Behind the Scenes Part 3: Scott’s Hotrods N Customs Creates Handmade, Custom Truck Bed Floor On a 1951 Chevy Truck

By Kenneth “Stress Ball” DeKiserre – Photography by Camren Beattie

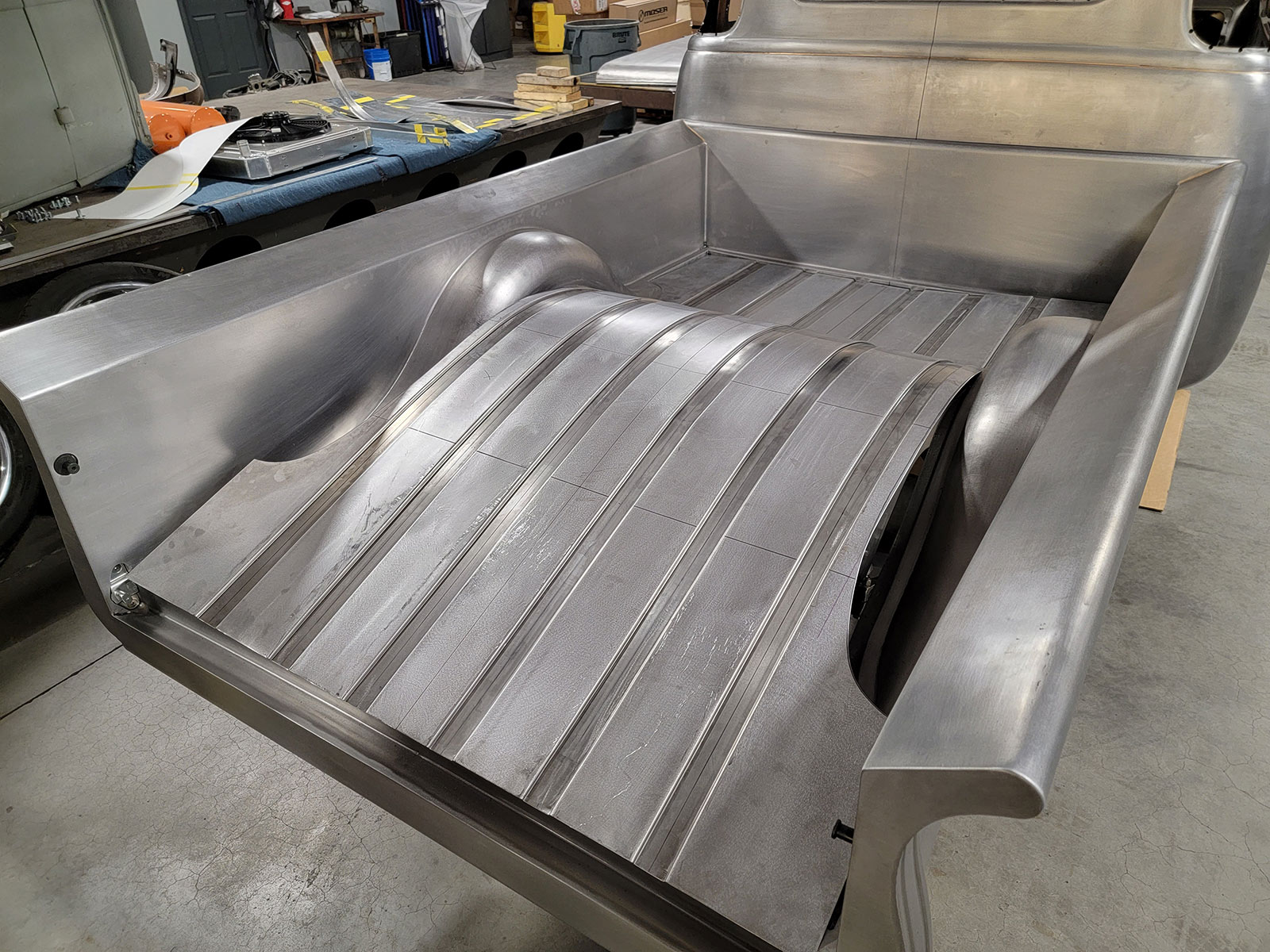

Initially, we weren’t really sure what we wanted to do with the bed in terms of design. All I knew was I wanted it to look stock-ish, but with a lot of very subtle adjustments and modifications to make it look timeless and correct from the outside. I wanted all the outside modifications to be just enough for anyone who knows these trucks to have to do a double take and get up closer to study it. Then, once you got closer, you could see the inside of the bed, which I still wanted to keep very simple and elegant yet also make a little bit of a statement.

Read Part One: Masterful Metalwork With Scott’s Hotrods N Customs

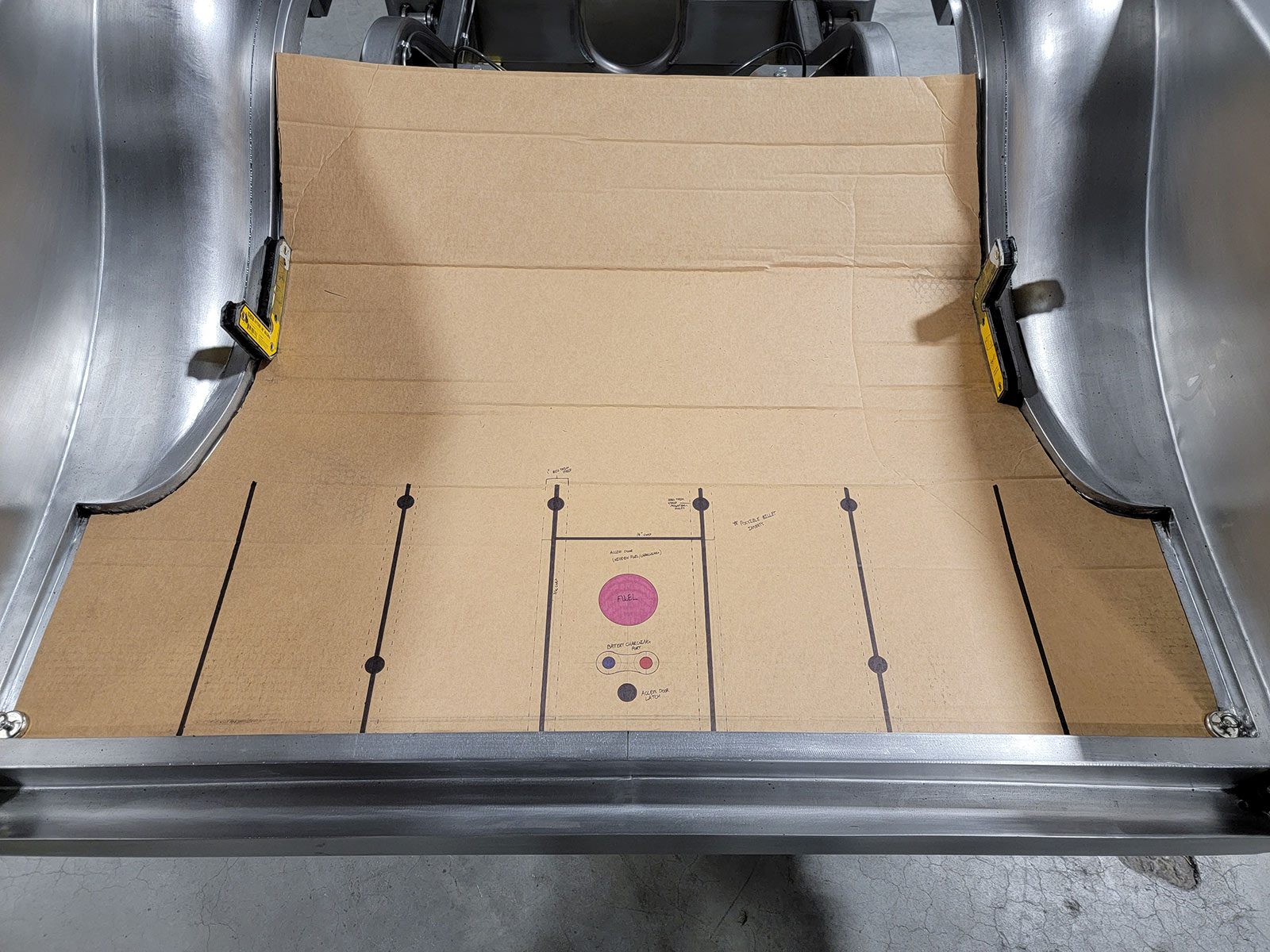

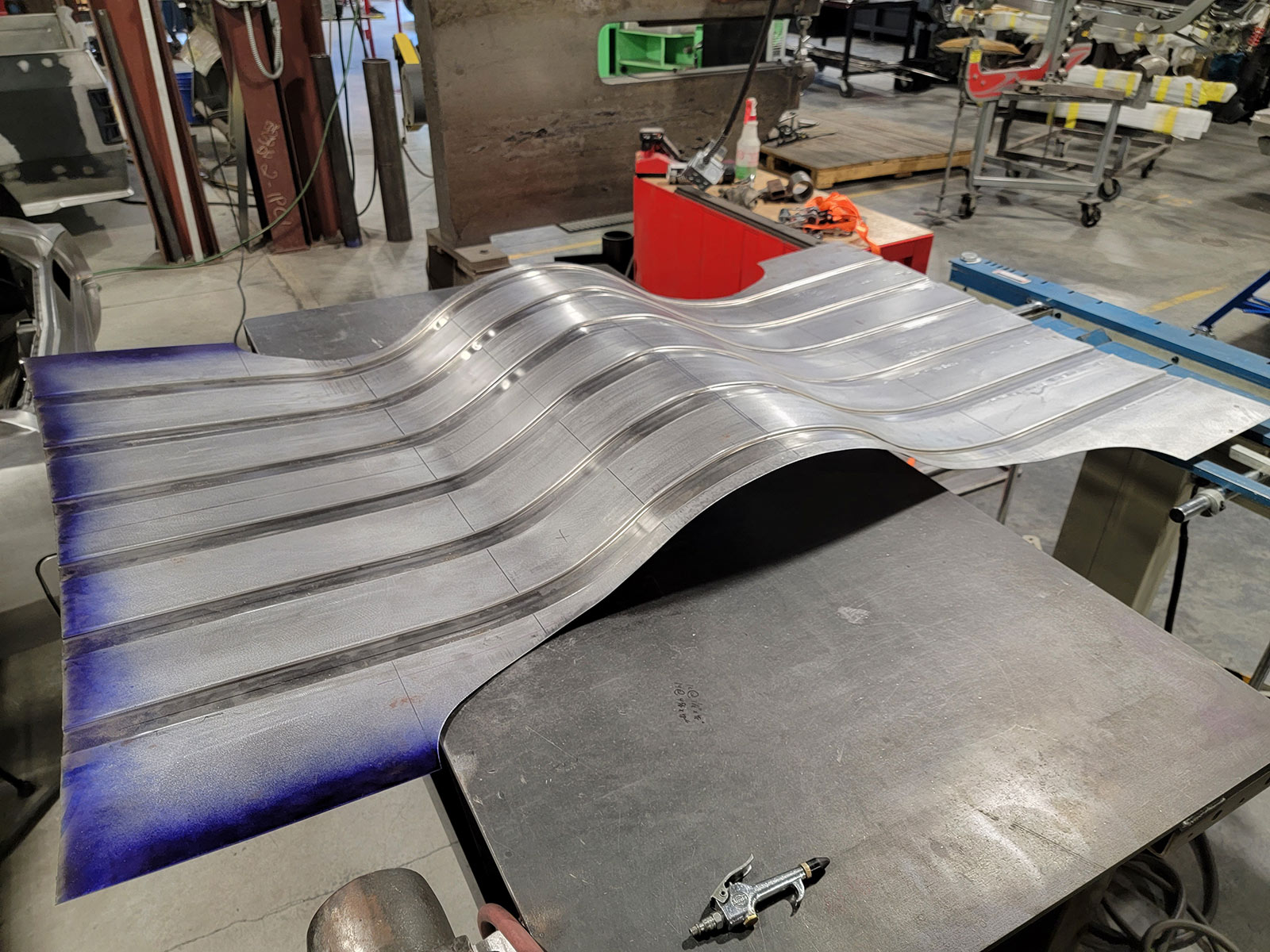

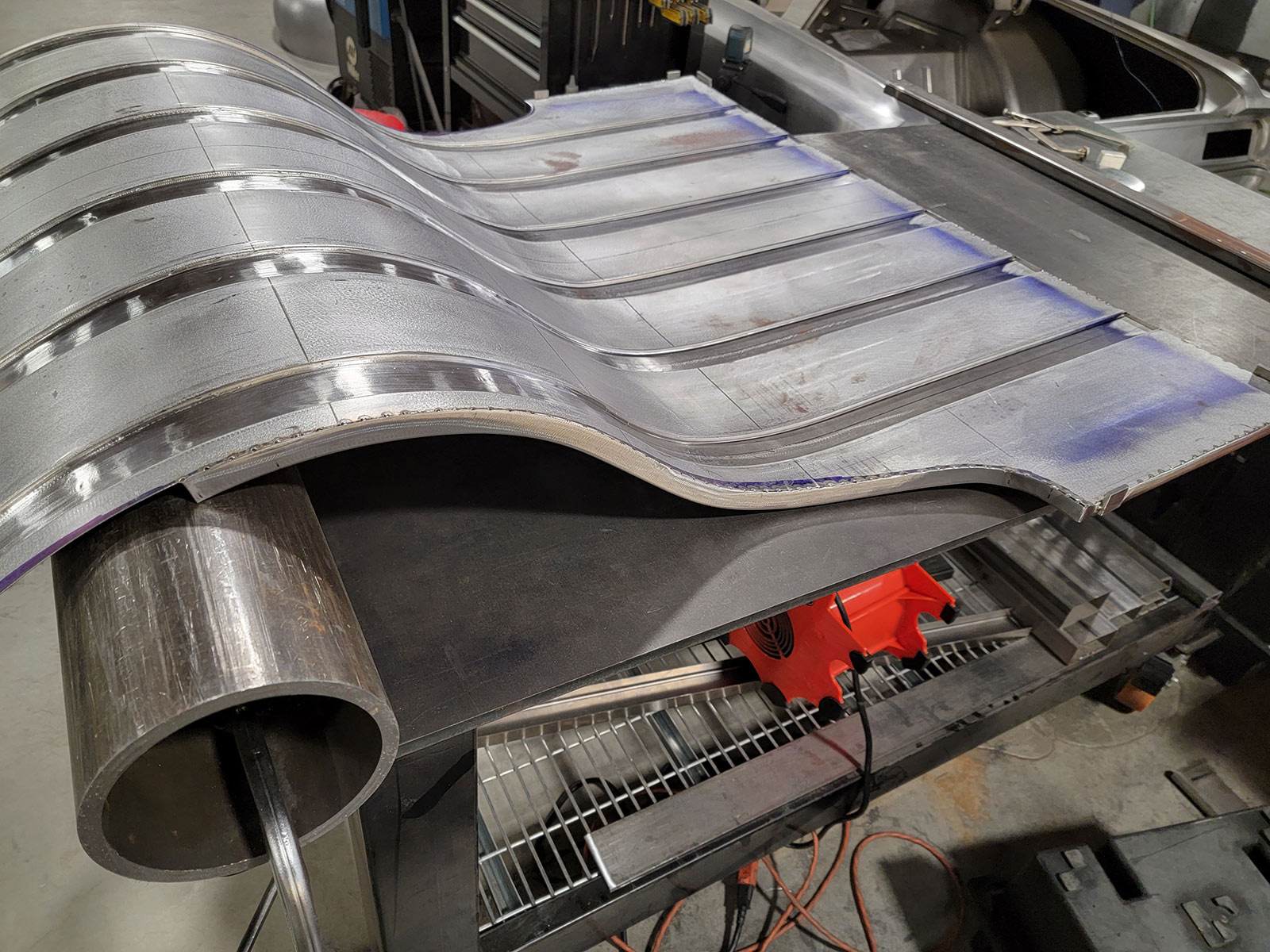

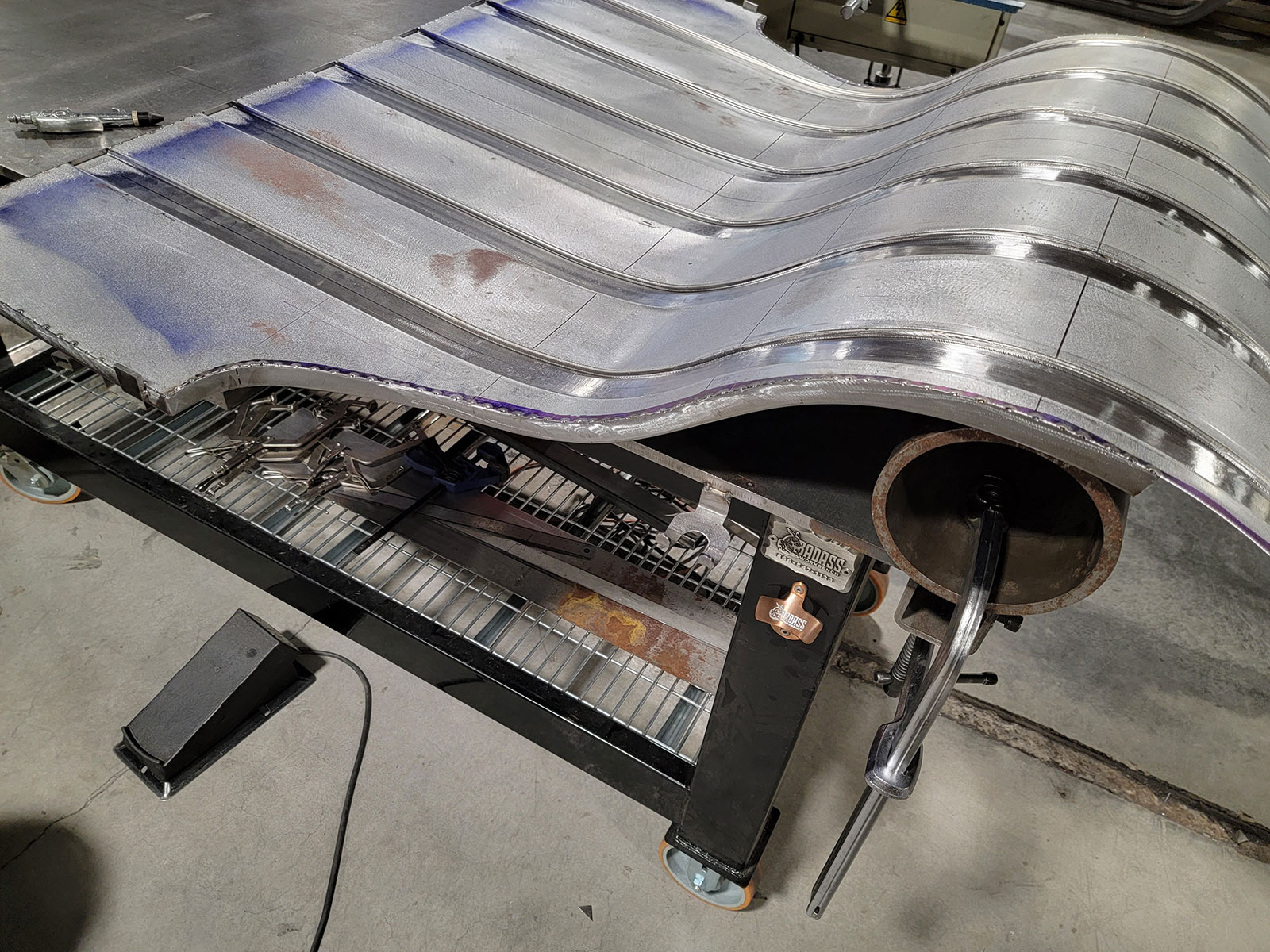

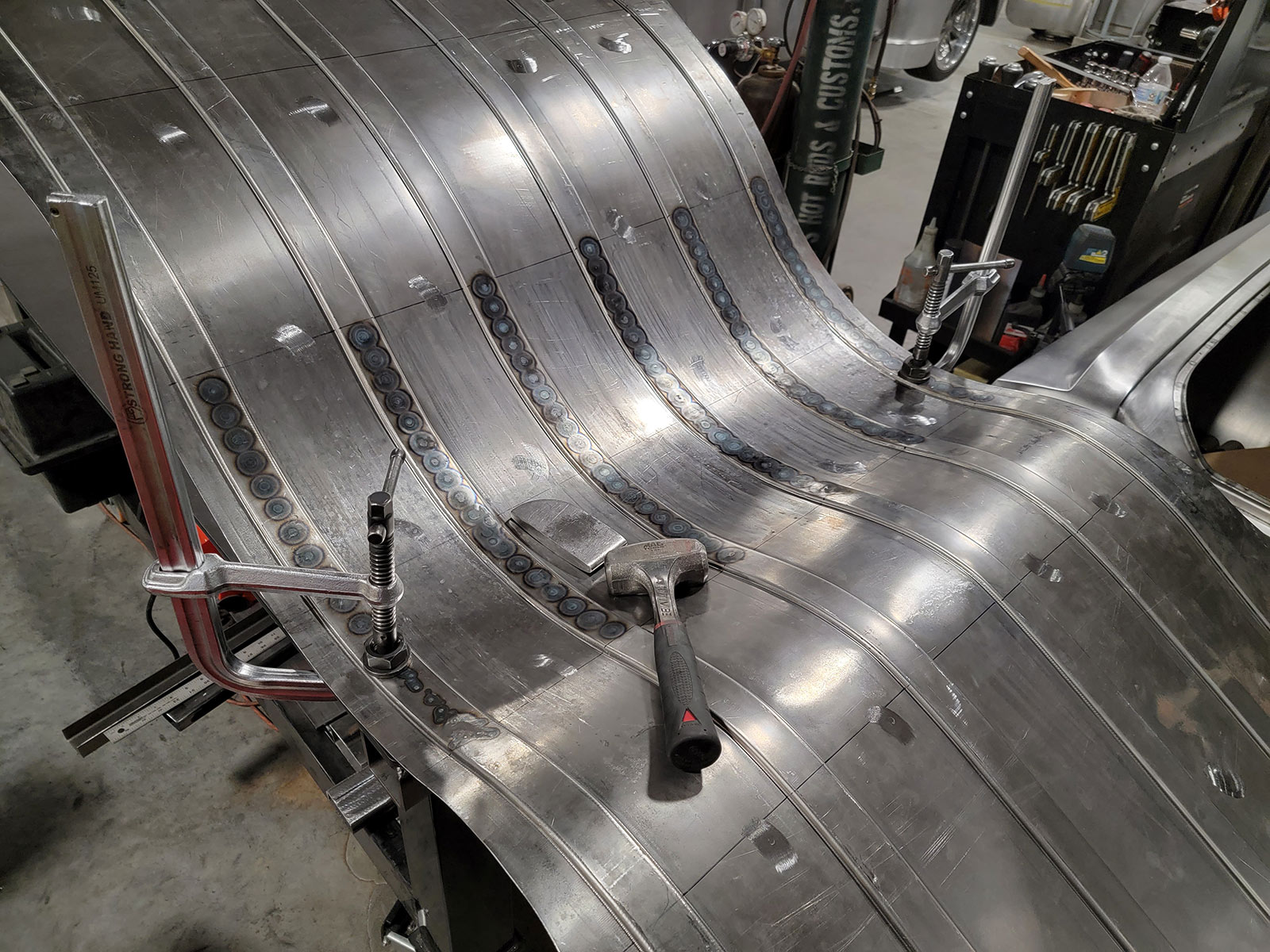

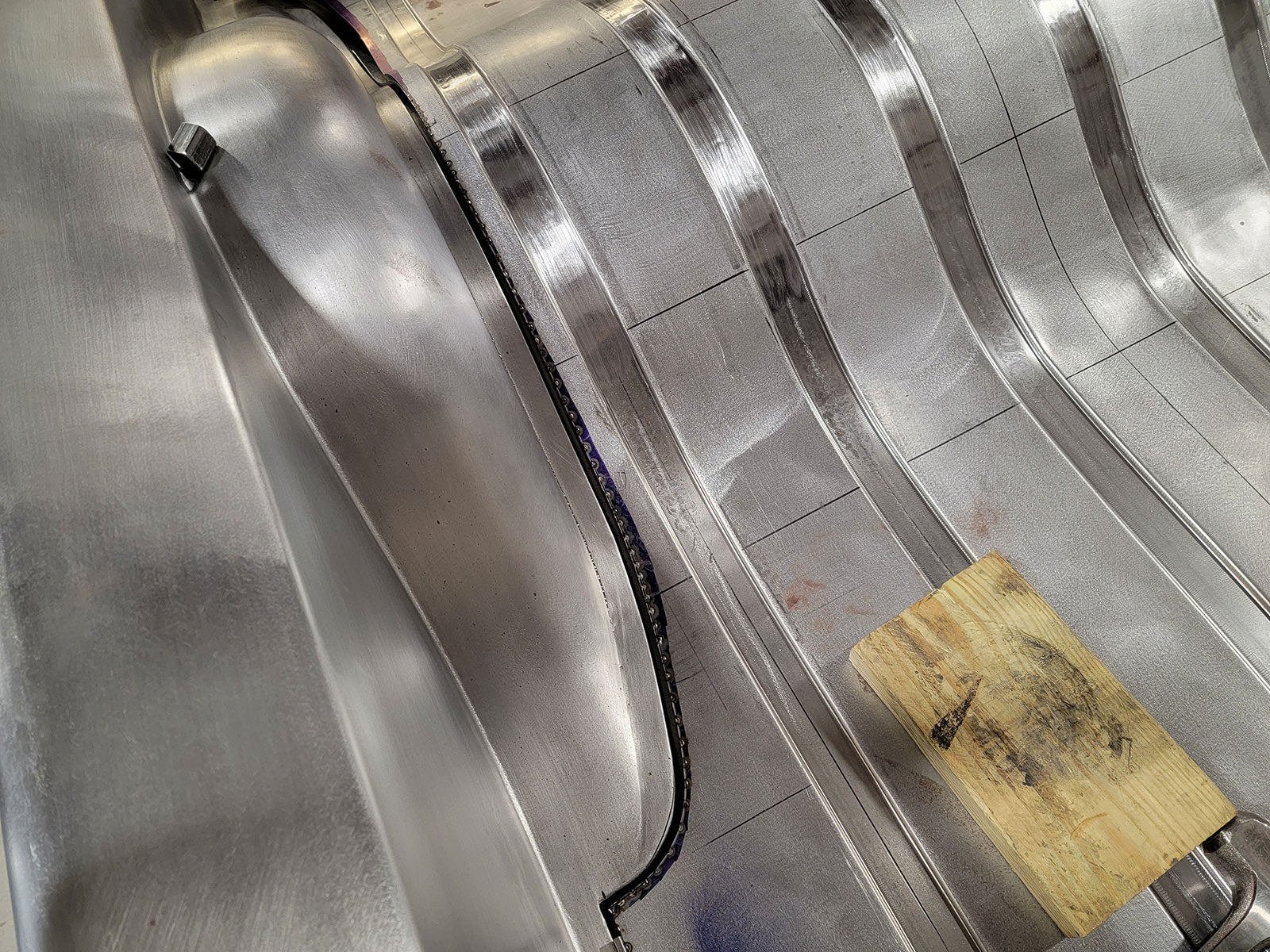

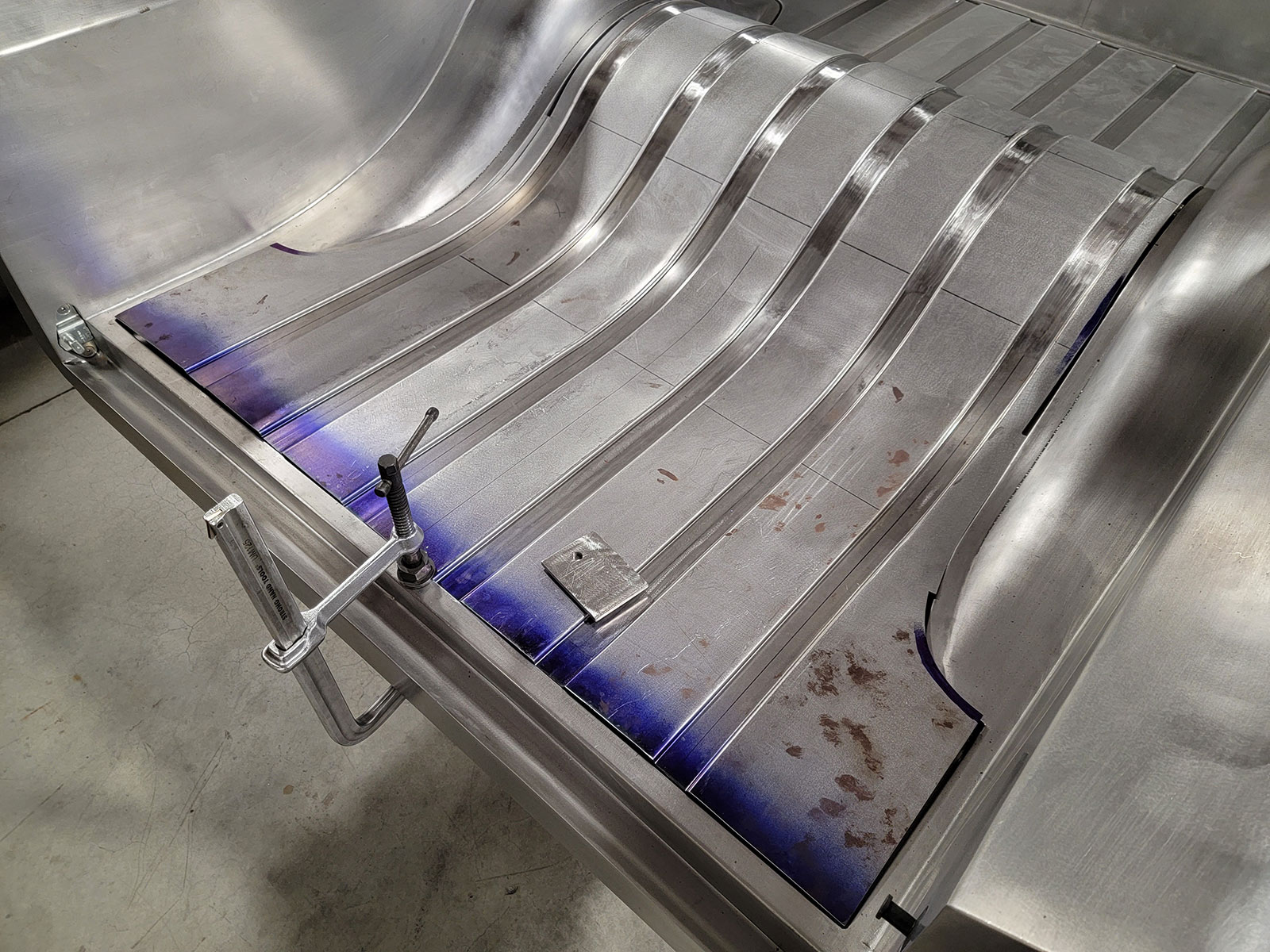

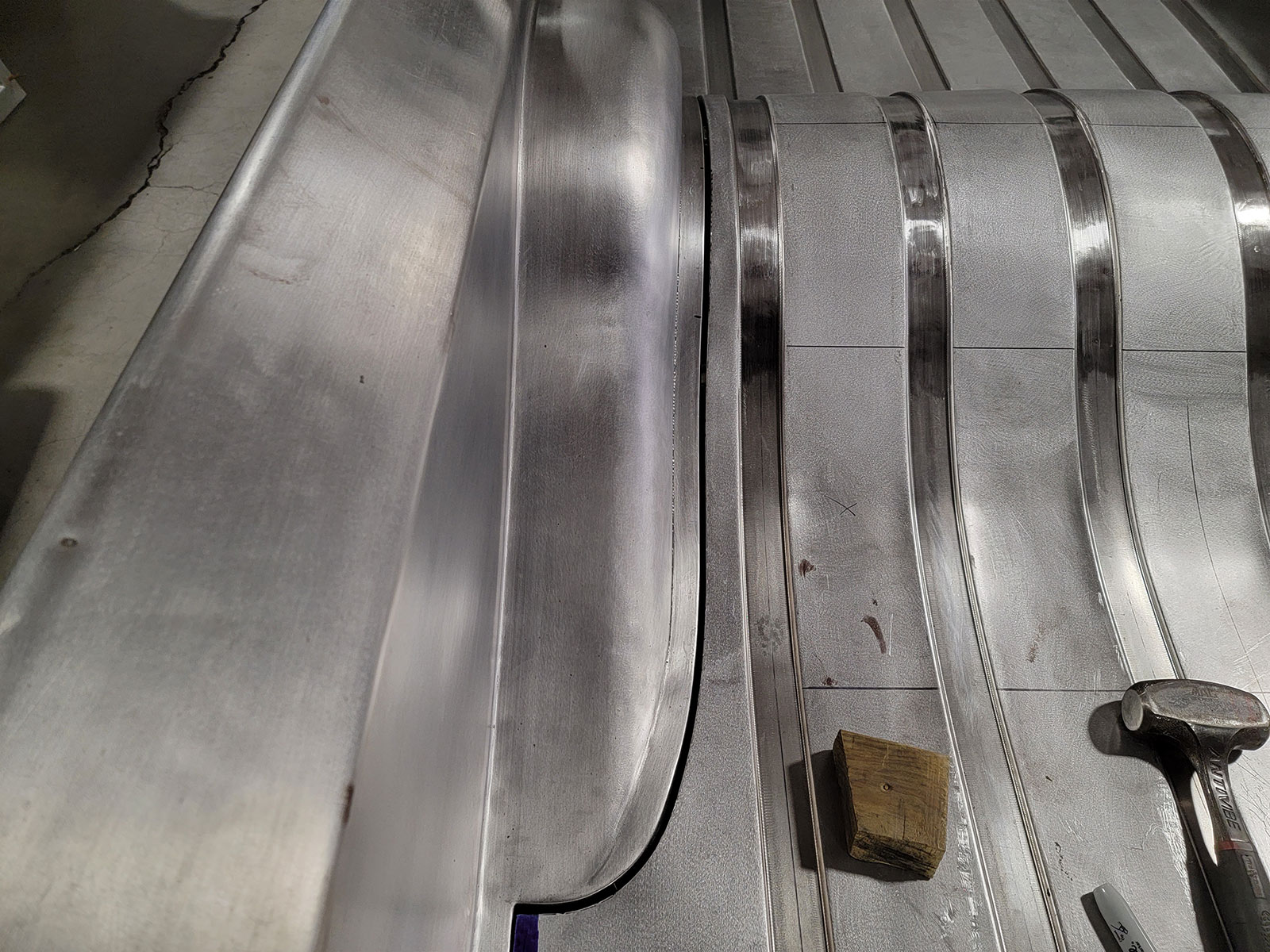

The very swoopy wheel tubs were a statement piece already so I wanted the truck bed floor to tie back in some of the factory look and feel. Originally, the plan was to do a smooth sheet metal floor with some recessed billet aluminum inserts throughout. But as time went on and I continued building the bed, my coworkers and I agreed that it needed something different, something simpler yet also more complex, which is how we ended up with the recessed ribs in the bed floor that you see now.

Those ribs will be filled with custom-machined billet aluminum truck bed strips and will make the old truck truly unique from everything else out there but also retain the stock classic truck look, making it look timeless (the theme I’ve tried to stick with throughout the build so far). And yes, I did eventually end up catching a little bit of hell because the custom truck bed floor was not done in the way that my boss (and the customer), Brian, had originally talked about, but I think they both realized that I gave them a much cleaner and more unique bed floor than they were originally planning, so it all worked out (I hope!). It gave them even more ideas to throw at me to make happen. That’s when I told my boss, “You tell me what you want to do, and I’ll find a way to make it happen, Captain!”.

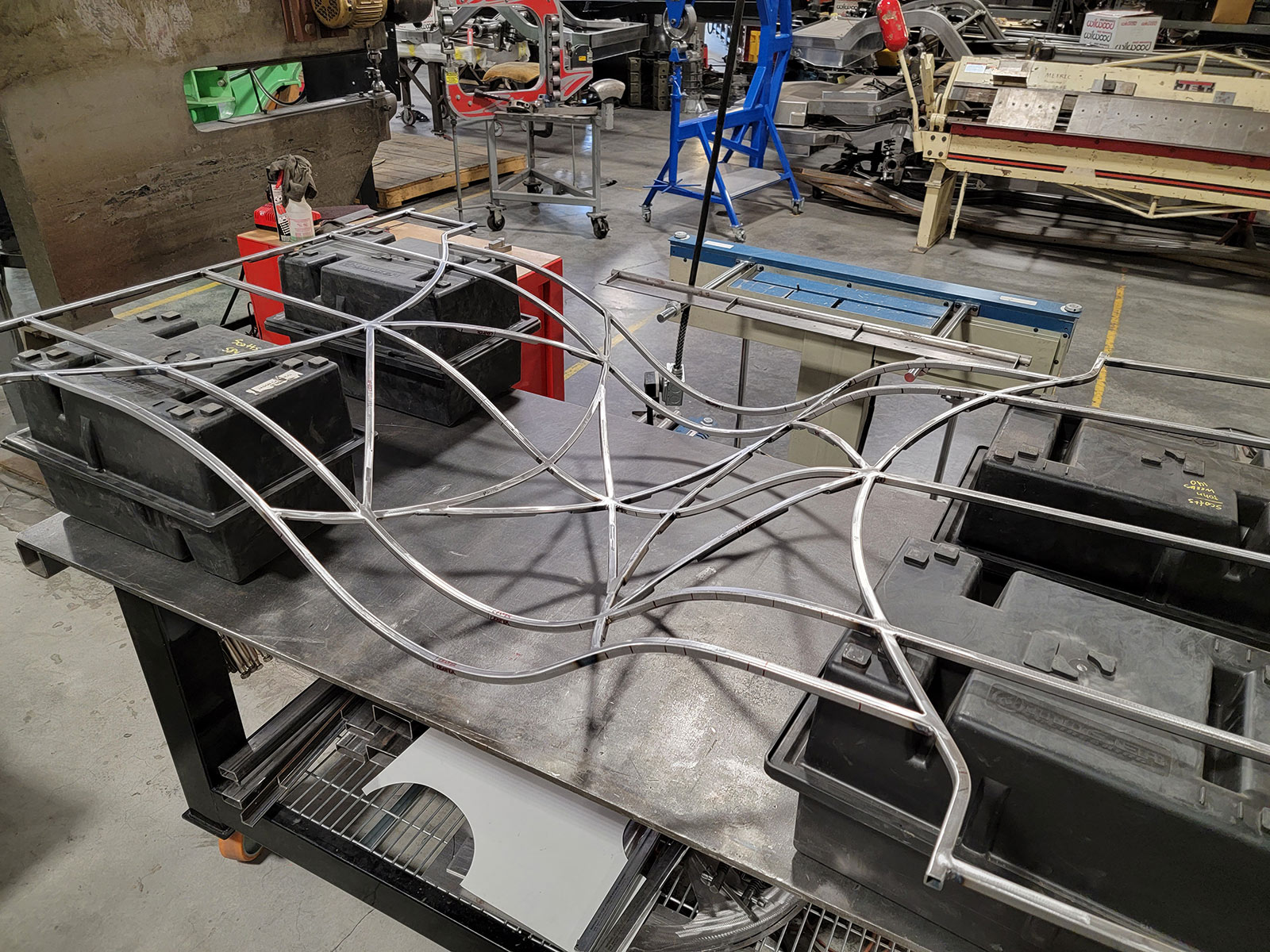

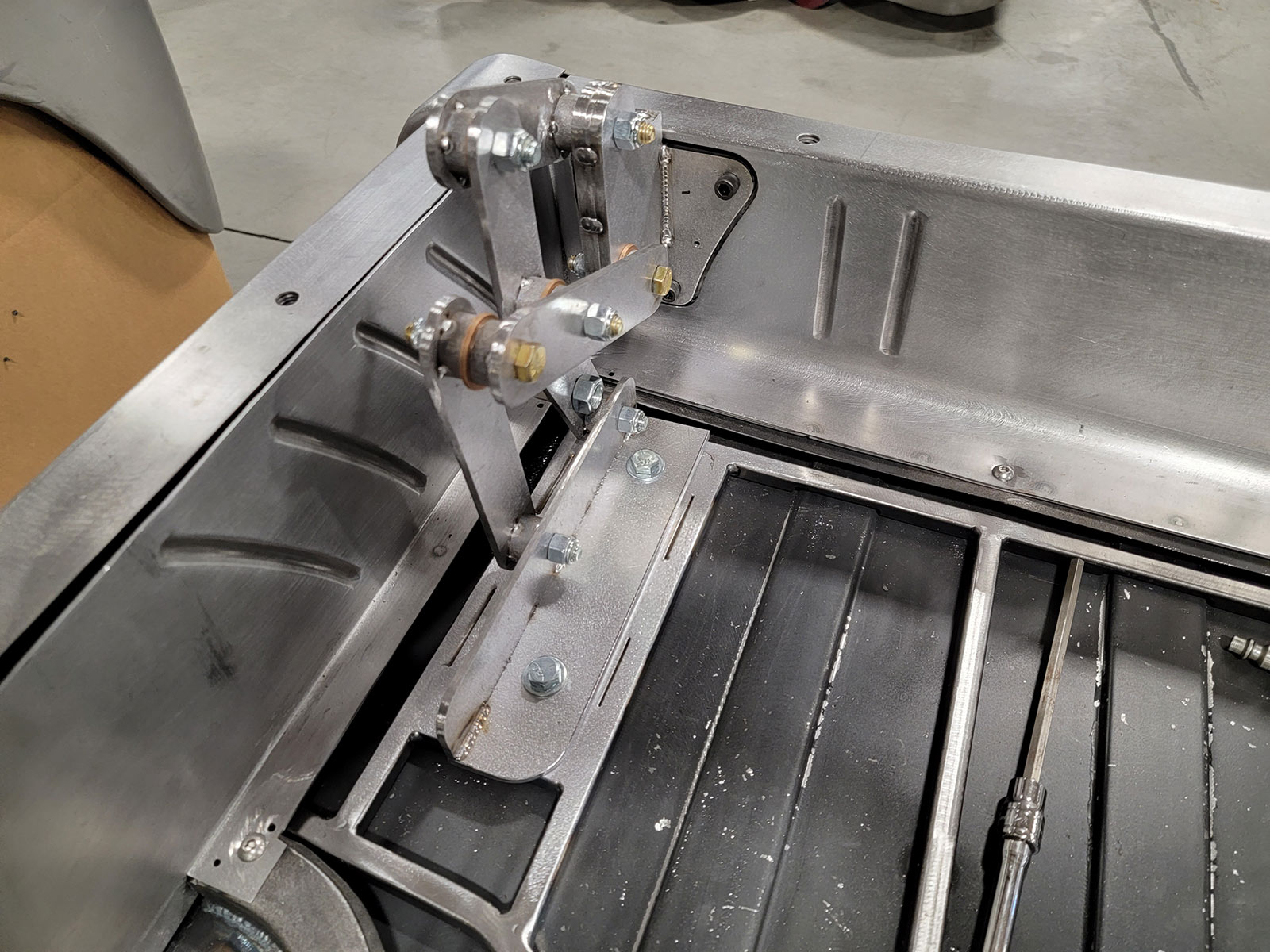

I’ve had a lot of fun building the bed so far (currently still building certain parts of it). I’ve never built a bed before, so it was immediately a very interesting challenge and it taught me a lot right away about keeping things braced and jigged up properly to maintain levelness and squareness, how to preplan how certain parts of the bed and panels were going to join together to leave the cleanest look in the end, and how certain things have to be engineered and re-engineered to accommodate other trick little custom features, like the slow-opening tailgate.

I know there are probably a lot of people out there who think, “It’s just a box, how complicated can it be?” Well, I know I certainly thought that at first, and boy did I get humbled because it has probably been one of the most challenging and most rewarding things that I’ve done yet. But if I had to do it all over again I absolutely would. Would I change certain things to make things easier? Yes. Hindsight is always twenty-twenty. There have also been a few curve balls thrown at me along the way, like making the bed floor open up. Things like that I would’ve done differently had I known we were going to do that earlier in the build. But anyone in this industry doing this kind of work will tell you that things will always change, especially once they reach this kind of budget. So that is just something you have to work with and around, and that’s honestly kind of a fun challenge in itself.

Read Part Two: Brian Schutte’s 1951 Chevy Truck: A Look At The Metal Magic

You know, that’s a question I don’t get very often. If anything inspires me to do things a certain way or not. Truthfully, no not really. I don’t want to sound shallow about it, but there are very few things, people, and builds that inspire me to do what I do. If I had to pick one particular truck that I’ve gone back to and studied from time to time, it’s probably the 2021 Goodguys Truck of the Year, gold ’50 pickup truck dubbed “#FastLaneFifty” built by L and S Customs.

I’ve talked to Troy Comer, who I believe is the one who did most of the fab work on the truck and he seems like a really nice guy and does some really nice custom fabrication work. I’ve also had the chance to see the truck in person a couple of times at Goodguys events and I’ve always liked the truck. I even told Troy once that I have this little friendly rivalry in my head. I want to build Brian’s Chevy truck to compete with the best trucks out there, and that little gold truck is where I want to set the bar. You don’t get Truck of the Year by having any old cookie-cutter truck following the same trends that everyone else is, and I want to be that guy giving that truck and all other trucks a run for their money.

That is where I find my motivation to keep doing better. There’s always a bar that someone has set, which means there’s always a chance for me to try and push that bar a little higher. I always want to do the best work that I possibly can, no matter what the project. In the short three years that I’ve professionally been doing fab work, I can say that I’ve got a lot to learn and there are going to be plenty more cars ahead of me to allow me to keep reaching for the bar that’s been set. Maybe one day I’ll be the guy to raise that bar.

Watch More: Scotts Hot Rods IFS Overview

I’d also like to take a moment to thank Justin Padfield and the rest of Scott’s Hot Rods for taking me in and giving me the chance to hone my skills and really create a career from my passion and realize my potential. They gave me a chance when nobody else would and have always been good to me and pushed me to do better.

Without them I wouldn’t be where I am today, honestly. I’m eternally grateful for what they’ve taught me and I wish more hot rod shops around the country would do the same.

Source

Scott’s Hotrods N Customs

(800) 273-5195

scottshotrods.com