Cosmetically Restoring a Good, Used Radiator

By “Rotten” Rodney Bauman – Photography by the Author

Just about a month ago, while sorting out a coolant recovery system for our ongoing second series 1955 Chevy truck build we painted up some pieces—and they turned out real nice. Ordinarily that’s a good thing, but we were hoping to illustrate clever ways to fix minor imperfections, too. This time around it looks as though we’ll have our chance to do that.

With a little help from nearby Reynolds Radiator we’re wrappin’ up the truck’s cooling system. When we first received the job, it came with a functioning used radiator. It wasn’t much to look at, but at the time it seemed to fit in with its surroundings just fine. Now that those surroundings are shiny like-new, the radiator needs a little attention.

Read more:1955 Chevrolet Task Force Hood Emblem Upgrade

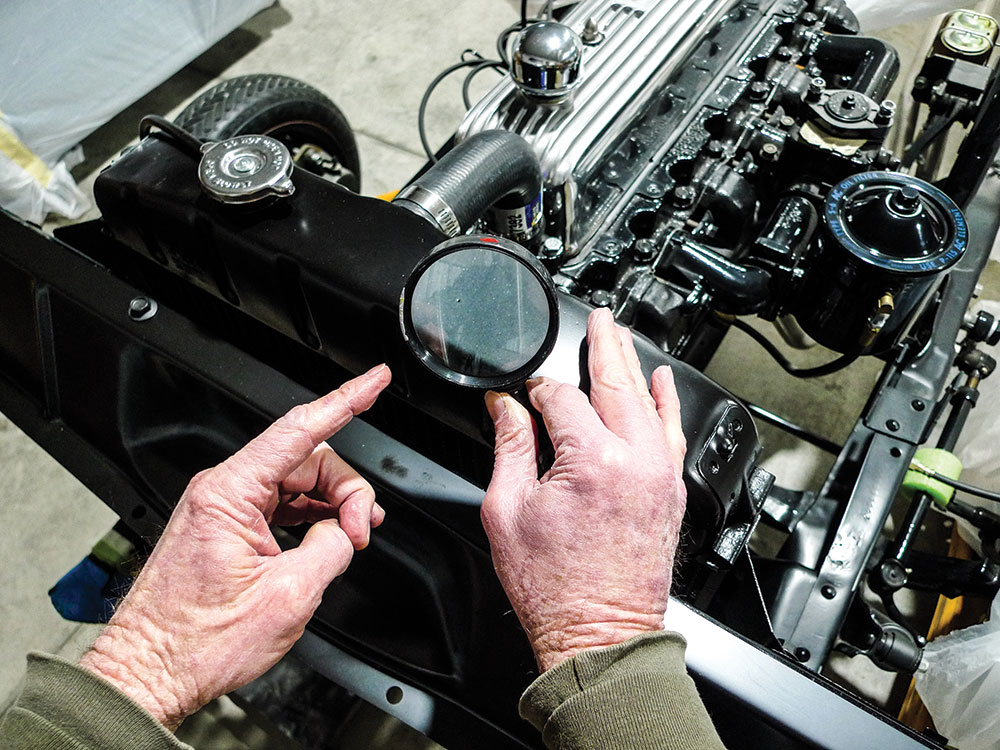

Just to catch us up, the truck’s OE style used radiator has already been flushed, pressure-tested, and pronounced healthy to run. Our radiator guru, Howard Lilly, offered to paint it with a waterborne coating, but we opted to pass on that. Then sure enough, back at our own shop, we began to notice a number of cosmetic hiccups, like a dented top tank and mangled copper fins.

For straighter rows of fins (like most AC condensers) a radiator fin comb could be handy. Through Summit Racing we’ve seen four types available. The trouble is here we’re not working with straighter rows of fins. We’ll be on our own to test and determine which of our sharp, pointy instruments are best suited to restoring the convoluted type of fins this radiator came with.

Read more: How To Repair a Cowl on a ‘55 Chevy Truck

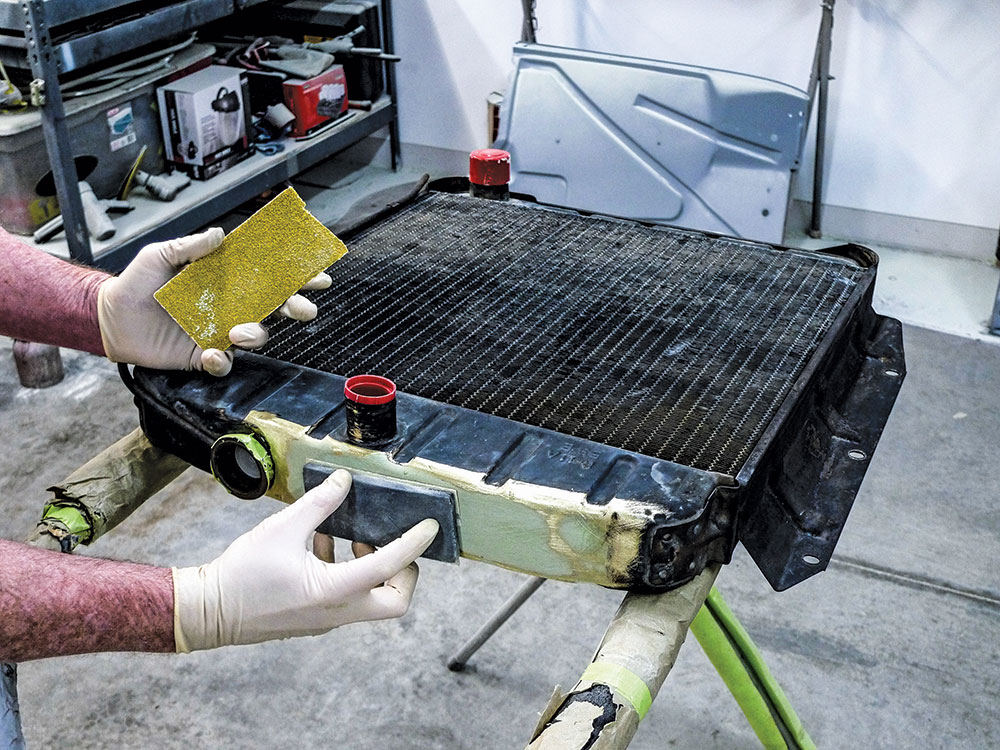

To properly repair this radiator’s top tank, it should be removed, metalfinished, and then soldered back into place. Considering the amount of attention that other parts still need, that radiator repair doesn’t seem like a good use of time. For situations such as these, cheatin’ comes to mind.

If you’ve been with us you may have noticed that we keep polyester auto body fillers on hand at all times. Through the years such fillers have come a long way, but would a 1/8-inch (or so) smear hold up to cooling system temperatures? Since we know the same fillers would hold up under black exterior topcoats, even in the blisterin’ summer sun, we’d hazard a guess that ours will hold up well right here.

Read more: Skim Coat Tips and Tricks on a ‘55 Chevy Truck

What our good, used radiator needs now is a good ol’-fashioned cosmetic restoration. For that we’ll use whatever’s in stock along with the Evercoat autobody fillers that we routinely order through Summit Racing. As a timesaving measure we’ll try out a convenient Dupli-Color aerosol Filler Primer, which coincidentally (like most of the materials we’ll use here) comes from Summit Racing as well.

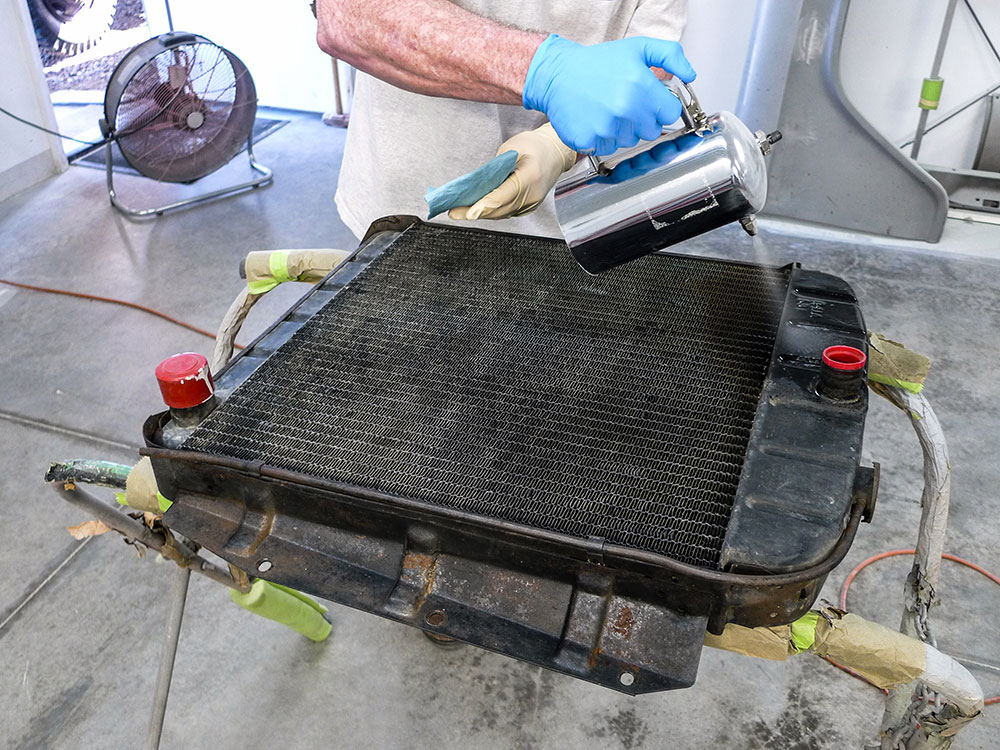

Toward the end of our story we’ll load up a ’gun for a spray application of our favored high-temp coating as a radiator paint. If things go our way, we’ll have the minor imperfections we’ve been hoping for.

Read more: Patch-Up ‘55 Chevy Pickup

Sources

Harbor Freight Tools

(800) 423-2567

harborfreight.com

Summit Racing Equipment

(800) 230-3030

summitracing.com