Prepping Our 302 Crate Engine From Ford Performance Parts

By Ron Ceridono – Photography By Brian Brennan

It was a great day for hot rodders when automobile manufacturers discovered there was a market for factory performance engines. It’s true that manufacturers have always seen the value of offering engines for replacement, industrial, or other purposes. That’s why even though the last Model T was produced in 1927 Ford produced the same basic Model T engine from 1908-41, which was arguably Ford’s first crate engine. But things on the crate engine scene have changed dramatically since the Model T days. Today Ford Performance Parts (FPP) offers a variety of brand-new engines in a range of performance levels; big-block, small-blocks, and modular engines are all available. To make them even more of a bargain, other than sealed race engines and those with mechanical lifter camshafts, Their Ford crate engines come with a 24-month, 24,000-mile warranty.

Read More: Creating A Nimble Chevy Nomad

Crate engines are an ideal option for powering a hot rod, a conclusion editor Brian Brennan came to when it was time to put a power plant in his Model A pickup. To combine performance with driveability he had Hot Rods by Dean install a 340 hp 302ci Ford Performance crate engine (PN M-6007-X302). This particular engine is from 2014 and has been languishing in the corner of his garage for some time (proving yet again that it takes Brennan longer to complete projects than the author). This was one of the last FPP crate engines that required external balancing, other than that difference installing it is the same as a current FPP small block Ford crate offerings.

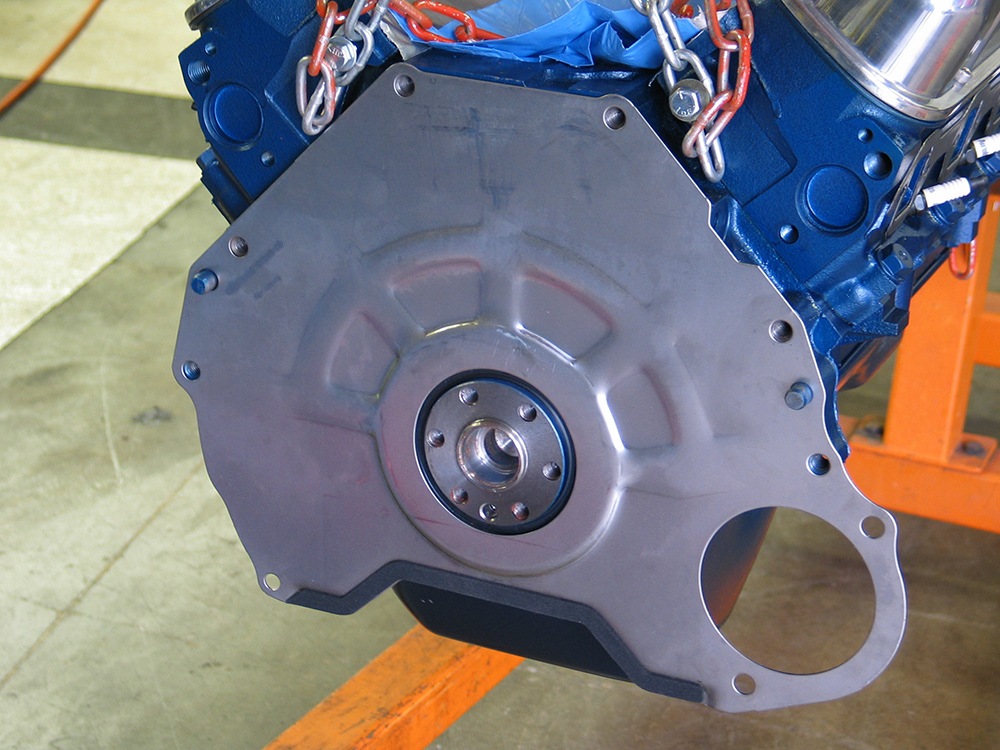

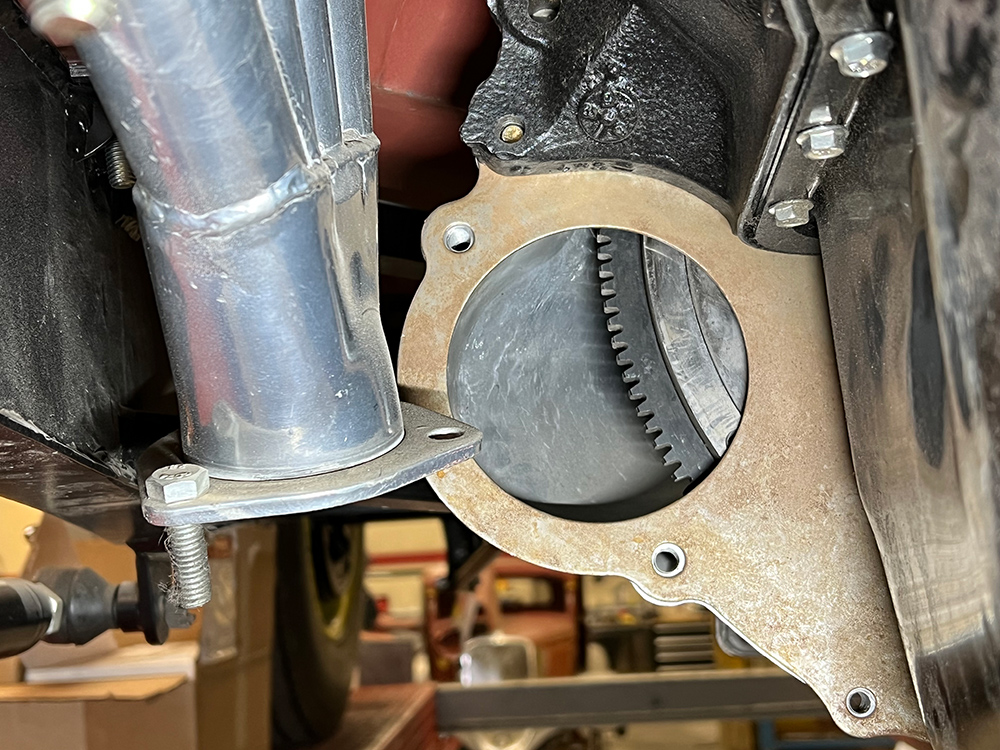

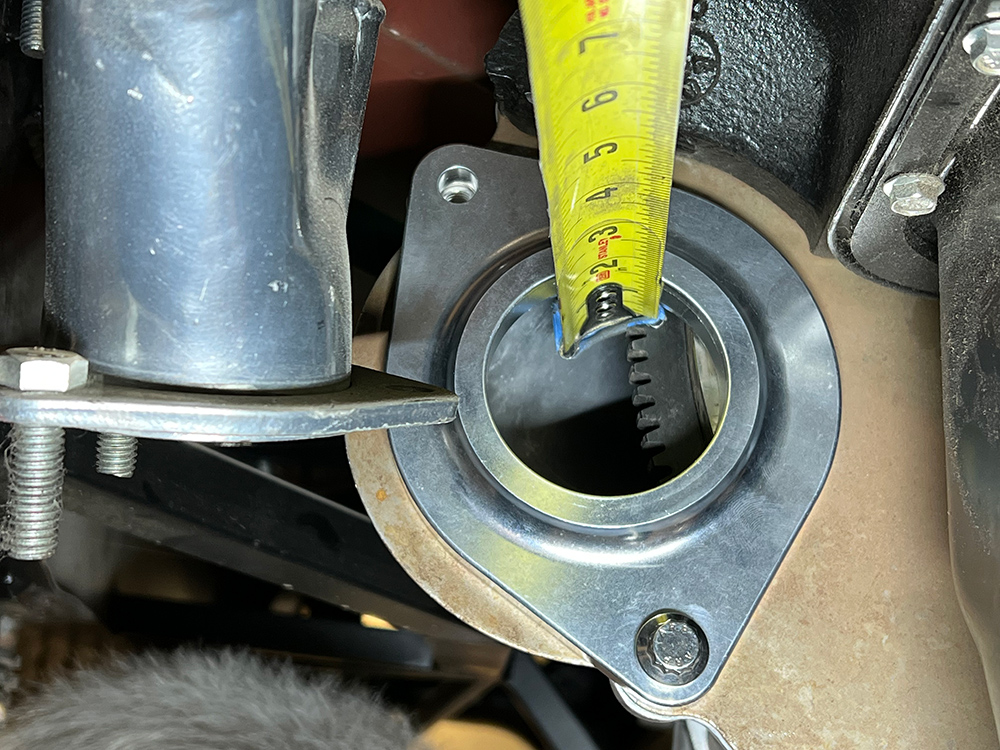

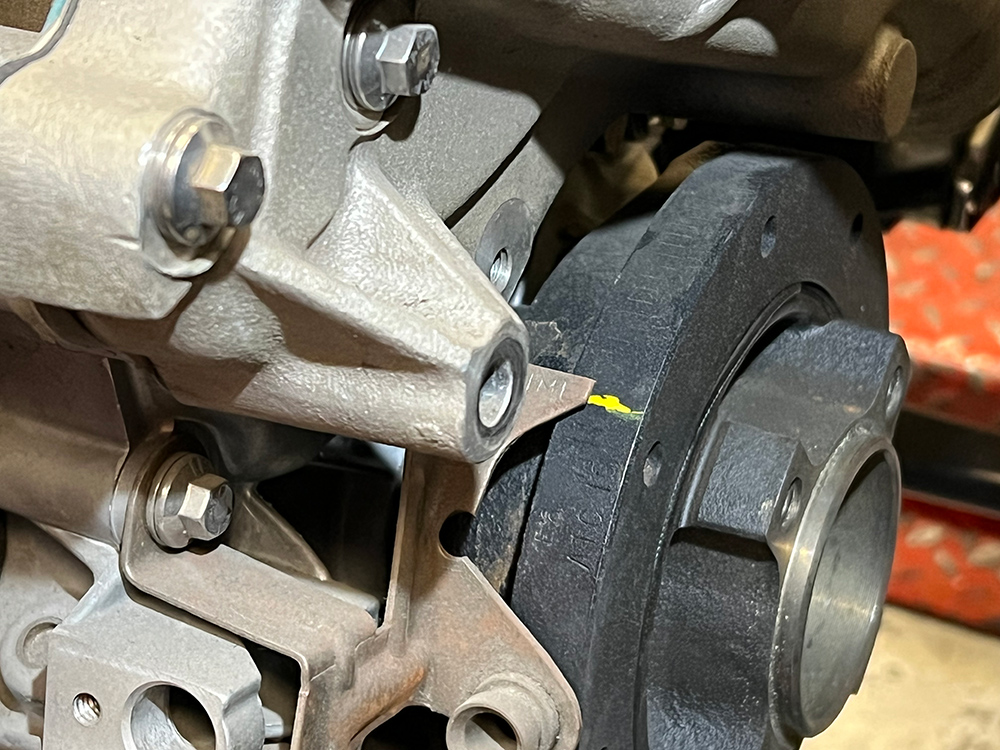

Starter

To get our crate engine assembly up and running the crew at Hot Rods by Dean had to add some ancillary components. Beginning at the back of the block the starter plate that fits between the engine and transmission was installed. Like all small block Fords, the Powermaster starter we would be using attaches to the bellhousing, but it’s the plate sandwiched between the block and transmission that ensures the starter is located correctly in relationship to the ring gear on the flywheel or flexplate. In our case the flywheel used included a 50 oz-in weight to bring the engine into balance.

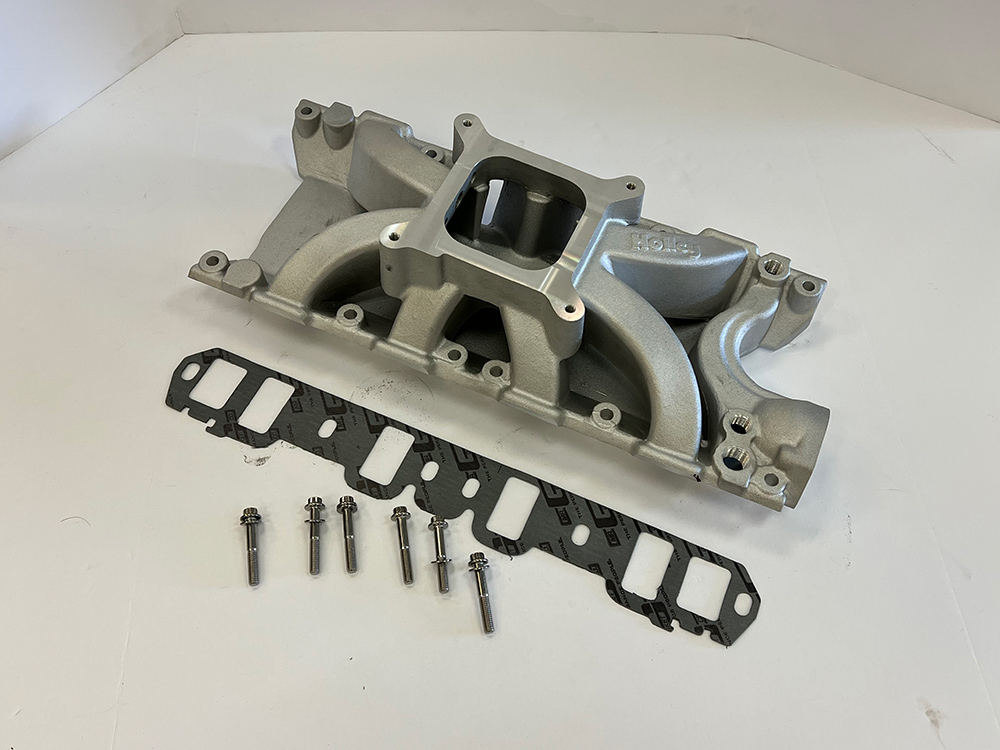

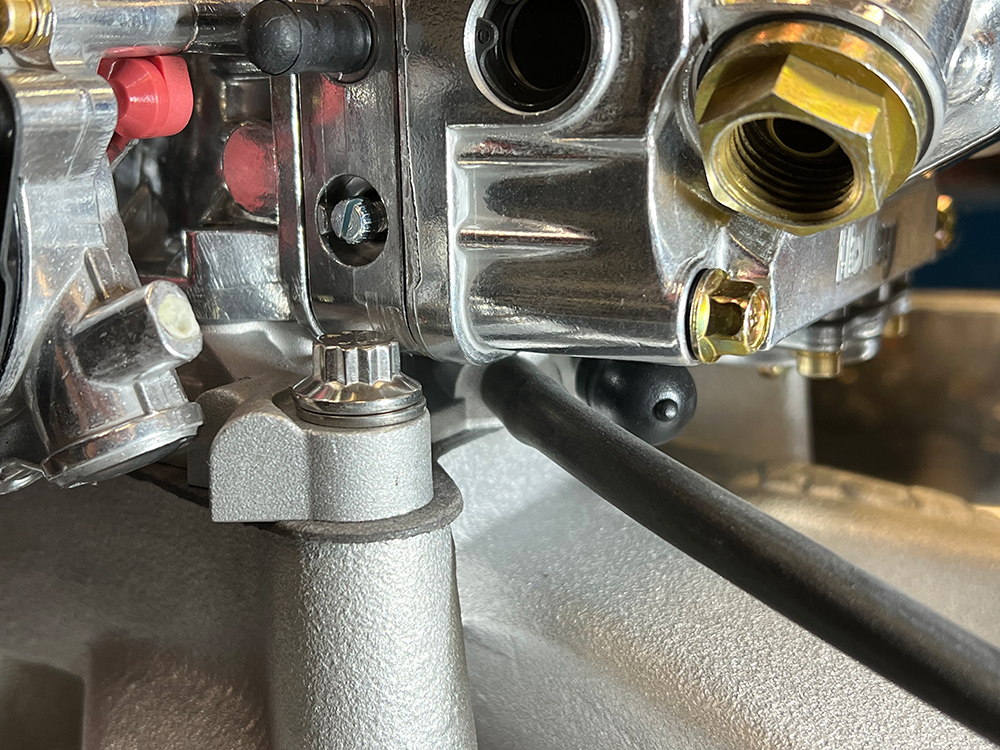

Intake Manifold

For the intake system we chose a tried-and-true combination—a single-plane Holley intake manifold (PN 300-277) topped by a 600-cfm (the size recommended by FPP) Holley Street Warrior carburetor. Before securing the intake manifold, put it in place without the intake manifold gaskets. There should be at least a 0.040-inch gap at the end rails to ensure the manifold will not “bottom out” on the block. If this is allowed to happen it’s likely that oil will be sucked into the intake runners during operation.

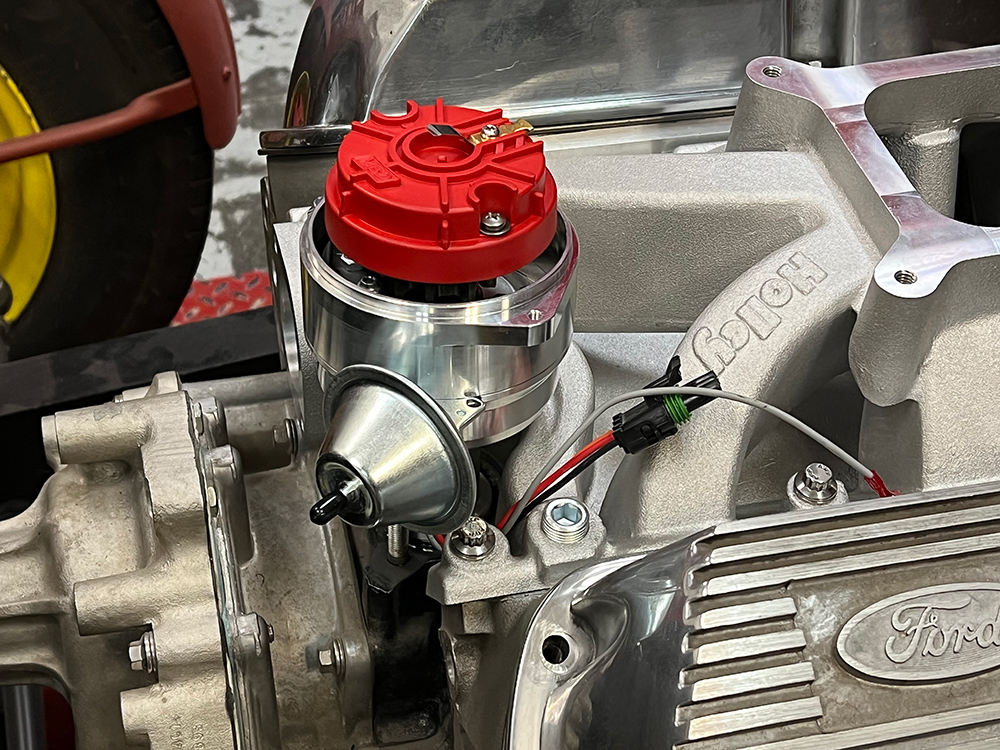

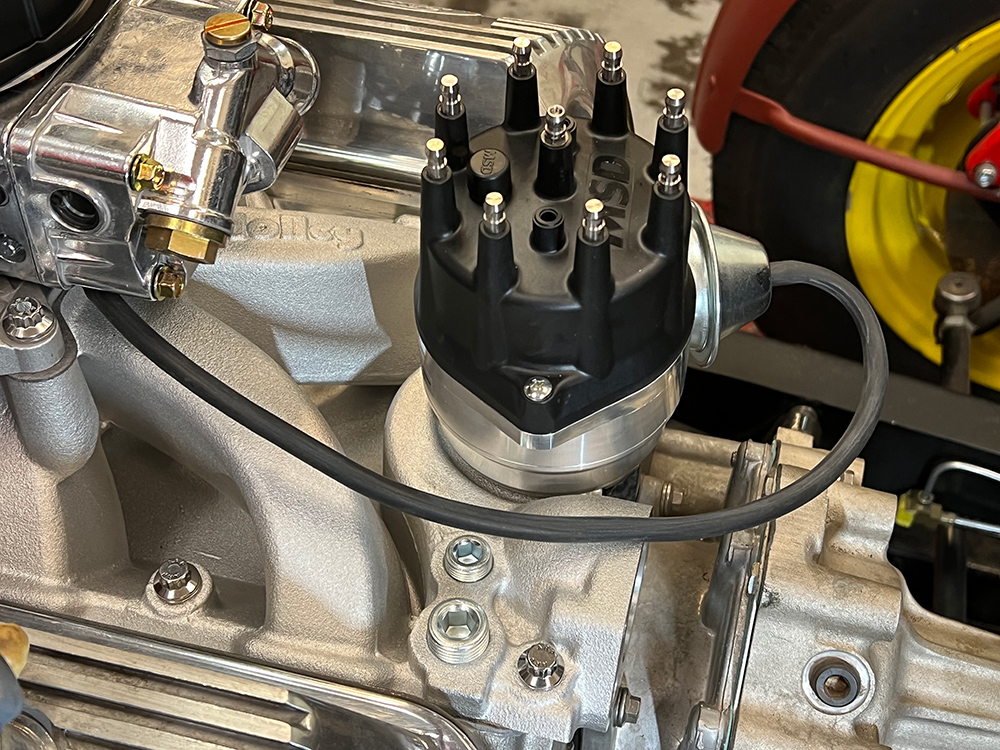

Distributor

When it came to selecting a distributor, one of the considerations was the drive gear; it had to be compatible with the camshaft. FPP cautions that cast-iron gears are required for cast-iron flat-tappet cams while steel gears are to be used with hydraulic roller cams like that in our engine. FPP offers a steel distributor gear (PN M-12390-B) that can be installed on most Ford distributors, however we elected to go with a Pro-Billet MSD Distributor (PN 83521). This distributor includes a built-in ignition module so no external control unit is required. It also comes with a melonized drive gear—which is an iron gear with a Melonite coating for use with either flat tappet or hydraulic roller camshafts.

Water Pump & Pulley System

Over the years Ford has used a multitude of water pump/crankshaft pulley and water pump combinations for V-belt and serpentine drives. Early crankshaft dampers and pulleys have three attachment holes; from late 1969-on passenger car (1977-on for pickup trucks and Broncos) crankshaft dampers and pulleys have four holes. Smitty Smith at Edelbrock tells us that 1965-69 small block water pumps (PN 8841) have the inlet on the right (passenger side) and measure 5.42 inches from the block mounting surface to the pulley mounting surface. Edelbrock water pumps (PN 8843) have the inlet on the left side (driver side) and measure 5.75 inches from the block surface to the pulley flange.

Read More: Latest Parts For Your Hot Rod November 2022

FPP offers a water pump (PN M-8501-E) with a lefthand inlet that shortens the engine 1-½ inches and is compatible with a four-bolt crank damper, but custom pulleys are required. To keep with the minimalist theme of the truck ye ol’ editor Brennan chose to stick with steel pulleys and V-belts. To that end the factory four-bolt vibration damper was replaced with a Summit Racing harmonic balancer that has both a three- and four-bolt pattern, and an early three-bolt crankshaft pulley and an Edelbrock water pump (PN 8843) was used.

Priming The Crate Engine

One of the most important steps in the installation procedure is properly priming the engine’s oiling system (this should never be done by cranking the engine with the starter). FPP recommends filling the crankcase with 5 quarts of 10W-30 or 10W-40 oil, then installing a mechanical oil pressure gauge and removing the valve covers. Then, using the appropriate tool (Summit Racing oil pump primer PN SUM-901011), rotate the priming tool counterclockwise using an electric drill. Once oil pressure appears on the gauge, keep priming for 1 minute, making sure oil comes up through the pushrods to the rocker arms (this may require rotating the crankshaft).

Read More: How To Build An LS Engine: Short Block Assembly

Setting The Ignition Timing

Once the crate engine was primed the distributor can be installed. Following FPP’s instructions simplifies the process. Before removing the distributor cap, mark the number one post location on the distributor. With the cap removed, rotate the distributor shaft so the blade on the rotor is to the left of the mark, but as close to the mark as possible. As the distributor gear engages the teeth on the camshaft, the rotor will turn clockwise. It may be necessary to slightly rotate the rotor/shaft assembly, until the drive gear “drops” into position. Sometimes rotation of the oil pump driveshaft is required to allow the distributor to drop all the way. Verify the rotor blade is pointing at the #1 mark on the distributor base, loosely install the distributor hold-down clamp and bolt, then install the cap and spark plug wires in order. Once the engine is started timing should be set at 14 to 16 degrees initially, with 36 to 38 total mechanical advance (with the vacuum advance disconnected).

Should You Buy A Crate Engine Or Build One?

A Ford Performance Parts crate engine makes sense for a variety of reasons. There are a variety of engine types and performance options to choose from, and all the components are the best current factory parts available. The cost of machining a used block, replacing all the internal components, and rebuilding heads gets expensive, and there is the time involved to make it all happen. In terms of convenience, cost, and performance, an FPP crate engine is a bargain, and they come with a warranty. Who would have thought hot rodding would be this easy? MR

Sources

Ford Performance Parts

performance.ford.com

Holley

(877) 712-0002

holley.com

Hot Rods by Dean

(800) 362-9709

hotrodsbydean.com

Lokar Performance Products

(877)-469-7440

lokar.com

MSD

(915) 857-5200

msdperformance.com

Powermaster Performance

(630) 957-4019

powermastermotorsports.com

Speedway Motors

(800) 979-0122

speedwaymotors.com

Summit Racing Equipment

(800) 230-3030

summitracing.com