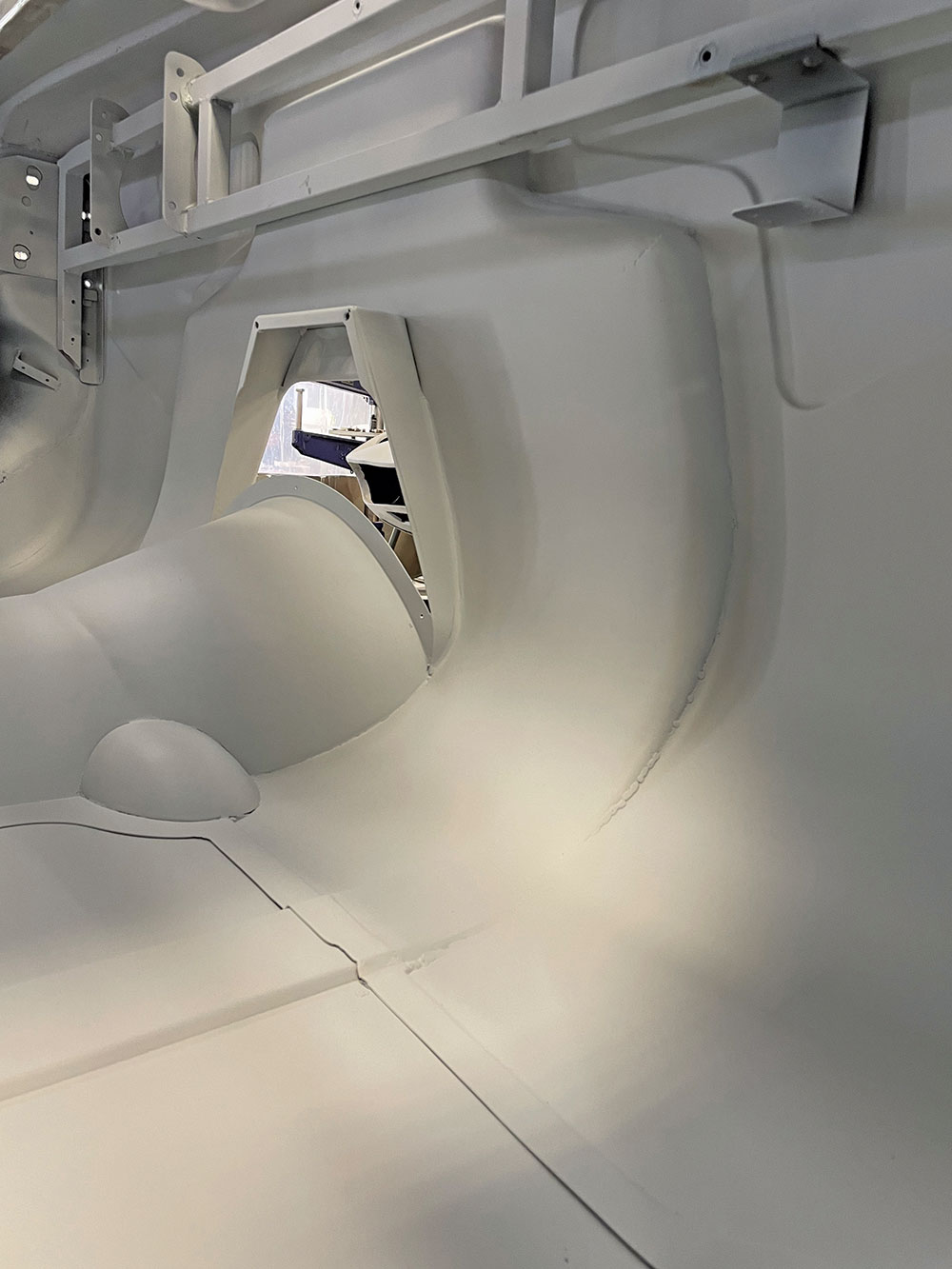

Emilio Belmonte is George’s sheet metal expert. After the chassis work was completed one of his first tasks was to make a new firewall and floor for the cab. He used a chip board to mock up the firewall, getting a close fit to the bellhousing but allowing adequate room for the powerful V8 engine to flex on its mounts. There will be raised panels formed on the firewall, inner fender panels, and inner bed panels to provide stiffness and style. Belmonte uses a Pullmax machine to form these panels, as you’ll see in the photos.

Read More: WOLF IN SHEEP’S CLOTHING: 1956 FORD F-100

Once the design and patterns for the new firewall were completed, the original firewall was removed. This provided the perfect opportunity to install bracing for the Kugel Komponents pedal system, and to get the pedals and master cylinder properly located and mounted. This job is so much easier with the firewall out of the way.

The photos will show the “intimate details” of how this work was done, and you can look for more articles on each of the major body modifications to come. Hang on for the ride–not only will this be an outstanding truck, it could very well give you some ideas for your personal projects!

Sources

Gary’s Rods & Restorations

(831) 728-7025

garysrods.com

Art Morrison Enterprises

(800) 929-7188

artmorrison.com

Mitttler Bros. (Hydroshox)

(800) 467-2464

mittlerbros.com

Total Cost Involved

(800) 984-6259

totalcostinvolved.com