1957 Ford Del Rio Ranch Wagon Coyote Swap

By Ron Ceridono – Photography by Brian Brennan & Tate Radford

In the Nov. ’21 issue of Modern Rodding we introduced Colin and Sue Radford’s ’57 Ford Del Rio Ranch Wagon as he installed an Art Morrison Enterprises Bikini Clip. Over the years we watched the Radford Automotive crew as they have turned out a number of top-notch street rods, trucks, and their own record-holding Bonneville car, doing everything from chassis construction to body- and paintwork. This time around we followed Colin and grandsons Tate and Caden as they installed a Vintage Air Front Runner onto a Ford Performance Coyote engine in a Ford station wagon where there was once a much-smaller Y-block.

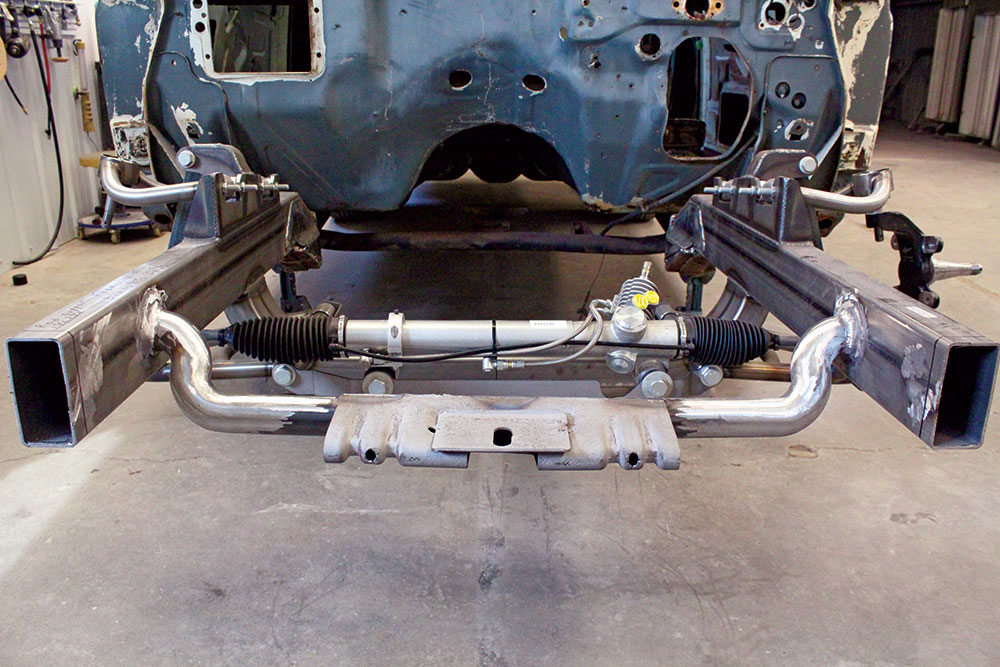

The Radford crew has a number of tips and tricks that have come from experience, not the least of which are to plan ahead and take lots of measurements. Before the Ford’s front suspension was replaced with the Art Morrison Enterprises bikini clip the car was placed on jackstands and all the critical points (chassis centerline, wheelbase, and so on) were recorded on the shop floor (see the first installment). Not only was it important to position the front suspension properly, prior measurements would also be used to position the core support bracket now that the new subframe is in place.

Read More: A 1952 Nash Rambler Wagon That’ll Make You Green with Envy

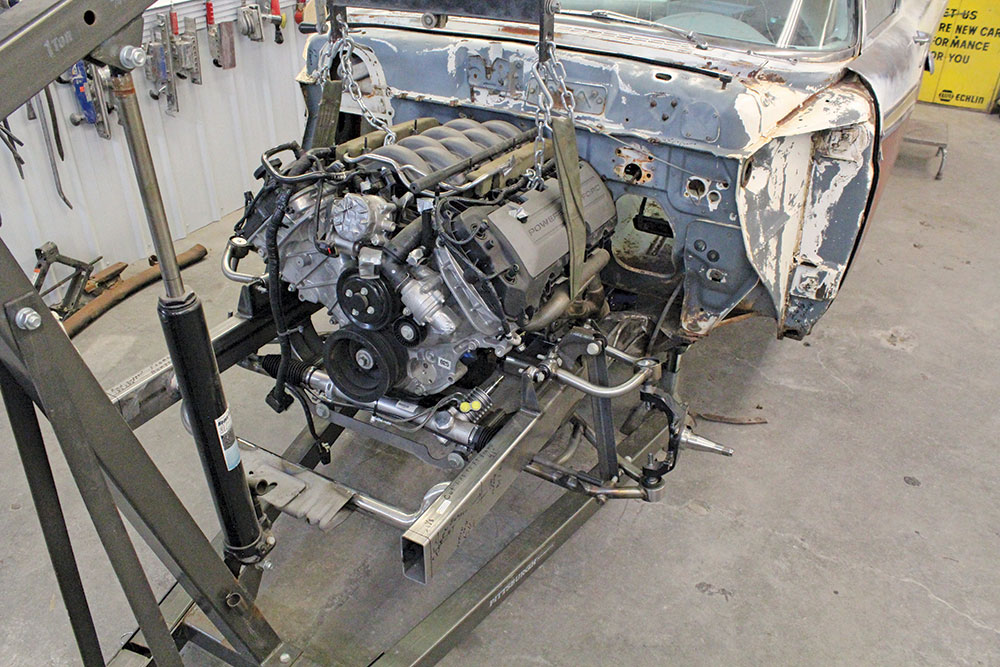

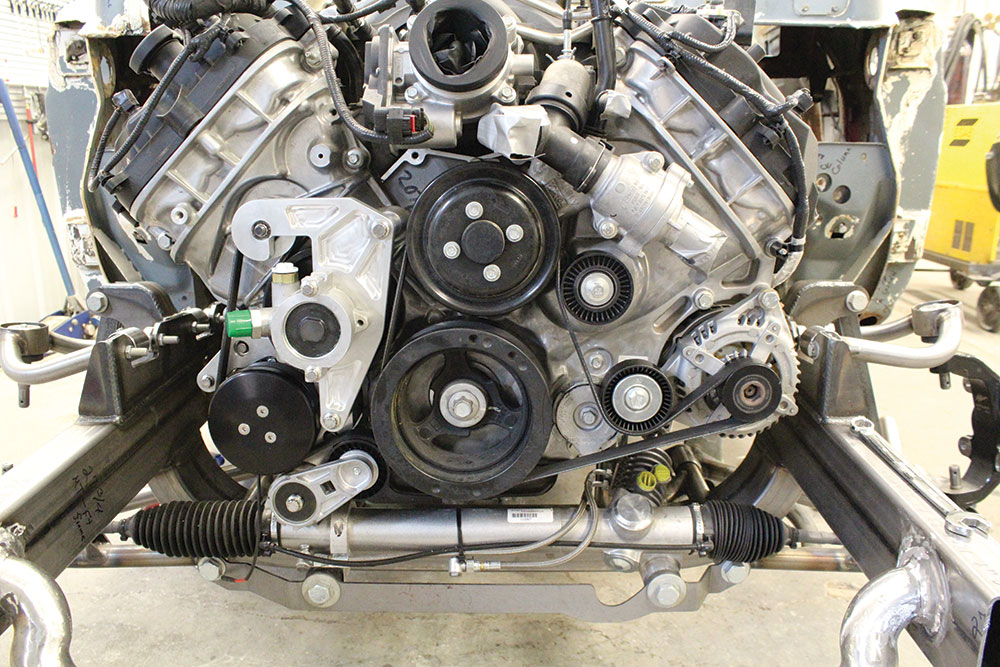

When swapping engines there are always a variety of problems that may appear, many of them are self-inflicted; radiator and fan clearance are probably the most common examples. Again, measurements and planning are critical and in this case to provide the necessary room for the radiator and fan the Coyote engine would have to be moved to the rear, which meant the firewall had to be modified. Certainly, something better done now than later when it’s discovered there’s no room for a fan.

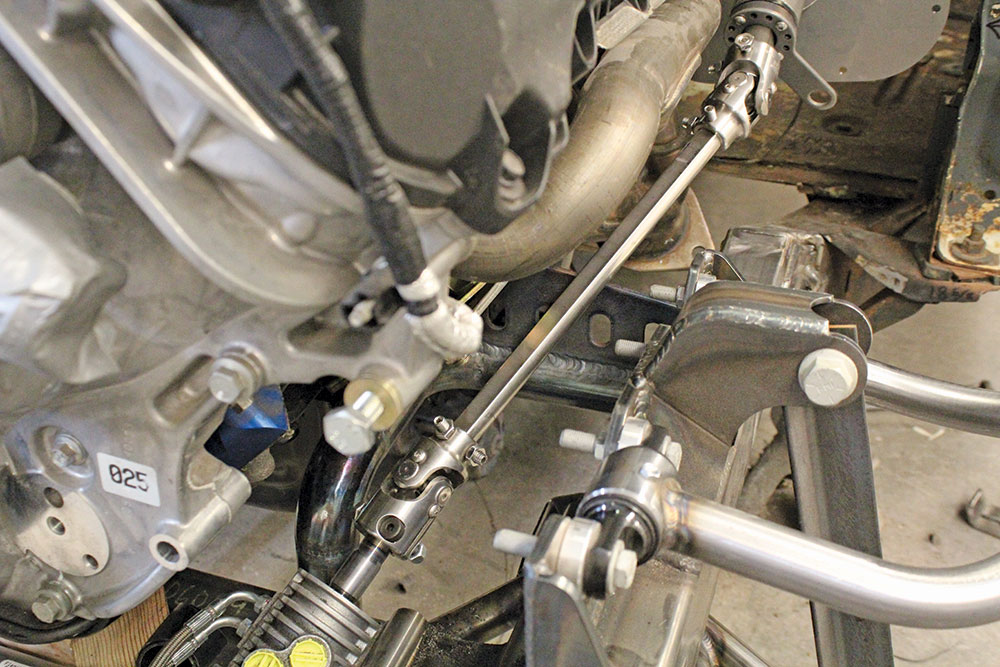

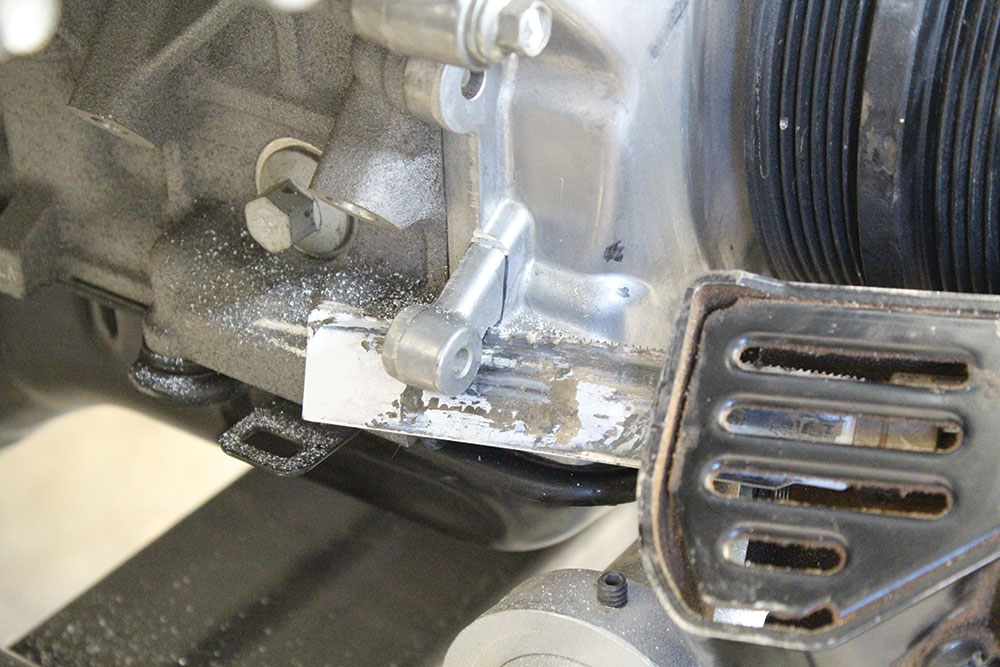

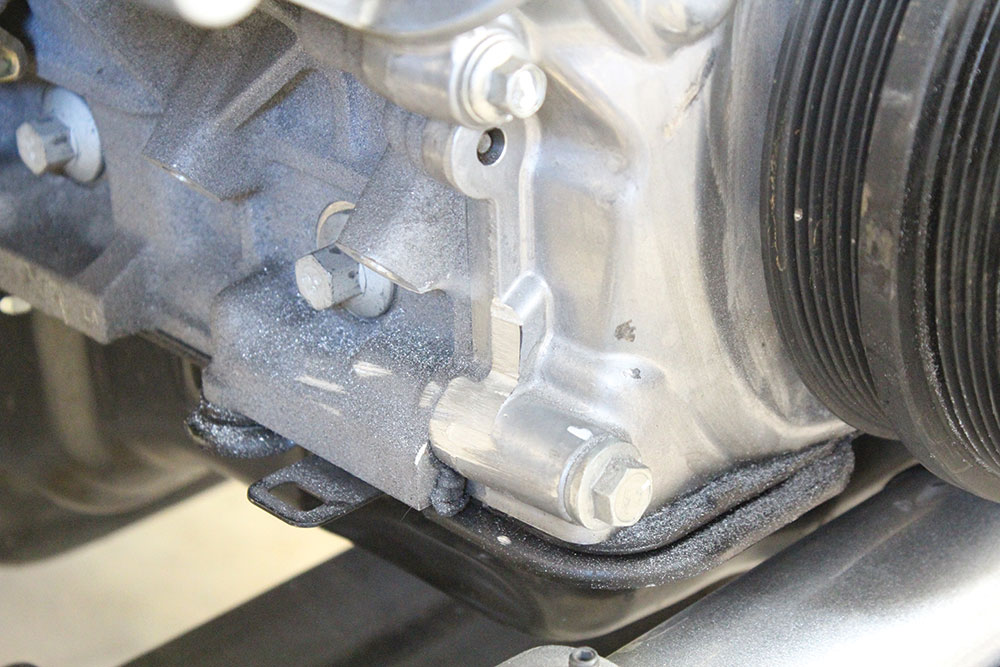

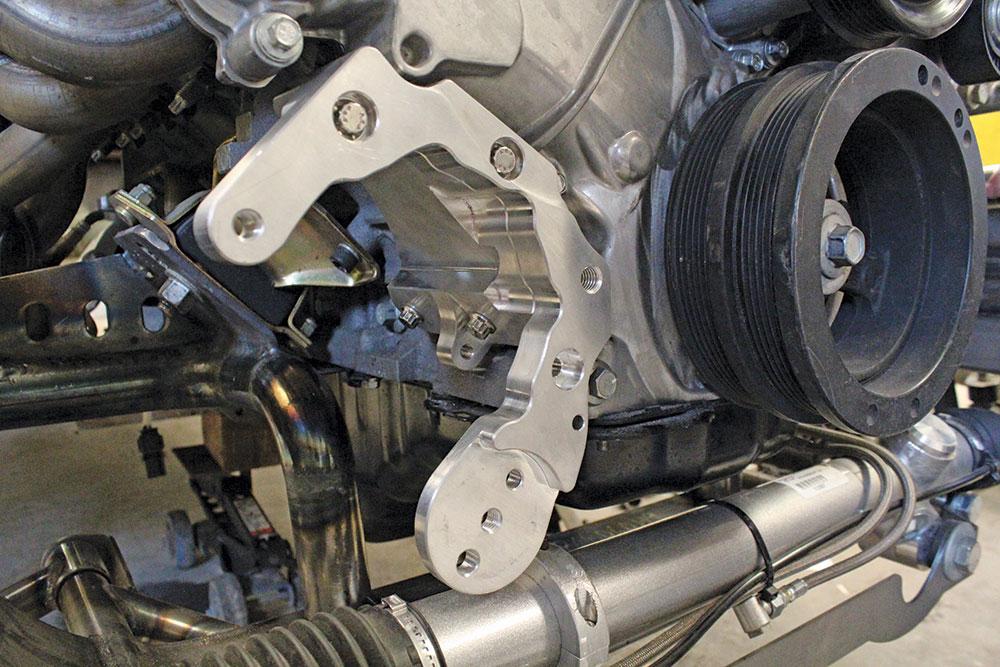

Additional considerations are the space for the steering and exhaust. In this case exhaust clearance on the passenger side wasn’t a problem, but it did take some creativity to fashion engine mount brackets that provided an unobstructed path for a shaft from the steering column, past the left hand header, and onto the rack-and-pinion. Another issue that often pops up is oil pan to crossmember/steering component clearance. In this case in addition to the vastly improved handling, the Art Morrison Enterprises Bikini clip with its front-mounted rack-and-pinion and contoured front crossmember provided much more room than the stock chassis configuration, so oil pan clearance wasn’t an issue.

Read More: A Rare Big-Block-Powered Two-Door Chevelle Wagon

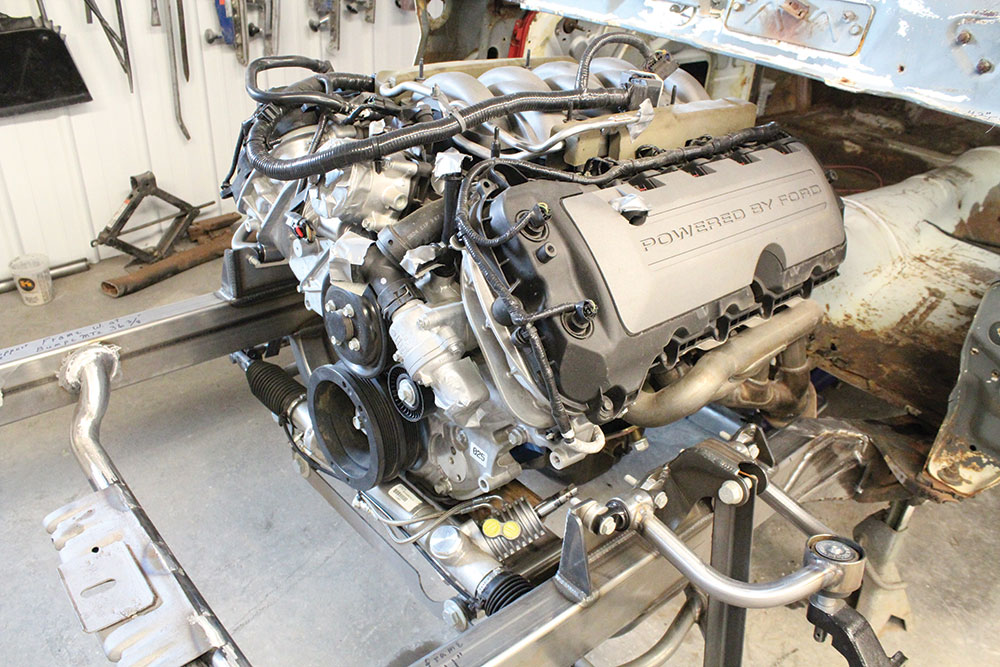

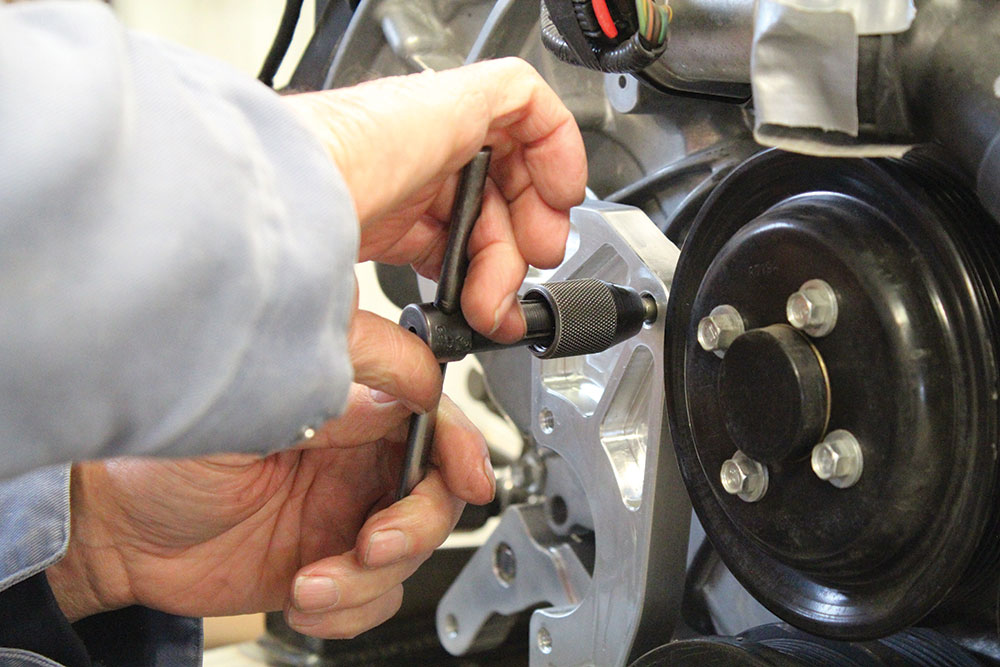

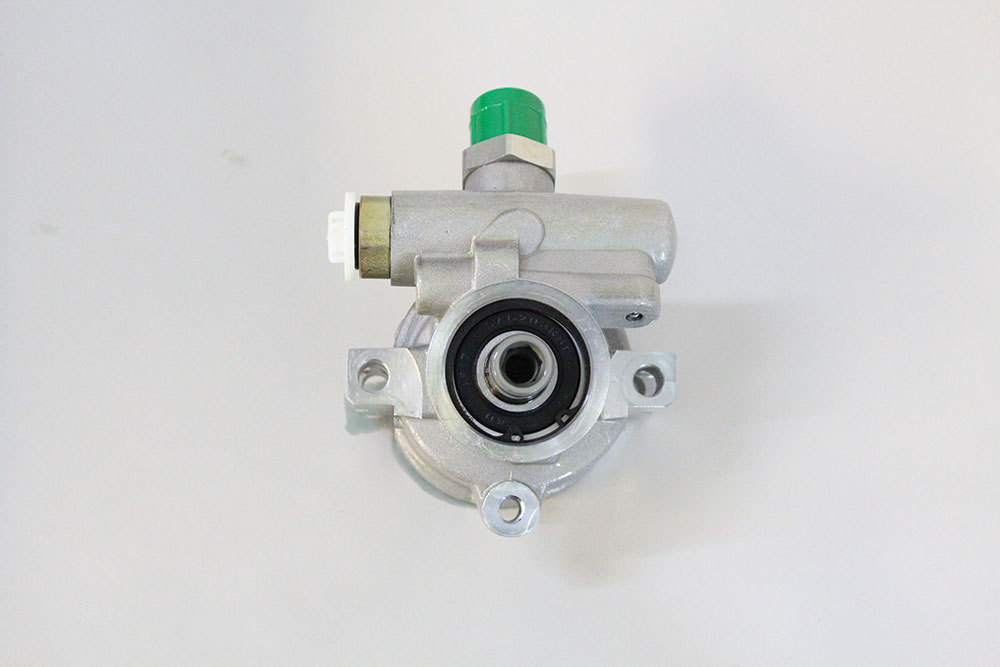

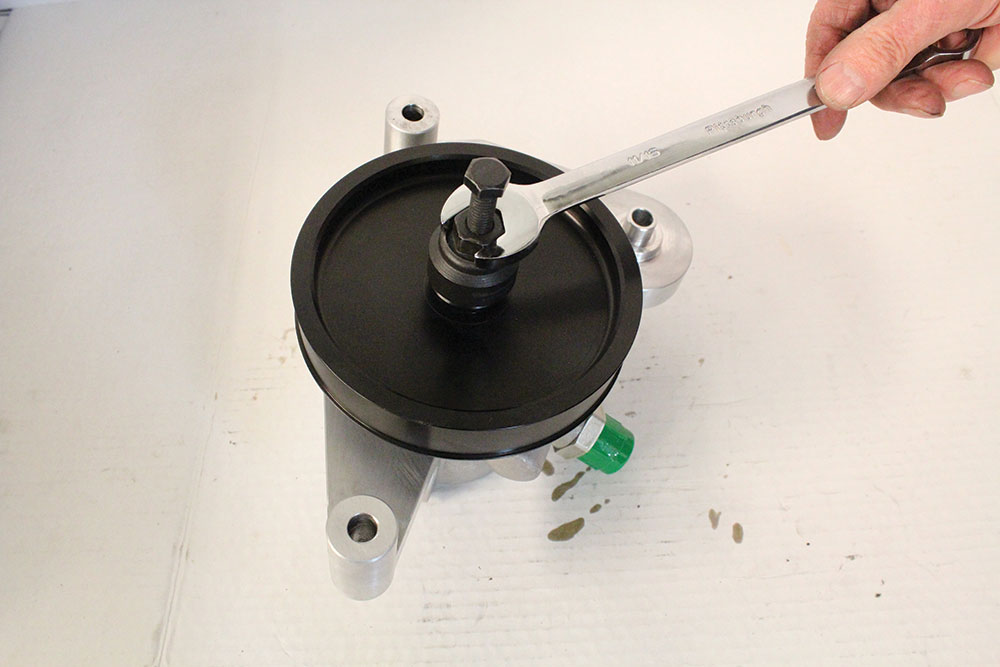

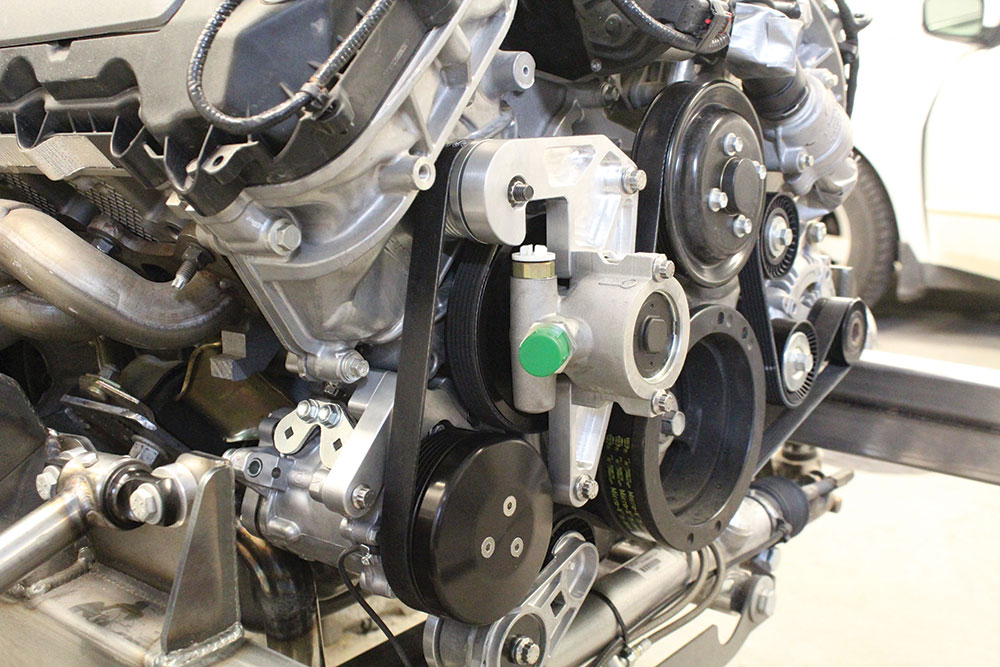

While the Coyote V8 is a big engine, like most cars of the era the Radfords’ wagon engine bay could accommodate its width, and setting the firewall back the required 2 inches wasn’t a problem. The real issue with this installation was the engine itself. Coyote engines don’t have a provision to mount the power steering pump that would be needed for the Flaming River rack-and-pinion as these engines came in vehicles equipped with electric power steering. The cure for that dilemma was a Vintage Air Front Runner kit. Well-engineered and beautifully executed, Vintage Air’s Front Runner is a compact drive system that is not only clean and simple but solid and strong. There are two versions of the Coyote Front Runner, one with a power steering pump and one without.

For this application a power steering pump was required, so a Vintage Air Front Runner (PN 174020) was ordered. The kit includes detailed installation instructions, along with the following items:

Sanden SD-7B10 natural finish AC compressor

Black-anodized compressor clutch cover

Detroit Speed aluminum power steering pump

Precision-machined power steering pump bracket

Power steering pulley

Dayco Performance serpentine drivebelt

Dayco OEM tensioner

Idler pulley

ARP stainless 12-point hardware kit

It should be noted that Vintage Air has identified three different Coyote timing cover configurations. The differences are the cast bosses in the cover, some are blank and must be drilled and tapped, others are drilled and tapped with 8mm threads (these holes are drilled and tapped to 10mm x 1.5 threads). The third is similar to the second example with the addition of stiffening ribs that must be carefully cut down to achieve adequate clearance (1/16 inch) for the tensioner assembly. As is typical with an OEM engine, there are other timing cover versions in the field and some may not be compatible with the system. Fortunately, the die-cast cover is available separately from Ford.

Read More: 1933 Ford Woodie Station Wagon That’s Truly Memorable

With the Front Runner installed the only concern was clearance for the AC and power steering pump belt tensioner. Again, planning paid off as the engine was positioned so the tensioner cleared the Flaming River rack-and-pinion, the pan cleared the crossmember, there was enough room to route the exhaust, and there was a straight shot for the steering shaft from the column to the Flaming River rack-and-pinion steering. With all those issues involved the engine and transmission mounts were fabricated and installed.

Building a hot rod often comes with challenges, and never think it’s unusual to have to tear out something that’s been built and installed because it didn’t work as planned. But learn to plan ahead and it won’t happen as often. MR

Sources

Art Morrison Enterprises

(866) 808-4759

artmorrison.com

Automotive Racing Products

(800) 826-3045

arp-bolts.com

Flaming River Industries

(806) 648-8022

flamingriver.com

Ford Performance

(800) 367-3788

performanceparts.ford.com

Radford Automotive

(208) 745-1350

Vintage Air

(800) 727-7094

vintageair.com